Visual verification method to ensure secure coupling of rail cars

Place du Centre

200 Promenade du Portage, 4th Floor

Gatineau QC K1A 1K8

14 November 2018

Safety advisory letter 617-05/18

Related occurrence: R17V0096

Letter addressed to:

Transport Canada

Technical Safety BC

Canadian Pacific Railway

Railway Association of Canada

Western Canadian Short Line Railway Association

Subject: Rail Safety Advisory Letter – 617-05/18: Visual verification method to ensure secure coupling of rail cars

On 20 April 2017, during switching operations, 11 loaded rail cars of logs rolled uncontrolled out of the Western Forest Products (WFP) reload centre, near Woss, B.C. The 11 rail cars rolled northward out onto the main trackFootnote 1 for about 4820 feet and collided with some engineering work equipment on the track (i.e., a work crane and a crew transport vehicle with employees on board). The uncontrolled movement continued down the grade, pushing the 2 engineering work equipment vehicles. About 1730 feet further, on a left-hand curve, the 7 tail-end rail cars derailed and separated from the 4 head-end rail cars. The 4 head-end rail cars and the 2 engineering work equipment vehicles then continued on the track for about 880 feet, where the rail cars and work equipment derailed in a right-hand curve. During the derailment, the logs spilled from the rail cars, striking and burying the work equipment vehicles. Three engineering employees sustained fatal injuries and two employees received serious injuries (TSB Occurrence No. R17V0096).

As part of its investigation into this occurrence, the TSB examined the manner in which verification of a successful coupling was determined after the joint was made between rail cars. At the Woss Reload Centre, consistent with industry practice, the standard pull test was used. No additional visual verification of the coupler lock-lift assembly was being used by employees at the Woss Reload Centre.

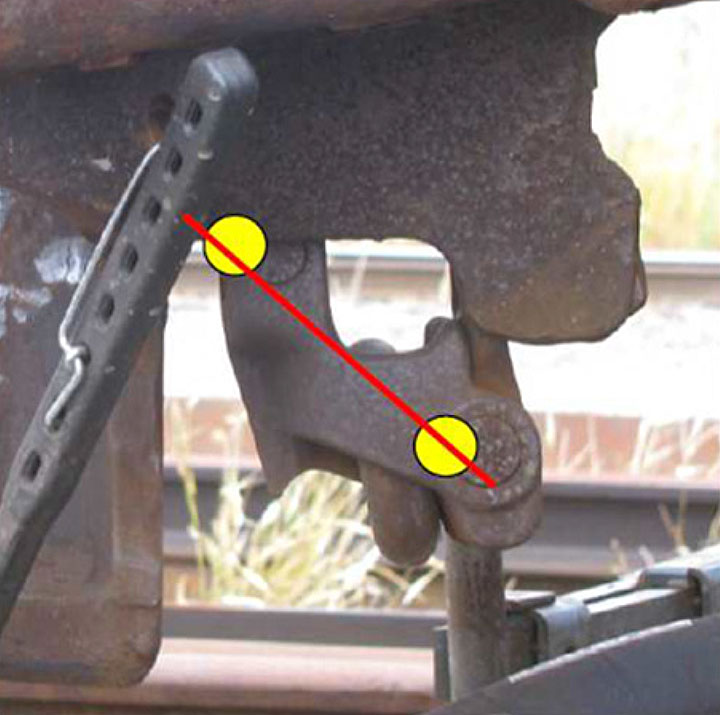

As part of a previous TSB investigation (R15T0173Footnote 2), it was determined that CN instructs its operating crew members to visually inspect the coupling after making a joint between rail cars and to ensure that the bottom-operated lock-lift assembly pivot points are properly aligned. Specifically, when the coupler locking block drops into place to secure the knuckle, the pivot points are horizontally aligned (Figure 1). If the coupler locking block is not in the fully dropped position, the pivot points would not be horizontal (Figure 2).

The use of this visual method (i.e., horizontal alignment of the pivot points on the bottom lock-lift assembly) as a visual indicator of a successful coupling may not be widely known or widely circulated in training material throughout the railway industry. Rather, general observation of the bottom lock-lift assembly to verify that the knuckle “pin” has dropped (i.e., the lock block has fully dropped and the coupling was successful) has been a long-standing practice throughout the railway industry.

Given the risks associated with an uncontrolled movement of rolling stock initiated by an inadvertent release of a coupling, additional defences such as the use of visual verification to ensure that the pivot points on the bottom lock-lift assembly are horizontally aligned should be implemented.

Original signed by

Kirby Jang

Director

Investigation Operations, Rail/Pipeline

Cc.

- BC Ministry of Transportation and Infrastructure

- Canadian National Railway

Background information

Occurrence No.

R17V0096

Contacts

Dan Holbrook, Manager, Head Office and Western Regional Operations - Rail, Head Office, Gatineau, Quebec

Peter Hickli, Regional Senior Investigator, Richmond Regional Office, British Columbia