Rolling stock collision with object and employee injury

VIA Rail Canada Inc.

Train No. 62/52

Mile 240.44, Kingston Subdivision

Brighton (Ontario)

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 02 February 2019, at 1007 Eastern Standard Time, VIA Rail Canada Inc. passenger train 62/52, with 302 passengers on board, was proceeding eastward at about 95 mph on the north track of the Kingston Subdivision when the train experienced a train-initiated emergency brake application near Brighton, Ontario (Mile 240.8). An inspection determined that the train had passed over track maintenance material placed between the rails. Some tie plates and ballast became airborne, damaged the train and struck a nearby Canadian National Railway Company engineering hi-rail vehicle. There were no injuries to the crew or passengers aboard the train, but an employee seated in the hi-rail vehicle was seriously injured. A fuel tank on one of the locomotives was punctured and released about 1600 gallons of diesel fuel.

1.0 Factual information

On 02 February 2019, at about 0835,Footnote 1 VIA Rail Canada Inc. (VIA) passenger train 62/52 departed Union Station in Toronto, Ontario, proceeding eastward on the Kingston Subdivision with 302 passengers on board (Figure 1). Train 62/52 was being operated as a “J” trainFootnote 2 from Toronto (Mile 333.8) to Brockville, Ontario (Mile 125.6), where the train would be separated. Train 62 would then continue on to Montréal, Quebec, and Train 52 would continue on to Ottawa, Ontario.

Departing Toronto, the train consisted of 1 head-end locomotive followed by 7 passenger cars (train 62), coupled together with a 2nd locomotive and 4 passenger cars (train 52). The train weighed 823 tons and was 992 feet long. The train crew consisted of 4 locomotive engineers, 2 positioned in the lead locomotive to operate the train and 2 positioned in the mid-train locomotive to operate train 52 after the train was separated.

1.1 Subdivision information

The Kingston Subdivision consists of double main track extending from Mile 10.3 (Dorval East, Quebec) to Mile 333.8 (Toronto, Ontario). The track is classified as Class 5 track according to the Transport Canada (TC)–approved Rules Respecting Track Safety. Train movements on this subdivision are governed by the centralized traffic control method of train control, as authorized by TC’s Canadian Rail Operating Rules, and are supervised by a rail traffic controller located in Montreal.

In the vicinity of the occurrence, the Kingston Subdivision is tangent and oriented east-west. There are 3 tracks in close proximity to each other: the north and south tracks of the Kingston Subdivision and the single main track of the Canadian Pacific Railway Belleville Subdivision, 75 feet to the south.

The authorized track speed on the Kingston Subdivision is 95 mph for passenger trains, 100 mph for passenger trains consisting of light rapid comfortable cars (LRC cars), and 65 mph for freight trains. Between Mile 240.00 and Mile 250.56, there were no temporary slow orders in place.

1.2 Rail replacement program

On 01 February 2019, a Canadian National Railway Company (CN) rail gang had been replacing rail on the south track of the Kingston Subdivision between Mile 250.56 and Mile 251.20. The rail gang’s shift began at 1800 in Cobourg, Ontario, with a job briefing to discuss the work plans. The shift continued throughout the night and into the morning of the following day.

On the morning of 02 February 2019, while track work was being performed on the south track, a crew from the rail gang was dispatched to the next work site (Mile 240.0 to Mile 240.44) to prepare the site for rail installation on the north track. This preparatory work would help expedite the track work that was to be performed the following day (03 February 2019).

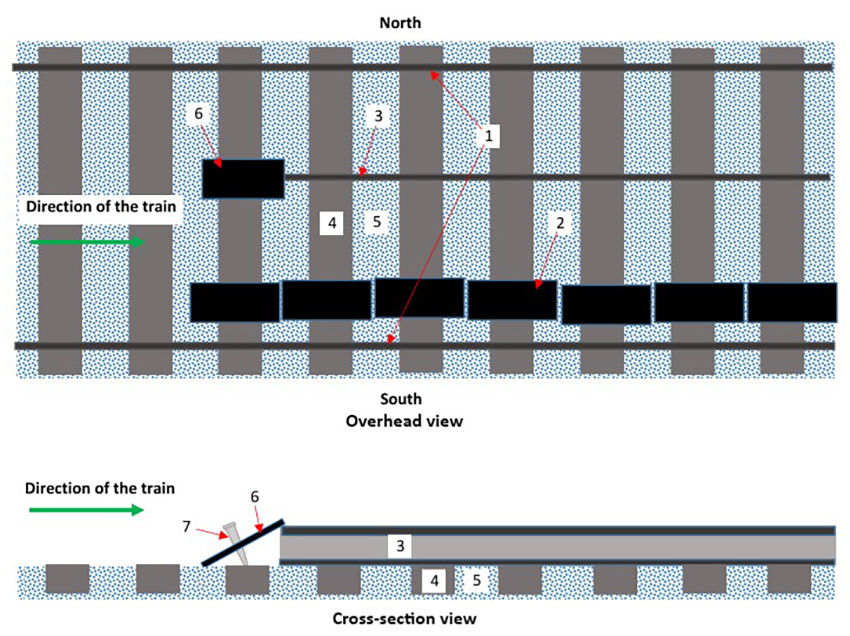

The preparatory work was performed as follows (Figure 2):

- Two continuous welded rails (CWR), each measuring about 2315 feet long, were placed from Mile 240.00 to Mile 240.44.

- One replacement rail was placed on the north side of the north track.

- The other replacement rail (number 3 in the track sketch) was placed between the north track rails. The rail ends were held in place with track spikes located on either side of the rail base.

- One angled deflector tie plate (number 6 in Figure 2) was leaned against each butt end of the replacement rail positioned between the rails and secured to a tie with a single track spike (number 7 in Figure 2). The plate was not to sit higher than 1 inch above the running rail of the north track.

- Replacement tie plates (number 2 in Figure 2) were pre-placed on each tie on the gauge sideFootnote 3 of the rail for the length of the replacement rail. The tie plates had generally been placed with the shoulders down and the bases facing up (i.e., upside-down).

Legend

1 Rails of the north track

2 Replacement tie plates

3 Replacement rail

4 Ties

5 Ballast

6 Deflector tie plate

7 Securement spike

1.3 The accident

On 02 February, after the track work was completed in the vicinity of Mile 251.20, 2 VIA passenger trains and 2 CN freight trains passed over the north track. Shortly thereafter, a track crew of 4 CN employees was sent to Mile 240.43 to inspect the preparatory work for the next evening’s shift.

At about 1006, the track crew arrived on site and parked just north of the north track, facing eastward about 500 feet east of the west end of the replacement rail.

At about 1007, the train, travelling at about 95 mph on the north track of the Kingston Subdivision, passed Mile 240.80, near Brighton, Ontario, when it encountered tie plates that had been left on the ties between the rails. A train-initiated emergency brake application occurred with the head-end of the train at Mile 240.38. The train continued in emergency braking for about 1.48 miles (7814 feet) before coming to rest at Mile 238.90.

At about the same time, the track crew’s hi-rail vehicle was struck by airborne tie plates, ballast and debris. One of the tie plates broke through the rear protective screen and window, entered the hi-rail vehicle cab, and struck one of the 4 employees in the vehicle, resulting in serious injuries. Once the train had passed, the crew began first aid and arranged for an ambulance to transport the injured employee to hospital. As a precaution, the other 3 crew members were also transported to the hospital, and were subsequently released. There were no injuries to the crew or passengers of train 62/52.

All movements on the adjacent Kingston Subdivision south track and the adjacent CP Belleville Subdivision were stopped to inspect the tracks and remove the debris.

1.4 Weather information

The ambient temperature at the time of the occurrence was −4.7 °C. The wind was blowing from the southwest at about 26 km/h.

1.5 Site examination

Impact marks were observed on the head of the replacement rail that was positioned between the rails of the north track, about 150 to 300 feet from the west end of the rail.

Tie plates and ballast had been displaced. The tie plates were no longer positioned in an orderly manner on the ties. Some tie plates remained between the rails and some were displaced to either side of the north track. Some tie plates and ballast had been propelled more than 100 feet away. Among the first 10 ties, 3 did not have tie plates on them (Figure 3). In addition, debris from various damaged components of the train was strewn about the site. About 100 feet west of the replacement rail, there was disturbed ballast between the rails of the north track.

With respect to the VIA cars, panels from the underside of the cars were hanging down, and snow had accumulated on the undersides of the cars.

1.5.1 Examination of the tie used to secure the angled deflector tie plate

The tie to which the angled deflector tie plate had been secured displayed the following (Figure 4):

- A square hole, that matched the profile of a spike, was observed within a crack in the tie, just in front of the west end of the replacement rail between the north track rails.

