Striking of the anchored vessel Pan Acacia

Bulk carrier Caravos Harmony

Vancouver Harbour, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

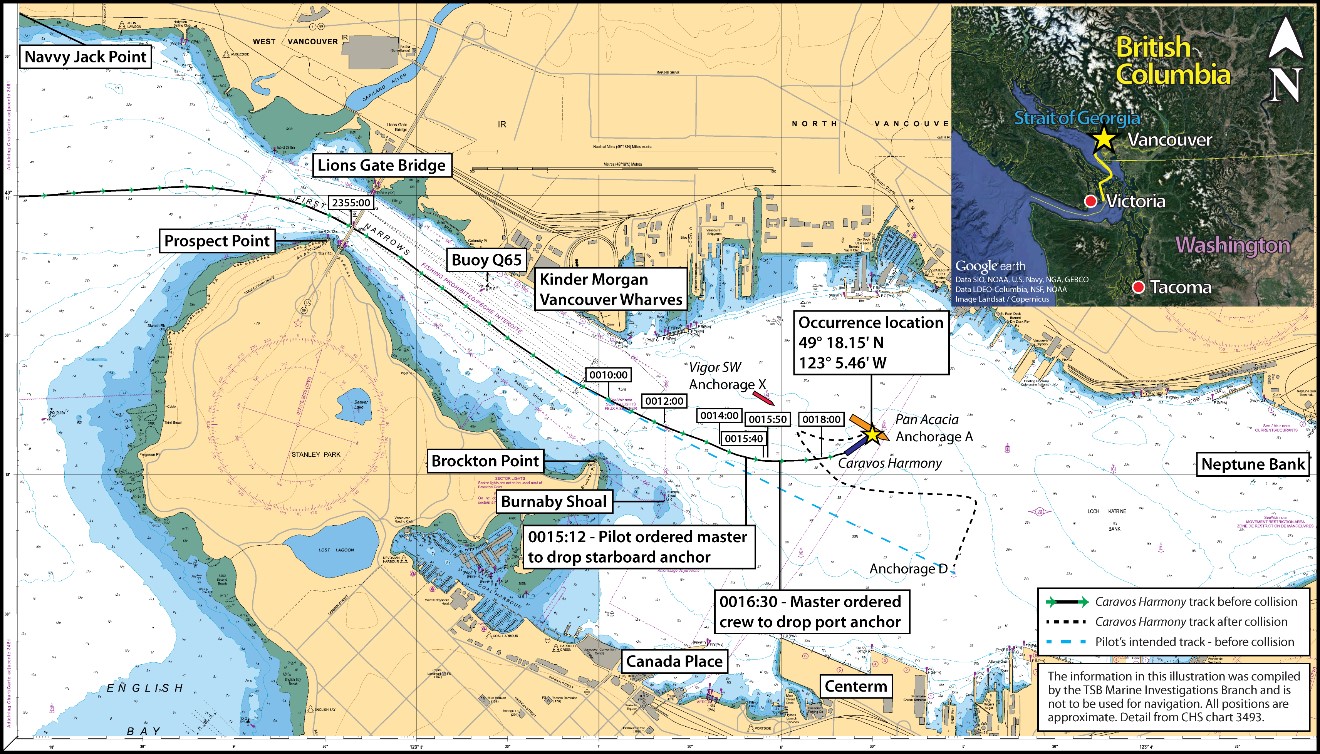

On 17 March 2019, the bulk carrier Caravos Harmony, under the conduct of a pilot, was proceeding to an anchorage in Vancouver Harbour, British Columbia, when it struck the anchored bulk carrier Pan Acacia. Both vessels sustained damage. No pollution or injuries were reported.

1.0 Factual information

1.1 Particulars of the vessel

| Name of vessel | Caravos Harmony | Pan Acacia |

|---|---|---|

| International Maritime Organization number | 9595589 | 9510515 |

| Flag | Marshall Islands | Panama |

| Classification society | Registro Italiano Navale | Korean Register of Shipping |

| Type | Bulk carrier | Bulk carrier |

| Deadweight tonnage | 81 670 | 175 141 |

| Gross tonnage | 44 289 | 92 080 |

| Length overall | 229.0 m | 291.8 m |

| Moulded breadth | 32.26 m | 45.0 m |

| Cargo | 69 500 tonnes of corn | None |

| Draft (at the time of the occurrence) | 12.95 m (forward), 13.02 m (aft) | 7.52 m (forward), 8.53 m (aft) |

| Propulsion | One 2-stroke direct reversing engine providing 9480 kW, driving one fixed-pitch propeller | One 2-stroke direct reversing engine providing 16 860 kW, driving one fixed-pitch propeller |

| Crew | 21 | 21 |

| Built | 2013 | 2010 |

| Registered owner | Octapus Shipping Corporation, Greece | POS Maritime GC SA, South Korea |

| Ship manager | Iason Hellenic Shipping Co. Ltd, Athens, Greece | Pan Ocean Company Ltd., Seoul, South Korea |

1.2 Description of the vessel

1.2.1 Caravos Harmony

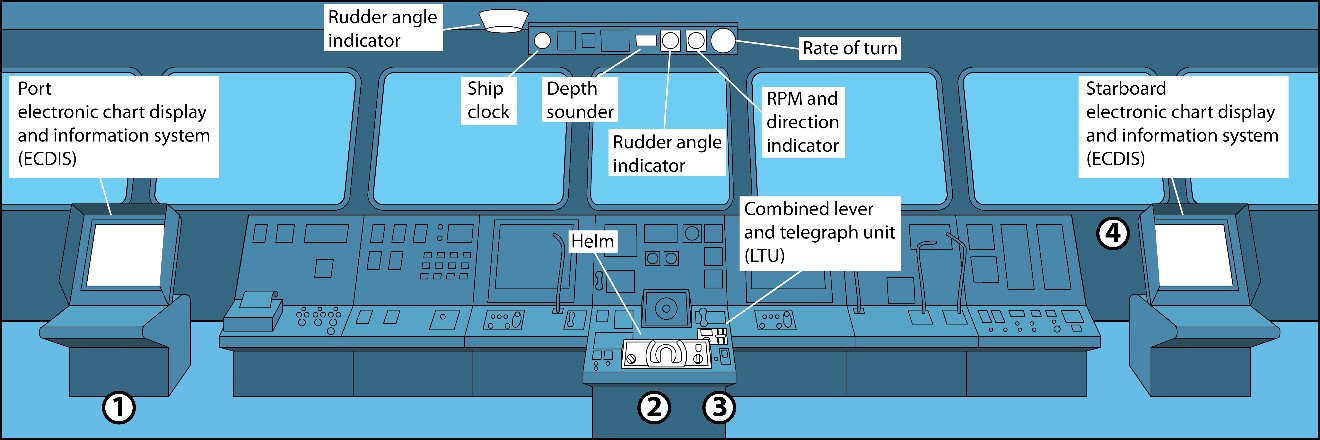

The Caravos HarmonyFootnote 1is a Panamax/Kamsarmax-type bulk carrier of steel construction with 7 cargo holds (Figure 1). The bridge, machinery space, and accommodation are located aft. The bridge is equipped with all navigational equipment required by the International Convention for the Safety of Life at Sea (SOLAS) and is also fitted with a voyage data recorder (VDR).Footnote 2 The bridge also has a navigation console that includes a steering wheel for helm control and a combined lever and telegraph unit (LTU)Footnote 3 for propulsion control.

The vessel has 2 anchors, 1 on either side of the bow. Each anchor chain is restrained by a chain stopper and controlled by a windlass, and each windlass has a manual brake and gear that must be released in order to deploy the anchor. The vessel is not fitted with a bow thruster.

1.2.2 Pan Acacia

The Pan Acacia is a Capesize bulk carrier of steel construction with 9 cargo holds (Figure 2). The bridge, machinery space, and accommodation are located aft. The bridge is equipped with all navigational equipment required by SOLAS.

1.3 History of the voyage

On-board recordings are privileged under the Canadian Transportation Accident Investigation and Safety Board Act. The TSB has always taken its obligations in this area very seriously and has vigorously restricted the use of on-board recording data in its reports. Unless the on-board recording is required to both support a finding and identify a substantive safety deficiency, it will not be included in the TSB’s report. To validate the safety issues raised in this investigation, the TSB has made use of the available on-board recording in its report. In each instance, the material has been carefully examined in order to ensure that it is required to advance transportation safety.

On the night of 15 March 2019, the Caravos Harmony, which was anchored in Tacoma, Washington, U.S. while awaiting instructions, received directions from its ship manager, Iason Hellenic Shipping (sIHS), to proceed to Vancouver Harbour, British Columbia (BC) to refuel.Footnote 4 Just before the vessel departed, IHS sent an updated electronic chart of Vancouver Harbour to the vessel. The second officer uploaded this chart into the vessel’s electronic chart display and information system (ECDIS) and plotted the voyage from Tacoma to Vancouver Harbour.

At 0800Footnote 5 on 16 March, the vessel departed Tacoma under the conduct of a U.S. pilot, with propulsion controlled from the bridge. At around 1514, the U.S. pilot disembarked. The vessel continued to the Brotchie pilot station off Victoria, BC, where a British Columbia Coast Pilots Ltd. pilot (hereafter referred to as the pilot) boarded the vessel at 1655. Before boarding, the pilot checked the tide, the traffic in Vancouver Harbour, and the current in First Narrows.Footnote 6

The pilot joined the vessel’s bridge team, which consisted of the master, the second officer, and a helmsman. The pilot and master discussed the purpose of the vessel’s visit to Vancouver Harbour to refuel and noted that the current would be against the vessel all the way to First Narrows. They also briefly discussed disembarking arrangements for the pilot; the vessel’s expected arrival time at Anchorage D, its destination in Vancouver Harbour; and the fact that a tug had not been ordered for the vessel. At 1702, the pilot and master discussed the vessel’s sea speed. The pilot mentioned that the current could be as high as 4 knots against all the way to Vancouver Harbour and that he needed all the speed he could get to counter this current.

At 1705, the speed was increased to full sea speed (12 knots) with an rpm of 80. At 1715, the pilot and master discussed preparing the anchors once the vessel was nearing Vancouver. The pilot asked the master to have both anchors readied in case of emergency when the vessel was about 3 nautical miles (NM) from the Lions Gate Bridge in First Narrows. The master asked if the pilot had a preference for which anchor to be used in anchoring the vessel and informed him that the crew would stand by forward and have both anchors ready for emergencies. The pilot indicated that he had no preference for the anchors at this time. Soon after, the master left the bridge. The second officer and the pilot discussed whether the pilot had signed the vessel’s pilot card, which the pilot had not done. At approximately 1800, the third officer took over the watch from the second officer; the helmsman remained on the bridge. During the 5-hour voyage from Victoria to Vancouver, the pilot gave various helm orders to keep the vessel on track.

At 2319, as the Caravos Harmony neared Vancouver, the pilot told the third officer that he was to reduce the sea speed to manoeuvring speed. Soon after, the master returned to the bridge. The pilot asked the master to lower both anchors to about 1 m above the waterline.

Around 2323, the Caravos Harmony approached First Narrows at manoeuvring speed. The pilot told the master that the flood tide in First Narrows was about 3 knots and that he wanted a safe speed in First Narrows.Footnote 7

Around 2324, the master and the pilot discussed the anchorage point and the depth at the anchorage.Footnote 8 The pilot required 7 shackles on deckFootnote 9 to be used during anchoring. The pilot also advised the master that once close to the anchorage, he wanted one of the anchors lowered on gear down to 1 shackle in the water and then dropped at the prescribed moment.

At 2330, the master told the pilot that the starboard anchor had not been used in a whileFootnote 10 and asked permission from the pilot to use it for anchoring. The pilot agreed, as this would also help him anchor the vessel at the assigned location. At about 2332, the master ordered the chief officer to prepare the starboard anchor. The chief officer asked for clarification that the starboard anchor was to be readied, and said that the port anchor was ready and that he and the crew were standing by. The master asked the pilot if he should drop the anchor to 1 shackle on deck, and the pilot asked him to wait until the vessel was near Anchorage D. At 2358, the pilot confirmed that the current was still 3 knots at First Narrows.

Around midnight, the second officer took control of the propulsion from the third officer upon arriving on the bridge. As the vessel approached Lions Gate Bridge, the vessel’s course was progressively being altered to starboard. Soon after, the pilot ordered hard to port and slow ahead to check the vessel’s swing to starboard and to steady up on a heading of 125°T. The pilot then ordered dead slow ahead and the vessel entered First Narrows at a speed of 7.4 knots.Footnote 11 The main engine’s rpm was 42 and the vessel’s heading was 125°T. After entering First Narrows, the pilot ordered a course of 123°T and, at the same time, indicated the strong current at buoy Q65 near Kinder Morgan Vancouver Wharves;Footnote 12 the bridge team acknowledged the strong current. Soon after, an able-bodied seaman took over as helmsman.

At 0006:47 on 17 March, the pilot ordered a course of 115°T to steer the vessel away from Burnaby Shoal. The vessel’s speed at this time was 7.4 knots. Between 0006:54 and 0013:48, the pilot issued various engine and helm orders and observed that the vessel did not respond to starboard helm order as quickly as expected. The vessel’s heading gradually changed from 115°T to 105°T and the speed decreased from 7.4 to 6.1 knots.Footnote 13

When the vessel was abeam Canada Place the pilot reiterated the strength of the current and observed the vessel moving to port. At 0013:48, the pilot ordered the engine stopped, and then ordered hard to starboard and slow ahead. The second officer moved the LTU lever from the stop position to dead slow ahead and then slow ahead, pausing about 3 seconds between steps. At 0014:25, the pilot asked the second officer if the vessel was at slow ahead speed, and the second officer replied that the engine was in the process of getting to slow ahead speed. The vessel’s heading at this time was 098°T and the speed was 6 knots. The pilot asked if the vessel was going astern because the vessel was not responding to helm orders. At 0014:35, the pilot ordered hard to starboard again and, a few seconds later, the pilot ordered the engine stopped. The second officer moved the LTU lever from slow ahead to dead slow ahead and, after a pause, moved it to the stop position. At this time, the vessel’s heading was 095°T and speed was 5.9 knots.

At 0014:48, the pilot ordered emergency full aheadFootnote 14 and hard to starboard. The master queried the pilot’s order and the pilot confirmed the order and responded with concern about hitting the Pan Acacia, which was anchored at Anchorage A located to the Caravos Harmony’s port side. The second officer moved the LTU lever through dead slow ahead, slow ahead, half ahead, and full ahead, pausing for 4 to 5 seconds at every step. The pilot observed that the vessel was still moving to port to where the Pan Acacia was anchored.

At 0015:12, with the main engine in the process of responding to the full ahead orderFootnote 15 and the vessel’s speed at around 6 knots, the pilot ordered the master to let go the starboard anchor. Seconds later, the pilot ordered emergency astern.Footnote 16 In response to the pilot’s order of emergency astern, the second officer moved the LTU lever from full aheadFootnote 17 to stop, pausing at half ahead and slow ahead for about 3 seconds each. At the stop position, he paused for 5 seconds, then moved the lever to the emergency astern position, pausing at every intermediate position for about 4 seconds.Footnote 18,Footnote 19 Meanwhile, the master used a handheld radio and ordered the crew to deploy the starboard anchor. The pilot once again ordered to let go the starboard anchor and the order was repeatedly relayed by the master to the anchor station crew. At 0015:30, the pilot once again ordered emergency astern because the main engine had not responded to the first order for emergency astern.

At 0015:47, the pilot ordered full astern. At this time, the LTU lever was at emergency astern, but the rpm indicator still showed the engine rpm as 3 in the ahead direction and that the engine had not responded with astern propulsion. At 0016:01, the pilot used the vessel’s VHF radio telephone to request emergency assistance from any available tugs nearby, but none were ready to respond immediately. At 0016:04, the second officer moved the lever from emergency astern to full astern to provide astern propulsion, but the engine did not respond. At 0016:16, the engine start failure alarm sounded on the bridge and in the engine control room, indicating that the engine had failed to start 3 times in a row. In response to a low starting air -pressure alarmthe engine room staff opened the standby air receiver valve. This increased the starting air pressure and reset the low starting air pressure alarm.

While the second officer was trying to initiate emergency astern, the crew at the anchor station made several attempts to let go the starboard anchor, but it did not deploy. The chief officer and the master began discussing in Tagalog the stuck anchor. At 0016:30, the master ordered the crew in Tagalog to let go the port anchor. At the same time, the pilot repeated the orders for emergency astern and to let go the starboard anchor. The master responded that he had ordered the port anchor to be let go because the starboard anchor was stuck. The vessel’s bow moved further to port and toward the Pan Acacia while moving forward at about 6 knots.

At 0016:39, the second officer moved the LTU lever to the stop position, which caused the engine start failure alarm to reset. The second officer then moved the lever incrementally from stop to emergency astern, pausing at each position for 3 to 4 seconds. The main engine did not respond. The vessel’s bow continued to move toward port and the vessel continued forward on a collision course with the Pan Acacia at a speed of 5.8 knots.

At 0017:08, the pilot called Marine Communications and Traffic Services (MCTS) to advise of the impending striking. Meanwhile, the officer on duty on the bridge of the Pan Acacia, observing the emerging situation, tried to communicate with the Caravos Harmony over VHF but received no response.Footnote 20 He then called MCTS to inform it of the impending striking. The Pan Acacia bridge crew used the vessel’s whistle to sound a single long blast, then repeatedly sounded 5 short blasts until the striking.

At 0017:25, the pilot reiterated his order for emergency astern and ordered it again at 0017:42. The second officer moved the LTU lever from emergency astern to stop and back again to emergency astern with pauses of 4 seconds between each step. At 0018:02, the main engine responded in the astern direction. The vessel’s bow was approximately 0.23 NM (426 m) away from the starboard mid-section of the Pan Acacia and a striking was imminent.

The Caravos Harmony anchor station crew, recognizing the danger to their personal safety, retreated from the anchor station. The vessel continued ahead at a speed of about 5.5 knots and, at 0019:54, its bow struck the Pan Acacia’s starboard mid-section above the waterline. After the striking, the pilot ordered the main engine stopped. The second officer moved the LTU lever from full astern to stop, pausing about 4 seconds at every intermediate step on the LTU (see Figure 3 above).

At around 0021, the Caravos Harmony backed away under its own power from the Pan Acacia. At 0034, the pilot ordered the port anchor to be raised. The pilot requested an assist tug and, shortly afterwards, the tug Seaspan Raven arrived on site. The Seaspan Raven then escorted the Caravos Harmony while it proceeded under its own power to Anchorage D and anchored using the port anchor.

1.4 Damage

Pan Acacia Caravos Harmony1.5 Environmental conditions

At the time of the occurrence, the tide was flooding at maximum, with a current of about 3 knots southeasterly at a direction of 135°T. The wind was east-northeasterly at 4 knots. The swell height was 0.2 m.It was dark and the skies were clear, with visibility reported as 6 NM.

The Sailing DirectionsFootnote 21 that cover the area around First Narrows and the Vancouver Harbour state that between Brockton Point and Neptune Bank, tidal streams tend to circulate anti-clockwise both on flood and ebb. Inshore eddies within Vancouver Harbour are unpredictable. Crews should not rely on the anticipated direction of the tidal stream alongside any wharf. Vessels berthing should have anchors ready.

1.6 Vessel certification

The Caravos Harmony was crewed, equipped, and certified in accordance with existing regulations. As required by the International Management Code for the Safe Operation of Ships and for Pollution Prevention (ISM Code), the vessel held a valid safety management certificate. Footnote 22 The vessel was classed with Registro Italiano Navale (RINA) and its safety management certificate issued by RINA had last been renewed on 30 May 2018. The vessel had last undergone an annual inspection on 18 January 2019.

The Pan Acacia was crewed, equipped, and certified in accordance with existing regulations. It held a valid safety management certificate as required by ISM Code. The vessel was classed with Korean Register of Shipping and its safety management certificate had last been renewed on 30 May 2018. The vessel had last undergone an annual inspection on 23 May 2018.

1.7 Personnel certification and experience

The crew on the Caravos Harmony held certificates in accordance with the provisions of the International Convention on Standards of Training, Certification, and Watchkeeping for Seafarers, 1978, as amended in 1995 (STCW Convention).

The master held a master mariner certificate issued in 2012 and endorsed in 2015 by the Maritime Industry Authority of the Republic of the Philippines. He had worked as a master on bulk carriers since 2013 and had been working for IHS as a master since 2016. He joined the Caravos Harmony as master on 03 August 2018. He had completed a bridge resource management (BRM) course in 2012. His most recent voyage into Vancouver Harbour was on a bulk carrier in 2008.

The chief engineer held a Class 1, Motor certificate issued in 1999 and endorsed in 2015 by the Maritime Industry Authority of the Republic of the Philippines. He began his sea career in 1979, becoming a chief engineer in 2003. He worked in this role on various bulk carriers for approximately 4 years. He joined the Caravos Harmony on 10 March 2019 while the vessel was in Tacoma. The occurrence voyage was his first with IHS.

The chief officer held a master mariner certificate issued on 04 June 2016 by the Maritime Industry Authority of the Republic of the Philippines. He had completed a BRM course in 2016. He had worked as a chief officer since 2012. He joined the Caravos Harmony on 12 July 2018. The occurrence voyage was his first with IHS.

The second officer held an officer in charge of a navigational watch certificate issued on 30 August 2016 by the Maritime Industry Authority of the Republic of the Philippines. He had completed a BRM course in 2014. He had worked as a third officer from 2014 to 2018 and was promoted to a second officer in 2018. He joined the Caravos Harmony on 12 July 2018.

The helmsman held an able seafarer deck certificate issued on 26 April 2016 by the Maritime Industry Authority of the Republic of the Philippines. He had been a seafarer since 1995 and had 5 years of experience as a helmsman. He joined the Caravos Harmony on 21 September 2018.

The pilot held a Class 1 (unrestricted) pilot licence that had been issued by the Pacific Pilotage Authority (PPA)Footnote 23 in Canada on 02 August 2000 and had about 20 years of experience as a pilot. In March 2018, he had completed a 2-day course on BRM for pilots.Footnote 24

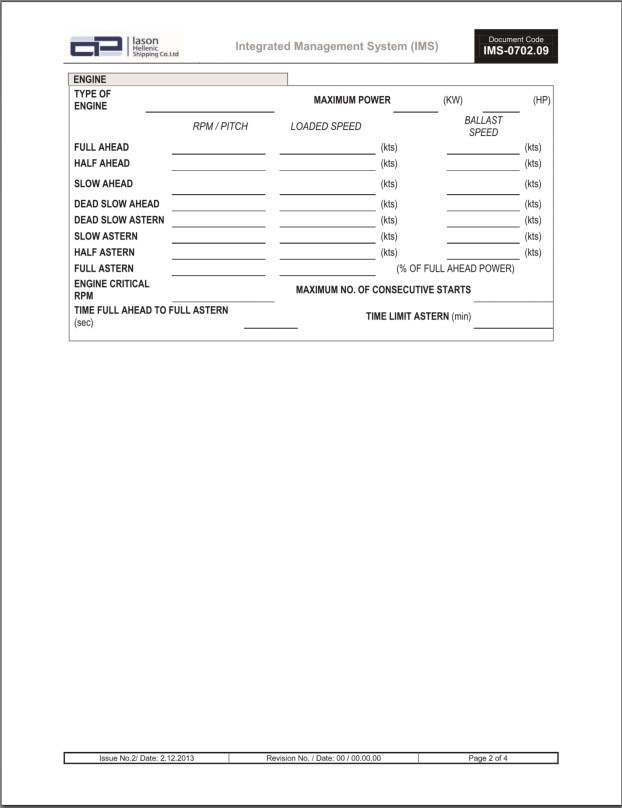

1.8 Propulsion

The vessel is propelled by one MAN B&W 6-cylinder 2-stroke direct reversing diesel engine, model 6S50MC-C2,Footnote 25 driving a fixed-pitch propeller. n ttBecause the engine is directly coupled to the propeller through a shaft, the propeller turns in the same direction and rpm as the main engine.

The main engine is normally started from stop, either in the ahead (clockwise) or the astern (anti-clockwise) direction, by means of compressed airFootnote 26 from an air receiver. The vessel is fitted with 3 air compressors to supply pressurized air to 2 air receivers, to a maximum pressure of 30 bar. Once the engine is turning on air, fuel is injected and the engine starts operating in the desired direction.

Normally, before the main engine’s direction of rotation can be reversed, the main engine rpm is brought to a complete stop by cutting off fuel injection. When the engine is on bridge control, its rotational direction and rpm are controlled by signal from the LTU by means of a control system.

The main engine is also equipped with a load-up and a load-down program to incrementally increase or decrease the loading of the main engine between full ahead and navigation full ahead. From full ahead to stop and then from stop to emergency astern, there is no load programming and the main engine is designed to respond instantaneously.

Propulsion can be controlled from the bridge, the bridge wings, the engine control room, and the engine room. The LTU on the bridge allows an operator to directly control both the engine’s speed and rotational direction (ahead or astern).Footnote 27

The LTU lever has 11 steps marked on it.Footnote 28 Each step represents a specific rpm command ahead or astern associated with it.Footnote 29 The lever can be moved seamlessly between any of the 11 steps for finer adjustments (Figure 6). When the LTU lever is moved to any one of these steps, corresponding orange light-emitting diodes illuminate on either side of the lever to indicate the lever position and the propulsion order.

An engraved plate affixed to the propulsion console indicates the corresponding main engine rpm and vessel speed for each propulsion order, except for emergency astern (Figure 7).

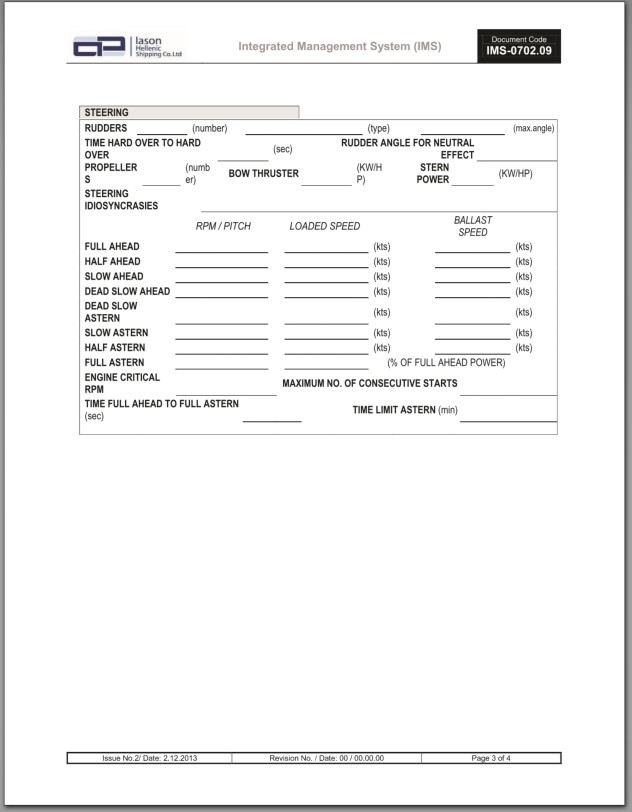

The wheelhouse posterFootnote 30 indicates that the time required for the vessel to go from emergency full ahead to full astern is 9 minutes and 9 seconds and to go from full ahead to stop is 7 minutes and 11 seconds. The maximum number of consecutive starts of the main engine is 25 based on air receivers capacity. The wheelhouse poster also has information about emergency manoeuvres and the vessel’s stopping distance during an inertial stopFootnote 31 (Appendix A).

In the same console as the LTU lever, there are digital displays for rpm and the direction of the engine’s rotation. There is also a bridge movement recorder which records telegraph movements on a printer. There is one other rpm indicator on the bridge above the bridge midship window in front of the steering console. This indicator provides information about the status and direction of the main engine’s revolutions. It is visible from the ECDIS on the port side of the bridge (Figure 8), which is where the pilot was standing throughout the voyage. The pilot’s portable pilot unit was also at this location.

Legend

1 Pilot

2 Helmsman

3 Second officer

4 Master

1.8.1 Main engine emergency astern

When a vessel is underway and the main engine is stopped, the vessel will not stop immediately but will continue moving through the water for a certain distance due to inertia. The Caravos Harmony wheelhouse poster showed that if the vessel travelling at 15.14 knots (navigation full ahead) in ballast condition has its engine stopped, the vessel will continue 0.78 NM and take 7.2 minutes before the speed reduces to 4.99 knots.Footnote 32,Footnote 33 Although fuel is no longer going to the engine once it is stopped, the vessel’s momentum through the water will drive the propeller and thereby turn the engine.

When a vessel is proceeding ahead and needs to be stopped urgently, astern propulsion is applied and the anchors may also be deployed as appropriate. In order for the vessel to go astern, the engine needs to be stopped first and then started again in the astern direction.

The emergency astern (crash stop) and other astern tests used to develop the Caravos Harmony’s manoeuvring characteristics information identified on the wheelhouse poster were conducted during sea trials with the main engine running at about 108 rpm with the vessel’s rudder at midships. The astern test indicated that if the vessel is travelling at 14.58 knots (navigation full ahead) in ballast condition and the engine is put to full astern, the vessel will continue ahead 0.88 NM (1629.76 m) and will take 9.15 minutes before the speed reduces to 0.34 knots.Footnote 34,Footnote 35 The test also showed that when emergency astern is initiated while the vessel’s speed is 6.13 knots, the vessel would travel a distance of about 0.173 NM (320 m) and it would take approximately 3 minutes and 9 seconds before the vessel’s speed reduced to 0.34 knots. In this occurrence, the order for emergency astern was initiated 4 minutes and 42 seconds before the striking when the vessel was travelling at approximately 6 knots. When the engine eventually responded to the astern order, the vessel’s bow was approximately 0.23 NM (426 m) away from the Pan Acacia’s starboard mid-section.

The Caravos Harmony’s LTU has a propulsion order for emergency astern, which allows the operator to initiate a command for astern propulsion quickly. A command for emergency astern bypasses the engine’s safety interlocksFootnote 36 to reduce the likelihood of the engine failing and to enable it to start in the astern direction. In order for emergency astern to activate on the Caravos Harmony, 2 conditions have to be met. The 1st condition is that a propulsion command has to be given whereby the engine rpm would change from at least 65 or more ahead to at least 50 astern. That is, the LTU lever has to be moved from a position of above half ahead to a position of slow astern or below. The 2nd condition is that the LTU lever has to be moved through this command within a 2-second timeframe.

Once emergency astern is applied, fuel injection to the engine stops. However, the propeller and engine continue turning ahead due to the vessel’s momentum through the water. As the momentum decreases, the rpm begins to decrease. When the rpm reduces to 16 or below, brake airFootnote 37 is continuously applied to the engine, reducing the rpm to 0. The camshaft is then shifted to the reverse position, starting air is applied and the main engine begins to turn in the astern direction until it reaches 12 rpm. At this point, fuel is injected and the engine begins to run on fuel in the astern direction.

Repeatedly applying brake air reduces the air pressure in the air receiver. If the engine does not start on fuel on the 1st attempt, the engine will try to start a 2nd time after a 5-second delay. If the 2nd start is unsuccessful, the engine will make a 3rd attempt after another 5-second delay. After 3 failed attempts, the starting failure alarm, which is both visual and audible, will activate. To reset the starting failure alarm, the operator must move the LTU lever to the stop position. At the time of the occurrence, there had been 3 engine starting failures and the starting failure alarm had activated on the bridge propulsion control panel and on the engine control room alarm panel. After the alarm was reset, the main engine started in the astern direction after 4 attempts.

The engine manufacturer’s manual contained information about applying emergency astern from the engine room.Footnote 38 For emergency astern while on bridge control, the manual referred the operator to the Kongsberg manual for the LTU. The Kongsberg manual stated that emergency astern will be initiated “when the bridge lever is moved from the Ahead to Emergency Astern position, according to a set of parameters which included the 2 conditions (main engine rpm and time limitations).”Footnote 39 The Kongsberg manual did not specify the rpm needed to initiate emergency astern. Section 3.2 of the Kongsberg manual mentioned only the time parameter of moving the LTU lever within 2 seconds.Footnote 40 At the time of the occurrence, the vessel had an electronic copy of the Kongsberg manual, but the bridge and engine crew were unaware of the 2 conditions (rpm and time) for initiating emergency astern that the manual mentioned. None of the vessel’s other documentation contained information about these conditions. The main engine manual stated that if the vessel’s speed is too high, the astern start-level rpm of 12 will not be reached quickly enough for the main engine to run on fuel, which will cause a loss of starting air.Footnote 41

In this occurrence, there were a total of 5 attempts to initiate emergency astern. The initial attempt was done with the engine rpm at 61. During subsequent attempts, the engine rpm had decreased. The time taken to move the LTU lever to emergency astern also exceeded 2 seconds in all of the attempts because the lever was paused at each position for more than 2 seconds out of concern for overloading the engine.

1.9 Testing of astern propulsion

IHS’s integrated management system manual recommends that astern propulsion be tested before berthing to ensure the vessel’s safe manoeuvring while berthing.Footnote 42 There is no recommendation about the testing of astern propulsion while proceeding to anchorage. While unberthing in Tacoma, the Caravos Harmony had used astern propulsion with no problems. The astern propulsion was not retested after the British Columbia Coast Pilots Ltd. pilot boarded.

1.10 Preparing anchors for use

IHS’s integrated management system manual states that anchors must be ready for use whenever the vessel is approaching an anchorage, in restricted waters, or entering or leaving a harbour. The manual stated that both anchors are to be readied and the anchor to be dropped should be lowered up to almost 1 m above sea level and remain on brake and gear. Except in emergencies or if required by the port, the anchor should always be lowered on gear and not be dropped from the fully stowed position. Footnote 43

In this occurrence, while approaching the anchorage, the anchor station crew prepared the anchor by lifting the chain stopper and switching on the windlass power for each anchor. Both the port and starboard anchor remained in their stowed position and in gear until the master ordered them to deploy. The starboard anchor had not been used since 28 December 2018.

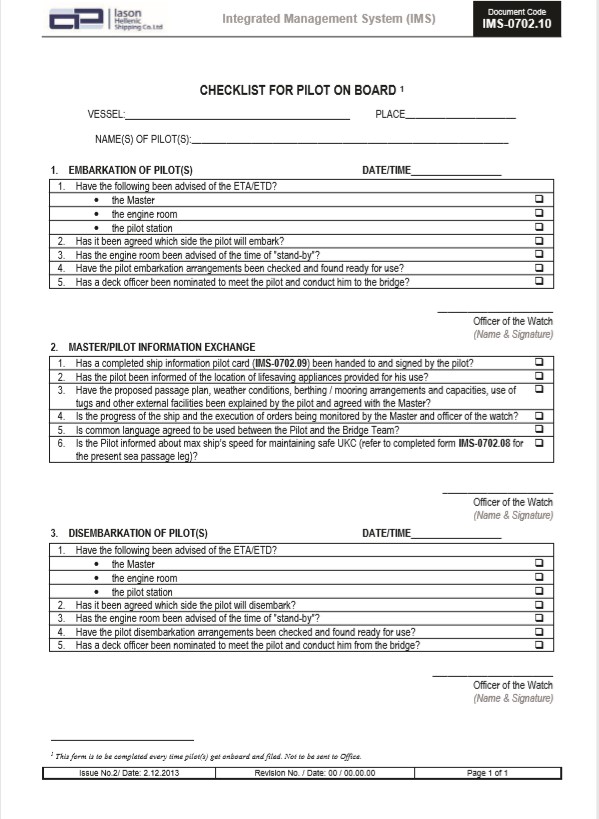

1.11 Master–pilot exchange

According to IMO Resolution A.960, each pilotage assignment should begin with an information exchange between the pilot and the master. The exchange should include, at a minimum,

- general agreement on plans and procedures, including contingency plans, for the anticipated passage;

- discussion of any special conditions, such as weather, depth of water, under keel clearance, tidal currents, and marine traffic;

- discussion of any unusual ship-handling characteristics, machinery difficulties, navigational equipment problems, or crew limitations;

- information on berthing and mooring arrangements; and

- confirmation of the language to be used on the bridge and with external parties.

Sharing the vessel’s voyage plan and the pilot’s passage plan during the initial master–pilot exchange and throughout the pilotage operation enables pilots and all bridge team members to construct a shared mental model of how the voyage should progress. Footnote 44 IMO Resolution A.960 states that the master–pilot exchange “should be a continuous process that generally continues for the duration of the pilotage.” Footnote 45

The STCW Code also emphasizes the importance of an ongoing information exchange between the master and the pilot, and states that

[d]espite the duties and obligations of pilots, their presence on board does not relieve the master or officer in charge of the navigational watch from their duties and obligations for the safety of the ship. Footnote 46

The PPA leaves passage planning Footnote 47 to the expertise of the individual pilot, who determines which course to steer based on expertise, local knowledge, and an assessment of the environmental conditions for the voyage.

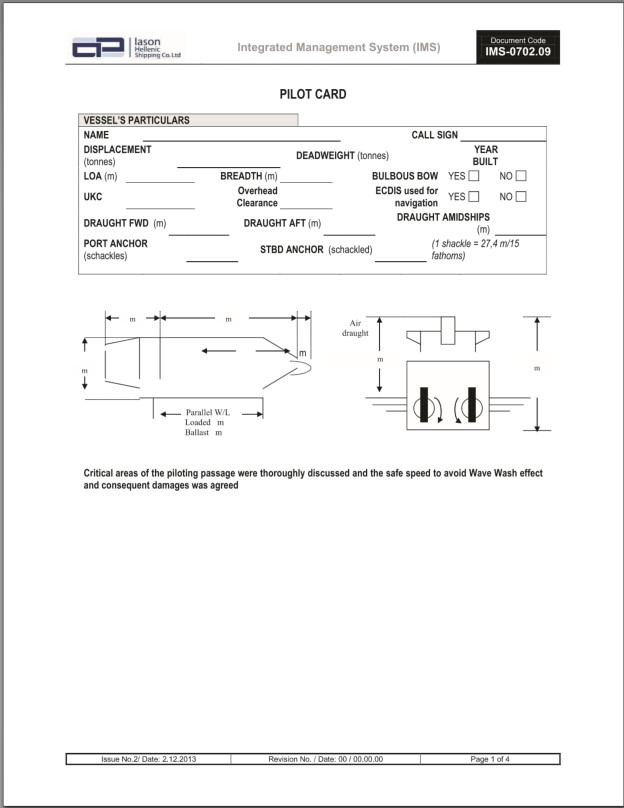

Upon boarding, the pilot and master had a brief exchange about the purpose of the voyage, and the pilot verbally shared current and tide conditions and certain details of his plan with the bridge team as the voyage progressed. The PPA has a standardized master–pilot exchange card that it encourages pilots to complete upon boarding a vessel (Appendix B). The master-pilot exchange card had been filled out by the pilot and signed by the master and pilot.

IHS’s integrated management system manual also includes a vessel pilot card to be completed by the bridge team. The pilot card states that critical areas of the passage should be thoroughly discussed. The vessel pilot card has sections for the signatures of both the pilot and the master (Appendix C). Footnote 48 The vessel pilot card includes information about a number of items, including anchor readiness, various rpms and speeds, and the time the main engine needs to go from full ahead to full astern.

In this occurrence, the master signed the vessel pilot card before giving it to the pilot. The pilot saw but did not read the information on it and signed it post-occurrence.

IHS also has a checklist that is to be completed by the officer of the watch when a pilot is on board (Appendix D). One of the checklist items prompts the bridge team to verify that the proposed passage plan has been explained by the pilot and agreed to by the master.

1.12 Bridge resource management

BRM is the management and use of all resources, human and technical, to ensure the safe completion of the voyage. Footnote 49 Effective BRM mitigates the risk that an error on the part of one person, or a single point of failure, will result in a dangerous situation. Team situation awareness (TSA) and communication are key to effective BRM.

1.12.1 Team situation awareness and communication

When people operate in a team environment, TSA is important for safe and effective operations. Effective TSA allows team members to develop accurate expectations for team performance by drawing on a common knowledge base. As team members develop a shared understanding of a situation, the team can coordinate what it perceives and decide collectively on a course of action. Footnote 50

TSA is crucial for effective decision making. When a team has a shared understanding of a situation, the members develop a shared understanding of tasks, including who is responsible for what as well as their information needs and requirements. When TSA is optimal, all the team members involved can create a true picture of the situation. Footnote 51

For TSA to develop and be maintained, the right information needs to get to the right person at the right time, which involves coordination among the team. Footnote 52 A team’s effectiveness is often reflected by the degree to which team members share information (e.g., questioning, cross-checking, coordinating, setting priorities, and contingency planning Footnote 53). TSA can be compromised by breakdowns in communication. These breakdowns may result in information that is shared too late to be of use, that is not consistently complete and accurate or that is ambiguous, and problems that are left unresolved until a point of urgency. Footnote 54 Communication breakdowns may also result when individuals are excluded from the communication process.

1.13 TSB pilotage survey

In 1995, the TSB conducted a survey of Canadian marine pilots Footnote 55 to identify safety deficiencies associated with teamwork on the bridge, including communications between pilots and masters or officers of the watch. The Board was concerned by the frequency and potential consequences of occurrences involving vessels in Canadian pilotage waters under the conduct of a pilot. It carried out a preliminary review of 273 occurrences from February 1981 to May 1992 and identified the most significant contributing factor in each one. Of the 273 occurrences, 200 were identified as involving human factors, of which 46% involved misjudgment by the pilot or master.

As a result of this preliminary data examination, the Board decided to study the conditions or practices that lead to such breakdowns in more depth, with a view to identifying safety deficiencies.

The survey found that, with respect to the overall exchange of information, there was a tendency among pilots, masters, and officers of the watch to assume that each individual knew the necessary information and that if they do not, that they will request it. It also found that significant misunderstandings could arise when pilots, masters, and officers of the watch mistakenly assume that everyone was aware of the vessel’s manoeuvring characteristics, the local conditions, and the intended passage plan.

1.13.1 Working language

IHS’s integrated management system manual states that the working language on its vessels is English and all the communication on board should be in English. Footnote 56 A sign was posted on the Caravos Harmony bridge to this effect. The PPA’s master–pilot exchange card mentions that the pilot is required to have the conduct of the vessel at all times and that all communication relevant to the conduct of the vessel is to be in English.

In this occurrence, the master and crew members communicated with the pilot in English and communicated among themselves primarily in Tagalog, which was their first language.

When the starboard anchor failed to release, the crew informed the master in Tagalog, who then responded in Tagalog to deploy the port anchor. At the same time, the pilot was still insisting on deploying the starboard anchor. While the anchor station crew was witnessing the imminent striking, they were communicating with the master mostly in Tagalog. The pilot on board during this occurrence did not speak or understand Tagalog.

1.14 Safety management system

The ISM Code provides an international standard for the safe management and operation of ships and for pollution prevention. The ISM Code applies to SOLAS vessels and establishes safety management objectives. It includes a requirement that a safety management system (SMS) be established. Footnote 57

Under the ISM Code, a company is required to establish and implement a policy to provide for safe practices in vessel operations and for a safe working environment. All identified risks to vessels, personnel, and the environment must be assessed, and appropriate safeguards against those risks established. The company must also continuously improve the safety management skills of personnel ashore and on board vessels and provide the necessary resources and shore-based support.

To fulfill the requirement of an SMS under the ISM Code, IHS had an integrated management system that contained various policies and procedures for recruitment, familiarization and handover, and training of crew.

1.14.1 Recruitment

IHS’s integrated management system sets out the steps for recruiting crew. These steps include the requirement for a candidate to undergo a briefing and debriefing at the company’s head office, or at the local crewing agent’s office, and to have a performance assessment completed by the crewing agent. The performance assessment includes verifying the candidate’s ability to communicate in English, and candidates who are unable to do so are screened out from subsequent interviews by the appropriate managers.

IHS requires a master to have at least 2 years of experience as a master and 3 years of experience on the same type of vessel as the one that the master will be commanding. The master is required to know the operating principles of marine power plants.

The chief officer is required to have at least 2 years of experience as a chief officer and 3 years of experience on the same type of vessel as the one on which the chief officer will be serving. The chief officer is required to know the operating principles of navigational equipment and other machinery, including the operation of windlasses.

The chief engineer is required to have at least 2 years of experience as chief engineer and 4 years of experience on the same type of vessel as the one on which the chief engineer will be serving. The chief engineer is to be experienced with various engine types, maintenance systems, automations, etc.

The second officer is required to meet the requirements of the STCW Code and have 1 year of experience on the same type of vessel as the one on which the second officer will be serving. The other officers and engineers must meet the requirements of the STCW Code but there are no other specific requirements for them. All officers and engineers are required to have a good command of English.

1.14.2 Crew briefing, familiarization, and handover

The integrated management system also includes crew briefing, familiarization, and handover procedures. The briefing is carried out by managers or crewing agents and includes topics under the ISM Code. The duration of the briefing can differ for senior officers depending on their experience with the company and the type of vessel.

1.14.2.1 Pre-boarding briefing and debrief

When a master, chief officer, or chief engineer who has previously been with IHS joins a company vessel for the first time, they are required to have a 1-day briefing before joining the vessel. If joining the company for the first time and experienced on the same type of vessel, they will receive a 2-day briefing before joining the vessel.

The chief engineer is also to be briefed on specific engine room operations by the IHS technical manager. The chief engineer on the Caravos Harmony was not briefed on engine room operations before boarding the vessel.

There are no briefing requirements for other officers before joining the vessel.

In this occurrence, before joining the vessel, the master, chief officer, chief engineer, and second officer were not briefed by IHS department managers.

The company requires masters and chief engineers, when they disembark a vessel, to provide a debrief on the conditions, operational status, and technical, operational, and procedural standards on board. In addition, a department manager carries out a review of the master’s performance. Following the occurrence, IHS did not debrief the chief engineer. It is not known if the master was debriefed after leaving the Caravos Harmony.

1.14.2.2 On-board familiarization

IHS sets out requirements for crew familiarization and handover on board vessels. When a master, chief officer, or chief engineer who has previously been with IHS joins a company vessel for the first time, they are required to have 1 day of familiarization on board. If joining the company for the first time and experienced on the same type of vessel, they will receive 2 days of familiarization on board the vessel.

The chief engineer is also to be familiarized in engine room operations by the IHS technical manager. The chief engineer on the Caravos Harmony was not familiarized in engine room operations before boarding the vessel.

The on-board familiarization is customized to each officer and includes handover for certain officers. For masters, chief engineers, and chief officers, familiarization and handover are done concurrently.

During familiarization and handover, the outgoing officer informs the incoming officer of all pertinent duties, responsibilities, and safety and emergency procedures, as well as the condition of equipment for which the officer is responsible. The outgoing officer must also hand over all of the vessel’s property, publications, records, documents, and equipment for which the incoming officer will be responsible. The outgoing officer must also, together with the incoming officer, thoroughly inspect the areas of the incoming officer’s responsibilities. Any reported defects must be immediately recorded and bought to the company’s attention.

IHS provides all deck officers with familiarization on ECDIS, which includes an overview of how to initialize the system, perform basic operations, access charts and other navigation tools and functions, and plan routes. Familiarization also covers monitoring and assessing the performance of the ECDIS. IHS did not provide any familiarization to any of the officers or engineers on board the Caravos Harmony about specific main engine automation fitted on board vessels.

1.14.3 Familiarization forms and checklist

IHS has different familiarization forms and checklists for different ranks. Footnote 58 The familiarization checklist for the master, chief engineer, deck officers, and engineers is divided into general sections, each of which contains a more detailed list of items to be covered during familiarization. The general sections are as follows:

- Safety procedures and equipment

- Initial briefing

- Duties, responsibilities, and job-specific procedures

- Emergency procedures

- Integrated management system

- Environmental protection procedures

On 04 August 2018, the master on the Caravos Harmony had 1 day of familiarization with the outgoing master. During this time, the master went though the vessel’s files and records. The master also received handover notes about the vessel before he assumed the responsibility as master. The handover notes indicated that the main engine had mechanical problems when operated between slow ahead and half ahead. There was no indication that this was discussed at the vessel’s regular safety meeting or that the company was advised.

On 11 March 2019, the chief engineer on the Caravos Harmony had 2 days of familiarization with the outgoing chief engineer. During this time, the chief engineer went through the vessel’s files and records, and received handover notes about the vessel before assuming the responsibility as chief engineer. The chief engineer handover notes did not indicate the problems with the main engine that were stated in the master’s handover notes.

One item on the chief engineer’s familiarization list was knowledge of the telegraph control and main engine operation. The chief engineer’s familiarization checklist did not include operation of main engine control systems, including overrides and emergency operating procedures, manual control, etc., which was in the familiarization list for other engineers. The chief engineer was also not familiarized with the main engine automation on the Caravos Harmony.

The chief officer’s and other deck officers’ familiarization checklists required knowledge of the main engine’s telegraph control. The chief officer and other deck officers were not familiarized with main engine normal or emergency manoeuvring operations.

1.14.4 Training

The company has training plans for each officer, which emphasize critical shipboard operations, such as bridge operations, ship handling, etc. The training plan includes a variety of training, such as in-house training, external training (including refresher training at selected training centres), and training on board (on-the-job training, training during drills and exercises, video training, demonstration of equipment and/or procedures, etc.). The staff involved in operational incidents attend specific refresher training seminars with an emphasis on incident prevention, safety monitoring, and environmental protection procedures.

IHS has provisions to provide basic training on ECDIS fitted on board vessels to all navigating officers. IHS did not provide any training on specific main engine automation such as the Kongsberg AutoChief C20 fitted on board the Caravos Harmony to any of the officers or engineers.

1.15 Tug assist requirements by the Vancouver Fraser Port Authority

In 2017, the Vancouver Fraser Port Authority, anticipating increases in the number and size of vessels frequenting terminals in the Burrard Inlet, initiated a review of the existing First Narrows movement restriction area (now known as Traffic Control Zone 1 [TCZ-1]). Footnote 59 At that time, a movement restriction area was already in place for Second Narrows. A study was commissioned that, among other things, looked at the types of vessels that would need a tethered tug escort when transiting First Narrows. Footnote 60 The study resulted in modifications to the First Narrows TCZ-1 procedures in the Port Information Guide Footnote 61 for deep sea vessels that transit through First Narrows.

The study had a special focus on assessing transits of bulk carriers greater than 70 000 in deadweight tonnage with a loaded draft greater than 12.5 m; it did not consider bulk carriers of 250 m or less that transit the First Narrows TCZ-1 inbound to Vancouver. The study was done through simulations using 3 types of vessels: an ultra-large container vessel, a Capesize bulk carrier, and an Aframax tanker. The study examined the transits of these vessels at various periods in the tidal cycle, predominately focusing on maximum ebb and flood tide. The vessels in the study used traffic lanes that were on a heading/track of approximately 125°T for the transit from Prospect Point to Burnaby Shoal. The study required the inbound vessels’ speed through the water to be 7 knots or less when the vessels passed Navvy Jack Point. The study also examined existing and potential future vessel traffic transiting First Narrows at a speed of 6 knots and on a flood tide exceeding 2 knots.

The study highlighted that, to mitigate the risks associated with groundings or allisions, tethered tug escorts may be required for certain vessels entering and leaving Vancouver Harbour. Based on this study, the First Narrows TCZ-1 procedures in the Port Information Guide were updated to include a table to help identify when vessels with a length overall of between 250 and 310 m require the use of escort tugs when entering or exiting Vancouver Harbour. The requirements are based on the draft and transit direction of the vessel, as well as the tide and current, as follows (Table 2):

| Draft (m) | Transit direction | Tide | Current | Tugs and bollard pull required |

|---|---|---|---|---|

| Less than or equal to 12.5 | Inbound | Flood | Greater than 2 knots | 1 tug, 50 tons bollard pull |

| Ebb | Not applicable | Not applicable | ||

| Outbound | Flood | For first 2 hours after flood or greater than 2 knots | 1 tug and 50 tons bollard pull | |

| Ebb | Not applicable | Not applicable | ||

| Greater than 12.5 | Inbound | Flood | Greater than 2 knots | 2 tugs, 50 tons bollard pull |

| Ebb | Greater than 2 knots | 1 tug, 50 tons bollard pull | ||

| Outbound | Flood | Greater than 2 knots | 1 tug, 50 tons bollard pull | |

| Ebb | Greater than 2 knots | 1 tug, 50 tons bollard pull |

Outbound bulk carriers having a length overall of 225 to 250 m and a draft of greater than 12.5 m, when sailing on a flood tide, may also retain an adequate tractor tug or ASD tug at the master’s or pilot’s discretion.

Where tugs are required, they have to be tethered prior to entering TCZ-1 and must remain tethered until clear of TCZ-1. The table does not provide information for inbound bulk carriers with a length overall of 250 m or less.

In this occurrence, the loaded Caravos Harmony, with a length overall of 229 m, was inbound, with a draft of 12.96 m, and a deadweight of 81 670 tonnes. The vessel’s speed was 7.4 knots and the flood tide in First Narrows was about 3 knots.

The investigation determined that between 01 January 2017 and 31 August 2020, a total of 3978 bulk carriers of 250 m or less in length proceeded/departed anchorages or berthed/ unberthed in Vancouver Harbour. Of those, 26 encountered propulsion or steering problems in Vancouver Harbour. Eleven of these vessels were inbound proceeding to anchorages and did not have assist tugs.

During the investigation, the TSB was also made aware that, on 13 March 2019, the Pan Acacia, with a length of about 292 m, drawing a draft of 8.53 m, and under the conduct of a pilot, transited First Narrows without escort tugs. Soon after transiting First Narrows, the pilot ordered astern movement, but the vessel’s main engine did not respond to the astern order. The pilot requested a tug. Meanwhile, the master ordered astern movements and the main engine responded. Soon after, the tug Charles H. Cates I arrived and escorted the Pan Acacia to safely anchor at Anchorage A.

The Port Information Guide does not establish tug requirements for bulk carriers of 250 m or less transiting the First Narrows.

1.16 Voyage data recorder

Objective data are invaluable to investigators when seeking to understand how an accident occurred. Different modes of transportation use voice and data recorders to support accident investigations. In addition to bridge audio, a voyage data recorder (VDR) must record date and time, a vessel’s position, speed (through water or over ground), heading, alarms, VHF radiotelephone communications, radar data, water depth, rudder order and response, engine order and response, hull opening status, watertight and fire door status, acceleration and hull stresses and wind speed and direction.

The Caravos Harmony was fitted with a VDR, as required by regulation.Footnote 62,Footnote 63 The investigation determined that the VDR data port was not connected to the LTU and the VDR had not recorded propulsion orders and engine responses.

1.17 Previous occurrences

1.17.1 Bridge resource management with a pilot on board

M17A0390 (SBI Carioca) – On 11 October 2017, the bulk carrier SBI Carioca, with a pilot and 22 crew members on board, ran aground while approaching the pier at the Port of Belledune, New Brunswick, in Chaleur Bay. One risk the TSB identified during its investigation was that if the principles of BRM are not used effectively, particularly with a pilot on board, bridge teams may be deprived of a shared mental model to safely navigate vessels.

M16C0005 (MSC Monica) - On 22 January 2016, the container vessel MSC Monica ran aground 1 NM north-northeast of Deschaillons-sur-Saint-Laurent, Quebec. One risk the TSB identified during its investigation was that if bridge team members do not share a complete and common understanding of an emerging problem and continuously exchange information to solve problems, there is a risk that the bridge team's response will be premature, uncoordinated, and ineffective.

M14C0193 (Vachon) - On 12 September 2014, the tug Vachon struck the breakwater in Port Cartier, Quebec, while assisting the bulk carrier Orient Crusader to enter the harbour. One risk the TSB identified during its investigation was that if bridge team members do not continue to actively participate in the monitoring of the vessel's progress when a pilot is on board, there is a risk that errors in navigation may go undetected.

M14P0014 (Cap Blanche) – On 25 January 2014, the container vessel Cap Blanche grounded within the buoyed channel in Steveston Bend, BC. The vessel was under the conduct of a pilot and was in reduced visibility due to fog. One risk the TSB identified during its investigation was that if information that may affect the vessel’s safe passage is not communicated between bridge teams and pilots, there is a risk that unsafe situations and conditions may persist.

M12L0147 (Tundra) - On 28 November 2012, the downbound vessel Tundra ran aground south of buoy S129, near Sorel, Quebec. One contributing factor the TSB identified during its investigation was that the pilot and other members of the bridge team were not exchanging information pertaining to the navigation of the vessel, and so the bridge team was unaware of a planned course change.

M04L0092 (Horizon) – On 24 July 2004, the loaded container vessel Horizon was downbound from Montréal, Quebec, under the conduct of a pilot when the vessel overshot an alter-course position and grounded. One contributing factor the TSB identified during its investigation was that in the minutes leading up to the grounding, effective BRM techniques were not used and the communication between team members was minimal.

1.17.2 Voyage data recorders

The TSB has conducted 5 investigations in which data from the VDR, in particular the bridge audio recordings, were not available to the investigation. In each of these investigations, it made a risk finding stating that if such data are not available to an investigation, it may preclude the identification and communication of safety deficiencies to advance transportation safety.

M17P0400 (Seaspan Swift) - On 15 November 2017, the roll-on/roll-off ferry Seaspan Swift struck the No. 2 berth at the Seaspan Ferries terminal on Tilbury Island, Delta, BC.

M15C0094 (Northern Spirit) - On 13 June 2015, the passenger vessel Northern Spirit I was on an evening cruise when a passenger fell overboard, in a position approximately 4 NM west of Toronto, Ontario. Search and rescue authorities were notified and conducted a search of the area without success.

M14C0193 (Vachon) - On 12 September 2014, the tug Vachon struck the breakwater in Port Cartier, Quebec while assisting the bulk carrier Orient Crusader to enter the harbor.

M11L0160 (Orsula) – On 15 December 2011, the bulk carrier Orsula was proceeding downbound on the St. Lawrence River under the conduct of a pilot when the vessel lost steering control and ran aground near Bécancour, Quebec.

M11C0001 (BBC Steinhoeft) – On 31 March 2011, the BBC Steinhoeft, under the conduct of a pilot, ran aground in the South Shore Canal of the St. Lawrence Seaway near St. Lambert, Quebec.

1.18 TSB Watchlist

The TSB Watchlist identifies the key safety issues that need to be addressed to make Canada’s transportation system even safer.

Safety management is a Watchlist 2020 issue. The Caravos Harmony had an SMS that was certified and audited by an approved authority. However, the investigation identified gaps in the effectiveness of safety management relating to emergency astern propulsion procedures and the familiarization of these procedures for the master and the officers.

| ACTIONS REQUIRED Safety management will remain on the Watchlist for the marine transportation sector until:

|

2.0 Analysis

The investigation determined that the Caravos Harmony struck the anchored Pan Acacia after attempts to slow the vessel’s speed and change its course were unsuccessful. The investigation examined the role of bridge resource management (BRM), the crew’s familiarization and training on the operation of the main engine, as well as the availability of the information related to the conditions needed to initiate emergency astern propulsion.

2.1 Factors leading to the striking

As the Caravos Harmony entered First Narrows, the strong current and eddies caused the vessel to move to port. The pilot gave full ahead and starboard helm orders in an attempt to increase water flow across the rudder and correct the vessel’s course. Because the second officer was not familiar with the bridge control automation he was pausing about 4 seconds at each intermediate step for fear of overloading the engine. The pausing of 4 seconds at each intermediate step meant that the main engine responded to each of the intermediate steps in sequence as typical engine orders rather than as a single order.

As the vessel was not responding as quickly as expected and the vessel was still moving to port, the pilot ordered the starboard anchor to be deployed and to apply emergency astern. Unware of the 2 conditions to be met to initiate astern propulsion, the second officer’s repeated attempts to initiate emergency astern were unsuccessful. As a consequence of the second officer’s lack of familiarity with the main engine bridge control automation, the engine orders were ineffective and the vessel was slow to respond and continued moving to port.

The pilot then ordered the starboard anchor to be released in order to swing the vessel to starboard. However, because neither anchor had been previously prepared for deployment by lowering them to 1 m above the water as requested by the pilot, the crew found the starboard anchor stuck in the stowed position and could not release it.

With only the port anchor available and having a differing understanding of the situation from the pilot, the master ordered the port anchor to be dropped in order to stop the vessel, but this caused the Caravos Harmony to move further to port until it struck the Pan Acacia.

2.2 Bridge resource management

The continuous exchange of information and team situation awareness (TSA) are key components of BRM, and contribute to the vessel’s safe navigation. BRM is effective only when a team shares a similar understanding of a task and the right information gets to the right person at the right time. Breakdowns in communication can have detrimental effects on TSA and therefore on BRM.

In this occurrence, there were communication breakdowns that impacted TSA and resulted in different understandings of the emerging situation. The 1st communication breakdown arose from an incomplete sharing of information during the master–pilot exchange. Although the master and pilot had discussed certain aspects of the voyage, including the strength of the current and which anchor to use at Anchorage D, they had not discussed the vessel’s pilot card, which included information about critical areas of the passage and avoidance of wave wash effects. Neither the Pacific Pilotage Authority pilot card nor the vessel’s pilot card, both of which are intended to facilitate the sharing of information on areas such as passage plan, manoeuvring characteristics, common language, and under keel clearance were discussed. Additionally, the master and pilot did not discuss the various rpms of the main engine, speeds, or the time needed to go from full ahead to full astern. This information is important to understand how the vessel will respond during manoeuvres. Without a complete master–pilot exchange, the master did not have a detailed understanding of the route that the pilot was planning to take, and therefore could not identify whether the vessel was proceeding according to plan.

The 2nd communication breakdown arose when the Caravos Harmony approached the Pan Acacia and the master and pilot reacted differently and independently from one another to avoid the striking. Because they had not developed a shared situational awareness, the master ordered the port anchor to be dropped in order to stop the vessel, whereas the pilot ordered the starboard anchor to be dropped in order to change course. Dropping the port anchor caused the Caravos Harmony to move further to port and toward the Pan Acacia.

The degraded information sharing between the pilot and the bridge crew resulted in a different mental model of the intended use of the starboard anchor and a mismatched understanding of the evolving situation.

A 3rd example of a communication breakdown occurred just after the pilot ordered the starboard anchor to be let go twice. When the anchor did not drop, the master and chief engineer discussed this in Tagalog. Given that he did not understand Tagalog, the pilot was not made aware of the situation and repeatedly ordered the starboard anchor to be dropped. In response, the master informed the pilot that he had dropped the port anchor. Although he was then made fully aware of the situation, the dropping of the port anchor subsequently limited any action the pilot might have taken to avoid the collision.

The pilot and bridge crew did not share critical information to build a common and accurate situational awareness and this impeded timely and effective coordination of actions to safely manoeuvre the vessel and avoid the striking.

Effective communication is important in developing and maintaining a shared situational awareness, a key component of BRM. The TSB has previously investigated a number of occurrences whereby breakdowns in BRM relating to communications between pilots and bridge teams contributed to the accident, which emphasizes the need for pilots and bridge teams to communicate effectively in order to develop TSA.

If effective communication is not employed to develop team situation awareness, there is a risk that team members will have differing understandings of a situation, which may impede timely and effective actions to safely manoeuvre the vessel.

2.3 Familiarization procedures

Effective familiarization is important for helping new officers to become familiar with safety protocols, emergency procedures, and the proper use of the vessel’s equipment and machinery, among other things. Familiarization introduces new officers to the specific details of their jobs and gives officers a chance to go through pertinent manuals and specific instructions on the use of vessel equipment and machinery.

In this occurrence, the 2 conditions required to initiate emergency astern had not been covered in the familiarization for the master or the bridge officers. There was no information on the bridge about these 2 conditions, nor were they mentioned in the vessel’s documentation. None of the bridge team members or engineers was aware of them, and the bridge team and the engineers believed that the main engine would be overloaded if the rpm was increased or decreased rapidly between full ahead and emergency astern.

Machinery often differs considerably from vessel to vessel, and seafarers rarely serve on the same or similar vessels throughout their careers. As handovers are usually short because of the lack of time in port, the speed at which the incoming officer or engineer can assimilate information depends on their familiarity with the same or similar vessel and/or equipment. The end result is that seafarers may sometimes obtain only a superficial familiarization with machinery. Although user manuals offer detailed information and instructions on the vessel’s machinery, crew members are often unable to read the manual thoroughly upon joining the vessel due to the lack of time allotted to familiarization. This leads to situations where crew members are operating equipment with which they are not fully familiarized. Instead, they rely on previous experience and improvise. In some cases, the crew member may rely on experience with a previous device that is similar to the new one but that does not necessarily have the same operating characteristics. All of these factors combined create the potential for operational errors.

If familiarization on essential shipboard machinery and equipment is not effective and if necessary instruction manuals and vessel-specific procedures and training are not provided, the crew may not be proficient in the use of the equipment, increasing the risk of accident or injury.

2.4 Tug assist requirements by Vancouver Fraser Port Authority

The 2017 study commissioned by the Vancouver Fraser Port Authority did not consider bulk carriers of 250 m or less that transit the First Narrows Traffic Control Zone-1 inbound to Vancouver Harbour, but did consider outbound bulk carriers between 225 m and 250 m with a draft of more than 12.5 m that are in loaded conditions. For those outbound bulk carriers, the Vancouver Fraser Port Authority Port Information Guide indicates that an assist tug to transit First Narrows may be requested at the pilot’s discretion.

A review done by the TSB indicated that between 01 January 2017 and 31 August 2020, 26 of 3978 bulk carriers with a length overall of 250 m or less had issues with their propulsion or steering systems in Vancouver Harbour. Of these, 11 were inbound to Vancouver Harbour with no requirements for tug escort.

If the Vancouver Fraser Port Authority does not evaluate the unescorted transit of bulk carriers 250 m or less inbound through the First Narrows, the hazards of these transits may not be mitigated, increasing the risk of groundings or strikings.

2.5 Voyage data recorder

The objective of a voyage data recorder (VDR) is to maintain a secure and retrievable record of information about the position, movement, physical status, and control of a vessel. Investigators often rely on these data when seeking to understand the sequence of events and actions of a bridge team.

Although the Caravos Harmony was fitted with a VDR as required by regulation, the propulsion orders and response data signals were not recorded by the VDR because the data port was not connected. This prevented investigators from being able to confirm engine orders and response times in relation to other VDR data items in real time.

If relevant data from the VDR are not available to an investigation, this may prevent the identification and communication of safety deficiencies to advance transportation safety.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- As the Caravos Harmony entered First Narrows, the strong current and eddies caused the vessel to move to port.

- The pilot gave full ahead and starboard helm orders in an attempt to correct the vessel’s course. As a consequence of the second officer’s lack of familiarity with the main engine bridge control automation, the engine orders were ineffective and the vessel was slow to respond and continued moving to port.

- The pilot then ordered the starboard anchor to be released in order to swing the vessel to starboard. However, because neither anchor had been previously prepared for deployment by lowering them to 1 m above the water as requested by the pilot, the crew found the starboard anchor stuck in the stowed position and could not release it.

- With only the port anchor available and having a differing understanding of the situation from the pilot, the master ordered the port anchor to be dropped in order to stop the vessel, but this caused the Caravos Harmony to move further to port until it struck the Pan Acacia.

- The pilot and bridge crew did not share critical information to build a common and accurate team situation awareness and this impeded timely and effective coordination of actions to safely manoeuvre the vessel and avoid the striking.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If effective communication is not employed to develop team situation awareness, there is a risk that team members will have differing understandings of a situation, which may impede timely and effective actions to safely manoeuvre the vessel.

- If the bridge team and pilot do not use a common working language, there is a risk that not everyone will have the same information and the response will be uncoordinated and ineffective.

- If familiarization on essential shipboard machinery and equipment is not effective and if necessary instruction manuals and vessel-specific procedures and training are not provided, the crew may not be proficient in the use of the equipment, increasing the risk of accident or injury.

- If the Vancouver Fraser Port Authority does not evaluate the unescorted transit of bulk carriers 250 m or less inbound through the First Narrows, the hazards of these transits may not be mitigated, increasing the risk of groundings or strikings.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- If relevant data from the voyage data recorder are not available to an investigation, this may prevent the identification and communication of safety deficiencies to advance transportation safety.

4.0 Safety action

4.1 Safety action taken

4.1.1 Transport Canada

Following the occurrence, Transport Canada (TC) boarded the Caravos Harmony to conduct a port state control inspection and identified several contraventions of SOLAS, the Collision Regulations, and the Maritime Labour Convention (2006), including the following:

- One of the port windlass safety pins was missing.

- The rudder angle indicators on bridge had +1-degree errors.

- The under-keel clearance information was missing on the planned route.

- There was an error in the magnetic compass.

TC also identified items indicating a systematic failure to apply the International Safety Management (ISM) Code on maintenance and emergency preparedness. TC also requested that an ISM Code audit be carried out by the classification society Registro Italiano Navale (RINA).

TC also conducted a Port State Control inspection of the Pan Acacia.

4.1.2 Vancouver Fraser Port Authority

Following the occurrence, the Vancouver Fraser Port Authority amended its rules for vessels refuelling at English Bay. As of July 2020, refuelling of all vessels can occur in English Bay, thereby reducing the number of inbound laden bulk carriers transiting through the First Narrows Traffic Control Zone (TCZ-1).

4.1.3 Pacific Pilotage Authority

Following the occurrence, the Pacific Pilotage Authority (PPA) and British Columbia Coast Pilots Ltd. conducted a risk assessment on loaded bulk carriers entering Vancouver Harbour on a strong flood tide. Based on the result of the risk assessment, the PPA issued an interim notice to industry on 04 April 2019 that stated that while the TSB was completing its investigation of the occurrence involving the Caravos Harmony, the PPA recommended the following interim measures when the flood current exceeded 1.5 knots:

- An escort tug with a minimum bollard pull of 65 tonnes is to be ordered for any inbound loaded bulk carrier with a length overall of between 200 m and 250 m and a draft in excess of 12 m transiting to an anchorage between Vancouver Wharves and Centerm.

- The escort tug is to be made fast 2 cables west of the Lions Gate bridge on First Narrows.

- For vessels over 250 m in length, users should refer to the information about First Narrows TCZ-1 in the Port Information Guide.

A note in the interim notice also indicated that it would be amended and clarified once the TSB report was published.

4.1.4 Registro Italiano Navale

On 18 March 2019, a RINA surveyor carried out an ISM Code audit on the Caravos Harmony and issued the following 3 major non-conformities with a request for a follow-up audit in 2 months:

- Not all non-conformities are reported to the company’s designated person ashore.

- The measures to ensure response to all emergency situations are not always effective.

- The procedures for the completion of passage plans are not always fully addressed.

On 12 April 2019, a RINA surveyor attended the vessel to conduct a follow-up audit and confirmed that the non-conformities had been rectified. Between 24 and 30 April 2019, the vessel underwent repairs to its bow area. An additional ISM Code audit was carried out, which resulted in no further findings or actions required.

4.1.5 Iason Hellenic Shipping Co. Ltd

After the occurrence, Iason Hellenic Shipping Co. Ltd (IHS) reviewed the performance of the crew and the crewing agents and replaced the crewing agents at the time of the occurrence with a new fully certified agency. The new agency will recruit crew under the strict supervision of the IHS departments in order to ensure that crew selection and performance is rigorous and in full compliance with safety management system (SMS) procedures and policies.

IHS also asked the new crewing agents to provide additional training to masters and the senior bridge team before embarkation. The training covered the master-pilot relationship as well as passage planning, master-pilot exchanges, and bridge resource management and communications.

The company will review fleet-wide crew awareness and adherence to SMS procedures (mainly those related to navigation standards, maintenance and repair reporting, and safety practices) during more frequent visits on board until satisfied with the conduct of the new crew.

The annual office-to-ship exercises were amended to include a collision scenario in order to assess crew knowledge and reactions to this type of emergency, and lessons learned to be shared across the fleet.

Masters and chief officers of the fleet were instructed to ensure adherence to SMS procedures during anchoring operations. The master and the company will provide additional training on anchoring practices and maintenance after auditing, reviewing, and assessing new crew performance. A circular was sent to all of the fleet regarding the need for passage planning with the electronic chart display and information system.

4.1.6 Pan Ocean Company Ltd.

After the occurrence, Pan Ocean Company Ltd., the owner of Pan Acacia, took the following safety actions:

- The vessel’s crew was given a shipboard education session on emergency responses to various accidents, including collisions/allisions.

- The company’s orientation guide for masters was amended to include a specific reference to the allision involving the Pan Acacia and to provide guidance on anti‑collision measures to be taken while vessels are at anchor.

- Vessels in the fleet were instructed to post the company’s safe working rules for anchor watches and to remind crew to have thorough knowledge of the rules.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

Appendices

Appendix A – Wheelhouse poster of the Caravos Harmony

Source: Iason Hellenic Shipping Co. Ltd

Appendix B – Pacific Pilotage Authority master-pilot exchange card

Source: Pacific Pilotage Authority

Appendix C – Caravos Harmony’s pilot card

Source: Iason Hellenic Shipping Co. Ltd

Appendix D – Company’s checklist for pilot on board

Source: Iason Hellenic Shipping Co. Ltd