Fire and abandonment

Tug Ken Mackenzie

Fraser River, British Columbia

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

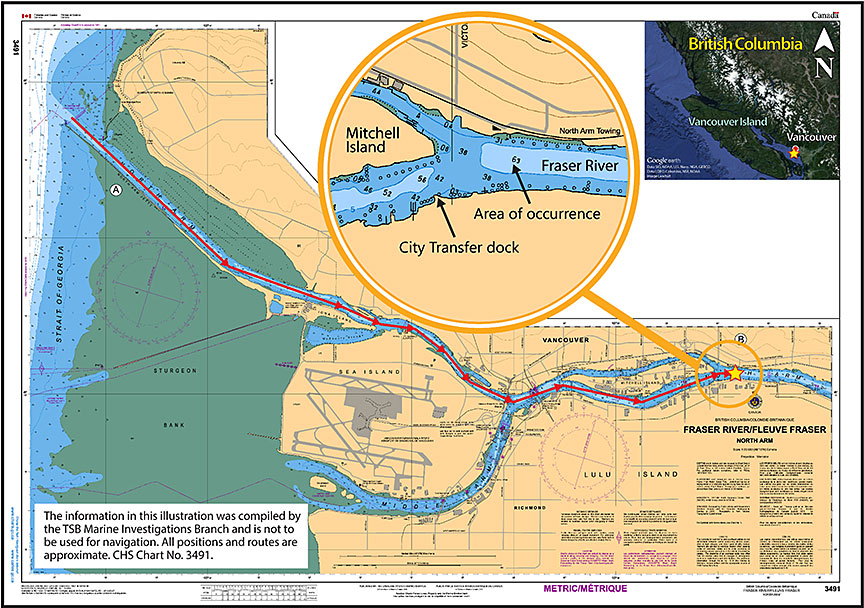

On 11 July 2016, at approximately 2230 Pacific Daylight Time, the tug Ken Mackenzie, with 2 people on board, reported a fire in the engine room while transiting the Fraser River, British Columbia. The 2 crew members abandoned the vessel and were picked up by the assist tug Harken No. 5. The fire was extinguished with the assistance of vessels in the vicinity.

This report is also available in English.

Factual information

Particulars of the vessel

| Name of vessel | Ken Mackenzie |

|---|---|

| Official number | 812323 |

| Port of registry | Vancouver, BC |

| Flag | Canada |

| Type | Tug |

| Gross tonnage | 8.79 |

| Registered length | 12.28 m |

| Draft at departure | 3.35 m |

| Built | 1989 |

| Propulsion | 2 diesel engines (1200 BHP) driving 2 fixed-pitch propellers |

| Cargo | Log tow |

| Crew | 2 |

| Registered owner | Tidal Towing Ltd., Port Coquitlam, BC |

| Manager | Harken Towing Co. Ltd., Port Coquitlam, BC |

Description of the vessel

The Ken Mackenzie (Figure 1) is a twin-screw, carvel/flush full displacement steel-hulled tug built in 1989. A small aluminum wheelhouse is located on the fore part of the main deck, and is bolted to the main steel base that is raised above the main deck. The wheelhouse is accessible from the main deck, on its port and starboard sides, through watertight doors. The wheelhouse is fitted with a centre steering console, propulsion controls, and navigation equipment consisting of 2 very high frequency (VHF) radiotelephones with digital selective calling, a radar, a magnetic compass, an autopilot, a global positioning system (GPS), an automatic identification system (AIS)Footnote 1, and an echo sounder. A galley containing a compact oven, a fridge, a microwave, and a settee is located aft of the helm station.

The hull below the main deck is subdivided by 3 transverse bulkheads that enclose 4 compartments (from forward): the forepeak space, the accommodation space, the engine room, and the lazarette. The accommodation space is accessible through a 762 mm round emergency escape hatch located forward on the main deck. The engine room is accessible through a raised watertight hatch that is situated on the aft raised deck between the exhaust funnels. Another watertight door connects the engine room to the accommodation space.

