Main-track train derailment

Canadian Pacific Railway Company

Freight train 401-02

Mile 128.9, Laggan Subdivision

Partridge, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 03 January 2019, at approximately 1015 Mountain Standard Time, Canadian Pacific Railway Company freight train 401-02 was proceeding westward on the Laggan Subdivision when 15 empty cars derailed in the Upper Spiral Tunnel at Mile 128.9, near Partridge, British Columbia. There was no fire, and no dangerous goods were involved in the derailment. No one was injured.

1.0 Factual information

On 02 January 2019, at about 2100,Footnote 1 Canadian Pacific Railway Company (CP) freight train 401-02 departed Alyth Yard in Calgary, Alberta, destined for Port Coquitlam, British Columbia (BC). Before departure, the train underwent a No. 1 brake test,Footnote 2 and no issues were noted.

The train was a mixed-merchandise freight train hauling 159 cars (86 loaded cars and 73 empty cars).Footnote 3 Some of the loaded cars were carrying dangerous goods: 12 cars were loaded with diesel fuel (UN1202), and 1 car was loaded with hazardous waste (NA3082).

The train was powered by 3 locomotives—2 positioned at the head end (CP 8959 and CP 8580), and 1 (CP 8867) in position 73, about mid-train. The mid-train locomotive was remotely controlled from the lead locomotive using distributed power (DP) remote control technology (remote locomotive).Footnote 4 The train weighed 13 896 tons and measured 10 044 feet. It had a total weight per operative brake of 87 tons.

According to the trip manifest document, the train would first travel westward to Field, BC, on the Laggan Subdivision and would traverse an area known as Field Hill. Field Hill is a 13.5-mile section of track with a steep descending grade (average 2.2%), sharp back-to-back reverse curves, and 2 spiral tunnels (the Upper Spiral Tunnel and the Lower Spiral Tunnel). West of Field, the train would make 2 stops along the way to set off 40 cars in Golden, BC, and another 94 cars in Kamloops, BC.

1.1 The occurrence

At around 0401 on 03 January 2019, the train started to descend Field Hill. At 0411, the locomotive engineer (LE) noticed a sudden increase in the airflow in the brake pipe on the remote locomotive while the air brakes were applied. Footnote 5 Shortly afterward, at 0412, an in-cab alert activated because of a sudden increase in brake pipe pressure, indicating a train-initiated undesired release of the air brakes (UDR). In response, to bring the train to a controlled stop, the LE gradually increased the dynamic braking. He also increased the minimum air brake application, adding 2 supplemental brake applications of 7 psi each. The train came to a stop near Mile 126 with the rear ⅔ of the train on level grade on the curve around Wapta Lake.

The LE communicated with the rail traffic controller (RTC). During the conversation, the LE expressed concern that another UDR could occur.Footnote 6 He indicated that once the train’s air brake system was recharged, the crew would “try again” (i.e., resume the trip), but reiterated his concern that another UDR would occur. The RTC confirmed that he understood that the crew would try again. He also indicated that he would inform his supervisor of the LE’s concern.Footnote 7

Given the location, and with the permission of the trainmaster, the train was held stationary by the independent brakes on the 3 locomotives while the air brakes were recharged for approximately 25 minutes. The train departed at 0445, continuing to travel westward.

A few minutes later, at 0448, a train-initiated undesired emergency brake application (UDE) occurred while the train was travelling at approximately 8 mph. This resulted in a second unplanned stop at Mile 126.3.

The conductor performed an inspection and identified a broken knuckle, with evidence of pre-existing rust on the fracture surfaces, possibly indicative of fatigue,Footnote 8 on the trailing (east) end of the 50th rail car (COER 353930, position 52 in the train consist). It was determined that, after the knuckle broke, the 50th car pulled away from the trailing 51st car, which resulted in separation of the adjoining air hoses, causing the UDE.

The conductor replaced the broken knuckle while the LE communicated again with the RTC and informed him that pressure-retaining valves (retainers)Footnote 9 needed to be set to the high-pressure (HP)Footnote 10 position before the train could recover from the emergency brake application and the air brake system could be recharged. This course of action was in accordance with the operating procedures and with instructions from the trainmaster. Subsequently, the retainers were set to the HP position on 50 cars between the lead locomotive and the mid-train remote locomotive.

The 2 unplanned stops caused significant delays. At 0600, while the train was still stopped at Mile 126.3 following the UDE, the crew members had been on duty for 12 hours, which is the maximum hours of service allowed under the Work/Rest Rules for Railway Operating Employees.Footnote 11 The RTC, aware that the originating crew’s shift would end before the train arrived at Field, had dispatched a relief crew; the relief crew members arrived at the train at about 0810. The 2 crews held a job briefing, which included discussions about the UDR and UDE events. The originating LE expressed his belief that there was a high likelihood of another UDR.

Once the relief crew had assumed operation of the train, it departed at 0954. At approximately 1010, the train entered the Upper Spiral Tunnel at Mile 128.8 at a speed of 15.6 mph.

At 1013, while the head end of the train was exiting the tunnel at about 12 mph, an in-cab alert activated, indicating a train-initiated UDR. In response, to bring the train to a controlled stop, the relief LE placed the locomotive throttle in idle and made a full service application of the air brakes, as required;Footnote 12 he also quickly applied the dynamic brakes (DB) and then progressively increased the application to the maximum (DB8). At about 1014, as the train was travelling at about 14 mph, a train-initiated UDE occurred, resulting in the train coming to an abrupt stop.

An inspection determined that a total of 15 empty rail cars had derailed in the Upper Spiral Tunnel (Figure 1). There was no fire, and no dangerous goods were involved in the derailment. No one was injured.

1.2 Site examination

The head end of the train came to a stop at Mile 129.95. There were 15 derailed cars (position 66, ahead of the remote locomotive, and positions 79 to 92, behind the remote locomotive); all had derailed within the Upper Spiral Tunnel. All but 1 of the derailed flat cars were bulkhead flat cars. They had derailed upright and jackknifed at 3 separate locations (Figure 2):

- a single flat car in position 66 (CP 315578, an empty 42-ton and 94.8-foot flat car), located 7 cars ahead of the remote locomotive; only its leading truck had derailed;

- a block of 7 flat cars (positions 79 to 85) located 6 cars behind the remote locomotive; for the car in position 79 (SOO 601688), only its trailing truck had derailed; and

- a block of 7 cars (positions 86 to 92) consisting of 1 flat car, 1 box car, and 5 flat cars.

There was a 100-foot separation between the 2 blocks of 7 derailed cars.

When TSB investigators arrived on site, the front portion of the train (the lead locomotive consist, all non-derailed cars at the head end, the derailed car in position 66, the remote locomotive, and the 5 non-derailed cars immediately behind the remote locomotive) had been moved away from the derailment location.

While inspecting the remaining derailed cars, the investigators noted that centrebeam flat car TTZX 85561 (position 85, the first car immediately before the 100-foot separation) was equipped with an older end-of-car trolley arrangement (Figure 3).Footnote 13

They also noted that the end hose gladhand couplings on some derailed centrebeam flat cars in the SOO series had been tie-wrapped; in one instance, the gladhand couplings were found rotated upward (Figure 4).

The track running through the tunnel and at the location of the derailment has a 10° curve. The derailment had caused some damage to the track structure, the tunnel walls, and the upper portal snow shed.

Wheel flange marks were present on the top of the rail at Mile 128.9, indicating that a wheel had climbed up and over the outside rail (Figure 5). This was determined to be the point of derailment.

After the occurrence, CP immediately sent the car in position 66 and all non-derailed cars in positions 67 to 162 of the train consist to its facilities in Golden for mechanical inspection and testing.

1.3 Weather information

At the time of the occurrence, the ambient temperature was about −1 °C. There was light snow falling with moderate gusting winds of about 41 km/h from the south. Although it had recently snowed heavily in the area, the top of the rail head was free of snow at the time of the derailment because of the recent passage of rolling stock.

1.4 Subdivision and track information

The Laggan Subdivision is part of CP’s main corridor to the west coast. The subdivision extends from Calgary (Mile 0.0) to Field (Mile 136.6) and consists primarily of a single main track, with a double-track portion between Lake Louise, Alberta (Mile 116.2) and Stephen, BC (Mile 123.1). At Field, the track connects with Mile 0.0 of the Mountain Subdivision.

The Laggan Subdivision is one of several subdivisions through the Rocky and Cascade mountains characterized by steep grades and sharp curves. This route traverses some of the most challenging railway operating terrain in North America.

