Third party damage to a natural gas pipeline

Manitoba Hydro

Minell Pipelines Ltd. (a wholly owned subsidiary of Manitoba Hydro)

Minell 6-inch natural gas pipeline

Near McAuley, Manitoba

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 05 October 2021, at approximately 1518 Central Daylight Time, the Minell Pipeline, a 6-inch natural gas pipeline operated by Manitoba Hydro, was struck by the blade of a farm tractor as it was scraping the ground in an agricultural field near McAuley, Manitoba. The pipeline ruptured and released approximately 84 000 m³ of natural gas. The released gas did not ignite and no evacuation was required. No one was injured.

1.0 Factual information

1.1 The occurrence

On 05 October 2021 at approximately 1518,Footnote 1 a landowner was operating a farm tractor pulling a ground-scraping blade on his agricultural property near McAuleyFootnote 2 when the blade struck the Minell Pipeline, a 6-inch natural gas pipeline owned and operated by Manitoba Hydro. The pipeline ruptured and began releasing gas. The released product did not ignite, and no evacuation was required. No one was injured.

The equipment was being used to scrape the ground, an activity conducted to manage surface water drainage.

At the time of the occurrence, the segment of the pipeline was operating at 3100 kPa, which is within the maximum operating pressure approved by the Canada Energy Regulator (CER).Footnote 3

As a result of this occurrence, the pipeline was shut down for approximately 3 days. The shutdown disrupted the supply of natural gas to the downstream distribution systems, extending to the town of Dauphin. Large commercial clients were asked to cut back operations to conserve the gas remaining in the pipeline. No residential customers lost gas service during the outage.

It was later determined that 84 000 m³ of natural gas had been released as a result of the accident.

At the time of the occurrence, the sky was clear with light southerly winds, and the temperature was around 29 °C.

1.1.1 Occurrence location

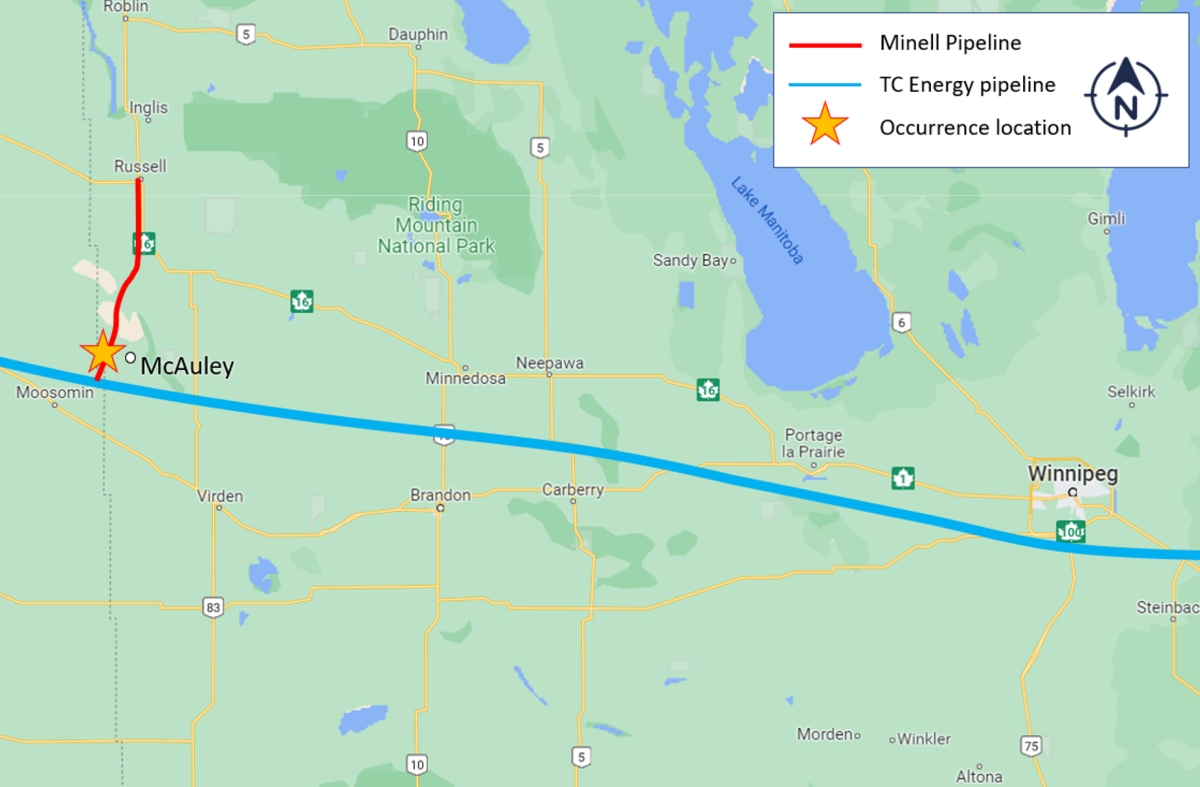

The occurrence took place in a rural area in southwestern Manitoba near the border with Saskatchewan. The pipe was struck in an agricultural field near the Minell Pipeline’s delivery point from TC Energy’s Canadian Mainline (Figure 1). Pipelines from both Manitoba Hydro and TC Energy cross agricultural property owned by the landowner.

1.2 Response to the occurrence

1.2.1 Landowner

The landowner, who did not have reliable cellular coverage at his location, informed a family member via radio that his equipment had struck the pipeline. At 1526, the family member called the emergency number for TC Energy to report the line strike.Footnote 4 TC Energy dispatched a technician from the nearby Moosomin compressor station and committed to calling the landowner back with more information.

The family member then called 911 to alert emergency services to the situation; the McAuley volunteer fire department was mobilized to the site.

Once on site, the TC Energy technician ascertained that it was not a TC Energy pipeline. At 1554, the family member, after being informed by TC Energy that TC Energy’s pipeline had not been damaged, contacted Manitoba Hydro by telephone.

1.2.2 Manitoba Hydro

At 1518, the line strike triggered a low-pressure alarm at Manitoba Hydro’s GS-100 (McAuley) gate stationFootnote 5 (1.76 km upstream of the rupture location), followed by a low odorant rate alarm at 1520. The gas system operator (GSO), located in the Winnipeg area, noticed the alarms on his remote terminal. After having confirmed that the alarms were not part of a pipeline occurrence exercise,Footnote 6 a measurement technician was dispatched from Brandon (145 km away by road) to investigate.

About 24 minutes later, at 1544, a low-pressure alarm was triggered at Manitoba Hydro’s GS-103 (Russell) gate station, 63 km downstream from the rupture, at which point a loss of primary containment was suspected. The GSO communicated this information to the gas system control manager.

At 1554, a call from the landowner’s family member reporting the line strike was received. Following the call, a service technician was dispatched from the Russell area (about 70 km away by road) to the site, to verify the reported line strike.

At 1630, the service technician arrived from Russell and confirmed that the pipe had ruptured and was leaking natural gas. Manitoba Hydro then decided to shut down the Minell Pipeline.

At 1710, the measurement technician, who had now arrived from Brandon, manually closed the valves at the McAuley gate station. At 1730, he closed the next downstream valve,Footnote 7 isolating a 19.7 km section of pipeline. The gas release stopped when the isolated section of pipeline was empty.