The engine room is equipped with two 600 hp diesel engines and an 11.3 kW diesel generator that drives 2 fixed-pitch propellers. An additional diesel engine provides power to drive the towing winch. The main distribution panels and switchboard are located on the forward bulkhead of the engine room. Within the engine room are 5 diesel tanks (2 forward tanks and 3 aft tanks) which, at the time of the occurrence, contained approximately 19 000 L of fuel. The tanks are fitted with supply and return valves in the engine room that can be remotely operated from the main deck by means of extended spindles connected to a manifold located on the starboard side. The fuel supply can be shut off at the supply and return valves, or, in an emergency, by means of remote levers operated from the wheelhouse or the main deck.

The main deck is equipped with a steering station and a hydraulic towing winch that is fitted with a secondary drum. The top of the wheelhouse is accessible by a ladder on its starboard side and has a helm station and towing winch controls. This space is also used to stow the life raft and scow pump.Footnote 2

The vessel's steering gear is located in the lazarette. The only access to the lazarette is through a raised hatch coaming on the main deck.

Fuel system

The vessel is equipped with 5 tanks that store diesel fuel, which is used to operate the main engines and the generator. Two tanks are located forward, and 2 are located aft on each side of the vessel. In addition, there is a centre skeg tankFootnote 3 between the aft set of tanks. The tanks are connected to a common supply and return manifold through steel piping (Appendix A). Each tank has an independent supply and return valve located in the engine room, which is fitted with an extended spindle that also allows the valve to be operated remotely from the main deck. An emergency shut-off valve is also fitted to each fuel tank. The emergency shut-off valves for the forward tanks are operated from the wheelhouse, and consist of steel cables that extend between the operating levers in the wheelhouse and the shut-off valves on the tanks. The emergency shut-off valves for the aft tanks are operated from the port side of the main deck, and consist of plastic sheathed control cables that extend between the operating levers and the shut-off valves.

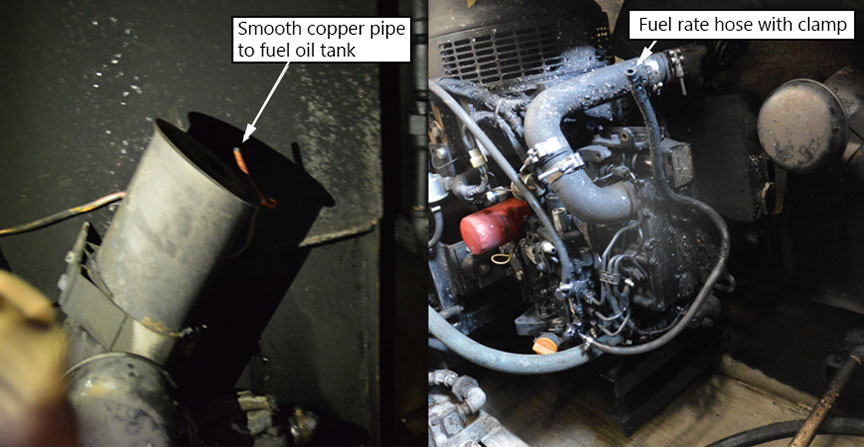

Fuel is transferred from the supply manifold to the generator through a flexible fuel hose. The return line from the generator is comprised of a flexible fuel hose connected to a copper tube, which leads to the return manifold.

Company operations

Harken Towing Co. Ltd. (the company) was founded in 1948 and provides a full range of marine towing services to the Pacific Northwest region. Its fleet consists of approximately 15 tugs, 9 water taxis, and 7 deck barges.

In 2009, the company voluntarily participated in a pilot project called the Canadian Alternate Compliance Program and Safety Management Systems in the Canadian Domestic Fleet. As part of this project, the company collaborated with Transport Canada (TC) and the Council of Marine Carriers to create an SMS in the Canadian domestic fleet for companies operating vessels with a gross tonnage (GT) of less than 500. Although TC discontinued the project in 2012, the company continues to operate its own safety management program.

Repairs and regular maintenance of company vessels are conducted in-house. The company employs a maintenance team that is responsible for ensuring that vessels are seaworthy and fit for service. A maintenance supervisor oversees the team's mechanics, welders, and all other maintenance staff. The requirement for the maintenance supervisor's position is acceptable practical experience in marine operations, repairs, or maintenance.