Train movements are governed by the centralized traffic control system, as authorized by the Canadian Rail Operating Rules, and dispatched by an RTC located in Calgary.

1.4.1 Field Hill

The section of the Laggan Subdivision known as Field Hill runs 13.5 miles from Stephen to Field. It is designated as mountain gradeFootnote 14 and drops from an elevation of 5290 feet at Stephen to 4045 feet at Field. The average descending grade is 2.2% (Figure 6); in the Upper Spiral Tunnel, the grade is about 1.7%.

There are several sharp curves, ranging between 8° and 10°, including back-to-back reverse curves.

1.4.2 Spiral tunnels

There are 2 spiral tunnels on Field Hill—the Upper Spiral Tunnel and the Lower Spiral Tunnel (see Figure 1). The tunnels follow a spiral path through the mountains; this design allows trains to more easily negotiate the steep change in elevation.

The Upper Spiral Tunnel is 3255 feet long and extends from Mile 128.8 to Mile 129.5. It turns through a total angle of 250° (about ¾ of a circle), with a total decrease in elevation of about 56 feet.

The Lower Spiral Tunnel is 2922 feet long and extends from Mile 131.0 to Mile 131.5. It turns through a total angle of 226° (about 3/5 of a circle), with a decrease in elevation of about 50 feet.

The horizontal alignment of the track through each of the 2 spiral tunnels has a maximum curvature of about 10°, and the vertical alignment through each tunnel has an average descending grade of 1.7%.

1.4.3 Track in the vicinity of the derailment

Inside the spiral tunnels, the rail consisted of 136-pound continuous welded rail, installed in June 2018. The rail was secured to steel ties using spring clips, with approximately 3170 ties per mile. The ballast was clean crushed rock. The shoulders were about 12 inches wide, the cribs were full, and the drainage was good.

The track is normally inspected at least twice per week, in accordance with the Rules Respecting Track Safety and as required by CP’s Red Book of Track & Structures Requirements. The last track inspection had been conducted on 03 January 2019, and no defects were noted. A rail flaw detection test was conducted in December 2018; no defects were found in the area of the derailment.

1.5 Crew information

1.5.1 Originating crew

The originating crew consisted of an LE and a conductor. Both crew members were qualified for their respective positions, were familiar with the territory, and met established fitness and rest standards.

1.5.2 Relief crew

The relief crew consisted of an LE and a conductor. Both crew members were qualified for their respective positions, were familiar with the territory, and met established fitness and rest standards.

1.5.3 Crew-to-crew transfer

The originating crew was called for duty at Alyth Yard at 1800 on 02 January 2019 for a shift that was scheduled to end in Field (Mile 136.6), where a crew change was planned. However, due to the unplanned stops on Field Hill and the significant delays that ensued, the train had only progressed to Mile 126.3 when the crew’s allowable hours of service ended at 0600 on 03 January 2019.

A relief crew was ordered for duty starting at 0650. The relief crew members were transported from Field to Yoho by road vehicle and then had to make the rest of the trip in a snow removal track unit, arriving at about 0810.

1.6 Recorded information

1.6.1 Locomotive forward-facing video camera

Forward-facing video cameras are designed to record continuously when a locomotive is operating. Many railways have taken the initiative to install forward-facing cameras on head-end locomotives, although they are not required by regulation.

In this occurrence, the lead locomotive was equipped with a forward-facing camera. The TSB requested the video recording from the camera but was informed that it was not possible to retrieve the data from this camera due to an on-board locomotive equipment malfunction.

The remote locomotive was also equipped with a forward-facing video camera. A review of the video recording showed a sudden and significant run-in of slack at the same time as the second UDR occurred inside the Upper Spiral Tunnel (more information on in-train forces and train slack is provided in Section 1.9).

1.6.2 Locomotive event recorder

The lead and remote locomotives were equipped with a locomotive event recorder (LER). The LER is an electronic data-logging device that captures real-time operational status data for on-board locomotive controls, such as the throttle, dynamic braking, air braking, bell, and whistle.

In this occurrence, the locomotives were equipped with legacy LERs that did not capture data on brake pipe airflow. As an alternative approach, the data transmitted to the lead locomotive LER by the sense and braking unit, commonly called an end-of-train (EOT) device,Footnote 15 were used in the investigation.

Data sent to the LER from the EOT represent the real-time status of brake pipe pressure at the tail end of the train. They provide an indirect indication of brake pipe performance characteristics, charging rate, and potential brake pipe anomalies between the remote locomotive and the last car. Additionally, when compared with the data on brake pipe pressure at the remote locomotive, the EOT data can provide insight into important changes in brake pipe leakage and/or airflow. In the case of a conventional train with only head-end power, the EOT data provide relevant information between the lead controlling locomotive and the last car.

Unexpected changes in the flow of air through the brake pipe can highlight an anomalous or emergent condition in the train’s air brake system. Such conditions include a change in the naturally occurring leakage of compressed air from the brake system and/or a critical change in brake pipe continuity. While changes in continuity are rare, they can nonetheless occur, if only momentarily, such as when the slack adjusts on a moving train in response to train handling commands or because of changes in terrain.

Relevant data from the LER and EOT are provided in Appendix A and Appendix B.

The TSB reviewed the data and concluded the following:

- Before the train began to descend Field Hill, the air brake system was performing as intended and there was no indication of any intermittent problems.

- The UDR events did not result from train handling actions by the LEs but occurred when the brake pipe pressure spontaneously increased, suggesting that there was a dynamic change in airflow in the brake pipe on 1 or more of the rail cars.

- At the time of the first UDR, the dynamic braking was in position DB1, and the LE had made a 7 psi air brake application. At the time of the second UDR, the throttle was in position 3, and the LE had made a 10 psi air brake application.

- The UDRs originated in the rear portion of the train between the remote locomotive and the tail end, most likely on a car positioned a short distance from the remote locomotive.

- The relief LE made a full service brake application, as required, in response to the second UDR, and the brake application was followed by changes in train speed: within 1 second, the train accelerated by 0.7 mph; then, within 2 seconds, it decelerated by 0.7 mph. The changes in train speed indicate a sudden and significant run-in of slack, which was followed by the derailment and a UDE less than a minute later.

CP also reviewed the LER and EOT data. The company deduced that the UDR was most likely initiated on car TTZX 86441 (position 96), based on the sequence of the brake pipe pressure increases at the lead locomotive, remote locomotive, and EOT device, and based on the results of its inspection and testing of the cars in position 66 to 162 (Appendix C).

1.7 Overview of freight train air brake system

1.7.1 Air brake components on a rail car

Freight rail cars operating in North America are equipped with pneumatically operated friction brakes, referred to as automatic brakes or, more commonly, air brakes.

Each rail car is equipped with the following basic air brake components: a rigid brake pipe, flexible end hoses, angle cocks, a combined air storage reservoir (which consists of auxiliary and emergency air reservoirs), brake cylinders, and a retainer valve, all connected to a car control valve (CCV) (Figure 7).

The CCV assembly includes 2 portions—a service portion and an emergency portion—both affixed to a pipe bracket. These portions are intricate pneumatic control devices that control all of the air brake functions on the car through many air passages, ports, chambers, piston assemblies, and specialized valves.

The CCV is connected to the brake cylinder, the brake pipe, and the combined air storage reservoir. It has 3 primary control functions: charge the auxiliary and emergency reservoirs from the brake pipe, apply the brakes, and release the brakes. In addition to performing these 3 basic functions, the CCV also provides specialized functions to speed up the transmission and propagation of a brake application or a brake release. Other important functions are also incorporated into the CCV to enhance rail car and overall train brake system performance.Footnote 16,Footnote 17

1.7.2 End-of-car arrangements

Rail cars are equipped at each end with an end-of-car arrangement to allow the car to be coupled to other rail cars and to connect the car air brake systems for operation in a train.

1.7.2.1 Flexible end hoses and gladhand couplings

A flexible air hose is provided on the end of each rail car to connect to the hose on the adjoining cars. Gladhand couplings are the interlocking connectors fitted to each flexible end hose to establish the actual connection between the hoses when coupling cars.

1.7.2.2 Coupler and draft system

A coupler is a mechanical apparatus on the end of each rail car used to connect rolling stock together on a train. A coupler assembly usually includes a coupler arm, a knuckle, a knuckle pin, and a locking mechanism.

In conjunction with the coupler, a draft system is installed on both ends of a rail car to help absorb the energy associated with train movements. Draft systems are essentially shock absorbers designed to compress and extend by a certain amount when a force is applied to them. Because of draft systems, the connection point between coupled cars has some amount of slack, depending on the system’s design.

The draft system may use either standard friction draft gears or end-of-car cushioning devices (EOCCDs), depending on the design and intended use of the rail car.

- A standard friction draft gear is the most basic draft system and provides a limited amount of shock protection. The maximum displacement of the draft gear due to the extension and retraction, referred to as coupler stroke length, is limited to only about 3½ inches. Because of this limited range of motion, the end hose is directly connected to the brake pipe angle cock and moves in unison with the coupler without the need for any additional apparatus.

- An EOCCD is designed to minimize lading damage by providing additional protection against shock impacts. An EOCCD’s cushion unit has a long-shank coupler and a piston that provides a long-travel stroke, ranging from 10 to 18 inches, owing to the cushion unit moving in and out of the EOCCD housing. To accommodate the extended range of motion in EOCCDs, a special end-of-car arrangement with an intermediate (extension) air hose is required. Trains with several cars equipped with EOCCDs have more slack.

1.7.2.3 Intermediate hose and trolley arrangements

To accommodate the extended range of motion in EOCCDs, a flexible intermediate air hose, located horizontally underneath the car body, is connected to the end hose and angle cock. In addition, a movable hose support apparatus, referred to as an end-of-car trolley arrangement, allows the hose to move in unison with the coupler.

A paper on brake system end arrangement tests presented at the 2022 Railway Supply Institute Expo and Technical Conference of states, in part, that

The end arrangement must ensure that end hoses stay coupled while in motion and accommodate:

- Up to 18 inches of longitudinal travel

- Up to 15 degrees of coupler angle (lateral swing)Footnote 18

1.7.3 Trainline

When rail cars are assembled into a train, the flexible air hose on each end of a car is connected to hoses on the adjoining cars, and the brake pipe angle cocks are set to the open position (Figure 8). Collectively, this forms a continuous brake pipe, often referred to as the “trainline,” which extends through the entire length of the train. The braking equipment on the individual rail cars operates together as part of an automatic air brake system.

Through the use of compressed air supplied by the locomotives, the train’s automatic air brake system provides a simple and reliable means for LEs to apply and release the brakes on the cars and locomotives, to slow down the train, control or stabilize train slack, control speed on descending grades, or stop the train. LEs control the compressed air and the brakes using an automatic brake valve handle in the operating cab of the controlling locomotive.

1.8 Air brake applications and releases

1.8.1 Air brake applications

To apply the brakes throughout the train, an LE moves the automatic brake valve handle by the desired amount to reduce brake pipe pressure. The brake application then propagates along the brake pipe at about 600 to 700 fps (depending on the specific characteristics of the various CCVs in the train consist).

The CCV on each rail car is connected to the brake cylinder, the brake pipe, and the combined air storage reservoir; the CCV detects and responds to pressure changes. Specifically, a main control piston in the CCV compares the brake pipe and auxiliary reservoir pressures. A difference in pressure of 1.5 to 2.0 psi or greater will cause the main piston to move and, depending on the pressure change, initiate a brake application or release.

When brake pipe pressure is reduced by 1.5 to 2.0 psi below the auxiliary reservoir pressure, the CCV will apply the brakes in proportion to the pressure reduction, until the brake pipe and auxiliary pressures equalize. Thus, during a service brake application, the auxiliary reservoir pressure follows and tracks the commanded reduction in brake pipe pressure, as made by the LE when the train brakes are applied. During this time, the emergency reservoir pressure will remain unchanged and retain the same pressure it had before the brakes were applied.

To apply the train brakes harder than a full service application requires an emergency brake application, in which the brake pipe air is vented to atmosphere, allowing the pressure to drop rapidly to 0 psi. In response, the CCV will immediately connect the auxiliary and emergency reservoirs to the brake cylinder to provide the maximum brake cylinder pressure. Once an emergency brake application is initiated, the drop in brake pipe pressure to 0 psi cannot be stopped. An emergency brake application can be commanded by an LE (by moving the automatic brake valve handle to the emergency position) or by the conductor (by activating the conductor’s emergency brake valve handle). It can also be train-initiated; for example, when air hoses between 2 rail cars separate, brake pipe pressure vents at a rapid rate.

1.8.2 Air brake releases

The air brake system on a freight rail car is designed to be direct-releasing. Once the automatic brakes have been applied, they cannot be released incrementally; they can be applied further, or fully released and recharged.

1.8.2.1 Commanded service release

To release the brakes on a train, the LE moves the automatic brake valve handle to the release position, which increases the pressure in the brake pipe. On each rail car, when brake pipe pressure is increased by at least 1.5 to 2.0 psi above the auxiliary reservoir pressure, the CCV will fully release the brakes, regardless of the total pressure increase. The signal to release the brakes propagates throughout the train at about the same rate as a service brake application.

1.8.2.2 Accelerated service release

CCVs have an accelerated service release (ASR) function designed to provide improved brake release performance. The ASR function, although part of the emergency portion in the CCV, is used to assist with the release of a service brake application by using the higher pressure stored in the emergency reservoir.

When the brake pipe pressure on a car increases by as little as 1.5 to 2.0 psi above the car’s auxiliary reservoir pressure, the ASR function temporarily allows compressed air to flow from the car’s emergency reservoir into the brake pipe. This reinforces the initial pressure increase, thereby ensuring a positive release of the brakes.

The localized pressure increase is detected by the CCVs on the adjoining cars. This similarly causes the brakes on the adjoining cars to release and compressed air from the car’s emergency reservoir to flow into the brake pipe. The combined ASR response from multiple cars triggers a domino effect that generates a pressure wave, ensuring the release of the brakes. As the wave propagates along the brake pipe toward the front and rear of the train, it results in a progressive release of the brakes throughout the length of the train.

The ASR function helps to quickly initiate the release of the brakes by creating a larger differential between the brake pipe and the auxiliary reservoir. This creates a strong pressure wave in the brake pipe, reducing the time required for the brakes to start releasing throughout the train. This is particularly beneficial on longer trains. For example, the faster brake release allows a stationary train to start moving much sooner than would otherwise be possible. Similarly, the faster release of the brakes throughout a train also allows LEs to make a running brake release at lower speeds without stalling.Footnote 19

1.8.2.3 Train-initiated undesired release

A train-initiated UDR occurs when the air pressure in a train’s brake pipe spontaneously increases independently of any train handling actions taken by the LE, causing the CCV on a rail car to automatically release the brakes on that car. As a result of the ASR function, once a UDR has occurred on 1 rail car, the brake release wave starts to propagate throughout the train.

After a UDR, and depending on its initiation point, several seconds may elapse before the LE becomes aware that the brakes are progressively releasing. When the brake release wave reaches either the EOT device, a remote locomotive, or the lead locomotive, whichever occurs first, the brake pipe pressure gauges monitored by the LE display an abrupt increase in pressure. On a DP train, an uncommanded pressure increase on the remote locomotive also immediately triggers an in-cab alarm to alert the LE.

To counter a UDR in progress, LEs must take quick action and reapply the brakes by reducing brake pipe pressure sufficiently. Otherwise, the air brakes will continue to quickly release on all of the cars in the train. Relatively light brake pipe pressure reductions following a UDR will not re-apply the brakes on the released cars.

1.9 In-train forces and train slack

In-train forces are dynamic buff (compressive) and draft (tensile) forces applied to the rail cars and their components when a train is in motion. These longitudinal forces put stress on rail cars and their components.

A train travelling on tangent track generates steady-state longitudinal in-train forces. On an ascending grade, a train generates draft forces. The magnitude of the draft force is determined by the train’s trailing tonnage, the amount of locomotive tractive effort, ascending grade slope, and train rolling resistance. Similarly, on a descending grade, when a train is decelerating or maintaining a constant speed, a train generates buff forces. The magnitude of the buff force is determined by the amount of locomotive dynamic brake and air brake retardation, the train’s trailing tonnage, and the descending grade slope.

Train slack refers to the longitudinal movement at the ends of a car and the cumulative movement of cars within a train. The movement occurs as the in-train forces are transmitted between cars during operation. Train slack can cause speed differentials within a train. A run-in or run-out of slack refers to an abrupt difference in speed between adjoining cars.

EOCCDs are designed to dampen in-train forces and minimize damage to lading. However, a large number of EOCCD-equipped cars grouped together on a train can also significantly increase the train’s total slack.

1.9.1 Effect of train slack on end-of-car arrangements

End-of-car arrangements are designed to accommodate the variations in slack as the train operates at various speeds on various terrains.

On a moving train, the couplers on the cars frequently swing from side to side, up and down, and in and out of the draft gear housing as they adjust to changes in track alignment, train speed, and/or train handling commands. Along with these variations in slack between cars, in-train buff force will often be exerted on the air hoses and gladhand couplings between adjoining cars and on the intermediate hose, if a car is equipped with one.

When a buff force is exerted on a car equipped with EOCCDs, the physical distance between the car and the adjoining car is reduced owing to the shock-absorbing action of the long-travel EOCCD. To absorb the buff force, the EOCCD piston is pushed against hydraulic fluid and the piston gradually retracts into the EOCCD housing. The distance between the cars changes in proportion to the buff force acting on the rail cars, the amount of available “free play” at the car-to-car coupler interface, and the stroke travel of the EOCCD.Footnote 20

To accommodate this slack, air hoses and coupled gladhand couplings must be free to move with sufficient range to follow the swing motion of the car’s coupler and to move in unison with the long-travel stroke of the cushion unit of EOCCDs. Ideally, the end-of-car trolley moves in and out with the coupler, so that the coupled gladhand couplings always stay in the same relationship with the coupler. When the coupler and cushion unit return to their neutral position, the gladhand couplings and hose arrangements should also return to their original positions.

If the compressive force exerted on the air hoses and gladhand couplings becomes excessive, an undesired change in the amount of air flowing in the brake pipe could occur due to kinking (Figure 9) of the air hoses or peaking of the gladhand couplings, which could result in a localized change in brake pipe pressure.

1.9.1.1 Peaking of the gladhand couplings

When a compressive slack adjustment occurs between cars, the alignment of the coupled gladhand couplings between adjoining cars often changes relative to each other as the gladhand couplings rotate vertically upward, a condition referred to as peaking (Figure 10).

While some degree of rotation is inconsequential, rotation in combination with the applied buff force can result in air momentarily leaking through the pneumatic seal created by the compressed gladhand coupling rubber gaskets. Because of the dynamic nature of the buff force and the swinging motion of the air hoses, the leakage rate can be highly variable, resulting in erratic airflow and localized pressure fluctuations in the brake pipe.

If the applied force results in the gladhand couplings rotating too much, the interlocked gladhand couplings eventually reach a position at which, by design, they unlock. When this happens, the gladhand couplings are pushed apart due to the force of the compressed air inside them, and the brake pipe pressure exhausts to atmosphere, resulting in an emergency application of the train’s air brakes as a fail-safe measure.

1.9.1.2 Kinking of the intermediate hose

Intermediate air hoses are also subject to buff forces. When movement of the intermediate hose is impeded by a poorly functioning trolley arrangement, the hose can bend where it is looped underneath the rail car. If the hose bends too much, possibly to the point where it folds over on itself in a kinked manner, the normal flow of air through the brake pipe can become partially restricted or even entirely blocked.

A rapid change in airflow through the brake pipe can create erratic pressure fluctuations. If the airflow is completely blocked owing to a kinked intermediate hose, the blockage may create a damming effect that will often result in an increase in brake pipe pressure. When the buff force on the hose subsides, the bent hose will invariably return to its original shape. When this happens, there is an initial inrush of air, often accompanied by a transitory decrease in localized brake pipe pressure until the airflow stabilizes and returns to its former flow rate.

1.10 End-of-car arrangements on the train

On the occurrence train, there were 120 cars with standard friction draft gears and 39 cars with EOCCDs. All of the derailed cars were equipped with EOCCDs and, consequently, with intermediate hose and trolley arrangements.

1.10.1 Configurations compliant with earlier versions of standards

Intermediate hose and trolley arrangements are governed by 2 Association of American Railroads (AAR) documents: the Manual of Standards and Recommended Practices (MSRP), applicable to new car builds, and the Field Manual of the AAR Interchange Rules (Field Manual), applicable to repairs in the field.

To cover the various coupler types and draft system designs that a rail car may be equipped with, there are more than a dozen former and current standards applicable to intermediate hose and trolley arrangements.

In this occurrence, 1 or more cars in the TTZX series were equipped with an older end-of-car intermediate hose and trolley arrangement based on the previous version of MSRP Standard S-4003.Footnote 21 Derailed cars in this series included car TTZX 85561 (position 85), which was observed to have the older trolley arrangement during site examination, and car TTZX 86441 (position 96).

In the previous version of Standard S-4003, the uncoupled resting position of the gladhand coupling extended beyond the pulling face of the coupler by about 4 inches. In addition, the end-of-car trolley used a movable channel design that could slide over the bottom support bracket. This allowed the intermediate hose to swing up to 6 inches laterally from the car centreline (Figure 11). This previous version of Standard S-4003 for end-of-car trolley arrangement was applicable to freight cars with 43-inch or 60-inch F-shank couplers and 10-inch to 15-inch EOCCDs. This version of the standard is still included in Section E of AAR’s MSRP as information but no longer applies to new cars.

Note: “Coupling” refers to the distance from the coupler face to where the flexible air hose threads into the rigid brake pipe.

In the version of Standard S-4003 in effect at the time of the occurrence,Footnote 22 a tray arrangement is used rather than a trolley arrangement; the lateral swing of the intermediate hose in the tray arrangement is limited to 2 to 3 inches on either side of the car centreline. Furthermore, the uncoupled resting position of the gladhand coupling is immediately under the coupler pulling face, thus eliminating the previous 4-inch extension. Together, these revised specifications reduce the compressive force on the hose and the upward and side-to-side movement of the coupled hoses. This reduces the risk that the car’s intermediate hose will kink (Figure 12). This version of the standard was applicable to freight cars with 43-inch or 60-inch F-shank couplers and 10-inch to 18-inch EOCCDs. Note, in Figure 12, the distance between the pulling face and the coupling and the limited swing.

Neither version of Standard S-4003, however, is well suited to cars having coupler shanks measuring 45 inches or less, as these cars do not need a long intermediate hose. In recognition of this fact, in 1999, the AAR introduced a new standard—Standard S-4021. The TTZX cars in this occurrence had coupler shanks measuring less than 45 inches but, because the cars were manufactured before 1999, their intermediate hose and trolley / tray arrangements were compliant with the former version of Standard S-4003, the only existing standard at the time.

Despite changes and improvements in the standards, there is no AAR requirement to upgrade end hose and/or trolley arrangements to comply with newer standards unless the end-of-car arrangements are found damaged and require repair.

1.10.2 Non-standard configurations

After the occurrence, CP performed inspection and testing of the car in position 66 and all non-derailed cars in positions 67 to 162 on the train consist. The details are provided in Appendix C.

CP found that some of the centrebeam cars in the TTZX series had intermediate hose and trolley arrangements equipped with non-standard lengths of intermediate hose. Of these, 3 also had trolley misalignment issues. These non-standard configurations would create a high potential for end hoses, and particularly intermediate hoses, to kink on these cars when the slack was in a buff state. In the train consist, 5 of the TTZX series cars were located between positions 77 and 104, inclusive, close to the remote locomotive in position 73.

The non-standard configurations were likely created when parts were replaced during car maintenance or repairs.

1.10.3 Tie-wrapped gladhand couplings

During site examination, it was observed that the gladhand couplings on some derailed centrebeam flat cars in the SOO series had been secured with tie wraps. The tie wraps would have been applied to the gladhand couplings when the cars were coupled together to assemble the train in Alyth Yard, in accordance with a mechanical services bulletin issued by CP in December 2002 and still in effect at the time of the occurrence. This bulletin required that gladhand couplings be secured with a tie wrap in certain situations—for instance, on any car with EOCCDs coupled to a car with a standard draft gear.Footnote 23

Gladhand couplings are designed to unlock and separate under excessive force (Figure 13). When they separate, the brake pipe pressure exhausts to atmosphere, resulting in a UDE. Securing gladhand couplings with a tie wrap, while not constraining upward rotation, does increase the amount of force that is required to pull the gladhand couplings apart. This can help prevent their separation, therefore minimizing operational disruption and en route train delays that can result from unplanned train stops. If the force exerted on the gladhand couplings exceeds the strength rating of the tie wrap, the tie wrap eventually breaks, allowing the stretched or peaked gladhand couplings to uncouple in a normal and unrestrained manner.

Securing gladhand couplings with tie wraps, however, can interfere with their intended operation. When tie-wrapped gladhand couplings are rotated upward into a peaked orientation and do not separate, they can partially open, leaking compressed air through the gladhand gaskets. Such leakage is intermittent and stops when the gladhand couplings return to a neutral position. In addition, the tie-wrapped gladhand couplings can place additional stress on the flexible end hoses and intermediate hoses (if the cars are equipped with these), creating a risk that the hose will kink.

1.11 Wheel–rail interaction in curves

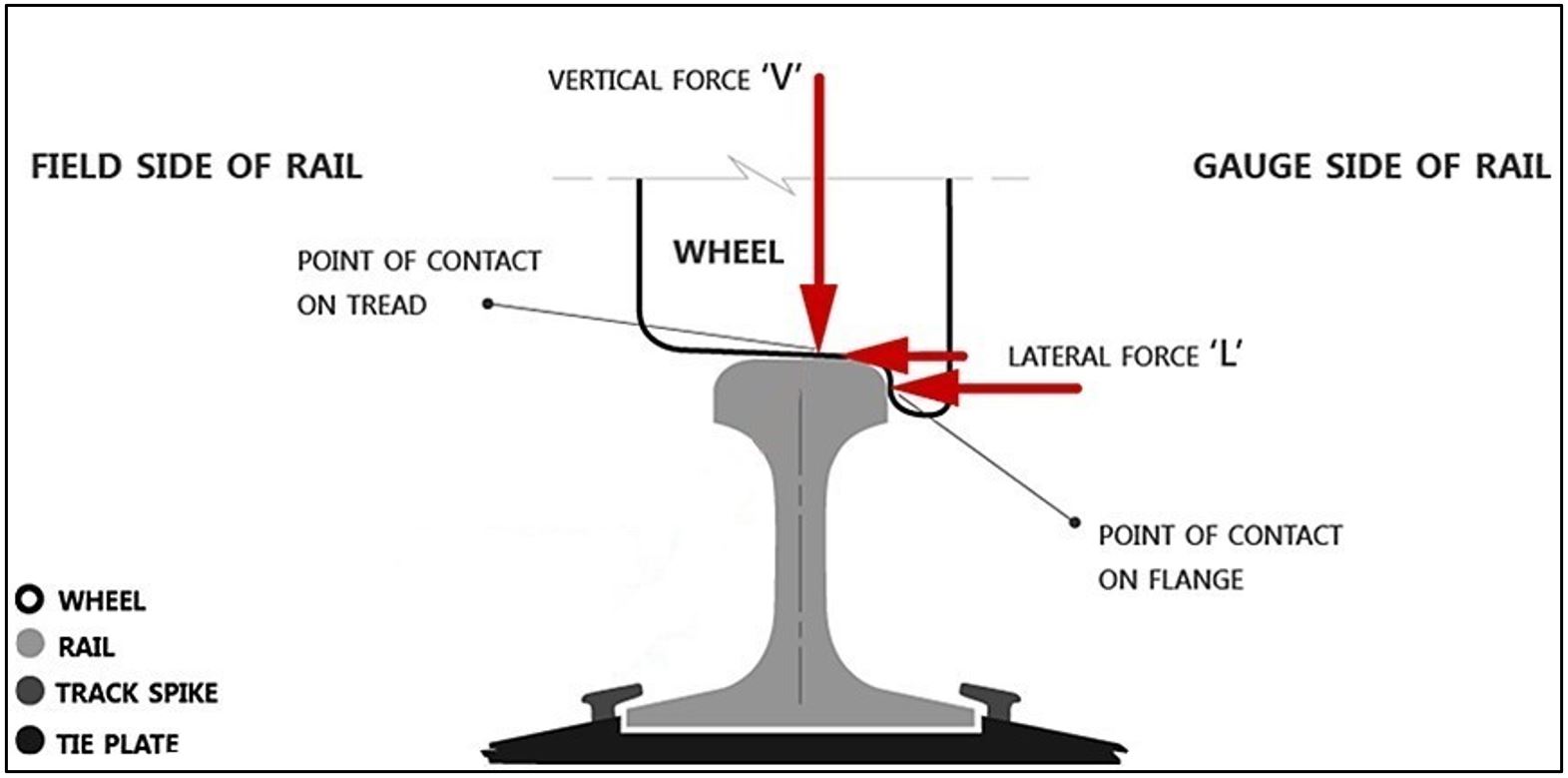

When a rail car passes over a curve, there is a combination of lateral (L) forces and vertical (V) forces at the wheel–rail interface.

The lateral forces are largely a by-product of longitudinal buff and draft in-train forces; that is, the longitudinal forces are transformed to lateral forces at the contact point between the wheel flange and the rail head. These forces arise from a number of sources, most notably the following:

- Flange contact: Lateral forces are generated when the car wheel flanges come in contact with the inside gauge corner of the rail. As the degree of curvature increases, so does the lateral force due to flange contact. For example, the lateral force resulting from flange contact on an 8° curve is more than twice the magnitude of the lateral force created on a 3° curve.Footnote 24

- Coupler alignment: Lateral forces are generated due to the alignment of the couplers between adjoining cars. To allow coupled cars to steer through a curve, the couplers are designed to move laterally with respect to the centreline of the car and track. The magnitude of the lateral force is proportional to the longitudinal forces acting on the cars and varies directly with the swing angle Footnote 25 of the couplers relative to the car’s centreline. The swing angle increases with the degree of curvature and the length of the coupler shank. Footnote 26

The magnitude of the lateral force that the car wheels exert on the rail is determined by several factors, including the longitudinal in-train force, the angle of the couplers relative to the centreline of the car, the grade, and the degree of curvature. Steep gradients and/or sharp curves, in particular, increase the longitudinal force required to keep the train moving and are associated with higher lateral forces.

Train dynamics can adversely increase the magnitude of the lateral forces exerted on the rail, and this is particularly true of train dynamics that result from unplanned and necessarily abrupt train handling actions to respond to an emergent situation.

Rail car vertical forces are equally important to ensure that the wheels stay in constant contact with the running surface of the rail. The magnitude of the vertical force exerted on the rail head is determined by the weight distribution of the rail car. For this reason, a loaded car will produce a proportionally greater vertical force due to its greater wheel loading.

In this occurrence, when the full service brake application was made in response to the UDR in the Upper Spiral Tunnel, the deceleration and resulting in-train forces were not evenly distributed along the length of the train.

1.11.1 Lateral-to-vertical forces ratio

The lateral-to-vertical forces ratio, referred to as the L/V ratio, is a basic measure of the interaction of the lateral and vertical forces (Figure 14). It is calculated as the lateral force pushing outward against the rail, divided by the vertical force pushing downward on the surface of the rail head.

The L/V ratio indicates the likelihood or potential for a wheel derailment. When rail cars travel on curved track, the likelihood that a wheel will derail increases as the numeric value of the L/V ratio increases. When there are high lateral forces (for instance, in sharp curves) combined with low vertical forces (for instance, empty cars), the wheel flanges tend to be pushed up and over the gauge face of the rail, resulting in a wheel-climb derailment. Conversely, when vertical forces are moderate to high, wheel lift is less likely. However, a high sustained lateral force can cant the rail outward and may cause the rail to roll over, resulting in a derailment.

To ensure safe train operations, the L/V ratio should not exceed industry-established threshold values. In January 1992, the AAR Research and Test Department issued Report R-802, Train Make-up Manual,Footnote 27 which discusses, among other things, the threshold of safe lateral loads at a wheel–rail interface. It determined the following threshold limits for single-wheel L/V ratios:

- L/V > 0.64 (poorly restrained rail may overturn)

- L/V > 0.75 (wheel may climb a worn rail)

- L/V > 0.82 (wheel lift impending)

1.11.2 Simulation of train dynamics

Using the Train Energy and Dynamics Simulator (TEDS) software program, the TSB laboratory performed train dynamics simulations and analyses to determine the in-train forces, particularly the buff forces, and the effect of these forces on the L/V ratios at the first derailed car. It showed the following:

- The front-most derailed car (CP 315578, position 66) was a long flat car (94.8 feet) with a long-shank coupler and 15° of free swing, making it more susceptible to push against the strikerFootnote 28 in a jackknifing position.

- If the coupler reached an angle of 8°, the transformed wheel- and truck-side L/V ratios from the simulated in-train forces would be in the critical range of 1.0 to 1.1, sufficiently high to result in the wheel climbing, and exceeding the AAR limit of 0.82 L/V ratio.