1.2.3 Sequence of events

Table 1 shows the sequence of events immediately following the occurrence.

| Time | Description |

|---|---|

| 1518 (approximately) | Farm equipment strikes Manitoba Hydro’s Minell Pipeline. |

| 1518 | The GSO at Manitoba Hydro receives a low-pressure alarm from the McAuley gate station. |

| 1520 | The GSO at Manitoba Hydro receives a low odorant rate alarm from the McAuley gate station. |

| 1525 | Manitoba Hydro dispatches a measurement technician from Brandon to McAuley, approximately 145 km away by road. |

| 1526 | A member of the landowner’s family calls TC 4Energy to report the line strike. TC Energy dispatches a technician to the occurrence site. The family member calls emergency services (911). |

| 1544 | The GSO at Manitoba Hydro receives a low-pressure alarm from the Russell gate station, at the terminus of the Minell Pipeline. |

| 1554 | A TC Energy service technician inspects the occurrence site and informs the landowner’s family that it was not a TC pipeline. A member of the landowner’s family, after being informed by TC Energy that TC Energy’s pipeline had not been damaged, calls Manitoba Hydro, who then dispatches a service technician from Russell, approximately 70 km away by road. |

| 1608 | TC Energy contacts Manitoba Hydro’s Russell office to confirm its awareness of the situation. |

| 1630 | The Manitoba Hydro service technician on site confirms the pipe rupture and a decision is made by Manitoba Hydro management to shut down the pipeline. |

| 1641 | Manitoba Hydro sets up an emergency operations centre. |

| 1710 | The measurement technician, having arrived at the McAuley gate station from Brandon, shuts the pipeline supply. |

| 1730 | The measurement technician closes downstream valve T6-010 to fully isolate the ruptured section of pipeline. |

1.3 Site examination

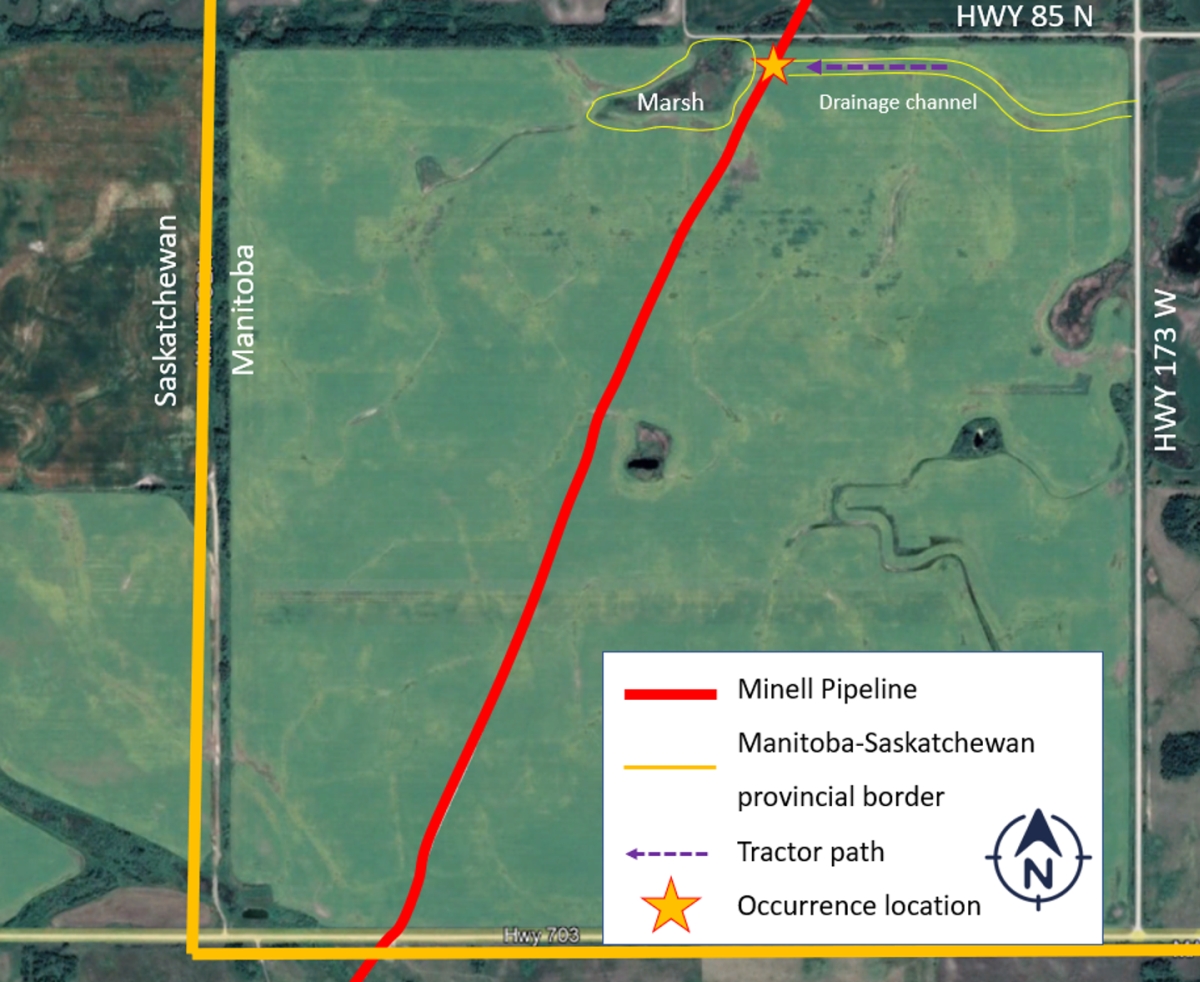

The occurrence took place on an agricultural field bound on the north by Road 85 N, on the east by Road 173 W, and on the south and west by the Manitoba-Saskatchewan border.

The Minell Pipeline crosses the agricultural field from south to north. On the north end, there is an access point to the land at the intersection between the Minell Pipeline right-of-way and Road 85 N. The access point, which is indicated by a Manitoba Hydro warning sign, is 55 m to the north of the occurrence location.

In the area of the occurrence, there is a drainage channel to the east of the pipeline; this channel crosses the pipeline and connects to a small marsh area with weeds (Figure 2).

In the vicinity of the occurrence, the land was mostly flat and there were remnants of harvested canola stalks at ground level.Footnote 8 The path of the tractor and ground-scraping blade was indicated by tire tread marks and by disturbed soil where the blade had scraped the surface (Figure 3). The ground scraping followed the path of the drainage channel west toward and across the pipeline, parallel to Road 85 N.

Following the occurrence, a rectangular area was excavated around the damaged section of pipeline (Figure 4). The depth of cover over the pipe where the blade made contact was determined to be less than 0.12 m.

The exposed pipe showed an oval-shaped rupture; the impacted material was bent and still attached to the pipe. The pipe coating was intact, except for the immediate area of the damage and where it had been removed by Manitoba Hydro during the excavation. There was no visible damage to any of the surrounding landscape.

A segment of the ruptured pipe was cut out and sent to the TSB Engineering Laboratory in Ottawa, Ontario, for analysis.

1.3.1 Farm equipment

The farm equipment was driven back to the landowner’s property south of McAuley after the occurrence.

The tractor was equipped with an 18-foot wide Pulldozer 1800 smooth bladed attachment manufactured by Bridgeview Manufacturing.Footnote 9 No modifications had been made to the equipment.

The ground-scraping blade is supported by an articulated wheeled base (Figure 5). At the time of the occurrence, the blade was in the flat position,Footnote 10 which has a maximum blade depth of 0.26 m according to the manufacturer.

1.4 The Minell Pipeline

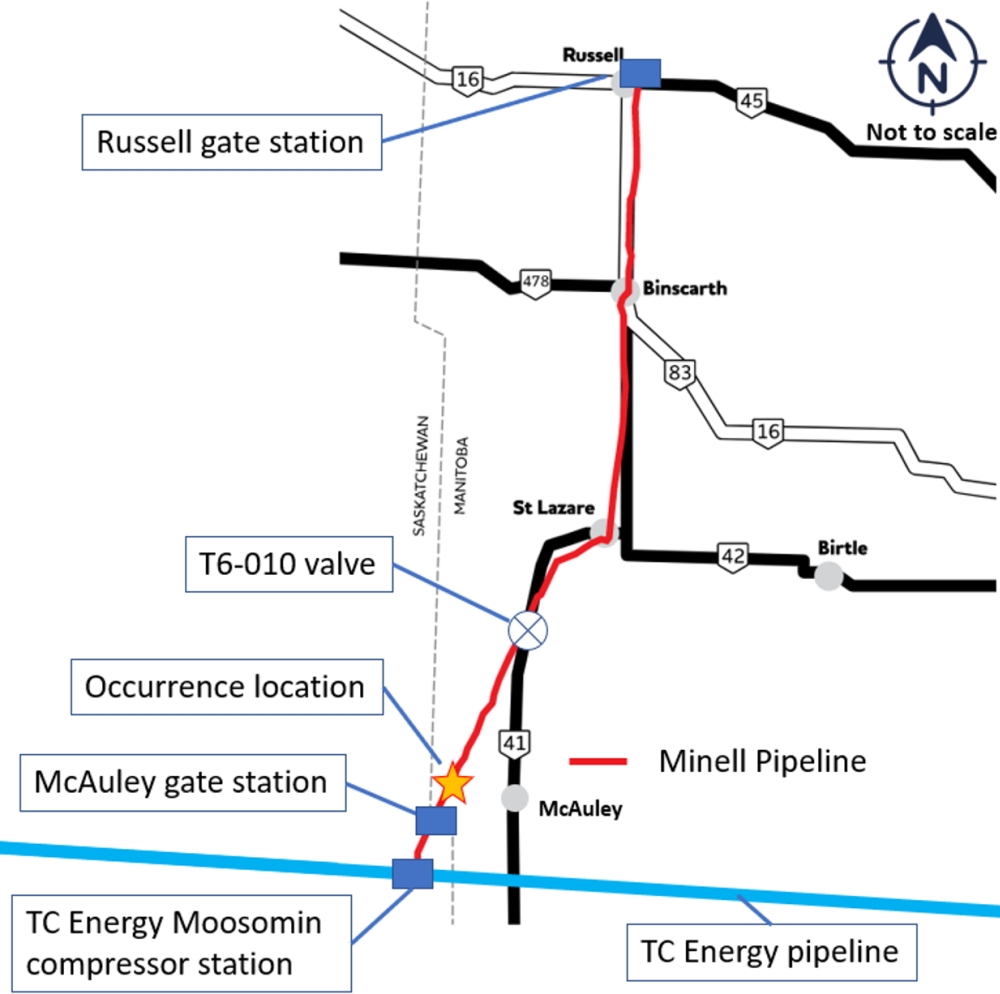

The Minell Pipeline, owned and operated by Manitoba Hydro, is part of the provincial gas transmission network in Manitoba. It originates near Moosomin, Saskatchewan, and extends for about 70 km to where it terminates in Russell at a gate station. The pipeline passes through or near the towns of McAuley (population of 270), St. Lazare (population of 257), Binscarth (population of 420), and Russell (population of 1395) (Figure 6).

The pipeline carries sweet, dry natural gas. It is supplied by TC Energy’s Canadian Mainline, from the Moosomin compressor station. At its terminus in Russell, it connects to provincial pipelines, including a 6-inch gas service line to Dauphin and a 3-inch line to Roblin. The estimated peak winter load is 11 700 m³ per hour.

The normal flow direction in the Minell Pipeline is from south to north. There are no compressor stations along the length of the pipeline, and pressure is regulated at gate stations.

The pipeline is controlled as part of Manitoba Hydro’s natural gas distribution system. There is no centralized control centre for the system. Operators work on remote devices connected to the Manitoba Hydro network. Communication between team members is through telephone, text message, and email.

The Minell Pipeline was commissioned in 1965. It was purchased from TransCanada Pipeline Ltd. on 08 February 1973 by Inter-City Gas Ltd., which was acquired by Centra Gas Manitoba which was, in turn, purchased by Manitoba Hydro in 1999. Manitoba Hydro is a provincial Crown corporation governed through the Manitoba Hydro-Electric Board. It serves natural gas customers through 18 000 km of transmission and distribution pipelines. The Minell Pipeline is the only federally regulated portion of the Manitoba Hydro natural gas system. The remainder of the system is subject to the regulations of the Manitoba Public Utilities Board.

The pipeline right-of-way is 10.1 m in width, centered on the pipeline. The minimum depth of cover (DOC) at the time of installation was 0.61 m.Footnote 11 At the time of the occurrence, there were no pressure reductions or restrictions on any segment of the Minell Pipeline with respect to its original licensed maximum operating pressure (MOP). At the occurrence location, the MOP approved by the CER was 7230 kPa.

The segment of pipe involved in this occurrence was X42 steel grade, with an outer diameter of 168.3 mm and a wall thickness of 3.962 mm. The longitudinal seam was welded using electric resistance. The pipe’s coating was an asphalt-based adhesive covered by a high-density sheath of extruded polyethylene.

1.4.1 McAuley gate station

The McAuley gate station is on the south side of Highway 703, near the Saskatchewan-Manitoba border (see Figure 6). It is the first gate station downstream of TC Energy’s Moosomin compressor station and is the first set of control valves on the Minell Pipeline accessible by Manitoba Hydro; there are approximately 4 km of pipeline between the 2 stations.

One of the main functions of the gate station is to regulate pipeline pressure depending on gas demand. In warmer months, when demand is reduced, the pressure is manually set to 3100 kPa. In the winter, the pressure regulation is bypassed, and the Minell Pipeline receives the TC Energy supply pressure. At the time of the occurrence, the McAuley gate station was in summer operation mode, with the outlet pressure set to 3100 kPa. The supply pressure to the station at the time was 5340 kPa.

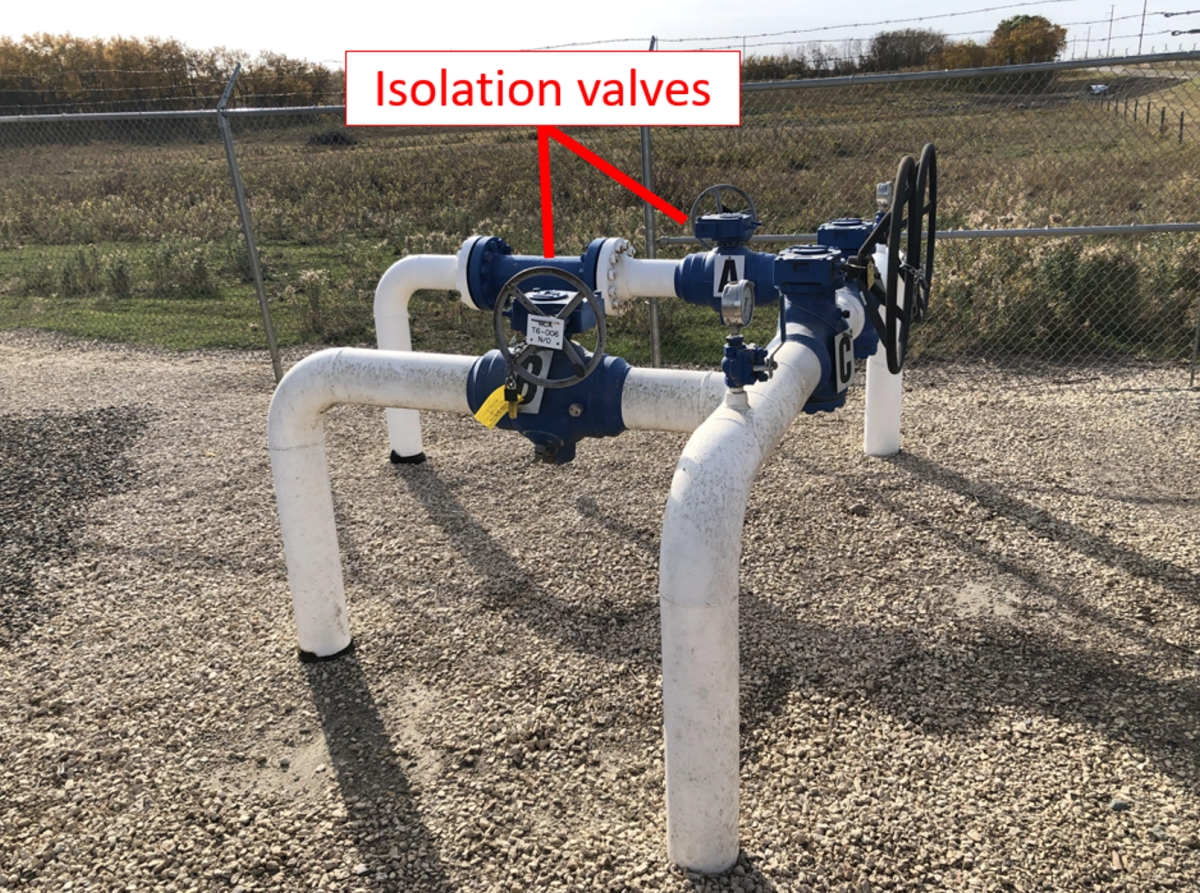

The gate station is fenced; within the yard area, there is a set of above-ground valves used to bypass or isolate the station (Figure 7). The valves are nominal 6-inch ball valves and are operated manually. The McAuley gate station is not staffed, and the nearest Manitoba Hydro staff are based in either Russell or Virden, each approximately 70 km away by road.

1.4.1.1 T6-010 valve

The T6-010 valve (see Figure 6) is a 6-inch manually operated ball valve. It is the closest valve downstream of the occurrence location that can be used to isolate the damaged section of the Minell Pipeline, and is located 19.7 km from the McAuley gate station. The valve is above-ground and accessible from Highway 41, between the towns of St. Lazare and McAuley.

1.5 Regulatory requirements for damage prevention

The CER regulates activities such as ground disturbances and crossings around pipelines under federal jurisdiction.

Under section 47.2 of the Canadian Energy Regulator Onshore Pipeline Regulations, pipeline companies are required to develop, implement, and maintain a damage prevention program. According to guidance notes published by the CER, companies must “[…] proactively identify hazards and potential hazards and manage the related risks for [their] pipelines that may be introduced by ground disturbance activities, the construction of facilities near [their] pipelines, and vehicle crossings over [their] pipelines.”Footnote 12

Activities related to the prevention of damage to pipelines are governed by the Canadian Energy Regulator Pipeline Damage Prevention Regulations – Authorizations (the Authorizations Regulations) and the Canadian Energy Regulator Pipeline Damage Prevention Regulations – Obligations of Pipeline Companies (the Obligations Regulations).

These regulations describe the shared responsibility for damage prevention between pipeline companies and land users.

1.5.1 Authorizations

The Authorizations Regulations describe the requirements for obtaining the consent of a pipeline company to conduct work across or near a pipeline. They apply to any person planning or undertaking an activity near a CER-regulated pipeline.

According to these regulations, all activities that cross a pipelineFootnote 13 or create a ground disturbance within a prescribed area (an area extending 30 m from either side of a pipe) must be authorized by the pipeline company in writing.

In the Canadian Energy Regulator Act, “ground disturbance” is defined as follows:

“ground disturbance means a ground disturbance other than one that […]

- is, in relation to a pipeline, caused by cultivation to a depth of less than 45 cm below the surface of the ground; or

- is, in relation to a pipeline, caused by any other activity to a depth of less than 30 cm and that does not result in a reduction of the earth cover over the pipeline to a depth that is less than the cover provided when the pipeline was constructed.Footnote 14

For specific agricultural activities, however, the Authorizations Regulations provide a specific exemption from obtaining consent.Footnote 15 Landowners who engage in activities that cross a pipeline for the production of crops and the raising of animals are not required to obtain consent, provided that the vehicle is operating within the manufacturer’s approved limits and that the location has not been specifically identified by the pipeline operator as one where the pipeline’s safety could be compromised by agricultural activity.

Agricultural activities that result in a ground disturbance are not covered by this exemption and must be authorized. Authorization for ground disturbances is obtained through a one-call centre,Footnote 16 which facilitates communication between the entity intending to conduct the ground disturbance and the owner of the underground facilities. If authorization is granted, a request must also be made for the owner to mark the location of the underground facilities.

In circumstances such as this occurrence, crossing the pipeline with equipment operating within manufacturer-approved limits and maintaining a drainage channel for the production of crops are activities that do not require the landowner to obtain authorization.

1.5.2 Obligations of pipeline companies

The Obligations Regulations apply to pipelines regulated by the CER and govern the requirements related to damage prevention activities. Section 16 defines the type of information that must be included in a pipeline company’s damage prevention program, a program that pipeline companies are required to develop, implement, and maintain under section 47.2 of the Canadian Energy Regulator Onshore Pipeline Regulations.

The CER, in its guidance notes for the Obligations Regulations,Footnote 17 provides direction in developing a damage prevention program; however, regulated companies have flexibility and discretion to develop a program that is tailored to their specific operations. A comprehensive damage prevention program must include processes to

- identify and analyze hazards and potential hazards,

- manage risks,

- train and manage workers,

- communicate with those who live and work around the pipeline,

- manage records and documentation, and

- monitor and evaluate progress and continually improve performance.

1.6 Landowner activities in the vicinity of the Minell Pipeline

The landowner operates agricultural vehicles on the land around the pipeline for the purpose of cultivating crops. Operations include tilling, harrowing, seeding, and harvesting to different depths depending on the type of crop being produced (crops are rotated from season to season). Other activities are carried out to maintain the land, including the management of surface drainage. On the plot of land where this occurrence took place, existing drainage channels are maintained to manage surface water in order to maximize the land area that can be seeded.

The marsh area to the west of the occurrence location varies in size from year to year based on the amount of rainfall. Weeds and silt build up in the drainage channel and the marsh area over the course of the season. The landowner removes them periodically to prevent flooding of planted areas. The ground-scraping blade used in this occurrence is regularly used for this type of task. The landowner has maintained the drainage channel in the same way since acquiring the property several decades before.

The landowner was aware that underground pipelines cross his property, including the Minell Pipeline. He was also aware of the requirement to obtain authorization from the pipeline operator before disturbing the ground near the pipeline, and that authorization for agricultural activities can be suspended in certain circumstances. For instance, in 2009, Manitoba Hydro suspended the landowner’s authorization for agricultural work near a marsh 700 m upstream of the occurrence location after the company had discovered a DOC issue in that area. The suspension was lifted in 2016 after Manitoba Hydro installed a culvert to rectify the issue.

In this occurrence, the landowner did not consider his activity to be a ground disturbance.

1.7 Manitoba Hydro’s damage prevention program

At Manitoba Hydro, the damage prevention program is incorporated into the Pipeline System Integrity Management Program (P-SIMP). This program is implemented in accordance with the applicable regulatory requirements,Footnote 18 and is a compilation of activities and systematic practices that Manitoba Hydro applies to ensure the continued safe and reliable operation of its pipeline system. The program includes a process for conducting integrity risk assessments of the company’s entire gas pipeline network, including the Minell Pipeline. The network consists of 18 000 km of pipeline divided into approximately 40 000 individual line segments.

Within the P-SIMP, Manitoba Hydro classifies hazards in 6 categories:

- Corrosion/degradation

- Material, manufacturing and construction

- Natural forces

- External interference

- Incorrect operations

- Unable to classify

The “external interference” category encompasses the hazards associated with intentional or unintentional damage to natural gas assets due to human activity. Hazards in this category are the main focus of the damage prevention program.

Each hazard has associated integrity activities that serve as a control or mitigation measure to one or more types of hazard.Footnote 19 Below are some examples of the integrity activities conducted to prevent damage from external interference:

- DOC surveys and investigations

- below-grade leak detection surveys

- right-of-way inspections

- landowner awareness program

- “Click before you dig” public awareness program

- integrity incident analysis

- integrity risk assessments

1.7.1 Depth of cover surveys

DOC surveys and investigations are conducted to detect any location where the pipeline is shallow or the cover is insufficient to minimize the potential for damage by a third party.

For the Minell Pipeline, complete DOC surveys of the entire pipeline are performed at 15-year intervals. Partial surveys may be conducted on an as-needed basis to support other integrity activities. The most recent complete survey was performed in spring 2009. In addition, a partial survey was completed in fall 2018 between the TC Energy Moosomin compressor station and the McAuley gate station, as a preliminary measure before conducting integrity excavations in the area. Although Manitoba Hydro was in the process of transitioning to a survey frequency of 10 years, the next complete survey was scheduled for 2024.

As part of the 2020/2021 annual review of the P-SIMP, no external interference damage was identified on the Minell Pipeline. Since a watercourse survey in 2015, no new areas of shallow cover were identified, and the risks associated with DOC were assessed and deemed to be adequately managed.

1.7.1.1 Results of the 2009 depth of cover survey

The DOC survey performed in spring 2009 was done in accordance with the requirements determined by Manitoba Hydro, and measurements had to be recorded as follows:

- at 25 m spacing

- at 3 m spacing across sloughs, depressions, or abrupt changes in elevation

- at key features such as the bottom of ditches, drains, and streams

- at each edge of the feature in swamp areas and areas where surface water is present

- in any area where DOC is less than 0.60 m

All locations found to have a depth measurement of less than 0.60 m were to be evaluated through Manitoba Hydro’s Insufficient Cover and Slope Stability Issue Engineering Assessment Process. This process is used to determine the priority for monitoring and remediation work in those areas.

The survey identified 11 potential DOC issues, which were included in an Insufficient Cover Priority Report and were evaluated through the risk assessment process for insufficient cover. None of the identified potential issues were in the immediate vicinity of the occurrence. The closest was approximately 700 m upstream of the occurrence, on the landowner’s property, and was addressed by installing a culvert in 2016.

The DOC measured nearest to the occurrence location was 0.88 m, taken 4.5 m downstream of the damage location. As the measurement was above 0.60 m,Footnote 20 it did not trigger a more detailed assessment in the area of the occurrence.

1.7.1.2 Depth of cover survey conducted after the occurrence

After the occurrence, the CER ordered Manitoba Hydro to conduct a DOC survey of the entire Minell Pipeline. The survey identified 10 locations where the DOC was less than 0.65 m,Footnote 21 including the occurrence location.

1.7.2 Right-of-way inspections

In accordance with standard CSA Z662, Manitoba Hydro conducts leak detection surveys of all its transmission and high-pressure pipelines, including the Minell Pipeline. Manitoba Hydro also performs right-of-way inspections, including signage verification, during these surveys. The surveys and inspections are completed annually by an employee walking along the right-of-way, and generally conducted during the seasons where the ground is not visually obstructed by crops or snow.

During the surveys and inspections, surveyors/inspectors record leaks as well as significant deficiencies, abnormalities or unsafe conditions such as apparent earth movement, damaged warning signs, or other evidence of external damage to the pipe. The DOC is not measured during these activities.

The 2020/2021 survey and inspection of the Minell Pipeline was conducted from 13 to 19 June 2021; no leaks or unsafe conditions were identified in the area of the occurrence.

1.7.3 Landowner awareness program

Once a year, Manitoba Hydro sends out a letter to all landowners within 100 m on either side of the Minell Pipeline (about 60 landowners) to remind them that they must contact Click Before You Dig MB before they excavate on their property. The letter is accompanied by a landowner awareness brochure with guidelines, referencing the CER damage prevention regulations.

The information provided by Manitoba Hydro mentions that landowners must obtain authorization from the pipeline company before conducting activities that cause a ground disturbance. The general focus of this information, however, is on excavation work and on agricultural work performed below a certain depth.

In 2018, as part of a follow-up to a compliance verification activity, Manitoba Hydro confirmed to the CER that it had updated its damage prevention documentation, including its landowner guidelines.

1.7.4 Risk assessment due to external interference

For each pipeline segment, the risk of pipe damage due to external interference incidents is determined based on several factors, including the historical and current damage rates experienced on the pipelineFootnote 22 and the cause of damage, which can be any one of the following:

- Locate not requested (no facility request was made)

- Locate requested (locate request was made, but excavation went outside the specified area)

- Insufficient cover (where the pipeline had insufficient cover or burial depth)

For the assessment of the risk of damage due to insufficient cover, Manitoba Hydro’s methodology does not include a mathematical term to quantify loss of cover over time and instead bases risk on the historical damage rate. This risk assessment is reviewed annually. In 2021, the risk assessment looked at aggregate risk across all risk categories and presented the top 25 by normalized risk ranking; no segments on the Minell Pipeline were in the top 25.

When DOC issues are discovered, they are assessed through a separate risk assessment process.

1.7.5 Damage prevention program audit

Manitoba Hydro conducted an internal audit of its damage prevention program in 2018. The audit found inconsistencies in how corrective actions are implemented, and that there was no procedure to guide personnel from the discovery of a deficiency to the completion of a control measure. These issues were noted as an area of concern. A subsequent audit in 2021 found that there was no procedure to evaluate risks relevant to the damage prevention program. This area of concern was addressed in part by involving the damage prevention coordinator in the annual leak detection survey and updating the survey procedure to identify and track deficiencies.

1.8 Pipeline emergency shutdown and isolation

The Minell Pipeline is a single-feed pipeline, and is shut down by manually closing the 2 isolation valves (see Figure 7) at the McAuley gate station. No valves can be actuated remotely or automatically to isolate or shut down any part of the Minell Pipeline in the event of an emergency.

Requests for shutdown are made to the manager of Manitoba Hydro’s local Parkland West area, which is the service region where the Minell Pipeline is located. In the case of an event occurring outside of business hours, the request is forwarded to an on-call supervisor.

After a shutdown request is received, personnel from Manitoba Hydro’s Russell and Brandon regional offices are dispatched to the McAuley gate station. The target response time for natural gas emergency calls, as indicated in Manitoba Hydro’s safety and loss management program, is 60 minutes.Footnote 23

Gas flow into the 4 km section of the Minell Pipeline connecting TC Energy’s Moosomin compressor station and the McAuley gate station (see Figure 6) can only be turned off by TC Energy. This is achieved by the manual shutdown of a valve located within TC Energy’s Moosomin compressor station. During business hours, when TC Energy staff are on site, the valve can be closed within 5 minutes; after hours, calls can be responded to by TC Energy staff within 2 hours. Manitoba Hydro does not have access to the Moosomin compressor station and does not have a formal agreement with TC Energy to isolate the Minell Pipeline or to cooperate in emergency response activities.

1.8.1 Regulatory requirements for emergency shutdown

Under section 32 of the Canadian Energy Regulator Onshore Pipeline Regulations, companies are required to develop emergency management programs that manage and mitigate the risks and effects of incidents and emergencies. These regulations do not include specific criteria such as response time to emergencies or for isolating a ruptured section of pipeline. The CER requires companies to conduct assessments and enhance their capabilities for mitigating consequences resulting from a pipeline emergency.

Standard CSA Z662, Annex M—Guidance for system control, monitoring, and protection of hydrocarbon pipeline systems—provides guidelines for the design and operation of equipment, devices, and system components that are used to control and monitor pressure and flow. This annex includes general guidance on shutdown system design, but it does not specify any maximum time by which a pipeline must be shut down following the identification of a rupture. The annex is provided as a recommended practice only.

1.8.2 Emergency shutdown requirements in other jurisdictions

The United States Pipeline and Hazardous Materials Safety Administration recently published a final rule titled Pipeline Safety: Requirement of Valve Installation and Minimum Rupture Detection Standards.Footnote 24 This new rule, which came into effect on 05 October 2022, applies to new or replaced pipelines and establishes requirements for the provision of rupture mitigation valves (remote-controlled, automatic, or manual). The rule also includes requirements for those valves to be shut off no longer than 30 minutes after a pipeline rupture has been identified.

1.9 Regulatory oversight

After the introduction of the set of regulations governing pipeline damage prevention in 2016, the National Energy Board (NEB) had conducted compliance verification activities pertaining to Manitoba Hydro’s damage prevention program.

Following these verification activities, Manitoba Hydro updated relevant documents pertaining to its integrity management program and added new content related to its damage prevention program to satisfy the new regulatory requirements.

Manitoba Hydro periodically conducts emergency response exercises as part of compliance verification activities by the regulator. The last exercise, conducted on 01 December 2020,Footnote 25 simulated an accident at the Russell gate station (see Figure 6). The exercise objectives were generally met. An exercise conducted on 23 March 2017Footnote 26 included discussions regarding cooperation between Manitoba Hydro and TC Energy to facilitate valve closure at the McAuley gate station and the need for response readiness in remote areas. No formal agreement with respect to response to emergencies on the Minell Pipeline has been developed.

1.10 Laboratory analysis of failed pipe

The TSB laboratory analysed the segment of pipe (0.864 m) recovered at the site of the occurrence to determine its mechanical properties and its mode of failure.

The resultsFootnote 27 indicate that the pipe’s dimensions, as well as the chemical composition and tensile properties of the steel, met specification requirements.

The nature of the damage observed on the pipe (Figure 8) was consistent with a low-speed strike by a hard, external object. Therefore, it was determined that this damage was done by the ground-scraping blade pulled by the tractor. The low-speed intrusion caused the pipe to open without generating sparks, avoiding ignition.

1.11 Other similar occurrences

Between 2006 and 2021, there have been 15 other TSB-reportable occurrences involving a pipeline that was struck, and that resulted in the release of product (Appendix A). The majority of these occurrences involved construction equipment contacting a valve component.

1.12 TSB laboratory report

The TSB completed the following laboratory report in support of this investigation:

- LP160/2021 – Pipe Examination

2.0 Analysis

The analysis will focus on the integrity management systems, specifically the damage prevention program, and the response to the emergency.

2.1 The accident

On 05 October 2021 at approximately 1518, a landowner was operating a tractor pulling a ground-scraping blade on his agricultural property near McAuley, a rural area in southwestern Manitoba, when the blade struck a buried pipeline. It was later determined that the blade had struck the Minell Pipeline, a 6-inch natural gas pipeline owned by Manitoba Hydro.

Finding as to causes and contributing factors

The 6-inch Minell Pipeline, operating at normal pressure, was struck by a ground-scraping blade pulled by a farm tractor in an agricultural field, resulting in a rupture and release of natural gas.

At the time of the occurrence, the landowner was scraping the ground in a drainage channel, an activity that he conducted regularly to manage surface water and ensure proper drainage. The ground-scraping blade removes weeds and silt from the channel, which ensures that the water can flow freely and does not accumulate on the crops.

The Minell Pipeline was required by regulation to be buried to a depth of at least 0.61 m when it was constructed in 1960, to protect it from external damage. The maximum depth at which the ground-scraping blade is designed to operate is 0.26 m, and it was determined to be penetrating the ground less than 0.12 m when it contacted the Minell Pipeline.

Finding as to causes and contributing factors

The depth of cover of the pipeline at the occurrence location was insufficient to prevent the ground-scraping blade from contacting the pipeline.

2.2 Manitoba Hydro’s damage prevention program

Manitoba Hydro’s damage prevention program is incorporated into the company’s Pipeline System Integrity Management Program (P-SIMP). The overall aim of the P-SIMP is to ensure that hazards affecting the safe operation of pipelines are effectively identified and mitigated to ensure suitability of the pipeline system for continued service.

Manitoba Hydro’s P-SIMP in effect at the time of the occurrence recognized that external interference is an integrity hazard, and it identified activities to mitigate these hazards, including landowner awareness, right-of-way inspections, and depth of cover (DOC) surveys.

2.2.1 Landowner awareness

The landowner was aware of the presence of pipelines on his property, including the Minell Pipeline. He had received information from Manitoba Hydro about working around pipelines, including information about the regulatory requirements to obtain authorization from the pipeline company before performing certain agricultural activities, including activities that can cause a ground disturbance. With respect to ground disturbances, the general focus of the information provided by Manitoba Hydro was on excavation work and on agricultural work performed below a certain depth.

Agricultural activities do not require authorization unless they cause a ground disturbance. The occurrence activity was one that the landowner had been conducting in the same way for multiple seasons. As there had been no communication from Manitoba Hydro that stated otherwise, he assumed that the activities he had been performing would not affect the buried pipeline on the property. Although the landowner was aware of the requirement to “click before you dig,” he did not consider the activity in this occurrence to be a ground disturbance requiring authorization.

Finding as to causes and contributing factors

The landowner did not request the consent of Manitoba Hydro before undertaking the ground-scraping activity as he did not consider it to be an activity requiring authorization.

2.2.2 Right-of-way inspections

Right-of-way inspections are an activity that Manitoba Hydro uses as part of its damage prevention program. Inspections are conducted once a year. Inspectors record significant deficiencies, abnormalities, or unsafe conditions affecting the pipeline right-of-way.

While the right-of-way inspections do not include a DOC measurement, they can provide insight into any changes that occur from year to year and, as they involve personnel physically walking along the right-of-way, they present an opportunity to interact with landowners.

In an internal audit of its damage prevention program, Manitoba Hydro recognized that the results from these inspections can be used to identify and track locations where risks to the pipeline exist. However, in the last inspection before the occurrence conducted in June 2021, the drainage channel at the occurrence location was not identified as an area of concern, and no unsafe conditions were noted in the area.

Finding as to causes and contributing factors

Although Manitoba Hydro conducted annual right-of-way inspections, which were an opportunity to identify potential deficiencies with the DOC, it did not note any unsafe conditions at the occurrence location.

2.2.3 Depth of cover

DOC surveys are conducted to identify areas of insufficient cover so that mitigations can be implemented to reduce the risk of pipeline damage from external interference. Although Manitoba Hydro was in the process of transitioning to a survey frequency of 10 years, the next complete survey was scheduled at a 15-year interval.

The last survey before the occurrence was performed in 2009. The results identified 11 potential DOC issues. The closest identified issue was approximately 700 m upstream of the occurrence, on the same landowner’s property.

The amount of cover over a pipeline can change over time. Such changes can be caused by natural phenomena, such as erosion, or by human activity, such as excavation or digging. The drainage channel where the landowner was working in this occurrence regularly required the removal of weeds and silt to function as intended for agricultural purposes. The activity of removing weeds and silt inherently removes some amount of soil, including some of the cover over the pipeline. However, Manitoba Hydro’s damage prevention program did not identify the removal of small amounts of cover over time as a hazard.

Finding as to causes and contributing factors

Over time, the removal of weeds and silt from the drainage ditch gradually reduced the DOC over the pipeline. This was not identified by Manitoba Hydro and, as a result, the pipeline kept operating with reduced ground cover.

Agricultural activities that disturb the ground less than 0.30 m and cultivation activities that disturb the ground less than 0.45 m do not require that authorization be obtained from a pipeline company. Pipeline companies must be aware of the DOC over their pipelines and be able to properly assess the risk of these activities resulting in contact with the pipe in order to ensure that pipelines are sufficiently protected.

Manitoba Hydro’s damage prevention program does not consider changes in the DOC as time passes. Instead, Manitoba Hydro’s methodology for external interference risks uses historical damage rates. Manitoba Hydro relies on its other integrity activities, including right-of-way inspections, to identify risks to the pipeline, including DOC issues in the interval between DOC surveys.

Manitoba Hydro’s landowner awareness program consists of one-way communication from the company to landowners, in the form of mailed letters that serve to inform landowners of their responsibilities when working around the Minell Pipeline. The program does not collect information about the agricultural work being conducted in the vicinity of the pipeline, such as the types of equipment and the frequency with which they are used. This information could be used to estimate potential DOC variations over time.

Without this information, Manitoba Hydro cannot reliably know if the Minell Pipeline is sufficiently buried to be protected from agricultural activities that do not require authorization.

Finding as to risk

If a pipeline company’s damage prevention program does not consider variations in a pipeline’s DOC over time, DOC reductions may go unmitigated, increasing the risk of pipe damage due to agricultural activities.

2.3 Emergency shutdown procedures

Following the occurrence, the initial alarms received through Manitoba Hydro’s gas control system provided enough information to recognize an issue on the Minell Pipeline, and a technician was dispatched to the site within 8 minutes of the pipeline being struck. Information received by Manitoba Hydro about other events after the line strike, including a subsequent low-pressure alarm at the Russell gate station and a member of the landowner’s family reporting the incident by phone, indicated that there was a loss of primary containment. This information was communicated to Manitoba Hydro’s management; however, the decision to shut down the pipeline was only made once the leak was confirmed on site by a Manitoba Hydro employee, 46 minutes after the rupture was suspected.

Manitoba Hydro’s emergency procedure does not consider contacting TC Energy to request assistance during incidents on the Minell Pipeline. TC Energy’s Moosomin compressor station is located 4 km upstream of the McAuley gate station, and TC Energy is capable of shutting off supply to the Minell Pipeline from its compressor station within 5 minutes when staff are on site; however, TC Energy was not asked to do so in this occurrence. In a previous emergency exercise, the potential for cooperation with TC Energy in emergency response activities was discussed; however, no formal agreement was developed.

The McAuley gate station is the first point where Manitoba Hydro has access to control flow on the Minell Pipeline. Gas supply into the 4 km segment between the pipeline supply at TC Energy’s Moosomin compressor station and the McAuley gate station (see Figure 6) can only be shut down by TC Energy. Manitoba Hydro does not have an isolation plan for the segment of pipe upstream of the McAuley gate station.

Finding: Other

Manitoba Hydro can isolate the 4 km segment of the Minell Pipeline located between its McAuley gate station and TC Energy’s Moosomin compressor station only with the participation of TC Energy.

Finding as to causes and contributing factors

Manitoba Hydro’s procedures do not identify TC Energy as a possible resource in the response to an occurrence, and the flow of gas continued into the ruptured section of pipeline until Manitoba Hydro was able to isolate it, 106 minutes after the rupture was suspected.

Once a decision is made to shut down the pipeline, Manitoba Hydro’s procedure requires personnel to visit the McAuley gate station and manually turn valves to stop the flow of gas. No emergency shutdown valves were installed that can be activated remotely or automatically, and Manitoba Hydro personnel, located 70 km away, would take approximately 45 minutes to arrive. In this occurrence, 106 minutes elapsed between the suspicion of a rupture and the complete isolation of the affected section.

Finding as to risk

If a ruptured pipeline is not isolated in a timely manner, the consequences will be more severe, increasing risks to people, property, and the environment.

On 05 October 2022, the United States Pipeline and Hazardous Materials Safety Administration final rule titled Pipeline Safety: Requirement of Valve Installation and Minimum Rupture Detection Standards came into effect. The rule applies to new or replaced pipelines and establishes requirements for rupture mitigation valves. It also sets a 30-minute maximum time for shutting down those valves from the time that a rupture is identified.

Finding: Other

There are no regulatory provisions in Canada that specify a response time for isolating a ruptured section of pipeline.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- The 6-inch Minell Pipeline, operating at normal pressure, was struck by a ground-scraping blade pulled by a farm tractor in an agricultural field, resulting in a rupture and release of natural gas.

- The depth of cover of the pipeline at the occurrence location was insufficient to prevent the ground-scraping blade from contacting the pipeline.

- The landowner did not request the consent of Manitoba Hydro before undertaking the ground-scraping activity as he did not consider it to be an activity requiring authorization.

- Although Manitoba Hydro conducted annual right-of-way inspections, which were an opportunity to identify potential deficiencies with the depth of cover, it did not note any unsafe conditions at the occurrence location.

- Over time, the removal of weeds and silt from the drainage ditch gradually reduced the depth of cover over the pipeline. This was not identified by Manitoba Hydro and, as a result, the pipeline kept operating with reduced ground cover.

- Manitoba Hydro’s procedures do not identify TC Energy as a possible resource in the response to an occurrence and the flow of gas continued into the ruptured section of pipeline until Manitoba Hydro was able to isolate it, 106 minutes after the rupture was suspected.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If a pipeline company’s damage prevention program does not consider variations in a pipeline’s depth of cover over time, depth of cover reductions may go unmitigated, increasing the risk of pipe damage due to agricultural activities.

- If a ruptured pipeline is not isolated in a timely manner, the consequences will be more severe, increasing risks to people, property, and the environment.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- Manitoba Hydro can isolate the 4 km segment of the Minell Pipeline located between its McAuley gate station and TC Energy’s Moosomin compressor station only with the participation of TC Energy.

- There are no regulatory provisions in Canada that specify a response time for isolating a ruptured section of pipeline.

4.0 Safety action

4.1 Safety action taken

4.1.1 Transportation Safety Board of Canada

The TSB issued Pipeline Safety Advisory Letter 01/22, “External risks to pipelines in agricultural areas,” to Manitoba Hydro on 15 March 2022.

The letter indicated that pipeline operators need to be aware of the depth of cover (DOC) over their pipelines to ensure that they are sufficiently buried or otherwise protected against normal agricultural activities that do not require explicit authorization.

Given the risk of damage to underground pipelines by activities conducted on agricultural land, the letter indicated that Manitoba Hydro may wish to review the management practices associated with its damage prevention program to ensure that the Minell Pipeline is adequately protected.

4.1.2 Manitoba Hydro

Manitoba Hydro took or initiated the following actions:

Contacted all landowners along the right-of-way to suspend agricultural cultivations and heavy load traffic from 13 October 2021 to 12 November 2021.

Sent a pipeline safety awareness alert to the Keystone Agricultural Producers and the Association of Manitoba Municipalities.

Completed a DOC survey between 12 and 22 October 2021 for the entire Minell Pipeline. Ten locations were found to have cover less than 0.65 m. The locations were staked and/or barricaded. Manitoba Hydro met with the affected landowners and provided written notifications in November 2021 prohibiting agricultural work, vehicle crossings and other ground disturbance activities in the staked/barricaded areas. The landowners were contacted in person or by telephone in May 2022 to remind them of the restrictions.

Added a new measure to the Pipeline System Integrity Management Program to report on the progress of planned insufficient cover remediations.

4.1.3 Canada Energy Regulator

On 09 October 2021, the Canada Energy Regulator (CER) issued order MEL-001-2021 to Manitoba Hydro with respect to the occurrence. Among other things, the order required Manitoba Hydro to

- notify affected landowners (including any persons who are engaged or are likely to be engaged in agricultural activities, rent or lease the land, or work as service providers or employees) as soon as practicable of temporary safety measures, including requirements to contact Manitoba Hydro to request a locate before performing an agricultural activity on the pipeline right-of-way until such time as the landowner is advised that adequate DOC has been confirmed by Manitoba Hydro for the lands of the landowner; and

- complete a DOC survey for its entire Minell Pipeline as soon as practicable and beginning no later than 12 October 2021.

On 13 April 2022, the CER issued Safety Advisory SA 2022-01, “Depth of Cover in Agricultural Areas,” to all regulated companies, and provided specific guidance on how to interpret the regulatory requirements for the prevention of pipeline damage, including preventive actions that companies can incorporate into their damage prevention programs.

On 12 August 2022, following a compliance verification activity, the CER issued 4 notices of non-compliance to Manitoba Hydro.

In October 2022, following a field inspection, the CER identified additional requirements for DOC survey spacing and requirements for right-of way patrol and monitoring, which are being addressed with Manitoba Hydro.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

Appendices

Appendix A – TSB-reportable pipeline occurrences involving contact leading to a product release, 2006–2021

| Occurrence number | Date | Pipeline operator | Summary |

|---|---|---|---|

| P21H0143* | 2021-10-05 | Minell Pipeline Limited | A landowner struck a pipeline with a ground-scraping blade. |

| P21H0119 | 2021-07-04 | Westcoast Energy Inc. | A landowner struck a pipeline with an excavator. |

| P17H0109 | 2017-11-02 | TransCanada Pipelines Ltd. | A contractor struck a gas tubing with a mini excavator. |

| P17H0025 | 2017-05-05 | Plains Midstream Canada | Construction work struck an underground pipeline. |

| P17H0011 | 2017-02-17 | Enbridge Pipelines Inc. | A directional drill reamer struck a pipeline. |

| P13H0033 | 2013-03-13 | Enbridge Pipelines Inc. | A hydrovac truck struck a valve. |

| P12H0048 | 2012-03-29 | Nova Gas Transmission Ltd. | Construction equipment struck a pipeline component. |

| P11H0171 | 2011-12-15 | Enbridge Pipelines (Westspur) Inc. | Construction equipment struck a valve. |

| P10H0027 | 2010-05-03 | Nova Gas Transmission Ltd. | Construction equipment struck a valve. |

| P09H0087 | 2009-09-30 | 2193914 Canada Limited | Construction equipment struck and damaged a valve. |

| P09H0011 | 2009-03-23 | Westcoast Energy Inc. | A snowmobile drove over a receipt point, striking a valve. |

| P08H0061 | 2008-10-16 | TransCanada Pipelines Ltd. | Construction equipment struck a valve. |

| P07H0049 | 2007-08-15 | Minell Pipeline Limited | A farmer’s cultivator struck a valve. |

| P07H0040 | 2007-07-24 | Trans Mountain Pipeline | A construction backhoe struck an underground mainline. |

| P06H0053 | 2006-10-06 | TransCanada Pipelines Ltd. | Construction equipment struck a valve. |

* This occurrence