Non–main-track collision and derailment

Canadian Pacific Railway

Yard Assignment CW11-06

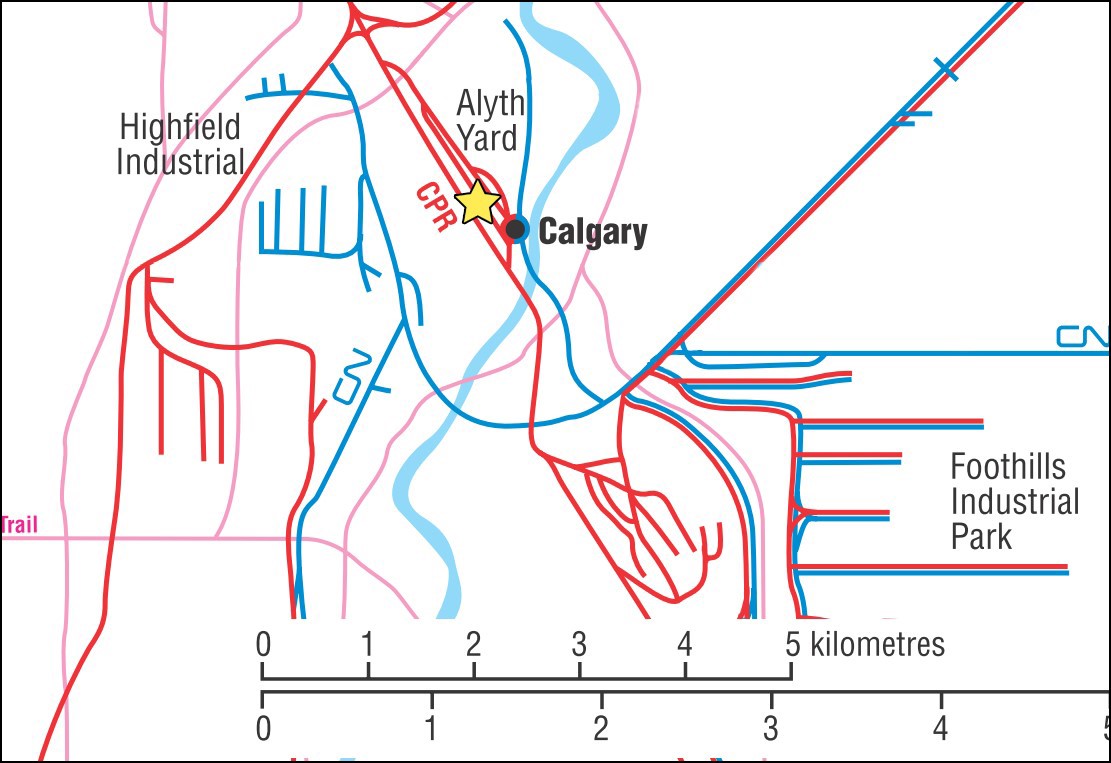

Alyth Classification Yard

Calgary, Alberta

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 06 January 2019, at approximately 0655 Mountain Standard Time, the crew of Canadian Pacific Railway Yard Assignment CW11-06 was switching cars eastward into the classification tracks at Alyth C-Yard in Calgary, Alberta, when 56 cars disconnected from the movement and ran uncontrolled down the lead track into the designated emergency track, contacting a cut of stationary loaded hopper cars. As a result of the collision, a total of 22 cars derailed. No injuries were reported. A small amount of fertilizer pellets was spilled and later recovered. The product was non-regulated and posed no threat to the environment.

1.0 Factual information

1.1 The occurrence

Footnote 1 Footnote 2 Footnote 3The assignment, consisting of 2 locomotives and 82 rail cars (56 loaded cars and 26 empty cars), weighed 7560 tons and was 4974 feet in length. The locomotives, CP 4440 and CP 4526, were both 4-axle, 2000-horsepower General Motors EMD GP38-2 locomotives. The cars were being switched without the air brake systems charged.Footnote 4

The crew for the assignment consisted of 2 conductors. The conductor located at the padFootnote 5 (the foreman) controlled the remote control locomotive system (RCLS) equipment and operated the uncoupling levers to separate the cars. The conductor located in the switch control room (the yard helper) operated the switches remotely once the cars were separated. Both crew members were qualified for their respective positions and met established fitness and rest requirements.

The foreman had 32 years of experience working yard operations and had been trained and qualified in RCLS since August 2015. Prior to his work shift that day, he had performed the role of foreman (at the pad) 7 times and the role of yard helper 3 times.

The yard helper had been provided with on-the-job training, which included being given a manual with instructions on how to operate the power switches. Because this was his first time working in the switch control room, he arrived 45 minutes prior to his shift to orient himself with the requirements of the job. During his shift, he was under the guidance of an assistant trainmaster who was also positioned in the switch control room. The yard helper had been qualified for RCLS operations since September 2015.

Prior to the occurrence, the crew had made 4 separate moves, switching cars to different tracks. The last of these moves consisted of kicking 3 empty tank cars (TIMX 19202, TILX 135677, and TIMX 19214) into Track CT-07. At this point, the number of cars in the cut of cars being handled had been reduced from 82 to 75.

The next move (the occurrence move) involved kicking a single empty car (SRIX 33958) into Track CT-21. As the car was being released, the foreman placed the RCLS into “stop,” as required by the manoeuvre. This triggered the application of the locomotive brakes, bringing the head end of the movement to a stop while the slack between the cars extended sequentially into a state of tension known as draft. The foreman then noted that 56 cars that should have stopped were still moving. Realizing that these cars were moving uncontrolled, he immediately made an emergency broadcast and informed the yard helper that there was an uncontrolled movement.

The yard helper lined the switch for Track CT-01, the designated emergency track. The 3 tank cars from the preceding movement and the uncontrolled cut of cars entered track CT-01, where they struck 14 stationary loaded hopper cars about 440 feet east of the west clearing point.

The uncontrolled movement consisted of 56 cars, including the single empty car that was destined for Track CT-21 but had not separated from the cars behind it. Of these 56 cars, 40 were loaded and 16 were empty. The uncontrolled movement weighed 5660 tons and was 4130 feet long. After the 56 cars caught up to the 3 empty tank cars from the preceding movement, the uncontrolled movement, which was now 59 cars long, weighed 5751 tons and was 4310 feet long. It had reached an estimated speed of 13.5 mph at the time of the collision.Footnote 6

1.2 Sequence of events

Table 1 summarizes the sequence of events in this occurrence. This summary is based on various sources of information, including but not limited to video recordings from cameras in Alyth Yard and the locomotive event recorder from the occurrence locomotives.

The crew members reported for duty at about 0630. A job briefing was performed with the assistant trainmaster at 0640. During the briefing, a revised procedure on emergency tracks was discussed, and it was established that tracks CT-01 and CT-19 would be the designated emergency tracks.

| Time | Event |

|---|---|

| 0642:58 | Two loaded cars of grain (DME 52206 and SOO 118464) were kicked into Track CT-08. |

| 0647:16 | Empty car PROX 34422 was kicked into Track CT-06. |

| 0650:51 | Empty car TILX 305980 was kicked into Track CT-13. |

| 0654:19 | Three empty tank cars (TIMX 19202, TILX 135677, and TIMX 19214), weighing about 91 tons, were kicked toward track CT-07. |

| 0655:00 | The crew initiated the next movement, which involved kicking empty car SRIX 33958 into Track CT-21. After placing the RCLS into “stop” as part of this manoeuvre, the foreman noted that several other cars were still moving. |

| 0656:46 | The foreman, recognizing that there was an uncontrolled movement, made an emergency broadcast over the radio, and then informed the yard helper that there was an uncontrolled movement. |

| 0656:48 | The yard helper lined the switch for the designated emergency track (CT-01). |

| 0656:53 | The uncontrolled movement entered Track CT-01. Car SRIX 33958 had not separated from the movement. The uncontrolled movement had caught up to the preceding movement of 3 empty tank cars that had been kicked toward Track CT-07. |

| 0657:25 | The uncontrolled movement and the 3 cars from the previous movement collided with the 14 loaded hopper cars that were stationary in Track CT-01. |

1.3 Site examination

As a result of the collision, 22 cars derailed (Figure 2). Of these, 20 had derailed on tracks CT-01, CT-02, and CT-03, including 13 of the 14 hopper cars that were struck by the uncontrolled movement (the first car struck, LAFX 40177, was damaged but did not derail). These 3 tracks were separated by standard yard track centres. The remaining 2 cars had derailed on an adjacent track (Track VT-12) that is also used for mobile car repairs when they were struck by tank car SMLX 355, which had crossed the yard roadway by about 25 feet. Track VT-12 was not being used for mobile repairs at the time of the occurrence.

The 22 derailed cars consisted of 2 empty flat cars, 8 covered hopper cars loaded with fertilizer (non-regulated), 1 residue covered-hopper car last containing ammonium nitrate (UN 1942), and 11 residue tank cars. Of the residue tank cars, 4 last contained anhydrous ammonia (UN 1005) and 7 last contained molten sulphur (UN 2448). Eighteen cars were subsequently scrapped, and 4 cars were repaired and placed back into service.

None of the residue tank cars that last contained dangerous goods spilled any product. Four of the covered hopper cars loaded with fertilizer spilled varying amounts of product.

The separation between the uncontrolled cut of 56 cars and the rest of the assignment had occurred between the 19th car (AOKX 90294) and the 20th car (CP 429137). Preliminary examination indicated that a coupler knuckle had broken on the B end of car CP 429137. The broken knuckle was sent to the TSB Engineering Laboratory for metallurgical examination.

1.4 Emergency response

Immediately after the occurrence, supervisory personnel were notified and the emergency response was initiated. At 0800, emergency response personnel and equipment arrived on site.

Response agencies included CP (company officials, mechanical department staff, hazmat technicians and police services), Iron Horse Response (the hazardous materials response contractor), GHD,Footnote 7 and the Calgary Fire Department (CFD). The incident command system was implemented with the CFD as the lead agency.

The emergency response personnel

- set up an incident command trailer as the operations base;

- completed a scene size-up, including preliminary damage assessments and preparation of a site diagram to identify all cars involved and their contents;

- set up a perimeter to ensure that no one could enter the hot zone without authorization;

- identified all dangerous goods involved in the occurrence and made the safety data sheets available;

- conducted meetings to ensure that all personnel on site were aware of any safety issues; and

- used drones to determine if product was leaking and if other hazards existed.

At 1030, all agencies on site participated in the first safety briefing to outline existing hazards and to develop an incident action plan. The priority hazard was determined to be the contact point between the A-end head shield of a car containing residue anhydrous ammonia (SRIX 33958) and a knuckle from another car (SRIX 33931). Assessment teams entered the site with assistance from a CFD engine and tender (present to provide emergency water curtains if required). The damage was deemed to be non-critical, and the knuckle was removed from contact with the head shield.

Once the CFD was satisfied that the site was safe for remediation, the cleanup process began. Site control was passed to CP; however, the CFD maintained a presence on site. As part of the cleanup, CP provided a fire trailer on site to extinguish any fires if required, and heavy equipment was brought in.

Throughout the day, cars were slowly pulled away from the scene and staged for later removal when resources permitted. Further inspections and damage assessments were completed on the remaining residue ammonia cars. Fertilizer that had spilled during the derailment was cleaned up using vacuum trucks.

All cars were systematically removed from the site. The emergency response was concluded at 0140 on 07 January 2019.

1.5 Alyth C-Yard information

Alyth C-Yard, which had previously been used as a hump yard,Footnote 8 was deactivated in 2013 and re-opened on 22 December 2018 as a flat switching yardFootnote 9 (Figure 3). In both hump yards and flat switching yards, cars are sorted into specific tracks or “classified” based on designations given to specific tracks. For example, a track may be designated for cars destined to a specific city or for cars to be operated on a specific train.

At the west end of the yard, the location of the occurrence, track switches are operated remotely from the control room using a switch control panel. The physical location of the control room is off the southeast corner of the yard office between the yard office and the switching lead.

When CP re-opened the yard, it recognized the risk that cars could run out the east end of the yard and compromise the safety of other switching operations. To mitigate this risk, Alyth C-Yard Emergency Process Instructions, issued to employees when the yard commenced operations, indicated that tracks CT-09 and CT-20 were to be the designated emergency tracks. Subsequent operational experience led to the need for flexibility in the selection and designation of emergency tracks.

On 05 January 2019, the day before the occurrence, CP had issued revised procedures in the event of an emergency, entitled “Emergency Process Alyth Bowl.” Those procedures stated:

This is the procedure if we have cars that break away from the switching lead moving on their own momentum.

Have two [e]mergency tracks in place at all times, 1 track on the north side and 1 track on the [south] side that have as many cars as possible to make the coupling as close to the kicking pad as possible.

The [e]mergency tracks must be reviewed with each new switch cut and must not contain any [d]angerous [goods] cars at any time.

The running trade employee in charge of switches is to line into the Emergency track whenever he or she hears the word Emergency[.]

The [r]equirements for [e]mergency tracks are:

- There can be no dangerous cars in the emergency track at any time

- You must select an emergency track for each lead prior to coming down the west lead with a cut to switch

- You must be lined into one of these tracks either north or south as you first occupy the switching lead

- When the helper gets into the switch control room you can proceed with switching

In case of an emergency the employee at the pad is to:

- Broadcast “Emergency Emergency Emergency”

The running trade employee in charge of switches is to:

- At this point the running trade employee in charge of switches is to immediately line into one of the emergency tracks

- The running trade employee in charge of switches is to get in contact with the east end crews and communicate that there is [sic] cars rolling on their own and what track they are coming into [...]. Footnote 10

1.6 Car kicking operations in Alyth C-Yard

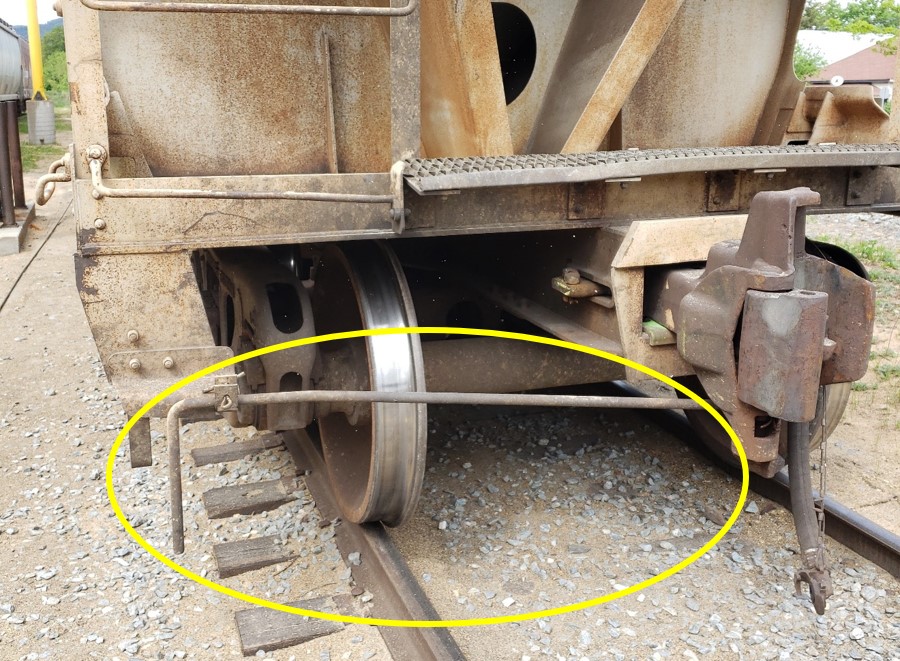

During switching operations at Alyth C-Yard, rail cars are kicked into the desired track using locomotives that are operated remotely by the foreman using RCLS. To kick cars, the locomotives push the movement until it attains the required speed.Footnote 11 While the cars are passing the pad location, the foreman manually operates the uncoupling lever to unlock the knuckle at the desired uncoupling location (Figure 4). To complete the uncoupling process and set the car in motion, the foreman applies the brakes on the locomotives. The deceleration initiates at the locomotives and is transferred sequentially toward the lead car, causing the slack between the cars to run out into the “draft” state. When the run-out of slack reaches the unlocked coupling, the intended car separates and continues rolling down the slight grade towards the classification yard. Multiple cars coupled together can be kicked using the same process.

As the cars are released, the foreman informs the yard helper by radio. The yard helper, who is able to observe the car movement from the window in the control room and from the video feed from various cameras positioned throughout the C-Yard, then remotely activates the power switch for the desired track by way of the control panel (Figure 5). When the yard helper is informed of an uncontrolled movement, the cars are routed into the designated emergency track.

1.7 Remote control locomotive system operations

A yard crew typically comprises a locomotive engineer (LE) and a conductor. The conductor, positioned on the ground, transmits instructions to the LE who, in turn, controls the locomotive.

In contrast, an RCLS crew typically consists of 2 conductors, neither of whom are located in the locomotive cab throughout the shift. The RCLS enables the crews to control the locomotive remotely from a position on the ground or while riding on a locomotive or car. RCLS has been implemented on many railways, predominantly in yard switching operations.

The RCLS equipment consists of 3 components:

- the remote-controlled locomotive(s) (RCL);

- an on-board control computer (OCC), which is mounted inside the RCL to interface with the controls; and

- an operator control unit (OCU), commonly referred to as a Beltpack.Footnote 12 The OCU is a lightweight remote control device that attaches to the operator’s safety vest.

1.8 Coupler assembly

At both ends of a rail car, coupler assemblies are used to connect the car to other cars, or disconnect it from other cars (Figure 6).

When coupling to another car, the knuckle is designed to automatically transition from an open position to a closed-and-locked position. When the coupler closes, the knuckle rotates around the knuckle pin such that the face of the knuckle engages with the knuckle face of the adjoining car’s coupler. When the knuckle tails retract into each car’s coupler body, the coupler locks then drop into place on each coupler, thereby locking the knuckles into place (Figure 7). During normal train operations, both the direction and magnitude of the forces in the couplers vary significantly. For example, when cars are being kicked, stress in the knuckle alternates between tension and compression as the in-train forces alternate between draft (stretched train) and buff (bunched train).

1.9 Inspection of freight car knuckles

The inspection of knuckles is included in safety inspections conducted by certified car inspectors in accordance with Section 4 of Transport Canada’s Railway Freight Car Inspection and Safety Rules to ensure “the freight cars [the railway company] places or continues in service are free from all safety defects described in Part II of these Rules.” Footnote 13

The rules specify, among other things, that a rail car is not to be placed or continued in service if

[t]he car has a coupler knuckle that is broken or cracked on the inside pulling face of the knuckle, except that shrinkage cracks or hot tears that do not significantly reduce the strength of the knuckle shall not be considered cracked;Footnote 14

The Association of American Railroads (AAR) Field Manual of the AAR Interchange Rules state the following with regard to coupler knuckles:

Knuckles found broken or with cracks are condemnable... Determination shall be by visual inspection and/or by utilizing non-destructive testing as defined in MSRP [Manual of Standards and Recommended Practices] M-220.Footnote 15

This rule also states that “ [a]ny coupler part bent, broken, cracked or missing is cause for renewal.”

Car inspectors traditionally perform detailed inspections of freight car components on repair tracks or car shop tracks. Detailed inspections include gauging of knuckles to AAR standards, which necessitates that a car be separated from the preceding and following cars so that the knuckles can be fully opened and inspected. However, not all repairs within the shop require cars to be uncoupled (changing a wheel in the wheel pit, for instance), and not all repairs require bringing the cars in the shop (railways across North America use “expedite” tracks for light repairs, where mobile yard repair crews perform repairs outside of the car shop).

1.10 Car repair history for CP 429137

Based on the TSB review of the 10-year car repair history for CP 429137 and the required car repair practices, each of the following activities would have provided opportunity for detailed inspection of the coupler knuckles on this car:

- Knuckle thrower replaced at “B” end of car (19 October 2018)

- Single car air brake test performed (25 February 2018)

- Truck bolster replaced at “B” end (16 September 2017)

- Single car air brake test performed (20 March 2017)

- Coupler changed at “B” end and knuckle thrower changed at “A” end (06 February 2015)

According to standard industry maintenance practice for coupler replacements, all components of the coupler must be inspected and replaced if required, including the knuckle. The coupler changeout that was completed on the “B” end of the car on 06 February 2015 likely included the installation of the occurrence knuckle. The investigation could not determine when the knuckle first went into service. There were at least 4 opportunities for a visual inspection of the knuckle since February 2015.

1.11 Laboratory examination of the broken knuckle

The broken knuckle was part of a coupler arrangement on the “B” end of car CP 429137, a gondola-type rail car. The coupler was an F type coupler (F70 CHT). Table 2 identifies the markings that were stamped on the knuckle.

| Marking | Meaning |

|---|---|

| F51 | Type F knuckle |

| AEX | Original design, Grade E quenched and tempered cast steel, conditionally approved |

| 08-11 | Date of manufacture – August 2011 |

| PD | Manufactured for Workhorse Rail by Qingdao Pingdu Sanheshan Precision Foundry, Shandong, People’s Republic of China. |

During the laboratory examination of the broken knuckle, it was determined that:

- The knuckle fracture initiated as fatigue cracking in the knuckle pin bore (throat), a highly stressed area of the knuckle.

- The fracture had divided the knuckle into approximately 2 halves—the nose portion and the tail portion (Figure 8).

- Each portion contained 2 distinct fractures—one on the pulling face and the second on the back face. The pulling face fracture was approximately 1.25 inches deep by 8 inches tall with a reduced cross-section of approximately 0.75 inches at the mid-section. The back face fracture was approximately 1 inch deep by 8 inches tall.

- One large and several smaller internal voids were observed on the fracture face (Figure 9). Several spherical green inclusions were observed, primarily at the periphery.

- Porosity and inclusions in the throat of the knuckle served as stress risers as well as fatigue crack initiators.

- Brinell hardness test results averaged 285 HBW.Footnote 16 This is consistent with the specified hardness range of 241 to 291 HBW for the knuckle.Footnote 17 Standardless energy dispersive spectrometer (EDS) analysis of the knuckle material sample gave results that are consistent with the AAR requirements specified for the major elements of grade E castings. EDS analysis of the green sphere-shaped inclusions indicated that they were primarily silica, likely formed during the casting process.

- To assess the wear of the knuckle nose, partial re-assembly of the fractured knuckle allowed gauging with the Go-No-Go gauge (#49822) for type F knuckles. As the gauge would not pass over the nose, the knuckle was within allowable wear limits.

- Portions of the fracture face were sectioned and examined using the scanning electron microscope (SEM). The fatigue crack at the origin area showed that corrosion had erased most of the fracture detail. Examination of the fresh fracture showed cleavage as the mode of failure, confirming an overstress rupture. SEM examination of the spherical inclusions showed that they varied in size, some of which were approximately 1 mm in diameter.

- The dark colouration and depth of the corroded fatigue cracks indicate that they had been progressing for an extended period. The largest of the fatigue cracks had propagated through approximately one third of the section thickness (Figure 10). Although cracks of that size and depth were likely visible, when the car was coupled to another car, the subject area of the knuckle would have been obscured.

1.12 Experimental couplers and parts

For any new component introduced by a manufacturer in North America, AAR formal approval must be obtained as outlined in AAR Specification S-060 (Application for Component Approval Procedure). At the initial stage, drawings, material specification and required laboratory testing must be conducted according to the particular AAR specification under which the new component falls. The specification for knuckles is AAR Specification M-211: Foundry and Product Approval Requirements for the Manufacture of Couplers, Coupler Yokes, Knuckles, Follower Blocks and Coupler Parts. The AAR Castings Committee then reviews the details of the proposed new product and may approve it for field testing. The foundry making the product must also be inspected and approved by the AAR, according to details listed in the pertinent specification.

In order to provide a uniform method of evaluating service experience, the AAR then grants what is known as a conditional approval of service allotment of the equipment for testing in North American railway interchange service. The allotment size can vary from 30 samples to thousands, depending on the component. For knuckles, the minimum allotment is 1000. Additional allotments can be requested as per Appendix C of Specification M-211. The manufacturer is required to follow up on these test samples by doing semi-annual field inspections and monitoring the performance of the samples with the railways where the conditionally approved components are applied. The test period is a minimum of 2 years and 36 000 miles. After a satisfactory evaluation, final approval is granted by the AAR with an approved designation of the component established for the AAR Field Manual of the AAR Interchange Rules.

The failed knuckle had a designation of F51AEX and was manufactured for Workhorse Rail in August 2011. The X referred to the knuckle's "conditionally approved" status.

The Field Manual of the AAR Interchange Rules states that “experimental couplers and parts for test are identified with suffix X after standard catalog numbers.” Footnote 18

Final unconditional approval for the Workhorse Rail F51AEX knuckle was granted on 02 August 2011. The failed knuckle was produced that same month, likely before tooling changes could be made to remove the X from the coupler nomenclature.

1.13 Coupler and knuckle force

The safe range of pulling force exerted on couplers and knuckles in particular is well known in the industry and is outlined in the AAR Train Make-up Manual. Although the document was produced in 1992, the information is still used by railways today. The manual states, in part:

4.0 Excessive Train Forces

4.1.1 Train Separation

Excessively high draft forces may exceed the strength of the materials used in the draft system resulting in mechanical failure and subsequent train separation. The knuckle is designed as the weak link, a mechanical “fuse”, in this system. When draft forces approach levels that might damage a car, the knuckle fails instead of the car.

Currently, two different coupler system materials are used in North America, Grade C and Grade E steel. Grade C material, the weaker of the two, is normally used in unrestricted interchange equipment. It has an accepted working limit (pulling force) of 250,000 pounds in draft with an ultimate design load limit of 300,000 pounds. When calculating general merchandise train make-up, this value is generally used to develop guidelines for train make-up and train handling.

Grade E equipment, sometimes known as "high tensile" or marked "HTE" equipment, has an accepted working limit of 350,000 pounds in draft with an ultimate design load limit of 400,000 pounds. This value may be used to develop guidelines for train makeup and train handling where it is positively known that no Grade C equipment will be entrained.[…]Footnote 19

AAR Specification M-216 Footnote 20 stipulates the number of cycles and the minimum and maximum loads for fatigue testing. The maximum load of the cycle range is 283 000 pounds for grade E steel. By definition, the fatigue limit is the force level below which an infinite number of loading cycles can be applied to the casting without causing any fatigue type cracks and failures. For reference, knuckles on CP trains may be subject to normal service loads well in excess of this maximum. On CP high-tonnage trains, 2 head-end alternating current (AC) locomotives can generate in excess of 160 000 pounds of tractive effort each for a combined load of 320 000 pounds.

AAR Specification M-211Footnote 21 establishes permanent set (deformation) and ultimate strength requirements. Knuckles must give a maximum permanent set of no more than 0.03 inches when subjected to a load of 400 000 pounds. This deformation is around the throat of the knuckle, where the maximum forces will be during its service life. AAR also indicates that a grade E knuckle must endure a minimum one-time ultimate load of 650 000 pounds without failing.

Pulling loads above accepted working limits can result in permanent knuckle deformation and can ultimately result in knuckle failure and/or a train separation. Knuckles can have a reduced load capacity due to wear, particularly if cracks or material defects are present.

TSB dynamic analysis of the kicking movement that preceded the coupler failure determined that the slack run-out after the locomotive brakes were applied generated between 140 000 and 150 000 pounds of force at the “B” end of CP 429137, the 20th car.

1.14 Train dynamics simulation of the uncontrolled movement

The TSB Engineering Laboratory conducted a train dynamics simulation of the uncontrolled movement to determine the most likely speed at the time of the collision and derailment. A train model was created with the Train Energy and Dynamics Simulator (TEDS)Footnote 22 software based on the weight and length profiles of the uncontrolled cut of cars. The simulation used track data provided by the railway that included track grades and curvature. The simulation led to the following observations:

- The uncontrolled cut of cars reached an approximate constant speed of 13.4 to 13.9 mph between the west and east clearance points of Track CT-01.Footnote 23

- The impact force at the initial collision would have been approximately 2000 kips,Footnote 24 sufficiently high to damage the cars involved and to result in the derailment.

- Although the initial speed at the kicking point was 6.3 mph, the identified speed of the movement when the knuckle failed was about 2 mph.

1.15 Other occurrences in Alyth C-Yard between the commencement of operations on 22 December 2018 and 06 January 2019

On 23 December 2018, the crew of CP switching assignment CW31-22 was kicking cars at Alyth C-Yard into Track CT-03 when the lead hopper car, TCMX 350679, a residue car that last contained ammonium nitrate (UN1942), derailed 1 truck on the inert retarders. There were no injuries and there was no loss of product. The uncontrolled movement did not enter the main track (TSB Rail Transportation Occurrence R18C0129).

On 28 December 2018, the crew of CP switching assignment CE31-27 was kicking cars at Alyth C-Yard into Track CT-11 when 31 cars rolled uncontrolled out the east end of TrackCT-11. The 31 cars travelled approximately 30 car lengths and through 3 switches before coming to a stop on Track PT-02 on the Bonnybrook Bridge. There was no derailment and there were no injuries. The track sustained damage to the 3 switches. The uncontrolled movement did not enter the main track (TSB Rail Transportation Occurrence R18C0131).

On 29 December 2018, the crew of CP Alyth C-Yard switching assignment CW11-29 released 4 loaded cars into Track CT-04 on top of 6 stationary empty cars. After connecting, the 10 cars rolled through the skate retarder and out through the east end of Track CT-04 where they side-collided with the East Production Job on the east lead track. The lead car of the uncontrolled movement, a residue tank car that last contained anhydrous ammonia – UN1005, derailed 1 truck. None of the cars on the East Production Job derailed, but 2 loaded covered hopper cars sustained sideswipe damage. There were no injuries and there was no loss of product. The uncontrolled movement did not enter the main track (TSB Rail Transportation Occurrence R18C0134).

On 04 January 2019, the crew of CP Alyth C-Yard switching assignment CW21-04 was in the process of releasing 2 cars at 6.5 mph on the switching lead toward the classification yard when a knuckle broke on the 30th car behind the locomotives. As a result, 58 cars ran uncontrolled into Track CT-15 where they contacted 18 stationary cars. Subsequently, all 76 cars travelled out the east end of Track CT-15 and continued for a distance of about 3200 feet. Railway employees were able to climb onto the movement and apply hand brakes to bring it to a stop. As a result of the initial impact, 1 residue tank car, which last contained an ethanol and gasoline mixture – UN3475, derailed and 1 empty tank car sustained damage but did not derail. There were no injuries and there was no loss of product. The movement did not enter the main track (TSB Rail Transportation Occurrence R19C0003).

1.16 Risk assessment

CP’s safety management system (SMS) includes a Hazard Prevention Program and a Risk Assessment Policy and Procedure. These programs are routinely updated and refined to support continuous improvement. With these 2 programs, hazards can be reported, assessed, and mitigated. CP required a risk assessment to be conducted whenever:

- A safety concern (i.e., a hazard or condition that may present a direct safety risk to employees, or pose a threat to safe railway operations) is identified through analysis of safety data;

- A proposed change to CP operations that could:

- introduce a new hazard to the workplace resulting in adverse effects;

- negatively impact or contravene any existing policy, procedure, rule or work practice used to meet regulatory compliance or any CP requirements or standards;

- create or increase a direct safety risk to employees, railway property, property transported by the railway, the public or property adjacent to the railway; and

- require authority by a regulatory agency to implement.Footnote 25

In December 2018, CP conducted a risk assessment for its new classification yard. As part of this risk assessment, the issue of cars running out the east end of the yard and the potential for those cars to interfere with switching operations and safety at the east end was assessed.

CP developed a remedial action plan to address the risks identified, which included the following items:

- Conduct simulations

- Conduct live testing, kicking cars into C-Yard

- Develop an operator’s manual

- Develop a job aid for track skates

- Develop blue flag/lockout procedures

- Develop engineering track protection procedures

- Develop training and train the foreman and yard helper positions

- Issue bulletin for Alyth Yard employees, Alyth Yard operating plan, and new track

In addition, CP implemented a process for redirecting uncontrolled movements toward a designated, occupied emergency track to prevent the uncontrolled movement from running out of the east end of the yard. In this occurrence, the yard helper used Track CT-01, which was the designated emergency track for the shift, as discussed during the job briefing.

1.17 TSB occurrence statistics involving unplanned/uncontrolled movements

From 2010 to 2019, there were 589 occurrencesFootnote 26 reported to the TSB related to unplanned and uncontrolled movements among all railways in Canada (Table 3).

| Reason for unplanned or uncontrolled movement | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Loss of control | 2 | 3 | 0 | 3 | 0 | 1 | 4 | 2 | 5 | 1 | 21 |

| Switching without air | 10 | 16 | 12 | 24 | 21 | 22 | 18 | 21 | 27 | 31 | 202 |

| Securement | 25 | 32 | 44 | 42 | 38 | 37 | 29 | 39 | 34 | 46 | 366 |

| Total | 37 | 51 | 56 | 69 | 59 | 60 | 51 | 62 | 66 | 78 | 589 |

The TSB classifies uncontrolled movements into 1 of the following 3 causal categories:

- Loss of control: When an LE or an RCLS operator cannot control a locomotive, a car, a cut of cars, or a train with available locomotive and/or train air brake systems.

- Switching without air: When a movement is switching with the use of the locomotive independent brakes only with no air brakes available on the cars being switched or kicked. The vast majority of these incidents occur in yards.

- Securement: When a car, a cut of cars, or a train is left unattended and begins to roll away uncontrolled, usually because

- an insufficient number of hand brakes have been applied to a car, a cut of cars or a train; and/or

- a car (or cars) has faulty or ineffective hand brakes.

Table 4 provides a breakout, by consequences. Of the 202 uncontrolled movements that occurred while switching without air:

- 2 (0.9%) involved injuries or fatalities,

- 137 (67.8%) resulted in a collision, and

- 60 (29.7%) involved dangerous goods.

| Consequence* | 2010 | 2011 | 2012 | 2013 | 2014 | 2015 | 2016 | 2017 | 2018 | 2019 | Total | % of total switching without air occurrences |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Derailment of 1 to 5 cars | 4 | 8 | 3 | 6 | 5 | 8 | 12 | 7 | 11 | 14 | 78 | 38.6% |

| Derailment of more than 5 cars | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 1 | 2 | 2 | 7 | 3.4% |

| Collision | 9 | 13 | 10 | 19 | 15 | 17 | 7 | 16 | 15 | 16 | 137 | 67.8% |

| Affected the main track** | 0 | 1 | 1 | 1 | 1 | 0 | 2 | 1 | 0 | 1 | 8 | 3.9% |

| Involved dangerous goods | 3 | 4 | 0 | 4 | 10 | 8 | 5 | 7 | 10 | 9 | 60 | 29.7% |

| Injuries or fatalities | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 2 | 0.9% |

* Some occurrences may have more than one consequence.

** Originated on the main track, moved onto the main track, or fouled the main track.

Over the 10 years from 2010 to 2019, switching without air, as in this occurrence, was the causal category in 34% (202 of 589) of the occurrences. While uncontrolled movements due to switching without air have occurred frequently, 3.9% of them (8 out of 202) affected the main track.

Since 1994, including this occurrence, the TSB has investigated 37 occurrences that involved uncontrolled movements, 8 of which involved switching without air (Appendix A).

1.18 Board safety action relating to uncontrolled movements

Given the number of occurrences and TSB investigations involving uncontrolled movements due to various causes, the Board has issued 2 recommendationsFootnote 27 and a safety concern.Footnote 28

After completing its investigation into the Lac-Mégantic train disaster in July 2013 (TSB Railway Investigation Report R13D0054), the TSB stated that it had pointed out the need for robust defences to prevent runaways since 1996 (TSB Railway Investigation Report R96C0172) and that, from that time, there had been over 120 runaways in Canada affecting main-track operations. The TSB also acknowledged that equipment runaways are low-probability events, but as this accident demonstrated, they can have extreme consequences, particularly if they involve dangerous goods. As demonstrated in Lac-Mégantic, the cost to human life and our communities can be incalculable. For this reason, the Board recommended that

The Department of Transport require Canadian railways to put in place additional physical defences to prevent runaway equipment.

TSB Recommendation R14-04

Since that time, the TSB has followed up annually with TC on action being taken to address this recommendation. Each year, TC has provided a response indicating what action has been or will be taken, and the TSB has assessed that response. When the present report was published, TC’s last response had been received in January 2021. The TSB’s assessment (March 2021) of this response, as well as previous responses and assessments, are available on the TSB website.Footnote 29

Following the TSB investigation into an uncontrolled movement in Sutherland Yard in Saskatoon, Saskatchewan, in March 2016 (TSB Railway Investigation Report R16W0074), in which a car rolled uncontrolled through the yard and onto the main track within cautionary limits of the Sutherland Subdivision, the Board issued the following safety concern:

The Board is concerned that the current defences are not sufficient to reduce the number of uncontrolled movements and improve safety.

Following the TSB investigation into a fatal switching accident in December 2017 in Melville, Saskatchewan (TSB Rail Transportation Safety Investigation Report R17W0267), the Board issued Recommendation R20-01. In the investigation report, the Board indicated that the underlying causes of uncontrolled movements that occur while switching without air can vary greatly. Consequently, developing a comprehensive strategy to deal effectively with all of the underlying factors and associated risks in order to reduce the number of such uncontrolled movements is proving to be difficult. Therefore, the Board recommended that

The Department of Transport work with the railway industry and its labour representatives to identify the underlying causes of uncontrolled movements that occur while switching without air, and develop and implement strategies and/or regulatory requirements to reduce their frequency.

TSB Recommendation R20-01

In its September 2020 response to this recommendation, TC agreed with the recommendation and proposed an action plan. On 29 September 2020, TC issued a Ministerial Order requiring industry to create a new rule that provided additional requirements when conducting switching operations. The rule would require that, once switching was complete, the equipment would be left properly secured.

In its December 2020 assessment of TC response, the TSB stated that the effectiveness of the response could not yet be fully ascertained until the consultations with the railway industry and its labour representatives have occurred, the underlying causes of uncontrolled movements that occur while switching without air are better understood, and strategies have been developed and implemented to reduce their frequency. The TSB’s assessment of this response is available on the TSB website.Footnote 30

1.18.1 TSB Watchlist

The TSB Watchlist identifies the key safety issues that need to be addressed to make Canada’s transportation system even safer.

Unplanned/uncontrolled movement of railway equipment is a Watchlist 2020 issue. As this occurrence demonstrates, uncontrolled movements, even those within classification yards, can have serious consequences.

Unplanned/uncontrolled movement of railway equipment: ACTION REQUIRED While all three categories of unplanned/uncontrolled movements share some common causes, they each require unique strategies either to prevent the occurrences from happening or to reduce the associated risks. TC, the railway companies, and labour unions must collaborate, devise strategies, and implement physical and administrative defences to address each type of uncontrolled movement. For the safety of railway workers and the public, the TSB wants to see a downward trend in the number of such occurrences. |

1.19 Reporting marks on tank car SRIX 33958

Tank cars may have reporting marks stencilled on the top of the car as well as on each side and end. These reporting marks assist first responders with the identification of cars and to assess the risks posed by the contents if involved in an incident or if found leaking.

At the derailment site, it was noted that tank car SRIX 33958 had a different reporting mark, PLMX 137255, stencilled on the top of the car (Figure 11). The car identification was changed from PLMX 137255 to SIRX 33958 on 10 December 2012, and the reporting marks on the sides and end of the car were changed accordingly. However, the reporting marks on the top of the car were not changed.

1.20 TSB laboratory reports

The TSB completed the following laboratory reports in support of this investigation:

- LP040/2019 – Broken knuckle examination

- LP073/2019 – Train dynamics simulation

- LP154/2020 – Simulation of dynamic in-train force in kick-off

2.0 Analysis

Neither the actions of the train crew nor the condition of the track contributed to the accident. The analysis will focus on the metallurgical analysis of the broken knuckle, the remote control switching move that led to the uncontrolled movement of the cars, and the risk assessment conducted before Alyth C-Yard operations began.

2.1 The accident

Finding as to causes and contributing factors

The collision and derailment occurred when a knuckle on car CP 429137 failed while the cut of 75 cars was in motion, leading to the uncontrolled movement of 56 cars into the designated emergency track (CT-01).

2.1.1 The uncontrolled movement

Prior to the occurrence, the crew had performed several switching moves (kicks) that required them to shove against the cut of cars until the required speed was reached, operate the uncoupling lever at the appropriate location, then apply the brakes on the locomotives so that the selected car or group of cars would separate from the movement and roll toward the classification yard. In each of these moves, when the locomotive brakes were applied, the slack ran out, putting the couplers between the cars into the draft (closed) position and setting the desired car or group of cars in motion.

The yard movement during which the knuckle failed reached a speed of 6.3 mph, a speed anticipated to be sufficient to set the single car in motion toward Track CT-21 and to carry it to the intended location within that track. However, when the coupler failed between the 19th and 20th cars, 56 cars were set in motion. The uncontrolled movement of 56 cars, weighing 5660 tons, had considerably more inertia than the intended single-car cut. Additionally, the 56 cars caught up to the preceding 3 empty tank cars, adding about 91 tons to the uncontrolled movement.

Finding as to causes and contributing factors

Given the weight of the 59 cars, and the slight downgrade of the track, the uncontrolled movement accelerated to about 13.5 mph before contacting the stationary loaded hopper cars in track CT-01. After the initial collision and derailment, the uncontrolled movement possessed sufficient inertia to continue derailing cars and to propel them laterally in both directions, ultimately derailing 22 cars across 4 tracks.

When the collision occurred, the uncontrolled movement was travelling at a speed well above the normal coupling speed of 4 mph. TSB train dynamics simulations of the uncontrolled movement estimate that the impact force at the initial collision would have been approximately 2000 kips, sufficiently high to damage the cars involved and to result in the derailment.

When the foreman placed the remote control locomotive system (RCLS) control into “stop” and the front portion of the movement began to decelerate, it became immediately apparent that a separation had occurred and a cut of cars was rolling downgrade towards the classification yard under its own momentum.

Finding: Other

By making the required emergency radio call and lining the switch toward the emergency track, the crew took the appropriate action in a timely manner to mitigate the consequences of the uncontrolled movement.

2.1.2 Coupler knuckle fracture on car CP 429137

Finding as to causes and contributing factors

Testing at the TSB laboratory confirmed that the knuckle had developed fatigue cracking that initiated in the area of the knuckle pin bore and failed in the overstress extension of fatigue cracking.

The knuckle fracture initiated as fatigue cracking in the throat, a highly stressed area of the knuckle. During normal train operations, both the direction and magnitude of the forces in the couplers vary significantly. For instance, when cars are being kicked, stress in the throat of the knuckle alternates between tension and compression as the coupler forces alternate between draft (stretched train) and buff (bunched train).

Optical and metallurgical examination of the fracture showed inclusions and porosity in the material. Porosity and inclusions in the throat of the knuckle served as stress risers as well as fatigue crack initiators.

The knuckle was manufactured in 2011, but it is not known when it went into service.

Finding as to causes and contributing factors

The age of the fatigue cracks in addition to the observed porosity and inclusions suggest that manufacturing deficiencies in the casting process weakened the knuckle and it failed under normal service stresses.

2.2 Coupler knuckle inspection requirements

The dark colouration and depth of the corroded fatigue cracks on the knuckle indicate that they had been progressing for an extended period. The largest of the fatigue cracks had propagated through approximately one third of the section thickness. Although cracks of the size and depth that were present on the knuckle were likely visible and would have been deemed a condemnable safety defect under Transport Canada’s Railway Freight Car Inspection and Safety Rules, operating circumstances may provide infrequent opportunity for the detailed inspection and gauging of knuckles in service. Unless cars are uncoupled and the knuckles are fully opened, freight car inspectors are not able to identify the types of fatigue cracks that were present on the occurrence knuckle.

A review of the 10-year repair history for this car indicates that the occurrence knuckle was likely installed in 2015 and that there were about 4 opportunities for detailed inspection of the knuckles on this car prior to the occurrence. On the last known occasion for a detailed inspection, 2 months before the occurrence, the knuckle was removed and reapplied to accommodate the replacement of the knuckle thrower.

Finding as to causes and contributing factors

The fatigue crack was likely present during the last detailed inspection, 2 months before the occurrence, but was not identified during the repair.

2.3 Risk assessment

Risk assessments are performed when an operational change takes place within a work area to identify potential hazards. Once hazards have been identified, the associated risks can be removed or mitigated. Canadian Pacific Railway (CP) conducted a risk assessment of its new classification yard (Alyth C-Yard) in December 2018. One of the risk areas identified was cars running out the east end of the yard and compromising the safety of other switching operations. As a result, CP implemented a process of redirecting uncontrolled movements towards a designated emergency track.

In this occurrence, the uncontrolled movement was redirected into a designated emergency track. Although this resulted in a collision and derailment, there were no injuries and no other switching movements were contacted, thereby minimizing the outcome of this occurrence.

In the 16 days that Alyth C-Yard was in operation between 22 December 2018 and 06 January 2019, there were 5 TSB reportable uncontrolled movements. Each of these events followed a yard switching move (kicking cars).

By design, kicking cars allows them to move under their own momentum into a predetermined track. These movements do not become uncontrolled unless they exit the intended track. One of these events, on 04 January 2019, involved a similar movement to the one under investigation in this occurrence, i.e., a kicking move while handling a long heavy cut of cars. In the January 2019 occurrence, 76 cars ran uncontrolled for about 3200 feet out of the intended track and were eventually brought to a stop by railway employees.

Although a risk assessment had been performed in anticipation of the operational change (the inauguration of the Alyth C-Yard), the series of uncontrolled movements that occurred in the first 16 days of operation indicates that either some of the hazards that existed were not identified, or the risk mitigation strategies that were applied were inadequate.

Finding as to risk

When an operational change takes place and the preceding risk assessment does not identify certain hazards, the associated risks may not be adequately mitigated, resulting in an increased potential for accidents.

2.4 Unplanned/uncontrolled movements

Of the 589 rail occurrences that resulted in unplanned/uncontrolled movements between 2010 and 2019, switching without air, as in this occurrence, was the causal category in 34% of them (202 of 589). Since 1994, including this occurrence, the TSB has investigated 37 occurrences that involved uncontrolled movements, 8 of which involved switching without air.

While uncontrolled movements due to switching without air are high-frequency events, only a small percentage of these movements, 3.9% of them (8 out of 202), affected the main track. Although most of these uncontrolled movements remain within the confines of the yard, there remains significant potential for adverse consequences. For example, uncontrolled movements can collide with other switching movements or trains that are either entering or departing the yard. Collisions of this nature can lead to the release of dangerous goods. These events can also result in injury or loss of life, as occurred in Melville, Saskatchewan, on 22 December 2017 (TSB Rail Transportation Safety Investigation Report R17W0267).

The TSB has 2 outstanding recommendations and a safety concern pertaining to uncontrolled movements. Annual occurrence statistics for uncontrolled movements for 2010 to 2019 reflect an overall increasing trend. These data indicate that the actions taken by the railway industry and Transport Canada are not having the desired effect in reducing the number of uncontrolled movements. Consequently, the TSB added uncontrolled movements to its 2020 Watchlist.

The consequences of uncontrolled movements in Canada have already proven to be catastrophic. Analysis of the occurrence data has led to the development of sub-categories of uncontrolled movements in an effort to better understand the underlying issues. With several distinct categories, there is a wide range of factors that can contribute to uncontrolled movements.

Finding as to risk

Until sufficient measures are put in place to effect a downward trend in the number of unplanned/uncontrolled movements or a reduction in the associated consequences, the risk to the public, railway employees, equipment, and environment remains elevated.

2.5 Reporting marks on tank car SRIX 33958

Reporting mark stencilling on rail cars can be used by emergency responders to identify rail cars and gain information from the railway or shipper related to the contents of such cars in the event of an accident or dangerous goods release.

In this occurrence, the reporting mark stencilled on the top of tank car SRIX 33958 was discovered to be inaccurate; however, it did not pose difficulties for emergency responders.

Finding: Other

Incorrect stencilling of car reporting marks can lead to potential delays and safety risks for emergency responders trying to identify rail car contents after an accident or a release of dangerous goods.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- The collision and derailment occurred when a knuckle on car CP 429137 failed while the cut of 75 cars was in motion, leading to the uncontrolled movement of 56 cars into the designated emergency track (CT-01).

- The knuckle had developed fatigue cracking that initiated in the area of the knuckle pin bore and failed in the overstress extension of fatigue cracking.

- The age of the fatigue cracks in addition to the observed porosity and inclusions observed suggest that manufacturing deficiencies in the casting process weakened the knuckle and it failed under normal service stresses.

- Given the weight of the 59 cars, and the slight downgrade of the track, the uncontrolled movement accelerated to about 13.5 mph before contacting the 3 cars from the previous move and the stationary loaded hopper cars in track CT-01. After the initial collision and derailment, the uncontrolled movement possessed sufficient inertia to continue derailing cars and to propel them laterally in both directions, ultimately derailing 22 cars across 4 tracks.

- The fatigue crack was likely present during the last detailed inspection, 2 months prior to the occurrence, but was not identified during the repair.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- When an operational change takes place and the preceding risk assessment does not identify certain hazards, the associated risks may not be adequately mitigated, resulting in an increased potential for accidents.

- Until sufficient measures are put in place to effect a downward trend in the number of unplanned/uncontrolled movements or a reduction in the associated consequences, the risk to the public, railway employees, equipment, and environment remains elevated.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- Emergency response operations were conducted in a timely and effective manner.

- By making the required emergency radio call and lining the switch toward the emergency track, the crew took appropriate action in a timely manner to mitigate the consequences of the uncontrolled movement.

- Incorrect stencilling of car reporting marks can lead to potential delays and safety risks for emergency responders trying to identify rail car contents after an accident or a release of dangerous goods.

4.0 Safety action

4.1 Safety action taken

4.1.1 Transportation Safety Board of Canada

On 06 January 2020, the TSB issued Rail Safety Advisory Letter 01/20 to Transport Canada (TC) and the Association of American Railroads. The advisory identified that porosity and inclusions in the broken knuckle had been present since the time of manufacturing and had likely been introduced during the casting process. The advisory stated:

Given the consequences of a failed knuckle, particularly when uncontrolled movements occur during switching operations, Transport Canada and the Association of American Railroads may wish to follow up with the appropriate equipment manufacturers to ensure that vulnerabilities (such as porosity and inclusions) are not introduced into the knuckle castings during the manufacturing process.

On 09 November 2020, TC provided the following response:

Transport Canada contacted the Association of American Railroads (AAR) Assistant Vice President of the Technical Services regarding the issue described in RSA 01/20. The AAR informed the department that the letter was forwarded internally to the Coupling Systems and Truck Casting Committee (committee) for review. The review concluded that the forces encountered from kicking cars was likely the most significant contributing factor to failure of the knuckle rather than the porosity of the material found in it.

The AAR establishes the requirements for knuckles in use in North American freight interchange service. This includes specifications on the design, mechanical and chemical properties of the cast component as well as the required testing. There are also AAR specifications that cover the requirements for foundries that manufacture castings, including knuckles, and a process to approve these foundries. Given this role, Transport Canada has requested that the AAR contact the knuckle manufacturer, Workhorse Rail, to seek their input and determine if additional measures are needed.

4.1.2 Canadian Pacific Railway

After the occurrence, Canadian Pacific Railway (CP) instituted the following changes to its Alyth C-Yard operation.

4.1.2.1 Immediate actions/changes

- A locomotive engineer was added to all working assignments in the C-Yard until all changes were made.

- Locomotive engineers were instructed to limit tractive effort to a maximum of 600 A.

- The speed for kicking empty cars was reduced to 4 mph and kicking loaded cars to 1 mph.

- The practice of kicking cars with brakes applied was eliminated.

- The maximum tonnage on the switching lead was set to 7000 tons.

- Ten percent of cars are to have air brakes coupled and charged for use while switching.

- The designation of emergency tracks is no longer discretionary. Track CT-01 became the designated emergency track for both sides of Alyth C-Yard.

4.1.2.2 Subsequent physical changes to Alyth C-Yard

- The pad was extended from 300 feet to 425 feet.

- The King Switch was raised 10 inches to add a slight ascending grade to facilitate pin pulling.

- Seven pincher retarders were installed on the pull-back track from 21 January 2019 to 06 February 2019. These retarders were placed west of the pad operator’s work location.

- Emergency retarder activation buttons were placed at each end of the pad.

- Pinch retarders were applied to all tracks on the east end of the classification yard.

4.1.2.3 Subsequent RCLS locomotive software changes

- Remote control locomotive system (RCLS) locomotives were reprogramed to limit maximum tractive effort to 600 A.

4.1.3 Transport Canada

On 18 January 2019, pursuant to section 31 of the Railway Safety Act, TC issued a Notice and Order to (CP for an immediate threat to safe railway operations due to the lack of sufficient safeguards during switching practices at the east end of the Alyth classification yard. The Notice and Order indicated that there was a risk of cars rolling uncontrolled that could cause harm to employees, the public or the environment.

TC received a response from CP that described the measures CP had taken following the Notice and Order. TC determined that the measures taken by CP addressed the immediate threat to safe railway operations, and the Notice and Order was revoked on 28 January 2019.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

Appendices

Appendix A – TSB investigations involving uncontrolled movements

| Occurrence number | Date | Description | Location | Cause |

|---|---|---|---|---|

| R19C0002 (this occurrence) | 2019-01-06 | Non–main-track collision and derailment, Canadian Pacific Railway, Yard Assignment CW11-06, Alyth Classification Yard | Calgary, Alberta | Switching without air |

| R18M0037 | 2018-12-04 | Employee fatality, Canadian National Railway Company, yard assignment L57211-04, Mile 1.03, Pelletier Subdivision | Edmundston, New Brunswick | Improper securement |

| R18Q0046 | 2018-05-01 | Non–main track uncontrolled movement and derailment of rolling stock, QNS&L Railway, cut of cars | Sept-Îles, Quebec | Switching without air |

| R18H0039 | 2018-04-14 | Uncontrolled movement of rolling stock, Canadian Pacific Railway, remote control locomotive system, yard assignment T16-13, Mile 195.5, Belleville Subdivision | Toronto, Ontario | Loss of control |

| R18E0007 | 2018-01-10 | Uncontrolled movement of rolling stock, Canadian National Railway Company, freight train L76951-10, Mile 0.5, Luscar Industrial Spur | Leyland, Alberta | Loss of control |

| R17W0267 | 2017-12-22 | Employee fatality, Canadian National Railway Company, extra yard assignment Y1XS-01 | Melville, Saskatchewan | Switching without air |

| R17V0096 | 2017-04-20 | Non–main track uncontrolled movement, collision, and derailment, Englewood Railway, Western Forest Products Inc., Cut of cars | Woss, British Columbia | Switching without air |

| R16W0242 | 2016-11-29 | Uncontrolled movement, collision and derailment, Canadian Pacific Railway, Ballast train BAL-27 and, Freight train 293-28, Mile 138.70, Weyburn Subdivision | Estevan, Saskatchewan | Loss of control |

| R16T0111 | 2016-06-17 | Uncontrolled movement of railway equipment, Canadian National Railway Company, Remote control locomotive system, 2100 west industrial yard assignment, Mile 23.9, York Subdivision, MacMillan Yard | Vaughan, Ontario | Loss of control |

| R16W0074 | 2016-03-27 | Uncontrolled movement of railway equipment, Canadian Pacific Railway, 2300 remote control locomotive system training yard assignment, Mile 109.7, Sutherland Subdivision | Saskatoon, Saskatchewan | Switching without air |

| R16W0059 | 2016-03-01 | Uncontrolled movement of railway equipment, Cando Rail Services, Co-op Refinery Complex, Mile 91.10, Canadian National Railway Company, Quappelle Subdivision | Regina, Saskatchewan

|

Securement |

| R15D0103 | 2015-10-29 | Runaway and derailment of cars on non-main track, Canadian Pacific Railway, Stored cut of cars, Mile 2.24, Outremont spur | Montréal, Quebec | Securement |

| R15T0173 | 2015-07-29 | Non–main-track runaway, collision and derailment, Canadian National Railway Company, Cut of cars and train A42241-29, Mile 0.0, Halton Subdivision, MacMillan Yard | Concord, Ontario | Switching without air |

| R13D0054 | 2013-07-06 | Runaway and main-track derailment, Montreal, Maine & Atlantic Railway, Freight train MMA-002, Mile 0.23, Sherbrooke Subdivision | Lac-Mégantic, Quebec | Securement |

| R12E0004 | 2012-01-18 | Main-track collision, Canadian National, Runaway rolling stock and train A45951-16, Mile 44.5, Grande Cache Subdivision | Hanlon, Alberta | Securement |

| R11Q0056 | 2011-12-11 | Runaway train, Quebec North Shore and Labrador Railway, Freight train LIM-55, Mile 67.20, Wacouna Subdivision | Dorée, Quebec | Loss of control |

| R09D0053 | 2009-09-09 | Non–main-track collision, VIA Rail Canada Inc. locomotive 6425, VIA Rail Canada Inc. Montréal Maintenance Centre | Montréal, Quebec | Switching without air |

| R09T0057 | 2009-02-11 | Runaway and non–main-track train derailment, Southern Ontario Railway, 0900 Hagersville Switcher, Mile 0.10 and Mile 1.9 Hydro Spur | Nanticoke, Ontario | Securement |

| R08V0270 | 2008-12-29 | Non–main-track train runaway and collision, Kettle Falls International Railway, Waneta Turn Assignment, Mile 141.20, Kettle Falls Subdivision | Waneta, British Columbia | Loss of control |

| R07H0015 | 2007-07-04 | Runaway rolling stock, Canadian Pacific Railway, runaway cut of cars, Mile 119.5, Winchester Subdivision | Smiths Falls, Ontario | Securement |

| R07V0109 | 2007-04-23 | Non–main-track train derailment, Kootenay Valley Railway (KVR), 0700 Trail Yard Assignment, Mile 19.0, Rossland Subdivision | Trail, British Columbia | Loss of control |

| R06V0183 | 2006-09-03 | Runaway and derailment, White Pass and Yukon Route, Work Train 114, Mile 36.5, Canadian Subdivision | Log Cabin. British Columbia | Loss of control |

| R06V0136 | 2006-06-29 | Runaway/derailment, Canadian National, Freight Train L-567-51-29, Mile 184.8, Lillooet Subdivision | Near Lillooet, British Columbia | Loss of control |

| R05H0011 | 2005-05-02 | Runaway and main–track train collision, Ottawa Central Railway, Freight Train No. 441, Mile 34.69, Alexandria Subdivision | Maxville, Ontario | Securement |

| R04V0100 | 2004-07-08 | Uncontrolled movement of railway rolling stock, Canadian National, Train M-359-51-07, Mile 57.7, Fraser Subdivision | Bend, British Columbia | Loss of control |

| R03T0026 | 2003-01-21 | Yard collision, Canadian Pacific Railway, Car No. HOKX 111044, Mile 197.0, Belleville Subdivision | Agincourt, Ontario | Switching without air |

| R03T0047 | 2003-01-22 | Yard collision, Canadian National, Tank Car PROX 77811, Mile 25.0, York Subdivision | Toronto, Ontario | Switching without air |

| R99D0159 | 1999-08-27 | Runaway cars, Canadian National, Mile 69.4, CN Kingston Subdivision, Wesco Spur | Cornwall, Ontario | Securement |

| R98M0029 | 1998-09-24 | Main track runaway, collision and derailment, Matapédia Railway Company, Canadian National Train No. A402-21-24, Mile 105.4, Mont-Joli Subdivision | Mont-Joli, Quebec | Securement |

| R98M0020 | 1998-07-31 | Main track runaway and collision, VIA Rail Canada Inc. Passenger Train No. 14, and an uncontrolled five-pak movement, Mile 105.7, Matapédia Railway Company Mont-Joli Subdivision | Mont-Joli, Quebec | Securement |

| R97C0147 | 1997-12-02 | Runaway/derailment, Canadian Pacific Railway, Train No. 353-946, Laggan Subdivision | Field, British Columbia | Loss of control |

| R96C0172 | 1996-08-12 | Main track collision, Canadian National, Train 117 and an uncontrolled movement of 20 cars, Mile 122.9, CN Edson Subdivision | Near Edson, Alberta | Securement |

| R96C0209 | 1996-10-09 | Runaway cars, Canadian Pacific Railway, CP 0700 yard assignment, Mile 166.2, Willingdon Subdivision, Clover Bar exchange track | Edmonton, Alberta | Securement |

| R96T0137 | 1996-04-24 | Runaway of five tank cars, Canadian National, Mile 0.0, Hagersville Subdivision | Nanticoke, Ontario | Securement |

| R96C0086 | 1996-04-13 | Runaway train, Canadian Pacific Railway, Freight Train No. 607-042, Mile 133.0, Laggan Subdivision | Field, British Columbia | Loss of control |

| R95M0072 | 1995-12-14 | Runaway cars, Canadian National Train No. 130-13, Mile 0.0, Pelletier Subdivision | Edmundston, New Brunswick | Securement |

| R94V0006 | 1994-01-18 | Runaway train, CN North America, Mile 175, Grande Cache Subdivision | Latornell, Alberta | Loss of control |