History of the voyage

On 11 July 2016, the Ken Mackenzie, with 2 people on board, was towing approximately 30 sections of logFootnote 4 at a speed of approximately 2.5 knots on the Fraser River, British Columbia.Footnote 5 The tug Harken No. 5, with 2 people on board, was assisting the Ken Mackenzie, and dropping off sections of the tow (cut-offs) at predetermined locations along the river.

At approximately 1900,Footnote 6 the Ken Mackenzie stopped in the north arm of the Fraser River, near Iona, for a scheduled crew change. The day shift crew informed the relieving crew that there had been a smell of diesel in the engine room. Unable to identify the source of the smell, the day shift crew completed a domestic safety management (DSM) report, but did not transmit it to the company office, because it was after business hours.

The night shift deckhand conducted a routine safety round in the engine room soon after the crew change, and looked for sources of fuel leakage that could explain the smell of diesel. The deckhand did not find any sources of leakage, and the vessel continued its voyage along the Fraser River.

At approximately 2225, the Harken No. 5. disconnected 6 sections of log and began dropping them off east of Mitchell Island (Appendix B).

The master of the Ken Mackenzie, who was navigating from the wheelhouse, noticed smoke coming out of the engine room's forced exhaust vent. The mastergrabbed the fire extinguisher from the wheelhouse and proceeded to the main deck. By this time, the vessel was engulfed in smoke, and the master observed flames exiting from the exhaust vents.

The master returned to the wheelhouse and, at around 2230, used the VHF radiotelephone to notify the Harken No. 5 that there was a fire in the engine room and it was out of control. By the time the master returned to the wheelhouse, the engine room's fire detection system had activated, causing the fire alarm to sound in the wheelhouse. The master shut off the main engines from the wheelhouse and activated the emergency fuel shut-off for the 2 forward fuel tanks.

The master and the deckhand exited the wheelhouse with their possessions and abandoned the Ken Mackenzie by jumping onto the log tow. Just before abandoning the vessel, the master shut off the fuel supply and return valves to the engine room from the main deck.

Once on the log tow, at 2237, the master of the Ken Mackenzie called 9-1-1 from his cellphone to advise emergency services of the situation. Shortly thereafter, the master and deckhand were picked up by the assist tug Harken No. 5. Once on board the Harken No. 5, the master of the Ken Mackenzie used the VHF radiotelephone to notify Marine Communications and Traffic Services and other vessels in the area of the situation. The assist tug then proceeded to stop the log tow, which had been drifting.

At approximately 2245, the tug Pacific Tyee responded to the radio call from the Harken No. 5 and arrived on scene. Crew from the Pacific Tyee boarded the Ken Mackenzie and smothered the fire with charged hoses directed through the engine room hatch. The Pacific Tyee's crew were assisted in firefighting by crew from the Harken No. 9, which also responded to the radio call, as well as the crew of the Harken No. 5.

At approximately 2300, the fire was under control. The covers for the engine room dampers, which were jammed in their storage brackets, were hammered loose and used to seal the openings. There was no means of sealing the forced exhaust vent for the engine room.

At approximately 2315, the Ken Mackenzie was towed to the City Transfer dock in Richmond, British Columbia, where the vessel was boarded and checked by the Richmond Fire Department.

Environmental conditions

The weather at the time of the occurrence was overcast. Visibility was approximately 5 nautical miles, and the wind was southeasterly at approximately 5 knots. The tide was flooding at approximately 0.5 knots, and the water surface was glassy with no swell.

Damage to the tug

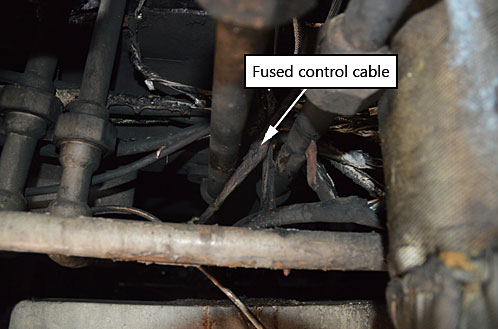

There was significant burning and charring of materials in the engine room, particularly around the generator. The heat from the fire melted and/or burned numerous components directly above the generator, and distorted some deck plating. The cable jacket and conduit liner of the control cables that operated the fuel shut-offs for the aft tanks were fused, rendering the cables inoperable (Figure 2). Both the cable jacket and the conduit liner were polyethylene-based.

Paint on the exhaust trunking was burned and discoloured by heat. The inside of the engine room was coated with soot from the fire, and the saltwater and foam used to extinguish the fire had contaminated other machinery and electrical systems.

The vessel was towed to a shipyard to repair the damage caused by the fire.

Personnel certification and experience

The master began his marine career in 1998 working on tugs as a deckhand, and has been employed by the company since 2003. In November 2005, he obtained a Master, Limited for a Vessel with Less Than 60 Gross Tonnage certificate, valid for tugboats operating in the Fraser River, Pitt River, Vancouver Harbour, Howe Sound, and the Strait of Georgia, British Columbia, within 20 nautical miles from shore. He took on the duties of master in 2006, and had performed log towing and barge towing operations on all the company's vessels. At the time of the occurrence, the master held a valid Master, Limited for a Vessel with Less Than 60 Gross Tonnage certificate. The master also held a Restricted Operator's Certificate - Maritime Commercial, a Marine Advanced First Aid certificate, and a Marine Emergency Duties A1 certificate.

The deckhand began working on tugs in 2011, and had been employed by the company since 2013. The deckhand had completed a bridge watch training course and held a Restricted Operator's Certificate - Maritime Commercial, and had also received Marine Emergency Duties training related to basic safety, survival craft, and first aid.

The shore-based maintenance supervisor began working for the company in 1999 as a welder/fabricator and took on the role of maintenance supervisor in 2014. The supervisor held a Level C welding certificate and a Structural Draftsman Certificate. The supervisor was also working towards achieving a Class 4 engineering licence from TC. During his time with the company as a welder/fabricator, the supervisor assisted with fabricating barges and a boat lift for the company, and also assisted with maintenance work on board company vessels. There are no prescribed qualifications by TC for persons performing such duties.

Regulatory oversight

Tugs less than 15 GT are not required, by regulation,Footnote 7 to be inspected by TC, nor are they required to operate under an SMS.

Under the Canada Shipping Act, 2001 (CSA 2001) the vessel's authorized representative (AR) is required to ensure compliance with applicable regulations and the safe operation of their vessel(s). Although TC marine safety inspectors have the authority to conduct random monitoring inspections to verify compliance with the CSA 2001, there are no records to indicate that the Ken Mackenzie had ever been subject to such an inspection.

To provide tools to help operators comply with the regulations and operate safely, TC is currently revising its Small Vessel Compliance Program to include tugs less than 15 GT. However, this program has not yet been implemented, and participation in the program is expected to be voluntary.

Following the sinking of the tug Syringa off Sechelt, British Columbia, in 2015, the Transportation Safety Board of Canada (TSB) issued a safety concern that "without adequate oversight by the Department of Transport, shortcomings in the safety management and operations of tugs less than 15 GT may not be addressed."Footnote 8

As a result of its analysis of past incidents, including the sinking of the tug Syringa, TC conducted a concentrated inspection campaign (CIC) targeting tugs and barges. The initial phase of the CIC took place between January and March 2017 on the west coast of Canada, and subsequent phases are under consideration in other regions.

Given the high rate of incidentsFootnote 9 involving towing vessels, in 2004, the U.S. Congress reclassified towing vessels as vessels subject to inspection. As a result, the Coast Guard developed a specific rule for towing vessels and tows that was intended to reduce these numbers. On 20 July 2016, the U.S. published new regulations that make up 46 Code of Federal Regulations (CFR), Subchapter M.Footnote 10 These regulations apply to all U.S.-registered towing vessels of 26 feet or more in length and those less than 26 feet that are moving barges carrying oil or hazardous material in bulk. The rule lays out new compliance options as well as new equipment, construction, and operational requirements for towing vessels, and establishes new requirements governing the inspection, standards, and SMSs for towing vessels.

Firefighting appliances

The Ken Mackenzie is equipped with 1 fire hose located on the port side of the main deck. There are 2 fire pumps on board. One pump is located in the engine room and is operated by engaging the power take-off from the winch engine, and a scow pump is stowed on top of the wheelhouse. The fire hose can be charged by either pump.

The vessel has 4 fire buckets and 2 fire extinguishers (one each in the wheelhouse and the engine room). Heat detectors, which are fitted in the engine room and galley, trigger an audible alarm and a visual indicator on the control panel in the wheelhouse.

The engine room ventilation system consists of 2 dampers for each trunking,Footnote 11 as well as a midship vent equipped with a forced exhaust fan.

The engine room is not equipped with a fixed firefighting system, nor was it required to be by regulation.

In a post-occurrence examination of the vessel and its equipment, the TSB noted the following unsafe conditions:

- The covers for the exhaust trunking were jammed in their storage location and were not easily accessible during the fire.

- The midship exhaust vent to the engine room had no means of being sealed.

- Heat detectors in the engine room and galley had not been tested.

Guidance concerning vessel modifications

In Canada, the Marine Machinery Regulations and the Hull Construction Regulations govern the installation and maintenance of machinery and associated piping on tugs under 15 GT.However, these regulations do not provide detailed guidance such as that contained within the Construction Standards for Small Vessels (TP 1332),Footnote 12 which applies to commercial passenger vessels and workboats, other than tugs, under 15 GT.

TP 1332 was developed for vessels constructed or operating in Canada. These standards derive their authority from the Small Vessel Regulations, made under the CSA 2001,which apply to commercial passenger vessels and workboats under 15 GT.With reference to fuel hoses, the standards specify that:Footnote 13

- shall be made from corrosion resistant material;

- shall not cut or abrade any fuel line; and

- shall be capable of resisting tensile force of 5 N without separating when tested under the fire resistance requirements for fuel systems, as set forth in ABYC Standard H-24 Gasoline Fuel Systems or ABYC Standard H-33 Diesel Fuel Systems, as applicable.

- shall be used with a hose that is designed for clamps;

- shall be at least one clamp width from the hose end;

- shall be fitted beyond the head or flare, or over the serrations of the mating spud, pipe, or hose fitting; and

- shall not depend on spring tension for compressive force.

Table 7-3. MINIMUM HOSE CLAMP Band WIDTH Outside Diameter of Hose Clamp Width Less Than 11mm (7/16 in) 6 mm (1/4 in) 11 mm to 20 mm (7/16 in to 25/32 in) 8 mm (3/8 in) Greater than 20 mm (25/32 in) 12.5 mm (1/2 in)

A vessel's AR is not required to notify TC that equipment has been installed or replaced unless major modificationsFootnote 14 are made, nor are they required to engage the services of a surveyor or the manufacturer's representative to verify that equipment is correctly installed before it is put into service.

Equipment replacement on the Ken Mackenzie

The company replaced the vessel's generator in 2009. The in-house maintenance team installed the new 11.3 kW, 240-volt single-phase generator, as well as the fuel piping that supplied diesel from the fuel manifolds to the generator.

Following the occurrence, the TSB examined the Ken Mackenzie while the vessel was secured to the dock in Port Coquitlam, British Columbia. The following observations were made:

- The fuel return line from the generator to the manifold was a combination of a 6 mm rubber fuel hose and an 8 mm copper tube. The rubber hose and the copper tube were connected by a single hose clamp. The end of the copper tube was smooth and without serrations or a bead at the end (Figure 3).

- There was no means of stopping the generator from outside the engine space in an emergency. The only way to stop the generator without entering the engine space was to shut off the fuel supply from the main deck. This would shut off the fuel supply to the entire engine room, in turn causing the main engines to shut down as well.

- The routing of cables used to operate the emergency shut-off valves in the engine room did not provide adequate shielding from heat or flames in case of a fire.

- The emergency shut-off valves for the aft fuel tank could not be operated remotely from the main deck. In this occurrence, heat from the fire in the engine room affected the cable jacket and conduit liner, causing the cable to seize within the conduit.

The Ken Mackenzie's new generator and fittings were not inspected or certified by TC or a similar authority (e.g., a classification society or a manufacturer's representative) before it was put into service. An inspection or certification is not required under current regulations for this class of vessels, nor does TC prescribe qualifications for persons conducting such installations.

Vessel safety management

The principal objective of safety management on board a vessel is to ensure safety at sea, prevent human injury or loss of life, and avoid damage to property and the environment. Safety management involves individuals at all levels of an organization and requires that a systematic approach be taken in the identification and mitigation of operational risks.

Some elements of effective safety management processes are the following:

- operating procedures for the vessel and the use of checklists

- maintenance procedures for the vessel and its associated equipment

- documentation and record keeping procedures

- procedures for identifying hazards and managing risks

- procedures to prepare for, and respond to, emergency situations

- drills, training, and familiarization for the vessel's crew

In 1998, TC implemented Safety Management Regulations under the CSA 2001 which introduced the requirements of the International Safety Management Code (ISM Code) to Canadian companies and vessels subject to the International Convention for Safety of Life at Sea (SOLAS).

In 2010, TC began formal consultations on a regulatory proposal to introduce safety management regulations to Canadian non-convention vessels. The Council of Marine Carriers entered into a pilot project with TC on the west coast, involving 5 towboat operators. This pilot project was intended to trial a domestic equivalent to the ISM Code called DSM, which would apply to non-convention vessels.

The company participated in this trial program and worked to create an integrated safety system for companies operating vessels under 500 GT. In response to stakeholders' concerns, TC amended its regulatory proposal in 2012 to include only vessels greater than 24 m in length and those carrying more than 50 passengers.

Since the completion of the pilot project, the company has continued to use DSM, so that all company operations can be carried out in the safest way possible.

Maintenance of vessel and equipment

The company DSM requires that vessels be maintained in accordance with TC regulations and manufacturers' prescribed procedures. In addition, equipment and technical systems that may result in a hazardous situation when subject to sudden operational failure must be identified. Equipment must also be inspected at regular intervals, and records of such inspections, non-conformities, and corrective actions must be maintained.

Although maintenance records for the Ken Mackenzie were available through a combination of a computerized system and physical check sheets, the issues noted with the fuel piping and its connection to the generator had not been identified.

Emergency drills

The CSA 2001 requires ARs of Canadian vessels to develop procedures for the safe operation of their vessels, and for dealing with emergencies.Footnote 15 The Marine Personnel Regulations under the CSA 2001 require that a vessel's master provide written instructions to the crew to ensure that they become familiar with safety equipment, operations, and duties. The Marine Personnel Regulations also require that ARs ensure crew members are provided with vessel-specific familiarization training.Footnote 16 With regard to fire and boat drills, the Fire and Boat Drill Regulations under the CSA 2001 require that boat and fire drills be conducted at intervals not exceeding one month;Footnote 17 however, these regulations do not apply to tugs less than 15 GT.

At the time of the occurrence, the company had procedures in place that required masters to conduct emergency drills according to a set schedule, and to report the completion of said drills to the company office by submitting a specific form called a Shipboard Safety Drill Report. Masters were also required to run through emergency scenarios such as fire in the engine room, galley, cabin, or wheelhouse each month. The company also required the vessel's lifesaving and firefighting equipment to be checked frequently. These checks included

- testing of the general alarm

- identifying the locations and operating features of all firefighting equipment

- reeling out and testing of hoses and pumps

- checking extinguishers and testing of fuel shut-offs

- closing of all engine room ventilation ducts

During its investigation, the TSB found that although the crew on board the Ken Mackenzie held informal discussions about responding to various emergencies, they did not carry out periodic fire and boat drills to simulate emergency scenarios and practise the use of lifesaving and firefighting equipment, and shipboard safety drill reports were not completed as required by the DSM.

Previous occurrences

In the past 5 years, the TSB has received reports of 2 other occurrencesFootnote 18 in British Columbia involving tugs less than 15 GT where a fire broke out in the engine room.

TSB laboratory reports

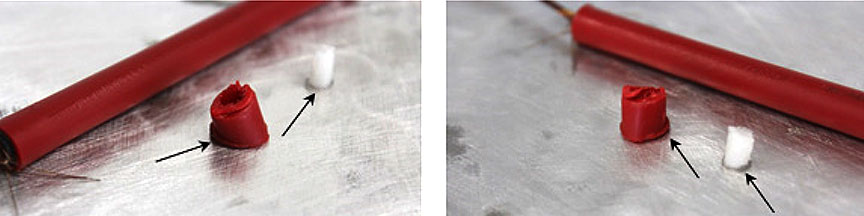

As part of the investigation, a control cable similar to that used to operate the fuel shut-off for the aft tanks on the Ken Mackenzie was sent to the TSB Engineering Laboratory for analysis. The purpose of the analysis was to determine the cable's heat rating.

The laboratory conducted a thorough examination and analysis of the cable, and TSB Engineering Report LP 287/2016 provided the following conclusions:

- Laboratory heating experiments (Figure 4 and Figure 5) show that the polyethylene materials in the control cable jacket and conduit liner started to melt above 110 °C. The jacket was destroyed after heating to about 130 °C, and the conduit liner was destroyed after heating to about 135 °C.

- Melting of the conduit liner resulted in the seizure of the core wire, and the cable became inoperable.

- The results were consistent with information provided by the manufacturer of similar control cables, which states that these cables should be protected against heat and should not be operated at sustained temperatures of 99 °C.

Analysis

This analysis will focus on the cause of the fire, vessel modifications, regulatory oversight, emergency preparedness and drills, and their contribution to the accident.

Cause of the fire

The crew detected a smell of diesel during the day. However, they were unable to find the source of the smell, and so the vessel continued its voyage along the Fraser River. The crew prepared a report but did not inform the company, in order to give personnel an opportunity to find the source and perform any necessary corrective measures.

The fuel oil piping that returned diesel fuel from the generator fuel pump to the fuel oil tank consisted of a 6 mm fuel hose and an 8 mm copper tube. The copper tube installed in 2009 was smooth and did not have serrations or a bead at the end. A single hose clamp held the copper tube and the flexible fuel hose together. The connection between the flexible fuel hose and copper tubing parted and sprayed diesel fuel onto components of the generator. The fuel on the generator components ignited, causing the fire.

Vessel modifications

Generator installation

When the new generator was installed in 2009, the return fuel line, consisting of a flexible fuel hose, was connected to a smooth copper tube using a single hose clamp, without provisions for serrations or a bead at the end of the tube to help retain the fuel hose. This resulted in the hose sliding off the copper tube, causing fuel to spray over components of the generator.

There is no guidance to authorized representatives (ARs) on the installation or replacement of machinery (such as main engines, generators, and fuel piping) on tugs with a gross tonnage (GT) of less than 15, such as that contained in the Construction Standards for Small Vessels (TP 1332) which applies to passenger vessels and workboats under 15 GT. Reference to this standard would have helped the AR ensure that best practices were followed when the generator was installed.

Vessel ARs are not required to notify Transport Canada (TC) that equipment has been installed or replaced unless major modifications are made, nor are they required to engage the services of a surveyor or the manufacturer's representative to verify that equipment has been correctly installed before it is put into service. Additionally, without requirements concerning the qualifications or certification of personnel conducting such installations, there is no mechanism to ensure that personnel are fully aware of appropriate regulations and standards.

Control cables for emergency fuel shut-off

The emergency shut-off valves for the aft fuel tanks are operated from the port side of the main deck, and consist of a plastic-sheathed control cable that connects the operating levers to the valve. The cable was a morse-type control cable typically used as a throttle or gear cable in the day-to-day operation of vessels.

Post-occurrence examination of the vessel determined that the valves were inoperative: heat from the fire in the engine room had affected the cable jacket and conduit liner, causing the cable to seize within the conduit.

Industry best practices state that only those control cables that have been designed and tested to withstand temperatures likely prevalent during an emergency (such as an engine room fire) should be used for emergency systems such as fuel shut-off and fixed-fire smothering appliances.

In addition, it was noted that the routing of cables in the engine room did not provide adequate shielding from heat/flames in case of a fire.

If components for emergency equipment and machinery are installed or replaced by personnel without adequate guidance or knowledge of industry standards, and such equipment is subsequently put into service without being inspected by a competent person, there is a risk that the installation will be unsafe.

Regulatory oversight

Effective oversight is required to ensure that vessels' ARs, including those of tugs less than 15 GT, comply with safety-critical regulations.

Unlike larger tugs, tugs less than 15 GT are not required to be certified under the current Hull Inspection Regulations or Vessel Certificates Regulations. Consequently, TC is often not aware of the mechanical condition of these tugs. Although TC has the authority to conduct random inspections of tugs less than 15 GT, these inspections are not conducted on a regular basis and normally only take place after an occurrence or incident.

As a result of its analysis of past incidents involving tugs, TC initiated a concentrated inspection campaign targeting tugs of less than 15 GT. TC also continues to work on expanding the voluntary Small Vessel Compliance Program to include tugs of this class, as a means of providing assistance to ARs as they ensure that their vessels are compliant with regulations.

Given the high rate of incidents involving towing vessels, the U.S. Congress, in 2004, reclassified towing vessels as vessels subject to inspection. As a result, the Coast Guard developed a specific rule for towing vessels and tows intended to reduce these numbers and published 46 Code of Federal Regulations(CFR) Subchapter M in June 2016 to include previously uninspected tugs of 26 feet and over in length. Regulations are now in place that will require these vessels to be inspected by the Coast Guard or another third party inspector (such as classification societies).Footnote 19

In this occurrence, the company operated under a voluntary safety management system, which required machinery to be maintained and inspected by company personnel at regular intervals, as specified in the computer-based maintenance system. Despite these checks, which are conducted internally by the company, the issues identified with respect to fuel piping went undetected.

If adequate regulatory oversight is not applied to this class of vessel, instances of unsafe equipment and operating conditions may continue to occur, putting people, assets, and the environment at risk.

Emergency preparedness and drills

Fire can spread quickly and create an emergency situation. To effectively respond to such emergencies, it is essential that firefighting appliances are maintained in good working order, and that crew are trained in the use of and have practised using firefighting equipment. Training and practice are particularly important because, in the event of a fire, there is little time to learn how to use firefighting equipment, and the stressful nature of the emergency makes it more difficult to remember the procedures or techniques to fight a fire.

Performing emergency drills on a regular basis not only provides an opportunity to ensure that firefighting equipment is in working order, but also is key to the crew becoming familiar with how to use the equipment. The more often drills are performed, the more the crucial actions needed in an emergency become reinforced, potentially saving critical seconds. Emergency drills that include realistic scenarios increase the crew's preparedness, readiness, and effectiveness.

The company recognizes the value of performing such drills, and its safety management program manual stipulates that firefighting equipment checks are to be conducted during routine emergency drills. This includes checking fire alarms, fire detectors, fire pumps, fire hoses, fuel shut-offs, and vent dampers.

However, the investigation determined that the master and other crew did not conduct emergency drills on a regular basis. In addition, shortcomings such as the seized exhaust trunking covers, as well as a lack of a means to effectively seal off the engine room, were not identified.

If emergency drills are not routinely practised or evaluated, there is a risk that inadequacies with emergency appliances will go unnoticed, and that crew will be unprepared in an emergency.

Findings

Findings as to causes and contributing factors

- Although a diesel smell, indicative of fuel leaking, had been detected in the engine room, the crew was unable to identify the source of the smell and continued to operate the vessel.

- The copper tube installed in 2009 was smooth and did not have serrations or a bead at the end. A single hose clamp held the tube and the flexible fuel hose together.

- The connection between the flexible fuel hose and copper tubing, which returned diesel fuel from the generator to the fuel tank, separated, resulting in diesel fuel spraying onto components of the generator.

- The fuel on the generator components ignited, causing a fire.

Findings as to risk

- If components for emergency equipment and machinery are installed or replaced by personnel without adequate guidance or knowledge of industry standards, and such equipment is subsequently put into service without being inspected by a competent person, there is a risk that the installation will be unsafe.

- If adequate regulatory oversight is not applied to tugs of less than 15 gross tonnage, instances of unsafe equipment and operating conditions may continue to occur, putting people, assets, and the environment at risk.

- If emergency drills are not routinely practised or evaluated, there is a risk that inadequacies with emergency equipment will go unnoticed, and that crew will be unprepared in an emergency.

Safety action

Safety action taken

Transportation Safety Board of Canada

On 02 February 2017, the Transportation Safety Board of Canada issued a Marine Safety Advisory Letter to Transport Canada (MSA 01/17) and a Marine Safety Information Letter to the owners (MSI 02/17). These letters provided information about the shortcomings concerning the polyethylene-based control cables that were used to operate the emergency shut-offs for the fuel tanks.

This report concludes the Transportation Safety Board of Canada's investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .