Lifeboat release hook failure

Passenger ferry Northern Ranger

Nain, Newfoundland and Labrador

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 11 October 2017, the starboard lifeboat of the passenger ferry Northern Ranger was undergoing operational testing at the dock in Nain, Newfoundland and Labrador, when its forward release hook failed. While the crew members were lifting the lifeboat to the vessel’s embarkation deck, the forward release hook suddenly released and the lifeboat swung downward, bow first, and hung over the water from the aft release hook and fall. Four crew members were on board the lifeboat at the time of the occurrence. One of the crew members fell through the lifeboat’s forward hatch and into the water; the other 3 crew members remained inside. All 4 crew members were recovered and their injuries were treated in hospital.

1.0 Factual information

1.1 Particulars of the vessel

| Name of vessel | Northern Ranger |

|---|---|

| International Maritime Organization number | 8512504 |

| Official number | 803748 |

| Port of registry | St. John’s, NL |

| Flag | Canada |

| Type | Passenger/cargo ship |

| Gross tonnage | 2573.09 |

| Length | 71.86 m |

| Draft | 4.25 m |

| Built | 1986 |

| Propulsion | 2122 brake horsepower |

| Passengers on board at the time of the occurrence | 22 |

| Maximum number of passengers | 131 |

| Crew members | 26 |

| Owner | Newfoundland and Labrador Government (Department of Transportation and Works) |

1.2 Description of the vessel

The Northern Ranger (Figure 1) is an ice-breaking coastal ferry that is managed by Nunatsiavut Marine Inc. and operates out of Newfoundland and Labrador. The vessel can carry up to 131 passengers and approximately 100 tonnes of cargo.

The Northern Ranger is fitted with 2 enclosed lifeboats, 1 on each of the port and starboard sides (Figure 2). Two rescue boats are also on board, 1 fitted aft of each lifeboat.

The Northern Ranger was originally fitted with 2 davits, including falls, on each side of the vessel. The enclosed lifeboats involved in this occurrence were purchased and installed in June 2014 to replace the originally fitted lifeboats. The occurrence lifeboats were fitted to the original davits and falls.

1.3 Description of the lifeboat

The Northern Ranger’s 2 enclosed lifeboats (Figure 3) and their forward and aft release hooks (Figure 4) were manufactured by Jiangsu Jiaoyan Marine Equipment Co., Ltd. in China. The lifeboats are model JY-QFP-6.0A1; their specifications are included in Table 1.

| Length | 6.0 m |

|---|---|

| Breadth | 2.3 m |

| Hook span | 5.6 m |

| Weight | 2507 kg |

| Full load weight (36 persons) | 5477 kg |

The release hooks are model JXN-1.

Crew members can launch each lifeboat individually from its respective davit. The lifeboats and hooks were type approved by a classification society under the International Convention for the Safety of Life at Sea (SOLAS), 1974.Footnote 1 The classification society did not test or include fall attachment devices, such as end links, in its certification, because it does not consider these devices to be part of the release hooks.

Each enclosed lifeboat is fitted with an on- or off-load release mechanism and hook-release instructions (Figure 5), which are located inside the lifeboat next to the aft steering console. The on- or off-load release mechanisms were manufactured by Shanghai Shenkong Machinery Co. Ltd., model SK-SMO2-JNX-1.

1.4 Description of the occurrence

The Northern Ranger docked in Nain on 11 October 2017. The vessel’s starboard lifeboat was due for a 3-month operational test per SOLAS requirements. At 1400,Footnote 2 the crew launched the lifeboat for operational testing, with 4 crew members on board. The 4 crew members operated the lifeboat on the water, and at 1423 they brought it alongside the Northern Ranger for retrieval.

At 1425, the crew on board the Northern Ranger and the 4 crew members inside the lifeboat made their first attempt to secure the end links on the fore and aft davit falls in the lifeboat’s release hooks. This attempt was not successful: the forward release hook operator could not get the release hook into the reset position, which prevented the on- or off-load release mechanism inside the lifeboat from resetting.

At 1430, the crew members operating the lifeboat inserted the davit’s fore and aft end links in the fore and aft release hooks respectively, then made a 2nd attempt to secure the hooks with the on- or off-load release mechanism. The coxswainFootnote 3 was able to reset the on- or off- load release mechanism inside the lifeboat and insert the safety pins. The coxswain ordered the davit operator to use the davit to lift the lifeboat slightly above the water, to determine if the release hooks could support the load of the lifeboat. The davit operator used the davit to lift the boat clear of the water and paused to await confirmation from the coxswain to continue with the lifeboat retrieval. When the release hooks supported the lifeboat’s load, the hook operators confirmed to the coxswain that the release hooks were secured.

The davit operator used the davit winch and falls to lift the lifeboat until it was level with the vessel’s embarkation deck. During retrieval, the forward davit fall became twisted and suddenly released as the lifeboat neared the davit arm. When the twist released, it created a vibration in the fall, end link, and forward release hook; the hook opened suddenly, releasing its end link. The bow of the lifeboat swung downward to the water below while the lifeboat hung from the aft release hook and fall, with the forward end of the lifeboat approximately 2 m from the water. All 4 crew members inside the lifeboat fell forward; the forward release hook operator fell through the forward hatch and into the water, injuring his eye, while the other 3 crew members remained inside.

The boatswainFootnote 4 on board the Northern Ranger threw a life ring to the crew member in the water, and the gangway was lowered to retrieve the crew member. The coxswain, who had sustained a head injury when the lifeboat swung downward, climbed up to the stern of the lifeboat, then climbed out of the aft hatch and jumped to the main deck of the Northern Ranger. The 2 remaining crew members in the lifeboat, who sustained abrasions and bruising when the lifeboat fell, exited through the forward hatch to a local speedboat that had arrived on scene.

Once all 4 crew members involved in the occurrence were recovered, they were treated for their injuries in hospital.

1.5 Environmental conditions

On the day of the occurrence, the sky was overcast with the wind blowing from the northwest at 8 knots. Wave height was less than 1 m.

1.6 Personal protective equipment worn by crew members

At the time of the occurrence, the crew members in the lifeboat were wearing safety footwear, coveralls, gloves, and hard hats. The crew were not wearing personal flotation devices, lifejackets, or seatbelts, nor were they required by regulation to do so.

1.7 Lifeboat’s on- or off-load release mechanism

An on- or off-load release mechanism opens and closes a lifeboat’s release hooks. The on- or off-load release mechanism in this occurrence, located next to the starboard lifeboat’s aft steering console, consists of a hydrostatic interlockFootnote 5 and a primary and secondary release handle, as well as the release handles’ respective safety pins.

Instructions for operating the on- or off-load release mechanism are posted above the mechanism itself.

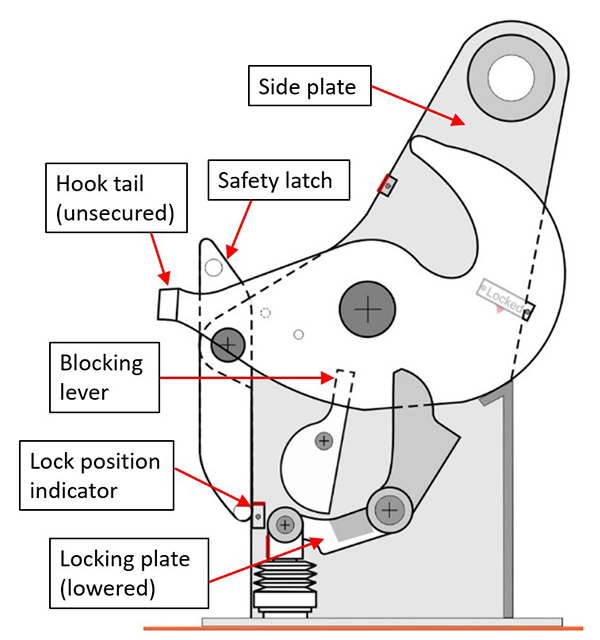

A cable connects the primary on- or off- load release handle to a locking plate in each of the lifeboat’s release hooks. The on- or off-load release mechanism operator operates this handle, which raises or lowers the locking plate that secures the hook tail within each fore and aft release hook.

Another cable connects the secondary release handle to a deadbolt-like plunger that secures the locking plate in each release hook. The on- or off-load release mechanism operator also operates this handle to secure both release hooks once the primary release handle is in the reset position.

1.8 Lifeboat’s forward and aft release hooks

Resetting and securing the lifeboat’s release hooks requires 3 crew members: 1 to operate the on- or off-load release mechanism, and 1 at each release hook. These operators work together to operate the on- or off-load release mechanism, and to reset and secure the release hooks.

Before the fore and aft release hooks can be reset as designed by the manufacturer, they must be open. According to the operation and maintenance manual, when the lifeboat is waterborne, the on- or off-load release mechanism operator opens both release hooks with the on- or off-load release mechanism inside the lifeboat.

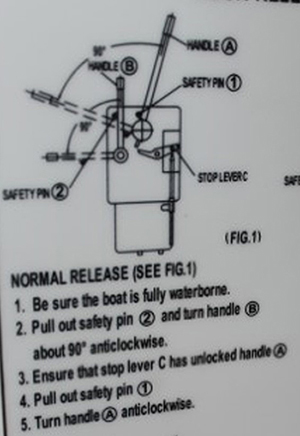

The instructions for the on- or off-load release mechanism (Figure 6) are posted inside the lifeboat and state:

NORMAL RELEASE (SEE FIG. 1)

- Be sure the boat is fully waterborne.

- Pull out safety pin ② and turn handle B about 90° anticlockwise.

- Ensure that stop lever C has unlocked handle A

- Pull out safety pin ①

- Turn handle A anticlockwise.

To open both release hooks, the on- or off-load release mechanism operator must first remove the safety pin (Figure 6, pin 2), holding the secondary release handle (Figure 6, handle B).

The operator then moves the secondary release handle counter-clockwise until it is in the open position, as indicated by the posted instructions. This action unlocks the primary release handle.

The operator then removes the primary safety pin (Figure 6, pin 1, handle A). Next, the on- or off-load release mechanism operator moves the primary release handle counter-clockwise, which lowers the raised locking plate (Figure 7 and Figure 8) within each release hook, releasing each hook’s tail and allowing each release hook to open.

Opening each hook allows each hook’s blocking lever to move to a vertical position and block its locking plate from rising.

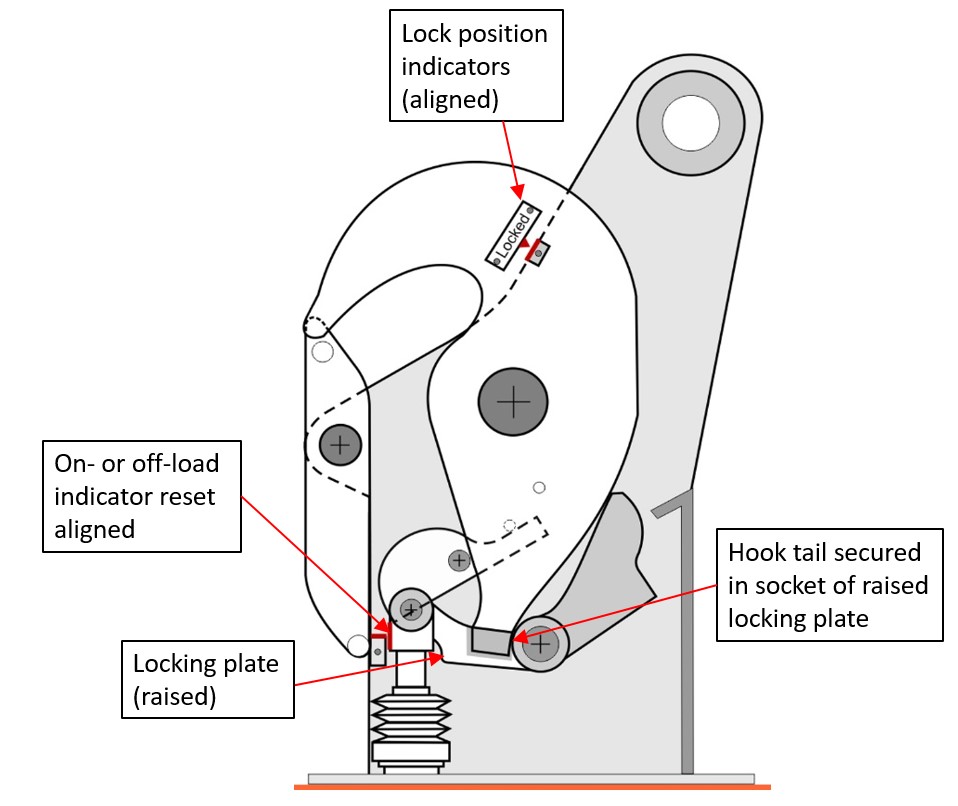

According to the manufacturer’s operation and maintenance manual, to reset the release hooks, the on-or off-load release mechanism operator moves release handle A back and forth while each hook operator manually rotates each release hook to the closed position.Footnote 6 As each hook rotates, it interacts with its blocking lever, moving the lever out of the vertical position. As the lever moves out of the vertical position, the tail of each hook enters the space between the side plates, then blocks its locking plate from rising until each hook is rotated such that its lock-position indicator aligns with the indicator on each hook’s side plate. During normal operation, when each hook and side plate indicators is aligned (Figure 8, Figure 9, and Figure 11), each hook’s tail is in line with the socket of its locking plate. When each hook’s tail is aligned with its locking plate socket, the locking plate is no longer blocked and is allowed to rise.

The on- or off-load release mechanism operator can now rotate the primary release handle clockwise to the reset position, which raises each hook’s locking plate, securing each hook in the socket of its locking plate (Figure 8, Figure 10, and Figure 12). Safety pin 1 is then inserted.

After the operator resets the primary release handle, he or she rotates the secondary release handle clockwise to its reset position. This action prevents accidental operation of the primary release handle. Safety pin 2 is then inserted.

Once the on- or off-load release mechanism is reset, each release hook operator checks his or her respective release hook’s lock-position indicator at the bottom of the hook assembly to verify alignment. A thin metal strip is attached between the side plates of each hook and is marked in its middle with a red indicator arrow. When the on- or off-load release mechanism is in the reset position, this arrow aligns with an indicator mark on the raised locking plate between the side plates (Figure 10 and Figure 12).

When both sets of indicators are aligned, each hook is in the reset and locked position (Figure 11 and Figure 12).

When both sets of indicators are aligned, they provide visual feedback to the release hook operator, confirming the reset of the on- or off-load release mechanism and each release hook. When each hook is reset, it is secure and ready to receive an attachment device, which the operator inserts into the throat of each hook and which is retained by the safety latch.

Testing at the TSB Engineering Laboratory determined that, if followed, the operating instructions in the manufacturer’s operation and maintenance manual help operators to reset the lifeboat’s release hooks and on- or off-load release mechanism, as designed by the manufacturer. Testing also revealed that the lifeboat’s deck design obscures the hook operators’ view of the on- or off-load release mechanism’s lock-position indicators, while the end links obscure the operators’ view of the release hook lock-position indicators.

The crew of the Northern Ranger typically follow instructions in the company’s operations manual and reset the lifeboat release hooks prior to retrieval. The lifeboat’s on- or off-load release mechanism operator used the mechanism’s reset as an indication that the lifeboat’s release hooks were in the reset/lock position and were ready to be secured.

In this occurrence, the forward hook operator inserted an end link in the forward release hook during the hook’s resetting procedure, before the hook was in the reset position. The davit operator then used the davit to lift the lifeboat slightly above the water; the hook operators used this lifting to test the hooks’ securement and did not confirm to the on-or off-load release mechanism operator that the hooks’ lock-position indicators were aligned.

1.9 Diameter of end links used during this occurrence

End links are attachment devices: steel rings providing a connection between the davit falls and the release hooks of a lifeboat. This connection enables the davit to raise the lifeboat to the stowage position on board a vessel when the release hooks are reset and secured.

The end links used in this occurrence were part of the originally fitted davit, and had a cross-section diameter of 28 mm.

The release hooks used in this occurrence are designed such that, when supporting a load, there is a specific distance from the centre of the pivot pin (pivot point) of each release hook to the centre of the diameter of each end link. This distance creates a momentFootnote 7 great enough to open each release hook if it is not reset in the locked position and is unsecured when a load is applied (Figure 13).

1.10 Documentation provided by the manufacturer

1.10.1 Operation and maintenance manual and final drawings

The lifeboat manufacturer provided a copy of its operation and maintenance manual and a series of final drawings to the company. The manual is written in English, and includes operating instructions for launching and retrieving the lifeboat used in this occurrence.

The manual instructions contain directions for resetting the lifeboat’s on- or off-load release mechanism and release hooks, including the following:

- Turn back release handle A about 30° clockwise,operator [sic] can adjust backwards and forwards handle according to action of operators at fore and aft until hooks can be restored.

- Operator restore the hooks [sic] simultaneously

- Turn back release handle A clockwise to locking position

- Insert safety pin 1, if the safety pin can not be inserted, the handle did not reach locking position and hooks are not reset. Restart procedure from step 1.

- Confirm hooks have been locked operators of fore and aft shall confirm following items when releasing [sic] operators give an order of confirmation of hook locked or not.

- Pull and push hooks by hand to confirm hooks locked or not.

- Arrows on hook of fore and aft have pointed at slot on lifing plate by vision [sic].

- Arrow on pull rod have pointed at locking mark.

- After confirmation of locking, report release operators [sic] that hooks have been locked.

- Turn back safety pin handle B clockwise to locking position,then [sic] insert safety pin 2

- Lifting ring is be put [sic] into hook center by personnel of fore and aft.

- Lifeboat is lifted out of water according to commander’s order

- Confirm stop lever C has been restored fully and under the condition of locking condition.If not OK [sic], the handle did not reach locking position and hooks are not reset. Restart procedure from step 1.Footnote 8

The company’s copy of the final drawings for the release hooks and on- or off-load release mechanism are written in English and include the details and dimensions for the lifeboat model and components used in this occurrence. These final drawings were on board the Northern Ranger at the time of the occurrence.

1.10.2 Documents sent by manufacturer to classification society and Transport Canada

The lifeboat manufacturer provided a copy of its operation and maintenance manual and the release hooks’ final drawing to the classification society. The flag state (Transport Canada) acquired these documents from the classification society that approved the lifeboat and release hook model and type. The operation and maintenance manual contains a graphic of the release hook model used in this occurrence, with a fall attachment device of an unspecified diameter inserted in it. However, the final drawing does not depict a fall attachment device, such as an end link or lifting ring, in the release hook.

The manufacturer also provided a copy of the release hook model’s strength calculations to the classification society and the flag state. The strength calculations include a drawing that depicts a fall attachment device in the release hook that could be an end link or a lifting ring.

Neither the company nor the crew on board the Northern Ranger had access to the strength calculations document that contained this drawing.

Transport Canada conducted a safety inspection of the Northern Ranger, including the installation of the new enclosed lifeboats, on 17 July 2014.

1.11 Company operations manual

The company that manages the Northern Ranger issued an operations manualFootnote 9 and general safety rules in March 2011. The manual provides employees with safe work instructions to follow while conducting their duties and tasks on board the vessel, including a section on launching the lifeboat and manoeuvring it away from the vessel.

The operations manual does not include detailed instructions for lifeboat retrieval; rather, the manual refers operators to the manufacturer’s operation and maintenance manual for details such as directions, and drawings illustrating lifeboat recovery and on-or off-load release mechanism and release hook reset procedures. The company operations manual and the manufacturer’s operation and maintenance manual were on board the Northern Ranger at the time of the occurrence.

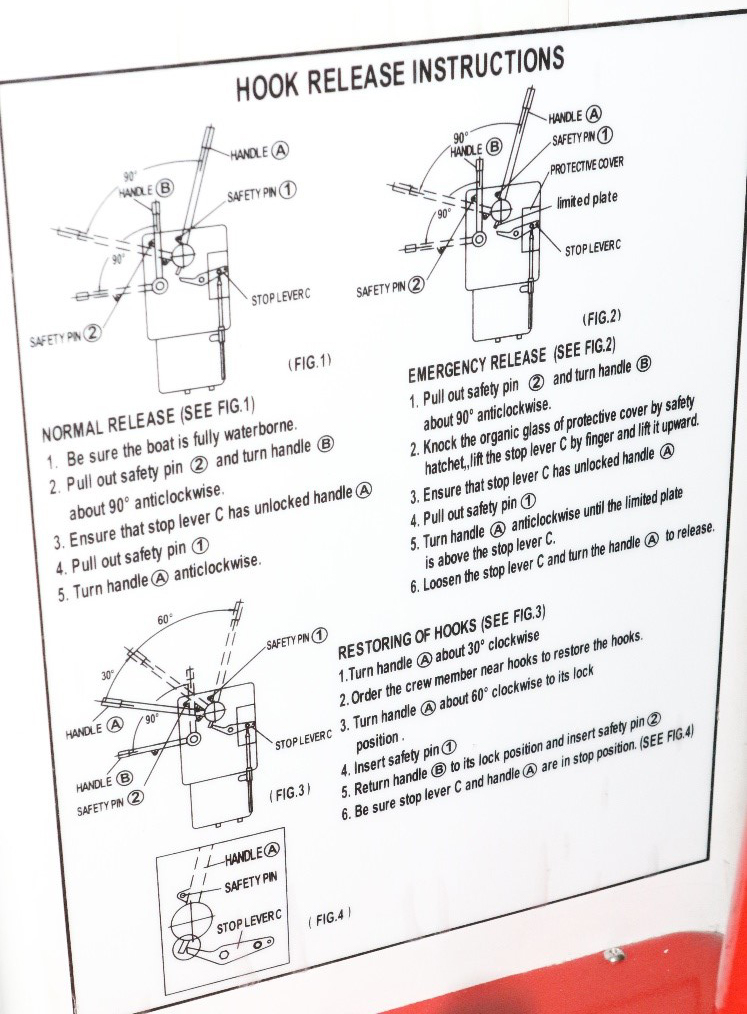

1.12 Signage on board the lifeboat

The procedure to release and reset the starboard lifeboat’s hooks and on- or off-load release mechanism when launching and retrieving the lifeboat, and during emergency release, is displayed on a placard mounted by the manufacturer beside the on- or off-load release mechanism (Figure 14). The crew relied on these instructions to operate the on- or off-load release mechanism and release hooks. The chief officer was given an on-the-job training session by the company that installed the lifeboat on the Northern Ranger. This training session relied on instructions provided on the placard in the lifeboat.

The placard includes 6 steps for resetting the lifeboat’s release hooks:

RESTORING OF HOOKS (SEE FIG.3)

- Turn handle A about 30 º clockwise

- Order the crew member near hooks to restore the hooks.

- Turn handle A about 60 º clockwise to its lock position.

- Insert safety pin 1

- Return handles B [sic] to its lock position and insert safety pin 2

- Be sure stop lever C and handle A are in stop position (SEE FIG.4).

1.13 Post-occurrence examination of the lifeboat, on- or off-load release mechanism, release hooks, and end links

Following this occurrence, the TSB Engineering Laboratory examined the starboard lifeboat and its equipment. The examination revealed the following:

- The forward release hook was not forced open, cracked, or broken.

- The parts of, and the rigging between, the release hooks and on- or off-load release mechanism met the manufacturer’s design specifications.

- The 28 mm end links used in this occurrence showed plastic deformation of the inner diameter due to interaction with the throat of the hooks (Figure 15), whereas the release hooks’ contact surface did not show any deformation. The deformation increased the surface area of, and friction between, the contact points of the end links and the release hooks.

- The diameter of the end link depicted in the strength calculations that the manufacturer provided to the classification society and flag state was 45 mm.

- The location of the forward hook in relation to the deck design significantly obstructs the visibility of the locking plate position indicator on the forward hook.

- A caution sign reminding operators to check the forward release hook’s position indicators is posted on the inside of the forward hatch, but this sign is not immediately visible to the forward hook operator when the forward hatch is open.

- The lifeboat’s onboard signage is written in English, and the bag of lifeboat equipment is labelled in simplified Chinese.

1.14 Testing of the on- or off-load release mechanism, release hooks, and end links

The TSB conducted testing to determine the cause of the forward release hook’s sudden release.

To test the operation of the release hook with the 28 mm end link used in this occurrence, the end link was inverted to lift the lifeboat with the unmarked contact surface on the inner diameter of the link. The forward and aft hooks were intentionally reset without being secured before the end link was inserted in each hook. Both the forward and aft hooks took load, lifted their respective ends of the lifeboat, and remained closed until the side plate of each hook was struck with a rubber mallet, creating a vibration. With the first strike, each release hook released its end link. During repeated testing, the previously unmarked inner diameter of the end link showed increasing contact wear and deformation due to friction. The release hooks did not show any signs of wear during testing.

The following determinations were made:

- The on- or off-load release mechanism and release hooks function as designed if the manufacturer’s operating instructions are followed.

- The on- or off-load release mechanism and release hooks did not function as designed in this occurrence, which indicates that the operating instructions were not followed.

- The blocking lever of each hook can be bypassed and the tail of each hook can be out of the blocking position; when this occurs, the locking plate of each hook can rise, allowing the primary handle of the on- or off-load release mechanism to rotate.

- During the reset procedure, an end link can be inserted into each release hook without the hook being in the reset position, and the on- or off-load release mechanism can be reset, resulting in the hooks being unsecured.

- The end links are made of a softer material than the release hooks.

- When repeated hook releases occurred during testing for end link securement in an unsecured release hook, the end links experienced wear and deformation. The wear and deformation increased the surface area where the end links contacted the release hooks, creating greater friction in the contact area.

- Both the forward and aft release hooks took load, lifted their respective ends of the lifeboat, and remained closed until the side plate of each hook was struck with a rubber mallet.

- The 28 mm diameter end links used on the originally fitted davit, and in this occurrence, do not create a sufficient moment for the hooks to release as designed by the manufacturer when unsecured and supporting a load.

When an end link of 45 mm in diameter was used to test the operation of the unsecured release hooks, the hooks functioned as designed and would not support a load before they released. In these tests, the 45 mm end link was introduced to the release hooks during the reset procedure, before the release hooks were in the reset and secured position.

The 45 mm diameter end link would not fit into the mouth of the release hooks when the manufacturer’s operating instructions were followed to reset and secure the release hooks.

1.15 International Convention for the Safety of Life at Sea, 1974 release hook requirements

Hook release mechanisms are designed to meet the International Life-Saving Appliance (LSA) Code, which is part of the requirements of the International Convention for the Safety of Life at Sea (SOLAS), 1974, as amended by International Maritime Organization (IMO) Resolution (Res.) MSC.81 (70), which is amended by IMO Res. MSC.274 (85) and MSC.321 (89).

Paragraph 4.4.7.6.8 of the LSA Code states that, “to prevent an accidental release during recovery of the boat, unless the hook is completely reset, either the hook shall not be able to support any load or the handle or safety pins shall not be able to be returned to the reset (closed) position without excessive force.”

1.16 Flag state requirements regarding life-saving appliances

Transport Canada enforces flag state regulations regarding the approval of life-saving appliances in Canada. The Northern Ranger’s registered flag state is Canada, and the vessel falls under Canadian regulations.

Transport Canada’s TP 14612E outlines procedures for the approval of life-saving appliances and fire safety systems on Canadian vessels. The publication states that “[a]ll instructions or markings that accompany life-saving appliances or are printed directly on the appliances must be in both English and French, as per Canadian Regulations.”Footnote 10

1.17 Safety management system

At the time of the occurrence, the company that owns and manages the Northern Ranger did not have a safety management system in place, nor was one required by regulation.

1.18 TSB laboratory reports

The TSB completed the following laboratory report in support of this investigation:

- LP111/2018—Analysis of Hook Release Mechanism

1.19 Previous occurrences

The TSB has conducted several investigations into occurrences involving lifeboats. The Australian Transport Safety Bureau and the United Kingdom’s Marine Accident Investigations Branch have also conducted similar investigations. Several of these are listed in Appendix A.

2.0 Analysis

The forward release hook on the Northern Ranger’s starboard lifeboat suddenly released because the release hook was improperly reset and the release hook’s safety defence did not operate in compliance with the Life-Saving Appliance (LSA) Code.

This analysis will focus on the causes for and contributing factors to the forward release hook’s sudden release. It will also discuss the requirements of the International Convention for the Safety of Life at Sea (SOLAS), 1974 regarding the operation of release hooks.

2.1 Factors leading to the hook’s release

The TSB analyzed the manufacturer’s operation and maintenance manual, which the manufacturer provided to the owner of the Northern Ranger, the release hook model’s final drawing, and the release hook model’s strength calculations. The analysis revealed discrepancies in the documentation: Nunatsiavut Marine Inc. was not provided with the diameter of the end links, which was required for the release hooks to function as designed. As a result, the crew used the end links on the originally fitted davit, which are of a smaller diameter than is needed for the release hooks to function as designed.

The lifeboat’s forward release hook was not reset according to the instructions in the operation and maintenance manual, and during a second reset attempt, the end link was inserted into the forward hook before the hook was in the reset position. The release hook lock-position indicators were therefore obscured by the end link during the hook resetting procedure, and the forward hook operator’s view of the locking plate indicators was also obstructed due to the location of the forward hook relative to the deck design. Without accurate visual feedback from the indicators, the forward release hook operator was unable to determine if the forward release hook was in the reset position before the on- or off-load release mechanism inside the lifeboat was reset.

When the operation and maintenance manual instructions for resetting the release hooks are not followed, the on- or off-load release mechanism can be reset without the tail of each hook secured by its locking plate. In this occurrence, the forward release hook’s blocking lever was bypassed, allowing its locking plate to rise without the hook’s tail being secured in its locking plate socket. This allowed the operator in the lifeboat to reset the on- or off-load release mechanism. This reset was used as confirmation that both the release hooks were in the lock position, and that the release mechanism and both forward and aft release hooks were secured. However, the forward release hook was not in the locked position and was unsecured.

Once crew members thought that the release hooks were reset and secured, they operated the davit to lift the lifeboat slightly above water to test hook securement before retrieval. The end links and release hooks initially supported the lifeboat’s load, confirming to the crew that both release hooks were secured.

The unsecured forward release hook initially supported the lifeboat’s load because of the deformation and friction between the contact points of the end link and release hook. The 28 mm diameter end link did not create a sufficient moment to overcome this friction and open the unsecured release hook.

During the lifeboat’s retrieval, the davit wires of the forward fall were twisted. As the twist released, the fall rotated suddenly, causing a vibration throughout the fall and forward release hook. This vibration decreased the friction between the forward release hook and end links’ contact points, allowing the hook to release.

2.2 Access to operating instructions

The lifeboat manufacturer provided a copy of its operation and maintenance manual to the company, which includes operating instructions for launching and retrieving the Northern Ranger’s lifeboats (including releasing and resetting the boats’ on- or off-load release mechanisms and release hooks). These instructions provide operators with guidance to operate the equipment as it was designed.

In this occurrence, crew members operated the starboard lifeboat’s on- or off-load release mechanism and release hooks according to the manufacturer’s instructions provided on a placard in each lifeboat. These instructions are a condensed version of those provided in the manufacturer’s operation and maintenance manual, and consequently, they do not contain the same details as the manual. For example, step 5 of 9 in the manufacturer’s operation and maintenance manual for resetting the on- or off- load release mechanism and release hooks in each lifeboat states:

- Confirm hooks have been locked operators of fore and aft shall confirm following items when releasing [sic]operators give an order of confirmation of hook locked or not.

- Pull and push hooks by hand to confirm hooks locked or not

- Arrows on hook of fore and after have pointed at slot on lifing [sic] plate by vision.

- Arrow on pull rod have pointed at locking mark.

- After confirmation of locking, report release operators [sic] that hooks have been locked.

These instructions tell the operator how to reset each lifeboat’s release hooks and use the hooks’ lock-position indicators to verify that the lifeboat’s on- or off- load release mechanism and release hooks have been reset and secured.

In contrast, the instructions on each lifeboat placard for resetting the release hooks and on- or off-load release mechanism contain only 6 steps, and do not include instruction to confirm or verify that the on- or off-load release mechanism and release hooks have been reset and secured.

Testing of the starboard lifeboat’s release hooks and on- or off-load release mechanism revealed that if the detailed instructions contained in the operation and maintenance manual are followed, the release hooks operate as designed. However, in this occurrence, crew members relied on the instructions provided on the lifeboat placard in order to operate and reset the release hooks and on- or off-load release mechanism.

Although instructions to verify the release hooks’ lock-position indicators were posted inside the lifeboat’s forward and aft hatches, when the hatches are open those instructions are not readily visible, and they did not serve as a reminder to the release hook operators in this occurrence. Without ready access to the detailed instructions in step 5 (shown above) and readily visible reminders to verify lock-position indicators, crew members reset the hooks and used the hooks’ ability to support a load to confirm that they were reset, instead of verifying the hooks’ lock-position indicators.

As seen in previous occurrences involving lifeboat operations (Appendix A), without comprehensive operating instructions, operators may not be aware they are not operating equipment as designed by the manufacturer.

When crews do not follow original equipment manufacturer instructions, there is a risk that equipment will not operate as designed.

2.3 Release hook requirements

Hook release mechanisms are designed to meet the LSA Code, which is part of SOLAS requirements.

Paragraph 4.4.7.6.8 of the LSA Code indicates that a release hook should be designed such that it will not support any load unless it is completely reset and the release mechanism can be reset without excessive force—that is, when the tail of the release hook is secured by the socket of the locking plate, which has been raised without excessive force by the on-or off-load release mechanism during that mechanism’s reset.

This requirement acts as a safety defence to prevent the accidental release of release hooks, if the hooks are not operated as designed. Without this defence,

- release hooks might support a load without being reset and secured; and/or

- excessive force might be used to reset the on- or off-load release mechanism when the hooks are not in the reset position, resulting in the release hooks being unsecured.

In this occurrence, although the crew did not follow reset instructions in the manufacturer’s operation and maintenance manual, operators were able to reset the starboard lifeboat’s on- or off-load release mechanism without using excessive force, and the forward hook’s locking plate rose without securing the tail of the release hook in the locking plate socket. Consequently, the forward release hook was not completely reset when it supported a load. The hook’s safety defence therefore failed, and the hook was not in compliance with LSA Code and SOLAS requirements.

2.4 Release hook’s sudden release

2.4.1 Bypass of blocking lever

A blocking lever interlock is designed to prevent a hook’s locking plate from rising until the hook tail has entered the space between the release hook side plates. While a release hook of the model and type used in this occurrence is being reset, it is possible to bypass its blocking lever interlock. If the hook stops rotating to the reset position as the hook tail approaches the entrance between the side plates, the blocking lever mechanism holds the blocking lever just out of the blocking position while the locking plate rises. The locking plate can therefore rise to stop the hook tail from entering the space between the side plates. When the locking plate rises, it permits the reset of the on- or off-load release mechanism in the lifeboat.

If a release hook’s blocking device is bypassed during the resetting procedure, although the on- or off-load release mechanism can be reset and safety pins inserted, there is a risk that the hook will not be secured.

2.4.2 Visibility of hook’s lock-position indicators

Accurately aligned reference marks such as hook lock-position indicators are an anchoring aid that prevents a drift in standards and reduces the possibility of error. When a lifeboat’s release hook indicators are not accurately aligned, the possibility of hook reset error exists; release hook operators no longer rely on an accurate reading but on estimation.

When the operator’s instructions for this model of lifeboat and release hooks are not followed and an end link is inserted into a release hook during the hook reset procedure (before the release hook is in the reset position and ready to receive the end link), the hook’s lock-position indicators are obscured by the end link and are not fully visible to the hook operator. Without accurate visual feedback from the hook lock indicators, the hook operator must make an estimation. This estimation may cause the hook operator to think that the hook is in the reset position when it is not. Furthermore, if the operator does not know to verify the position of the indicators, he or she will not know they are obscured.

In this occurrence, the forward release hook’s lock-position indicators were obscured by the end link, and the forward hook operator’s view of the locking plate indicators was obstructed due to the location of the forward hook relative to the deck design. These 2 conditions contributed to the forward hook not being reset and secured.

If operators are unable to verify the alignment of position indicators, there is a risk of operator error.

2.4.3 Diameter and material of end links

The starboard lifeboat’s unsecured forward release hook supported the load of the lifeboat until a vibration occurred throughout the forward davit fall wire, at which point the hook suddenly released its end link.

The forward unsecured release hook supported the lifeboat’s load due to a combination of friction between the contact surfaces of the release hook and end link, and the fact that the end link’s 28 mm diameter did not create a moment great enough to overcome that friction.

Because the 28 mm end links are made of softer material than the lifeboat’s release hooks, the weight of the release hooks deformed the end links’ contact surface, creating friction. The distance between the centre of the 28 mm diameter end links and the pivot pin of the release hooks is not great enough to create a moment to open the hooks if they are unsecured and a load is applied, especially when increased friction occurs. The vibration from the forward davit fall wires reduced the friction between the forward end link and forward release hook contact surfaces, allowing the forward release hook to release.

When a 45 mm diameter end link is used, the unsecured release hooks function as designed and do not support a load. This indicates that a 45 mm end link creates a moment great enough to open an unsecured release hook, allowing the hook to function as designed and in accordance with SOLAS requirements.

If crews use components that have not been included in the engineered design of vessel equipment, there is risk that equipment will not function as designed.

If companies use release hooks of the model and type used in this occurrence, there is a risk that their life-saving equipment will not be in compliance with SOLAS.

2.5 Discrepancy in documentation

The lifeboat manufacturer provided a copy of its operation and maintenance manual, as well as the release hooks’ final drawing, to the classification society and the company. The manual contains a graphic of the release hook model used in this occurrence with a fall attachment device of an unspecified diameter inserted in it. The final drawing does not depict such a device in its graphic of the release hook model.

The manufacturer also provided a copy of the release hook model’s strength calculations to the classification society. The strength calculations include an engineered drawing that depicts a fall attachment device (end link). The diameter of the device is not apparent, but TSB analysis of the strength calculations drawing determined that the diameter is 45 mm.

After the TSB determined the size of the end link that is depicted in the strength calculation’s engineered drawing, the operation of the starboard lifeboat’s release hooks and on- or off-load release mechanism was retested. It was found that the 45 mm end link creates a moment great enough to cause the release hooks to operate as designed and open in the unsecured position when a load is applied.

It was also found that when the manufacturer’s operating instructions are followed, the diameter of the 45 mm end link is too large to enter the mouth of the release hooks when the hooks are in the reset and secured position. For the 45 mm end link to be used, it must be inserted through the mouth of each hook before each hook is in the reset position and is ready to be secured with the on- or off- load release mechanism.

Although the use of a 45 mm end link permitted the release hooks to operate as designed, the manufacturer’s operating instructions cannot be followed.

If a manufacturer’s drawings and operating instructions contain discrepancies, operators may modify operating procedures, increasing the risk of injury or damage.

Because neither the company nor the crew on board the Northern Ranger had access to the strength calculations document that contained this engineered drawing, they did not have the information needed to determine the diameter of end link that they should use. Without this information, the company used the original 28 mm end link attached to the vessel’s originally fitted davit.

Without precise engineered documentation regarding vessel equipment, there is a risk that equipment will be assembled in an unsafe manner.

3.0 Findings

3.1 Findings as to causes and contributing factors

- The forward release hook’s safety defence failed and therefore did not meet the requirements of the Life-Saving Appliance (LSA) Code and the International Convention for the Safety of Life at Sea (SOLAS), 1974 (as amended).

- The lifeboat’s forward release hook was not reset according to the instructions in the operator’s manual.

- During the release hook resetting procedure, the forward release hook lock-position indicator was obscured by the end link, which led the operator to assume that the hook was in the locked position when it was not.

- The forward release hook’s blocking lever was bypassed, allowing the locking plate to rise without the hook’s tail being secured in its locking plate socket.

- The bypassed blocking lever allowed the operator in the lifeboat to reset the on- or off-load release mechanism, giving lifeboat operators the impression that the release mechanism and both forward and aft release hooks were secured.

- The end links and release hooks initially supported the load of the lifeboat, reinforcing the crew’s impression that both release hooks were secured.

- The crew used 28 mm diameter end links, which were of a smaller diameter than was needed for the release hooks to function as designed. Given the increased friction, the moment was insufficient to open the unsecured forward release hook.

- The sudden vibration through the forward davit wires decreased the friction between the forward release hook and the 28 mm end links’ contact points, allowing the hook to release.

3.2 Findings as to risk

- When crews do not follow original equipment manufacturer instructions, there is a risk that equipment will not operate as designed.

- If a release hook’s blocking device is bypassed during the resetting procedure, although the on- or off-load release mechanism can be reset and safety pins inserted, there is a risk that the hook will not be secured.

- If operators are unable to verify the alignment of position indicators, there is a risk of operator error.

- If crews use components that have not been included in the engineered design of vessel equipment, there is risk the equipment will not function as designed.

- If companies use release hooks of the model and type used in this occurrence, there is a risk that their life-saving equipment will not be in compliance with the International Convention for the Safety of Life at Sea (SOLAS), 1974.

- If a manufacturer’s drawings and operating instructions contain discrepancies, operators might modify operating procedures, increasing the risk of injury or damage.

- Without precise engineered documentation regarding vessel equipment, there is a risk that equipment will be assembled in an unsafe manner.

3.3 Other findings

- Life-saving equipment documentation and on-board signage was not in the flag state’s 2 official languages (English and French).

- At the time of the occurrence, the crew members in the lifeboat were not wearing personal flotation devices, lifejackets, or seatbelts.

4.0 Safety action

4.1 Safety action taken

Following the occurrence, the Transportation Safety Board of Canada (TSB) issued a safety advisory letter (MSA 04-18) regarding release hooks model JXN-1 to

- Jiangsu Jiaoyan Marine Equipment Co., Ltd.,

- RINA Classification Society,

- Nunatsiavut Marine Inc.,

- Transport Canada (TC) Marine Safety and Security, and

- the members of the International Association of Classification Societies.

Shortly after the occurrence, the company implemented a corrective action prohibiting the crew from being in lifeboats during retrieval.

On 19 March 2019, TC issued a Ship Safety BulletinFootnote 11 to inform the marine community of safety measures concerning life-saving appliances.

At the same time, TC released FlagStateNet FSN 01-2019 to bring this incident to the attention of inspectors and surveyors. TC also provided guidance material to all marine safety inspectors and recognized organization surveyors in regard to monitoring vessels equipped with these life-saving appliances.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 26 November 2019. It was officially released on 19 February 2020.

Appendices

Appendix A – Previous occurrences identifying issues relating to lifeboats

Occurrences investigated by the TSB

Since 1992 the Transportation Safety Board of Canada (TSB) has investigated 7 occurrences involving lifeboats. The main safety concerns in these occurrences include improper maintenance, insufficient knowledge of the release and retrieval procedures for totally enclosed lifeboats, and the improper functioning of release mechanisms.

M92N5015 (Sir Wilfred Grenfell) – When an enclosed lifeboat was launched during a lifeboat drill on 08 July 1992 at St. John’s, Newfoundland and Labrador, the forward hook prematurely released, followed by the failure of the aft hook assembly. The lifeboat fell to the water. There were no injuries to the 12 crew members in the lifeboat.

The investigation revealed that the hook tail was not secured by the release pin and the crew lacked training in the maintenance of the lifeboat on-load release equipment.

M93N5017 (Taverner) – On 31 July 1993, in Goose Bay, Newfoundland and Labrador, 5 crew members fell from a lifeboat after the aft falls released.

Following the occurrence, in February 1994, the Board issued a Marine Safety Advisory (MSA 01/94) to Transport Canada. The advisory highlighted the need to promote increased awareness among ship owners of the importance of preventative maintenance procedures for lifeboat release mechanisms, and to ensure adequate procedures for inspecting lifeboat release mechanisms are being followed by its surveyors.

M93W1021 (Oceanic Mindoro) – On 27 March 1993 a crew member was entangled in the lifeboat falls during a lifeboat drill alongside the Neptune terminals in Vancouver, British Columbia. The crew member suffered a severe injury to the leg.

The investigation revealed that there was a lack of knowledge of the launch and retrieval procedure.

M96L0043 (Farandole) – On 14 May 1996 in La Baie, Quebec, the forward on-load release hook of an enclosed lifeboat opened while the boat was being hoisted to the vessel’s deck level. The bow of the lifeboat fell, causing the stern on-load release hook to fail, resulting in an uncontrolled fall of the entire lifeboat.

The investigation revealed that the crew did not take all necessary actions to arm the hydrostatic hook release mechanism before hoisting the lifeboat, and the monthly inspection did not include checking the hydrostatic hook release mechanism. Thus, a safety pin was not replaced before the monthly abandon ship drill.

M98W0245 (Icolos Grace) – On 09 November 1998, during a lifeboat exercise at anchorage K in Vancouver Harbor, British Columbia, the forward release hook of the vessel’s lifeboat released prematurely. The forward end of the boat fell, and when the boat was perpendicular to the water the aft release hook also released. Five of the 6 crew members on board the lifeboat were rescued and 1 suffered fatal injuries.

The investigation revealed that the crew was unfamiliar with the procedures for resetting the lifeboat’s hook; the manufacturer's instruction manual for the lifeboat’s launch and retrieval operations was incomplete and difficult to comprehend; and an inspection by the vessel’s classification society and shipboard personnel was not thorough.

M00W0265 (Pacmonarch) – On the morning of 26 October 2000, while the Pacmonarch lay at English Bay anchorage 3, Vancouver Harbour, British Columbia, crew members began launching the vessel’s port lifeboat for a run ashore. The lifeboat was a davit-launched, totally enclosed type and was fitted with on-load release hooks. Four crew members boarded the lifeboat while 2 other crew members on the vessel removed the securing pins at the davits to prepare for the launch. Soon after the davits hit their stops and the lifeboat was about 15 m above water level, the aft hook separated from the aft suspension ring of the davit falls. Suspended from the forward hook, the lifeboat swung almost vertical, at which point the forward hook opened. Completely freed, the lifeboat fell stern first into the sea. Three of the 4 crew members in the lifeboat were fatally injured.

The investigation revealed that the release hook reference marks did not provide the crew with accurate indication that the reset lever and the release hooks were properly reset. In addition, the cam of the release hook had a manufacturing defect.

M06L0063 (Sea Urchin) – On the morning of 22 May 2006, while at anchor in the Bay of Sept-Îles, an abandon-ship drill was carried out on board the bulk carrier Sea Urchin. At 1150 Eastern Daylight Time, during the recovery of the starboard lifeboat, the lifeboat’s aft hook-release gear mechanism opened. The forward mechanism, unable to take the full load of the boat, also opened. The lifeboat then fell 11 m, stern first, into the sea, fatally injuring 1 of the 5 crew members on board.

The investigation revealed that the instruction manual was less than adequate for a thorough understanding; release gear mechanisms can appear to be resting properly when they are not, creating a false sense of security; the crew was not properly trained.

Occurrences investigated by the Australian Transport Safety Bureau

Since 2000, the Australian Transport Safety Bureau (ATSB) has investigated several occurrences involving lifeboats.

ATSB 160 (Washington Trader) – At 2036 on 05 August 2000, at Abbot Point, Queensland, Australia, the master and crew of the Washington Trader conducted an abandon ship exercise. When the port lifeboat was lowered approximately halfway to the deck, the master observed the aft end of the lifeboat jerk twice before the aft release hook released. The aft end of the lifeboat fell, and the forward end of the lifeboat was observed to jerk twice before the forward release hook released, causing the lifeboat to fall 15 m to the water below.

The investigation revealed that the release hooks and on-load release mechanism reset was complex, and the crew had poor knowledge of the operation of the on-load release system. The Washington Trader is sister ship to the Pacmonarch, and the on-load release systems on board both vessels are the same.

ATSB 164 (Alianthos) – At 1740 on 21 January 2001, at Greenlog, Victoria, Australia, the master of the Alianthos conducted an abandon ship drill. During the drill the port lifeboat was lowered to the embarkation deck, at which time the davit cradles hit their stops, causing the lifeboat to jerk and the after fall to release. The aft end of the lifeboat fell to the perpendicular and the forward release hook held it there.

The investigation revealed that the crew was insufficiently conversant with the operation of the on-load release system and had difficulty understanding the lifeboat manufacturer’s operating instructions.

ATSB 71 (Kayax) – At 1100 on 09 August 1994, at Portland, Victoria, Australia, an Australian Marine Safety Authority inspector conducted a port state control inspection on board the Kayax. Part of the inspection was to lower the vessel’s lifeboat to the embarkation deck and run the engine. After several minutes of running the engine, the lifeboat was unintentionally released from its davit falls by one of the on-board lifeboat operators and fell to the water.

The investigation revealed that the on-load release system was operated by a crew member who did not possess sufficient knowledge of the on-load release system and had a lack of practice with the system’s operation.

ATSB 128 (Maersk Pomor) – On 02 January 1998 at Gladstone, Queensland, Australia, during a port state control inspection of the vessel, its lifeboat released and fell to the water.

The investigation revealed that the 3rd engineer unintentionally operated the lifeboat’s release system owing to a lack of knowledge and training, and the release system’s instructions were not written in the language used by the crew.

ATSB 208 (Lowlands Grace) – On 07 October 2004, while at an anchorage at Hunt Point, Port Hedland, Australia, vessel crew conducted a lifeboat drill. The port lifeboat was lowered remotely to the water by the 3rd mate. When the mate released the cable that controlled the davit brake, the lifeboat suddenly stopped. The lifeboat’s aft release hook detached from the aft fall and the stern swung down towards the water, then up. Asthe boat was swinging, the forward hook released.

The investigation revealed poor maintenance practices of the hook release system. In addition, the suspension rings on the davit falls were of the incorrect size, which subjected the forward hook to greatly increased opening forces as the lifeboat was swinging.

ATSB 188 (Ma Cho) – On 09 December 2002 at Devonport, Tasmania, the master and crew of the Ma Cho conducted a lifeboat drill. During the drill, while the lifeboat was being lowered to the water, the boat’s aft release hook released. The boat’s stern fell perpendicular to the water. The crew on board the lifeboat disembarked and the lifeboat was lowered to the water.

The investigation revealed that the design of the hook was flawed with respect to its locking mechanism, and the ship’s safety management system was deficient with respect to both the operating and maintenance instructions, and crew training on the on-load release system.

Occurrences investigated by the United Kingdom’s Marine Accident Investigation Branch

Since 1992 the Marine Accident Investigation Branch (MAIB) in the United Kingdom has investigated several lifeboat accidents.

MAIB (Hoegh Duke) – On 20 August 1992 at Surabaya, Sumatra, Cayman Islands, the starboard lifeboat of the Hoegh Duke, with a crew of 12, was being lowered to the water when the aft hook slipped off its davit fall lifting ring. The lifeboat swung on the forward hook until it fell upside down to the water. Six crew members sustained fatal injuries and the other 6 were hospitalized.

The investigation revealed that the on-load release hook mechanism was improperly reset; release mechanism maintenance was neglected; and ship officers lacked understanding of the safe operation of the mechanism.

MAIB 25/2002 (Galateia) – On 26 January 2002, at Seaforth docks, Liverpool, United Kingdom, the crew of the Galateia conducted a lifeboat drill to obtain an Interim Safety Management Certificate. The lifeboat was launched, tested, retrieved, and then lifted to the embarkation deck, where the chief officer moved the on-load release handle to the stowage position. The release hooks opened and the lifeboat fell to the water.

The investigation revealed that a locking pin was not inserted into the release mechanism operating handle; the crew was not familiarized in the operation of the release hook system; and vessel officers were not aware of the operation of the safety pin.

MAIB 09/2015 (Nagato Reefer) – On 09 April 2014, at Southampton, United Kingdom, the crew of the Nagato Reefer conducted a lifeboat drill for a port state control inspection. As the lifeboat was being stowed, the forward fall preventer device was released and the forward hook opened, causing the bow of the lifeboat to fall to the deck below.

The investigation revealed that the vessel’s safety management system was poorly implemented, as the crew was not familiar with the operation of safety equipment on board the vessel, and routine maintenance of the on-load release system was not being carried out. This vessel’s on-load release system was the same as the system on board the Sea Urchin (TSB Marine Investigation Report M06L0063).