- If the coupler angle reached the maximum of 15°, the transformed wheel- and truck-side L/V ratios from the simulated in-train forces would be in the critical range of 2.1 to 2.3.

After the derailment, CP, in collaboration with Simon Fraser University, conducted extensive train dynamics simulations of the occurrence train to determine the magnitude of the in-train forces and the resulting L/V ratios. Simulations were also conducted for various alternative marshalling scenarios. The results indicated that, when there are more than 15 empty centrebeam or bulkhead flat cars on a mixed-merchandise train, they must be marshalled to the extreme rear of the train.Footnote 29

1.12 Train marshalling

The terms “train marshalling” and “train make-up” refer to the planned placements of rail cars in a train. There are different approaches to marshalling; for example, rail cars can be placed according to their length and/or weight, their destination, or other factors.

Marshalling requirements based on the length and weight of the rail cars serve to manage train safety by limiting the maximum in-train forces in specific operating scenarios. The interpretation of in-train forces and an in-depth understanding of how they affect train safety and derailment prevention are the cornerstones of best practices in train marshalling.

In destination marshalling, also known as destination blocking, cars are grouped together in blocks that are destined for the same location. This marshalling approach tends to reduce train delays by easing crew workload related to en route switching activities.

At the time of this occurrence, there were no specific Transport Canada–approved train marshalling guidelines, nor were there regulatory requirements for limiting maximum in-train forces through marshalling. Railways in Canada develop their own marshalling rules and instructions to help manage in-train forces and prevent derailments.

1.12.1 Canadian Pacific’s train marshalling

CP considers weight distribution when assembling a train in a yard or a major terminal and at locations where cars are removed from or added to trains. CP’s marshalling requirements are governed by its General Operating Instructions (GOIs) and other documents such as special instructions and bulletins.

To facilitate train marshalling verification, and to tailor the marshalling requirements to the particular characteristics of different geographic regions, CP implemented a proprietary computer-based train marshalling program called Train Area Marshalling (TrAM) in December 2003. TrAM verifications help to determine the safe placement of cars and DP remote locomotives in a train, to maintain in-train forces at acceptable levels under a normal range of train handling and operating conditions. Compared to traditional, non-automated methods, TrAM provides increased flexibility in how a train can be safely marshalled.

TrAM takes into account the operating characteristics of the subdivisions where the train will travel. It applies marshalling restrictions based on the particular aspects of a territory, to avoid restrictive marshalling rules where they are not required. For TrAM purposes, the entire CP network is divided into 5 different types of terrain (called TrAM “areas”), which differ according to their ascending and descending grades, track curvatures, and undulated track profiles.

TrAM area 1 is the least restrictive, while TrAM area 5 is the most restrictive. About 85% of CP’s entire track network is considered TrAM area 1. Some parts of the Laggan Subdivision are classified as TrAM area 1, others as TrAM area 3 or 5, depending on a train’s direction of travel and the mileage limits specified in time table footnote 11.1.Footnote 30 In this occurrence, the train was operating between Lake Louise and Field on the north track; this part of the subdivision is classified as TrAM area 3.

For each of the 5 TrAM areas a train is scheduled to traverse, the TrAM program

- calculates maximum draft and buff forces based on the number, placement, and characteristics of the locomotives on the train;

- evaluates trailing tonnage restrictions behind long and empty cars; and

- ensures that the expected L/V ratios will be below the critical level of 0.82 for safe train operations at all times.Footnote 31

When changes are made en route to a train’s power configuration (isolating 1 or more locomotives or cutting out traction motors), or the number and configuration of the freight cars changes (owing to set-out and pick-up of cars), a computerized TrAM check must be performed. The new check ensures that the train is still TrAM-compliant and marshalled correctly for the TrAM areas on the train’s route.

TrAM is not designed to consider in-train forces created by UDRs, UDEs, or improper train handling.

The placement of short and empty cars is governed by CP’s GOIs, which must be considered in parallel with TrAM when mixed-merchandise trains are marshalled at the initial terminal or anywhere en route.

CP’s GOIs require that freight trains be made up, to the extent practicable, with the loaded cars located closest to the locomotives. The GOIs prohibit the marshalling of blocks of heavy cars at the rear of the train unless the blocks ahead are equally heavy, and they require that light cars (cars that are empty or carry a light load), or blocks of light cars, be placed as close as possible to the rear of a train.

The applicable requirements are found in Section 7, Item 6 of the GOIs:

6.0 Mixed Train Instructions – Conventional and Distributed Power

These instructions apply to Mixed Conventional and Mixed Distributed Power Trains ONLY.

6.1 Marshalling Heavy and Light Cars or Blocks

To reduce undesirable track/train dynamics in Mixed trains, apply the following marshalling instructions, subject to destination blocking.

Heavy Cars and Blocks

- Marshall heavy cars as close as possible to the head end.

- Do not marshall heavy blocks of cars to the rear of train unless blocks of cars ahead are equally as heavy.

Light Cars and Blocks

- Marshall light cars or blocks as close as possible to the rear, unless the cars behind are also relatively light.

Notes:

- The Train Area Marshalling Messages do not indicate whether train marshalling fulfills the intent of this item.

- Destination blocking does not take precedence over TrAM marshalling violations that are shown on the train consist.Footnote 32

1.12.2 Marshalling of the occurrence train

In this occurrence, the train was marshalled with a group of loaded heavy cars at the front of the train, followed by a group of 71 empty cars in the middle, and 19 fully loaded cars near the rear, including a solid block of 16 loaded cars in positions 135 through 150.

The train was also marshalled using destination blocking. Forty cars were to be set off in Golden; these had been placed at the tail end of the train. Then, 94 cars were scheduled to be set off further west, in Kamloops; of these, 45 cars were placed in 3 separate blocks on the front half of the train, and a 49-car block was placed immediately behind the mid-train locomotive. The remaining 25 cars on the train were to be taken to the train’s final destination, the yard at Port Coquitlam.

Table 1 shows the destination of the various blocks of cars, the number of loaded and empty cars to be set off at each destination, and the position of the blocks of cars in the train consist.

| Destination | Number of loaded cars | Number of empty cars | Total cars | Car positions* |

|---|---|---|---|---|

| Golden | 16 | 24 | 40 | 123 to 162 |

| Kamloops | 48 | 46 | 94 | 3 to 8, 21 to 33, 47 to 61, and 74 to 122 |

| Port Coquitlam | 22 | 3 | 25 | 9 to 20 and 62 to 72 |

| 86 | 73 | 159 |

* The position of the cars in a train consist includes the locomotives. For example, if there are 2 head-end locomotives, the first car behind these locomotives is in position 3. In Table 1, the position of the cars includes the head-end locomotives (positions 1 and 2) and the mid-train remote locomotive (position 73).

A review of the train summary documents provided by CP indicates that the train was compliant with TrAM marshalling requirements for the Laggan Subdivision. The Train Marshalling and Restrictions Report for the train did not contain any marshalling caution messages in Part 2 – Caution Messages, nor did it show any marshalling violations in Part 3 – Marshalling Violations for the TrAM areas that the train would traverse.

The train did not, however, meet the marshalling requirements indicated in the GOIs, which state that blocks of heavy cars should not be placed at the rear of the train unless blocks of cars ahead are equally heavy.

Figure 15 shows the weight distribution on the train and the position of the derailed cars.

1.13 TSB laboratory reports

The TSB completed the following laboratory report in support of this investigation:

- LP286/2019 – Train Dynamics Simulations

2.0 Analysis

The analysis will focus on wheel–rail interaction, undesired releases of the air brakes (UDRs) on rail cars, end-of-car arrangements, coupler swing angle, lateral-to-vertical forces (L/V) ratio, and train marshalling. The condition of the track was not considered contributory to the accident.

2.1 The occurrence

On Canadian Pacific Railway Company (CP)’s Laggan Subdivision between Calgary, Alberta, and Stephen, British Columbia (BC) (the beginning of Field Hill), train 401-02 was performing as expected, with no indications of any problems with the air brake system.

The train began descending Field Hill at around 0401. At 0412, 11 minutes into the descent, an in-cab alert activated, indicating a train-initiated UDR. The locomotive engineer (LE) increased the brake application and brought the train to a controlled stop. After the rail traffic controller (RTC) and the trainmaster were informed of the situation, the air brakes were recharged. The LE also expressed his view to the RTC, and separately to the trainmaster, that the train would likely experience another UDR; however, no alternative plan of action was considered to address the LE’s concerns.

Once the brakes were recharged, the train continued its descent. A few minutes later, at 0448, a train-initiated undesired emergency brake application (UDE) occurred as a result of a knuckle breaking on the trailing (east) end of the 50th car. The crew noted visual evidence of pre-existing rust on the fracture surfaces.

The broken knuckle was replaced, pressure-retaining valves (retainers) were set to the high-pressure (HP) position on 50 of the 72 head-end cars, and the train was recrewed.

The RTC and the trainmaster instructed the relief crew to continue the trip to Field. The train resumed its descent at about 0954.

At approximately 1010, while the head end of the train was exiting the Upper Spiral Tunnel, an in-cab alert activated, indicating that another UDR had occurred. In response, the relief LE placed the throttle in idle and made a full service brake application; he also quickly applied the dynamic brakes and then progressively increased the application to maximum (DB8) to bring the train to a controlled stop. However, the run-in that resulted as the train was rapidly decelerating caused the leading truck on the car in position 66 to derail. The air hoses between cars in positions 66 and 67 separated during the derailment, triggering a train-initiated UDE. By the time the entire train had come to rest, an additional 14 cars had derailed in the curve of the Upper Spiral Tunnel.

Finding as to causes and contributing factors

Following a UDR and the subsequent full service and dynamic brake applications, train 401-02 decelerated rapidly; the resulting run-in caused the leading truck on the car in position 66 to derail in the curve of the Upper Spiral Tunnel.

2.1.1 Sequence of events following the undesired release of the air brakes in the Upper Spiral Tunnel

Based on extensive review and analysis of the available data, the investigation determined that the most probable sequence of events from the UDR inside the Upper Spiral Tunnel to the derailment was as follows:

- A UDR occurred on the tail-end portion of the train as it was descending the 1.7% grade in the tunnel at about 12 mph; this spontaneous release of the air brakes created a run-in of the heavy cars at the tail end.

- The run-in propagated toward the head end, generating high buff forces at this end of the train.

- The LE received an in-cab alert of a sudden increase in brake pipe pressure and, in response, moved the throttle to idle, increased the 10 psi air brake application to a full service application, quickly applied the dynamic brakes, and then progressively increased the application to the maximum (DB8).

- The brake applications created high brake retarding forces on all rail cars in the train consist, but especially on the 50 cars at the head end that had retainers applied, and hence the braking forces were not evenly distributed throughout the train.

- The combination of steep grade, sharp curve, and high braking forces exerted high lateral forces at the wheel–rail interface, whereas the vertical forces exerted on the wheels of the empty cars in the middle of the train were relatively low; for the car in position 66, an empty 42-ton and 94.8-foot flat car, the L/V ratio reached a critical level, and one or more of the car’s wheels climbed over the rail.

- While the car in position 66 derailed, its air hoses separated, resulting in a UDE.

- The UDE further increased the braking forces by about 20%, leading to critical L/V ratios on the empty rail cars in positions 79 to 92, which also derailed.

- Following the UDE and the derailment, the train came to an abrupt stop in about 253 feet.

2.2 Wheel–rail interaction

In this occurrence, lateral forces were applied to the rail as the train was descending the steep grade and negotiating the curves. The lateral forces were generated by the longitudinal buff forces acting through the alignment of the couplers between adjoining cars, and particularly the high coupling angle created by long-shank couplers on cars equipped with end-of-car cushioning devices (EOCCDs). Normally, moderate lateral forces are expected while descending Field Hill. However, the magnitude of these lateral forces increased suddenly during the UDR and subsequent application of the air and dynamic brakes in the Upper Spiral Tunnel.

The lateral forces did not result in critical L/V ratios on the loaded cars because their weight created an offsetting downward vertical force on the car wheels. However, the low weights of the empty cars and lower downward vertical forces acting on their wheels gave rise to critical L/V ratios on the empty cars in the middle of the train consist where the buff forces were higher.

The TSB simulation indicated that, even if the couplers reached an angle of only 8°, which is half of the maximum coupler swing angle on cars equipped with EOCCDs, the high in-train forces generated an L/V ratio of more than 1.0 in the curve. This L/V ratio exceeds the threshold of 0.82 established by research conducted by the Association of American Railroads (AAR) as the point at which wheel lift is impending; it was therefore sufficiently high for a wheel-climb derailment.

The high lateral forces, combined with the low vertical forces, destabilized the empty rail cars, leading to the derailment.

Finding as to causes and contributing factors

Elevated longitudinal buff forces following the full service, dynamic, and emergency brake applications resulted in critical L/V ratios, wheel lift, and the derailment of 15 empty cars that were travelling on the curve in the Upper Spiral Tunnel.

2.3 Undesired release of the air brakes

A UDR occurs when the air pressure in a train’s brake pipe spontaneously increases, causing the car control valve (CCV) on a rail car to automatically release the brakes on that car. The effect of this release, reinforced by the accelerated service release function of the CCV, is detected by the CCVs on the adjoining cars, triggering a domino effect in which the release propagates in a wave in both directions. This brake release then propagates along the entire length of the brake pipe at about 600 to 700 fps (depending on the specific characteristics of the various CCVs in the train consist).

In this occurrence, in response to the second UDR when the train was in the Upper Spiral Tunnel, the relief LE made a full service brake application in combination with the application of the dynamic brakes and the train began to decelerate rapidly. The brake application command was transmitted by radio to the mid-train remote locomotive. The brake application then propagated rearward from the head-end locomotives, while simultaneously also propagating in both directions from the mid-train remote locomotive. The cars closest to the head-end locomotives and the mid-train remote locomotive responded to the brake application first. The tail end of the train began decelerating a little later, as it takes time for a brake application to propagate along the length of a train.

A review of the video recording from the remote locomotive forward-facing camera confirms the sudden and heavy run-in of the rear of the train following the UDR.

Findings as to causes and contributing factors

When the air brakes and the dynamic brakes were applied in response to the UDR in the Upper Spiral Tunnel, the rapid deceleration and resulting in-train forces were not evenly distributed along the length of the train. As a result, the block of loaded cars at the tail end ran into the block of empty cars immediately ahead, creating high concentrated in-train buff forces on those empty cars.

2.4 Pressure-retaining valves

When retainers are set to the HP position, they provide brake-retarding force, which can help control speed when a train resumes its descent after the air brakes are released. The use of retainers is beneficial while the air brake system is recharging. However, if the air brakes are applied to a car on which the retainer has been set, the air brake application will further increase the brake-retarding force provided by the retainer on that car, increasing the overall in-train forces.

In this occurrence, after the first UDE on Field Hill as a result of the broken knuckle, the retainer was set to the HP position on 50 cars ahead of the mid-train remote locomotive.

When the UDR occurred in the Upper Spiral Tunnel, the relief LE made a full service brake application, as required by operating rules.

The retainers set on the cars at the head end of the train resulted in higher overall brake forces on those cars, creating an imbalance in the magnitude of the brake-retarding force along the train. The combination of retainers and the 10 psi brake application would theoretically result in having a brake cylinder pressure of 45 psi on the 50 cars at the head end; the balance of the cars on the train would have a brake cylinder pressure of 25 psi. After the full service brake application, the brake cylinder pressure on the cars with retainers set would equalize at a theoretical maximum of approximately 70 psi, whereas the pressure on the cars without retainers set would equalize at a theoretical maximum of 65 psi.

Finding as to causes and contributing factors

The retainers set on 50 cars at the head end of the train contributed to the uneven distribution of the brake forces along the length of the train.

2.5 End-of-car arrangements

A review of data from the locomotive event recorders and the end-of-train (EOT) device indicated that the UDR events occurred when the brake pipe pressure spontaneously increased on its own, suggesting that there was a dynamic condition on 1 or more rail cars. A dynamic condition is inherently intermittent, manifesting and then resolving as the train moves. A fluctuation in local brake pipe pressure of as little as 1.5 to 2.0 psi can actuate the CCV, resulting in a UDR.

Finding as to causes and contributing factors

The UDRs were triggered as a result of an increase in local brake pipe pressure of 1.5 to 2.0 psi while the train was in motion.

Dynamic conditions that lead to a temporary and spontaneous increase in brake pipe pressure are often caused by the motion of components in the end-of-car arrangements, such as couplers, draft systems, gladhand couplings, brake hoses, and trolley arrangements. This motion results from the buff and draft forces that are invariably present in a moving train.

The intermediate hose and trolley arrangements on cars equipped with EOCCDs are particularly vulnerable to performance issues under buff forces. This vulnerability is due in part to the large range of motion and in part to the fact that the intermediate hose is routed in a serpentine manner underneath the car body.

If an intermediate hose and trolley arrangement is a legacy design, improperly maintained or incorrectly repaired, the intermediate hose could fold over on itself in a kinked manner under buff forces, which could temporarily interrupt the normal flow of air until the hose returns to a neutral position. Likewise, if the movement of the trolley is impeded, the gladhand couplings could peak under high buff forces, temporarily leaking air until they return to a neutral position. In both cases, the movement of the components under high in-train forces could cause dynamic fluctuations in brake pipe pressure.

Following the derailment, to help determine the possible cause of the UDRs, CP conducted air brake inspections and testing on the mid-train locomotive, the EOT device, the first car to derail (position 66), and the non-derailed cars that had operated in positions 67 to 162 on the train consist. Visual inspection revealed that the centrebeam cars in the TTZX series were equipped with older end-of-car intermediate hose and trolley arrangements, compliant with a previous version of AAR Standard S-4003 (in the AAR Manual of Standards and Recommended Practices). In this previous version of the standard, the gladhand coupling extended beyond the pulling face of the coupler by about 4 inches, creating a risk that the gladhand couplings would peak or that the intermediate hoses would kink. CP found that, in at least 3 centrebeam cars with this configuration, there was a high potential for the intermediate hoses to become kinked due to misalignment issues when the train slack was in a buff state.

According to CP, the car considered most likely to have caused the UDRs in this occurrence, based on its review of the data from the locomotive event recorder and EOT, was a car in the TTZX series, TTZX 86441 (position 96 in the train consist).

The TSB investigation also determined that, on some cars, the end hose gladhand couplings had been wrapped together using tie wraps; this was observed specifically on some of the derailed centrebeam cars in the SOO series that were equipped with EOCCDs. Tie wrapping the end hose gladhand couplings is intended to reduce the likelihood of hose separation. However, it is an unconventional practice that could result in unnatural rotation or movement of the end hoses, creating a risk that the gladhand couplings would peak or the intermediate hoses would kink, and increasing the risk of erratic brake pipe leakage or brake pipe pressure fluctuations, all of which could lead to a UDR.

Finding as to causes and contributing factors

Fluctuations in brake pipe pressure likely resulted from older and non-conventional configurations of the end-of-car intermediate hose and trolley arrangements on some of the rail cars, causing the UDR.

The AAR has updated its standards for end-of-car intermediate hose and trolley arrangements. However, there is no AAR requirement to upgrade legacy arrangements to comply with newer standards unless the components are found damaged and require repair. Therefore, older hose and trolley arrangements that are not compliant with the latest standards will remain in service until the cars that are so equipped are removed from service for other repair work.

Finding as to risk

If rail cars equipped with older intermediate hose and trolley arrangements remain in service without complying with the latest standards, the performance of a train’s brake system can be negatively affected, increasing the risk of UDRs.

2.6 Train marshalling

Train marshalling refers to the planned placement of rail cars in a train. There are different approaches to marshalling; for example, rail cars can be placed according to their length and/or weight, their destination, or other considerations. An in-depth understanding of how in-train forces affect train safety and derailment prevention is the cornerstone of best practices in train marshalling.

Several factors can affect the magnitude of in-train forces, such as the manner in which car weights are distributed throughout a train, the placement of cars equipped with EOCCDs, and the overall length of the train. On long trains in particular, the placement of heavy and light cars in relation to each other is especially important; the risk of derailment increases when light empty cars are placed in front of, or between, heavier ones. Managing in-train forces on mixed-merchandise freight trains also brings additional challenges. These trains typically haul diverse rail car types (for instance, some cars might be equipped with EOCCDs while others are not) of different weights and lengths.

Trains can also be subjected to destination marshalling, also known as destination blocking. When using this approach, cars are grouped together in blocks that are destined for the same location. This approach tends to ease the workload related to en-route switching activities by minimizing the handling of cars. However, destination marshalling can lead to loaded cars being concentrated at the tail end of the train and behind empty cars toward the head end. Under these circumstances, train dynamics are affected and may not be optimal.

2.6.1 Marshalling of the occurrence train

The train in this occurrence presented several challenges in terms of managing in-train forces. The train was a large mixed-merchandise freight train hauling diverse rail car types having different weights and lengths. Many of the rail cars (39 cars, or 24.5% of the total cars) were equipped with EOCCDs, which increased the amount of slack in the train. The train would also be travelling on the Laggan and Mountain subdivisions, which present unique challenges due to grade and curvature.

In addition to managing in-train forces, the make-up of the train had to accommodate destination blocking. Forty cars were to be set off in Golden, BC, and another 94 cars were to be set off further west, in Kamloops, BC. The remaining 25 cars on the train were to be taken to the train’s final destination, the yard at Port Coquitlam, BC.

Given the competing objectives of managing in-train forces and assembling the train for efficiently setting off cars en route, the train was marshalled with a group of loaded heavy cars at the front of the train, followed by a group of 71 empty cars in the middle, and 19 fully loaded cars near the rear, including a solid block of 16 loaded cars in positions 135 through 150. The 40 cars to be set off in Golden had been placed at the tail end of the train. Of the 94 cars to be set off in Kamloops, 45 were placed in 3 separate blocks on the front half of the train and a 49-car block was placed immediately behind the mid-train locomotive.

This train make-up, for the most part, met industry best practices for train marshalling. However, the empty cars marshalled ahead of the loaded cars positioned on the tail end made the empty cars more susceptible to a wheel climb derailment on curves in certain operating conditions, such as a full service or emergency brake application, or in situations where retainers are set on some of the rail cars.

In this occurrence, the train’s weight distribution, with empty cars in mid-train positions, and particularly 32 empty bulkhead flat cars located behind the distributed power remote locomotive and ahead of the block of heavy loaded cars near the tail end of the train, resulted in the loaded cars running into the block of empty cars immediately ahead, creating high concentrated in-train forces.

After the derailment, CP, in collaboration with Simon Fraser University, conducted train dynamics simulations of the occurrence train. The results indicated that, when there are more than 15 empty centrebeam or bulkhead flat cars on a mixed-merchandise train, they must be marshalled to the extreme rear. These car types are equipped with EOCCDs and a large number of EOCCDs grouped together on a train can also significantly increase the train’s total slack.

Finding as to causes and contributing factors

The train was marshalled with heavy cars at the tail end, which contributed to the high in-train buff forces exerted on the empty cars near the middle of the train.

2.6.2 Interpretation of the rules and instructions governing train marshalling

At the time of this occurrence, there were no specific Transport Canada–approved train marshalling guidelines, nor were there regulatory requirements for limiting maximum in-train forces through marshalling. Railways in Canada develop their own marshalling rules and instructions to help manage in-train forces and prevent derailments.

At CP, marshalling requirements are governed by the company’s General Operating Instructions (GOIs), and trains must also be compliant with TrAM, CP’s proprietary computer-based train marshalling verification program.

According to Section 7, Item 6.1 of the GOIs:

- heavy cars must be placed as close as possible to the head of the train and not be placed at the rear of a train unless the blocks of cars ahead are equally heavy,

- light cars should be placed as close as possible to the rear, unless the cars behind them are also relatively light.

A note at the end of these instructions states that: “[t]he Train Area Marshalling Messages do not indicate whether train marshalling fulfills the intent of this item.” Footnote 33 TrAM, therefore, does not check that trains comply with these requirements. In the absence of automatic verification, the onus falls on operational personnel to ensure and validate compliance with these instructions.

In this occurrence, the train was TrAM-compliant when it left Alyth Yard. The TrAM marshalling and restrictions report did not contain marshalling caution messages, nor did it show any marshalling violations for the TrAM areas that the train would traverse. However, the train was not compliant with Section 7, Item 6.1 of the GOIs, since it was marshalled with a group of loaded heavy cars at the head of the train, followed by a group of 71 empty cars in the middle, and a smaller group of 19 heavy loaded cars near the tail end.

Finding as to risk

If a computer application used for train marshalling verification does not consider all applicable train marshalling requirements, such as requirements stipulated in GOIs, special instructions, and bulletins, a critical rule or instruction could be missed, increasing the risk of derailment.

Section 7, Item 6.1 of the GOIs also states that these instructions are “subject to destination blocking,” and that “[d]estination blocking does not take precedence over TrAM marshalling violations that are shown on the train consist.” Footnote 34