- The hole was consistent with the location of a spike that had been hammered into the tie to anchor the tie plate covering the west butt end of the rail.

- A shallow piece of wood fibre forward of the spike hole was missing.

- There was an inclined surface on the top edge of the spike hole.

- A shallow dent was present behind and to the left of the inclined surface.

- The crack extended from the edge of the tie plate to the center of the tie (Figure 5).

- The top surface of the tie plate had sunk below the surface of the tie indicating that the wood was in a state of decay.

During the site examination, TSB investigators observed several trains passing over the area of the accident. While some degree of deflection is expected under normal train operations, as the trains traversed the area, the track and ties—particularly the tie with the spike hole at the west end—deflected up and down with the passage of each wheel of the train.

1.5.2 Hi-rail vehicle examination

The CN engineering hi-rail vehicle sustained damage in the form of dents and broken glass. Impact damage from tie plates and ballast was evident on both the front and rear passenger-side doors. The rear window and the window of the rear passenger-side door were shattered. The protective metal screening on the rear window was punctured on the passenger side (Figure 6). The rear passenger-side seatbelt was damaged, as was the headliner above the driver’s seat. As a result of the damage, the hi-rail vehicle had to be towed to a shop facility for repairs.

1.5.3 Rolling stock examination

Following the occurrence, the train was taken to VIA’s Montréal Maintenance Centre for examination. No damage or missing parts were noted on the lead locomotive or the first 2 cars. The next 5 cars exhibited some undercarriage and belly plate damage. In addition, brake components such as disc brake pads, brake actuators, brake calipers, brake cylinders, and air brake hoses were damaged on these cars.

The mid-train locomotive and the 4 following cars were extensively damaged. The locomotive exhibited damage to the traction motors, gear cases, and axle generator. The fuel tank had been punctured, and about 1600 gallons of fuel had been released. The 4 cars following the mid-train locomotive displayed varying degrees of damage to brake components, wheelsets, belly plates, train air line and hose assemblies, as well as some passenger windows. A number of belly plates from the last 4 cars were missing.

1.6 Train movements prior to the arrival of the occurrence train

On 02 February 2019, 4 trains had safely passed on the north track over the area in the vicinity of the accident prior to the arrival of the occurrence train:

- At 0743, VIA passenger train 655 traversed the area, proceeding westward at 93 mph.

- At 0820, CN freight train X32122-01 traversed the area hauling 126 cars, weighing 7676 tons and measuring 7960 feet long.

- At 0915, VIA passenger train 60 traversed the area, proceeding eastward at 94 mph.

- At 0939, CN freight train Q12031-01 traversed the area hauling 128 cars, weighing 7080 tons and measuring 8106 feet long.

1.7 Instructions regarding track materials being left between the rails in advance of a rail relay program

At CN, it was common practice for rail gangs to leave rail and tie plates between the running rails in advance of a rail relay program involving CWR. The CN Engineering Track Standards state that:

- In preparation for a rail relay, CWR may be left in track between the running rails provided:

- The CWR does not sit higher than 1 inch above the top of the running rail.

- Deflectors are placed at each end of the rail.

- Ends of CWR are bypassed and spiked to allow expansion.

- CWR may be left between the running rails only until the next day’s work shift.Footnote 4

1.8 Passenger car inspection before departure

In accordance with the TC-approved Railway Passenger Car Inspection and Safety Rules, which prescribe the minimum safety standards for passenger cars operated by railway companies in trains at speeds not exceeding 125 mph, the entire consist of train 62/52 was inspected by a certified car inspector before it departed the VIA Toronto Maintenance Centre. The inspection covered, but was not limited to, the wheels, axles, roller bearings, trucks, car bodies, couplers, and draft arrangements.

The Railway Passenger Car Inspection & Safety Rules state that cars are not to be placed into service where

- any portion of the car body, under-car equipment, trucks, excepting wheels or their appurtenances has less than a 2 ½ inch (63.5 mm) clearance from the top of rail when fully loaded including passengers and baggage;

- any attachments for under-car equipment are loose, broken or missing.Footnote 5

During inspection of the occurrence train on the morning of 02 February 2019, no loose or low-hanging appurtenances were noticed on the cars or locomotives that could have come into contact with the track material that had been left between the rails of the north track.

1.9 Stopping distance for a passenger train

The stopping distance for a train is affected by many factors including brake application intensity, train speed, train weight, and type of rolling stock. Passenger trains are typically much shorter and lighter than freight trains. Although passenger trains will normally travel at higher speeds than freight trains, they are able to stop in much shorter distances. With properly functioning train air brakes, a passenger train similar to VIA train 62/52 travelling at the same speed (i.e., about 95 mph at the time of the occurrence) would normally be expected to stop within 3000 to 3500 feet following an emergency brake application.

1.10 Airflow and aerodynamic force beneath high-speed trains

The TSB Engineering laboratory conducted a review of available research literature relating to airflow beneath a high speed train. The review identified that this airflow is generally strong and turbulent, with speeds ranging from 0.4 to 0.8 of the vehicle’s speed, depending on the height of the airflow from the ballast bed and geometry of the trucks of the train.Footnote 6,Footnote 7 A report by the U.S Federal Railroad Administration identified the aerodynamic loadFootnote 8 beneath a high-speed train was one of the key factors that could cause ballast flight.Footnote 9

For this occurrence, engineering calculations based on aerodynamic principles were made. It was determined that aerodynamic force alone would not be sufficient to lift the tie plates from the position they had been originally placed in without the tie plates first being moved by something, and some preceding event would have been necessary to trigger the initial movement of the tie plates.

If a tie plate were moved and tilted up to an angle greater than 10° against the airflow, the moment created by the nominal aerodynamic force beneath a passing train would have the potential to cause a tie plate to rotate further upward. Further rotation of a tie plate in turbulent airflow would provide an opportunity for a tie plate to impact the underside of a car and other material in the vicinity.

1.11 Securement of the deflector tie plate

Based on the site examination and the engineering calculations, the following observations and conclusions were made relating to the securement of the deflector tie plate:

- The angled deflector tie plate, which was used to cover the west butt end of the replacement rail laid between the rails of the north track, was secured using a spike that had been hammered into a large crack in the tie.

- The deflections of the tie generated by passing trains likely caused the spike securing the angled deflector tie plate to become loose and to be displaced from the spike hole.

- A shallow piece of wood fibre that was forward of the spike hole was missing, and there was an inclined surface on the top edge of the spike hole. Both of these features were consistent with damage that could have been sustained by a spike that had loosened and rotated backwards.

- Once the spike was displaced, the angled deflector tie plate covering the end of the replacement rail between the rails of the north track was displaced within the turbulent airflow beneath the train.

- The shallow dent located immediately behind and to the left of the inclined surface was consistent with damage sustained from impact by a shoulder of the displaced angled deflector tie plate.

- Once displaced, the angled deflector tie plate likely triggered a chain of events when it struck some of the adjacent tie plates and the underside of the cars.

1.12 Other occurrences

Since 2015, there were 3 other occurrencesFootnote 10 in which VIA trains struck debris that caused damage to a train, including broken air reservoir shields, damaged air hoses, damaged brake actuators, and broken windshields. Vandalism was not identified as a contributing factor in any of these occurrences.

Following this occurrence, on 20 March 2019, at about 1445 Atlantic Daylight Time, VIA passenger train P01511-20, proceeding westward at approximately 70 mph on the CN Springhill Subdivision and operating with 2 locomotives and 14 passenger cars, was damaged and disabled after coming into contact with debris (a steel plate) at Mile 7.5. The debris caused some of the tie plates that had been placed between the rails by an engineering crew to strike and further damage the VIA train. Fuel was spilled from the fuel tank of the second locomotive. There were no injuries.Footnote 11

1.13 TSB laboratory reports

The TSB completed the following laboratory report in support of this investigation:

- LP095/2019 – Cause for the flight of tie plates underneath the passing train VIA train 62/52, Mile 241 of the CN Kingston Subdivision

2.0 Analysis

Neither the actions of the train crew nor pre-existing mechanical or track defects played a role in this accident. The analysis will focus on the displacement of track material left between running rails, the damage caused by airborne tie plates and ballast, and maintenance-of-way practices.

2.1 The accident

A Canadian National Railway Company (CN) rail gang had been replacing rail on the south track of the Kingston Subdivision between Mile 250.56 and Mile 251.20. A crew from the rail gang was dispatched to the next work site (Mile 240.0 to Mile 240.44 on the north track) to prepare the site for rail installation the following day. A replacement rail was placed between the rails of the north track. Replacement tie plates were placed between the rails of the north track on each tie, adjacent to the south rail. An angled deflector tie plate was leaned against either end of the replacement rail positioned between the rails and secured to a tie with a single track spike.

On 02 February 2019, 4 trains safely passed over the track material between the rails of the north track in the area of the accident, prior to the arrival of the occurrence train, VIA Rail Canada Inc. (VIA) passenger train 62/52.

After the track work was completed at Mile 251.20, another crew of 4 employees in a hi-rail vehicle drove to Mile 240.43 to inspect the work conducted to prepare for the next evening’s shift. At about 1006, the track crew arrived on site and parked just north of the north track, facing eastward where they remained in the vehicle and could see the train approaching in the rear view mirror.

At about 1007, the train was travelling at about 95 mph on the north track of the Kingston Subdivision when it began to pass over tie plates left on the ties between the rails. Subsequently, a train initiated emergency brake application occurred at Mile 240.38, and the train continued in emergency braking for about 1.48 miles (7814 feet) before coming to rest at Mile 238.90. There were no injuries to the crew or passengers aboard the train, but an employee seated in the hi-rail vehicle was seriously injured.

The accident occurred when the train began to pass over tie plates that had been pre-placed between the rails of the north track, in preparation for a rail gang to lay rail the following day.

2.2 Displacement of track material left between running rails

A square hole, that matched the profile of a spike, was observed within a crack in the tie, just in front of the west end of the replacement rail between the north track rails. The hole was consistent with the location of a spike that had been hammered into the tie to anchor the angled deflector tie plate at the west butt end of the replacement rail. The marks on the tie in the vicinity of the spike hole were consistent with damage that would have been sustained by a spike that had loosened and rotated backwards. The spike holding the angled deflector tie plate against the west end of the replacement rail had been driven into a crack in the tie exhibiting signs of decay, which reduced the holding capacity of the spike. The spike became loose likely due to repeated deflections generated by the 4 trains that traversed the north track prior to the arrival of VIA passenger train 62/52.

The additional deflections generated by VIA train 62/52 as it passed over the west end of the replacement rail then dislodged the loosened spike, which removed the tie plate securement. Once free of any securement, the angled deflector tie plate fell off the west end of the replacement rail as a result of either additional deflections or an impact from an object such as snow or ice.

While the lead locomotive and the first 2 cars passed safely over the area, airflow forces beneath the passing VIA train 62/52 built up to a level that was sufficient to cause the newly repositioned angled deflector tie plate to be displaced into the turbulent airflow and become airborne.

Once the angled deflector tie plate became airborne, it likely struck the train and the nearby unsecured tie plates that had been left between the rails, setting off a chain reaction that resulted in multiple tie plates and ballast becoming airborne.

2.3 Damage caused by airborne tie plates and ballast

Impact marks were observed on the head of the replacement rail that was positioned between the rails of the north track, and on the ties for about 150 feet to 300 feet from the west end of the replacement rail. Tie plates and ballast had been displaced, with some remaining between the rails and some being displaced to either side of the north track. Some tie plates and ballast had been propelled more than 100 feet away. Some of the airborne tie plates and ballast struck the train undercarriage, belly plate, and the exposed train and air brake components, resulting in extensive damage, particularly to the trailing half of VIA train 62/52.

2.3.1 Emergency braking

One locomotive and 9 of the 11 cars on VIA train 62/52 sustained damage to air brake components. The tie plates that became airborne under the passing train damaged disc brake pads, brake actuators, brake calipers, brake cylinders, and air brake hoses. The damage reduced the ability of the train to stop in emergency braking and resulted in a much longer stopping distance than usual.

The stopping distance for a train is affected by factors such as brake application intensity, train speed, train weight, and type of rolling stock. Passenger trains are typically much shorter and lighter than freight trains. Although passenger trains normally travel at higher speeds than freight trains, they are able to stop in shorter distances. With properly functioning train air brakes, a passenger train similar to VIA train 62/52 travelling at the same speed (i.e., about 95 mph at the time of the occurrence) would normally be able to stop within 3000 to 3500 feet following an emergency brake application.

However, in this case, the train initiated emergency brake application occurred at Mile 240.38 and the train continued in emergency braking for about 1.48 miles (7814 feet) before coming to rest at Mile 238.90. This is over twice as long as the normal emergency stopping distance for a train of this type. Although the train came to rest under its own braking power, the damage sustained by the brake components greatly reduced the train’s braking capacity and its ability to stop in emergency braking.

2.3.2 Hi-rail vehicle damage and employee injury

Tie plates and ballast were expelled from under the train. The CN engineering hi-rail vehicle that was positioned adjacent to the north track sustained impact damage and became immobilized due to airborne tie plates and ballast. An airborne tie plate struck the hi-rail vehicle from behind, broke through the rear protective screen and window, entered the vehicle, and seriously injured one of the 4 CN engineering employees inside.

2.4 Maintenance-of-way practices

It was common practice among CN engineering rail replacement gangs to place track material between the rails or along the right-of-way in advance of track maintenance programs. There are instructions guiding employees on how to safely position this material. Despite these instructions, a similar accident occurred about 6 weeks later which also involved a VIA passenger train and tie plates placed between the rails.

Furthermore, since 2015, there have been 5 occurrences, including this occurrence, where airborne debris struck a VIA train, indicating that debris can be set in motion by passing trains, sometimes damaging the train.

If track materials for work gangs are left between the rails of a track, they can be struck by debris and placed in motion in the turbulent airflow beneath high-speed passenger trains, creating a risk of damaging equipment and injuring people adjacent to the track.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- The accident occurred when the train began to pass over tie plates that had been pre-placed between the rails of the north track, in preparation for a rail gang to lay rail the following day.

- The spike holding the angled deflector tie plate against the west end of the replacement rail was driven into a crack in the tie exhibiting signs of decay, which reduced the holding capacity of the spike.

- The spike became loose likely due to repeated deflections generated by the 4 trains that traversed the north track prior to the arrival of VIA Rail Canada Inc. passenger train 62/52.

- The additional deflections generated by VIA Rail Canada Inc. train 62/52 as it passed over the west end of the replacement rail then dislodged the loosened spike, which removed the tie plate securement. Once free of any securement, the angled deflector tie plate fell off the west end of the replacement rail as a result of either additional deflections or an impact from an object such as snow or ice.

- Airflow forces beneath the passing VIA Rail Canada Inc. train 62/52 built up to a level that was sufficient to cause the newly repositioned angled deflector tie plate to be displaced into the turbulent airflow and become airborne.

- Once the angled deflector tie plate became airborne, it likely struck the train and the nearby unsecured tie plates that had been left between the rails, setting off a chain reaction that resulted in multiple tie plates and ballast becoming airborne.

- Some of the airborne tie plates and ballast struck the train undercarriage, belly plate, and the exposed train and air brake components, resulting in extensive damage, particularly to the trailing half of VIA Rail Canada Inc. train 62/52.

- An airborne tie plate struck the hi-rail vehicle from behind, broke through the rear protective screen and window, entered the vehicle, and seriously injured one of the 4 Canadian National Railway Company engineering employees inside.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If track materials for work gangs are left between the rails of a track, they can be struck by debris and placed in motion in the turbulent airflow beneath high-speed passenger trains, creating a risk of damaging equipment and injuring people adjacent to the track.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- Although the train came to rest under its own braking power, the damage sustained by the brake components greatly reduced the train’s braking capacity and its ability to stop in emergency braking.

4.0 Safety action

4.1 Safety action taken

4.1.1 Transportation Safety Board of Canada

On 25 March 2019, the TSB issued Rail Safety Advisory (RSA) 03/19 to the Canadian National Railway Company (CN) and VIA Rail Canada Inc. (VIA) on VIA trains coming into contact with track materials placed between the rails in preparation for track work. In the advisory, the TSB indicated that given the potential consequences when trains come into contact with track materials, CN, in conjunction with VIA, might wish to conduct a risk assessment to identify and implement appropriate measures to ensure that VIA trains can travel safely through locations where track materials are placed between the rails in preparation for track work.

4.1.2 Canadian National Railway Company

On 25 March 2019, CN issued instructions that effective immediately and until further notice, tie plates or other track materials will not be left between the rails before any work block is undertaken on all passenger train corridors.

In the future, should CN consider resuming the practice of leaving tie plates or other track materials between the rails on a passenger train corridor, CN has committed to conducting a risk assessment in conjunction with VIA Rail Canada.

4.1.3 VIA Rail Canada Inc.

On 18 April 2019, VIA responded to TSB Rail Safety Advisory 03/19, stating that it would support any future risk assessment CN may undertake that has an impact where CN and VIA jointly operate.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .