Loss of control and overturn on takeoff

ETA Aviation & César Camp du Nord Inc.

De Havilland Aircraft of Canada Limited DHC-2 Mk. I (Beaver), C-FYNT

St-Mathias Water Aerodrome (CSV9), Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

History of the flight

On the morning of 02 May 2025, the pilot of the float-equipped De Havilland Aircraft of Canada Limited DHC-2 Mk. I aircraft (registration C-FYNT, serial number 1054) operated by ETA Aviation & César Camp du Nord Inc. arrived at the facilities of the approved maintenance organization Aviation B.L. Inc. at the St‑Mathias Water Aerodrome (CSV9), Quebec. The pilot and the person responsible for maintenance (PRM) discussed the maintenance work that had been done on the 3 aircraft operated by ETA Aviation & César Camp du Nord Inc., which had been stored at Aviation B.L. Inc. over the winter.

The weather conditions forecast for that day were suitable for conducting a flight. The aircraft was refuelled so that there were approximately 79 imperial gallons of fuel on board.

The occurrence aircraft was placed in the water by the pilot, with the help of a passenger (who was also a pilot), and the pilot conducted a pre-flight inspection. The pilot and the passenger boarded the aircraft and taxied down the river in a northeasterly direction, buckling their safety belts and performing pre-takeoff checks, including the run-up.

At approximately 1100,All times are Eastern Daylight Time (Coordinated Universal Time minus 4 hours). the aircraft began its take-off run in a southwesterly direction to conduct a local private flight under visual flight rules. The pilot attempted to raise the right wing by rotating the control wheel to the left.Raising the right wing and float first during takeoff is common practice for seaplanes. The left wing began to lift, contrary to the pilot’s expectations. The pilot reacted by rotating the control wheel completely to the left, which only accentuated the lifting of the left wing. The aircraft then rolled to the right, the right wing touched the surface of the water, and the aircraft overturned.

The passenger unbuckled his safety belt and tried, in vain, to open the door on his side. He then managed to open the window and was able to egress through it. He received serious injuries to his right arm.

After catching his breath at the surface, the passenger went back under the water to try to help the pilot, but the water was very opaque and he had difficulty swimming due to his injury and wet clothing.

Eyewitnesses called 911. Emergency services went to the west shore. Given that no boats were immediately available, emergency services tried throwing ropes to the passenger to help him reach the shore. The passenger ultimately had to swim to the west shore on his own, where emergency services assessed him and drove him to the hospital for treatment of his injuries.

The pilot was found dead in the aircraft, with his safety belt unbuckled, when the aircraft was brought to shore later that day.

Maintenance activities before the flight

On 20 October 2024, the occurrence aircraft was brought to the approved maintenance organization’s facilities. The aircraft was then stored for the winter, during which time the annual and 300-hour routine inspections were to be performed.

The maintenance work began in February 2025, and while the work was being carried out, a crack that needed to be repaired was noticed in the control column. To perform the repair, the chain linking the control wheel to the aileron system cables had to be removed. After the repair was completed, the chain was reinstalled in mid-March 2025 by the apprentice who had worked on the aircraft and had removed the chain before performing the repair. When the chain was reinstalled, the ends did not match the aileron system cables, so the apprentice asked for assistance from another apprentice to fix the problem. The manufacturer’s procedures were not consulted for reinstalling the chain, and the work was not directly supervised by an aircraft maintenance engineer (AME).

After the control column and chain were reinstalled, the apprentice did not check the directional movement of the ailerons.

When maintenance work is completed on a flight control system, in addition to AME certification, an independent inspection must also be completed by another qualified person.AMEs who are authorized in accordance with the Aviation B.L. Inc. Maintenance Policy Manual to conduct independent inspections receive training every 3 years on how to inspect control systems. They must also demonstrate that they possess the skills and levels of knowledge required to perform the tasks referred to in the certification authority for the aircraft types maintained by Aviation B.L. Inc. The certification process and independent inspection both include verifying the assembly and its locking mechanism, as well as verifying the directional movement of the ailerons.

In this case, the work was not certified before the independent inspection. Knowing that an independent inspection had to be conducted, the apprentice who performed the maintenance work asked an AME to conduct this independent inspection.Transport Canada, SOR/96-433, Canadian Aviation Regulations, Standard 571: Maintenance, paragraph 571.10(4)(d). During the independent inspection, the AME was reportedly interrupted, and directional movement of the ailerons was not verified.

When the PRM certified all the work on 01 and 02 May 2025, the AME who had conducted the independent inspection signed the independent inspection of the flight control system with the same dates.

Weather information

The weather was favourable for this visual flight rules flight and was not considered to have contributed to the accident.

Pilot information

The pilot held the appropriate licences and ratings for the flight in accordance with existing regulations. He had approximately 11 000 total hours of flight time, almost all of which were on seaplanes. The pilot and passenger had both taken underwater egress training in the spring of 2023.

Wreckage examination

A cursory examination of the aircraft was carried out by TSB investigators when the aircraft was removed from the water. The right wing, which was torn off upon impact with the surface, was not found. The left wing aileron was still connected to the control wheel in the cockpit. The control column, which pivots so that the aircraft can be flown from the left or right seat, was positioned to fly the aircraft from the left seat. A continuity check carried out on the circuit connecting the aileron to the control wheel in the cockpit revealed that the aileron was moving in the opposite direction to what it normally would. Continuity and movement in the appropriate direction were confirmed for the other controls.

A more thorough examination of the wreckage determined that, during the recent maintenance work, the control column chain connected to the aileron system had been installed in the opposite direction to what was stipulated in the aircraft maintenance manual. Even though inspections had been carried out by the AME after the work and by the pilot before the occurrence flight, the incorrect installation went undetected, and the ailerons were moving in the opposite direction to that intended by the pilot.

Flight control maintenance

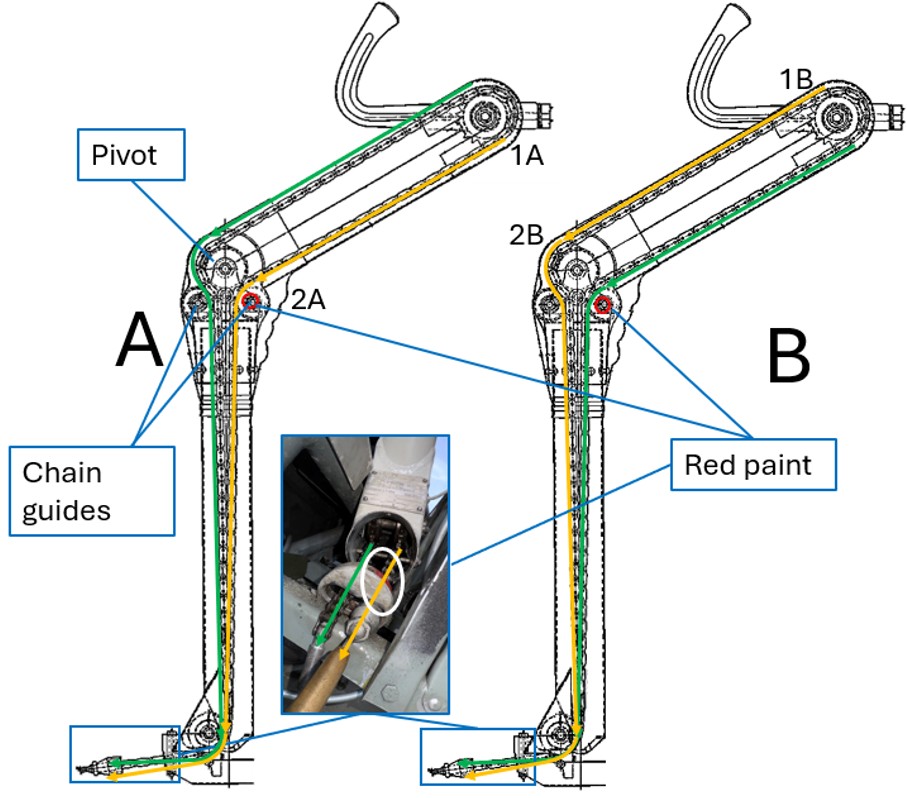

The aircraft’s control column has a chain that connects the control wheel to the aileron system cables at the base of the control column. When the chain is installed, it must first be threaded in the upper part of the control column where the control wheel is located. It is then passed down each side of the pivot, through chain guides, then down along the vertical part of the control column until it comes out beneath the floor, where each end is attached to its respective aileron system cable.

A warning in the aircraft maintenance manualDe Havilland Aircraft of Canada Limited, DHC-2 Beaver Maintenance Manual, Revision 4 (28 March 2018), section 2-41: Control Column, p. 2-37. indicates that the guide block at the base of the control column, where the chain comes out, is painted red on the side facing the front of the aircraft and the chain guide on the pilot’s side below the pivot is also painted red. Therefore, when the chain is threaded (Figure 1, from point 1A to point 2A), the end of the chain that attaches to the front cable of the aileron system must pass through these 2 red marks.

However, when the chain was threaded, the aircraft maintenance manual was not consulted. The apprentice was therefore unaware of the warning about the use of the red paint to thread the chain, and he unknowingly threaded the chain in the opposite direction (Figure 1, point 1B to point 2B).

On the occurrence aircraft, the guide block at the base of the control column had a red paint mark (Figure 2).

On the chain guide below the pivot point, grease was covering the spot that is normally painted red. When the grease was wiped off, very little red paint remained, and it flaked off easily (Figure 3). Other than the red paint marks, nothing in the design indicates the proper way to thread the chain or prevents the chain from being threaded the wrong way.

The TSB and the U.S. National Transportation Safety Board (NTSB)U.S. National Transportation Safety Board (NTSB) investigations ERA13LA229, ANC14FA050, ERA14LA015 and CEN15IA079. have previously investigated improperly connected flight controls that were not detected during aircraft maintenance and that resulted in a loss of control and collision with terrain. This occurrence is very similar to the investigation of a loss of control and collision with terrain by a Diamond Aircraft Industries GmbH DA 42 NG aircraft, which determined that that the rudder had been reversed.TSB Air Transportation Safety Investigation Report A22O0060. In that occurrence, an apprentice had performed maintenance on the flight controls without referring to the manufacturer’s procedures and with no direct supervision, and the independent inspection of the work was incomplete.

In 2001, Transport Canada issued an airworthiness notice designed to “explain the regulations applicable to the maintenance of engine and flight controls and to outline the applicable standards for control system maintenance.”Transport Canada, Airworthiness Notices – C010: Inspection of Control Systems, Edition 2 (10 October 2001), at https://tc.canada.ca/en/aviation/reference-centre/airworthiness-notices/airworthiness-notices-c010-edition-2-10-october-2001 (last accessed on 31 December 2025). Following TSB Air Transportation Safety Investigation Report A22O0060, Transport Canada stated that it intended to update this airworthiness notice.Ibid. At the time of writing the report about this occurrence (TSB Air Transportation Safety Investigation Report A25Q0051), the update was expected to be issued in 2026.

Pre-flight check

The investigation into this occurrence was unable to determine what type of pre-flight check the pilot conducted. However, before the first flight of the day, pilots are required to perform a pre-flight inspection of the aircraft. Checklists for this inspection are found in the aircraft flight manual.

For DHC-2 aircraft, the checklist includes a note to check that the flight controls are moving freely upon entering the aircraft, correctly (in the proper direction) and with full range.De Havilland Aircraft of Canada Limited, DHC-2 Beaver Airplane Flight Manual, Revision 11 (8 July 2002) Section II: Normal Procedures, paragraph 2.2 (d), p. 19.

In 2015, the NTSB issued a safety alert regarding the need to perform a thorough pre-flight check after maintenance work is carried out. This alert reminds pilots to:

- Become familiar with the normal directional movement of the flight controls […]

- […] check systems more thoroughly than the normal preflight checklist implies. […]

- Be prepared to abort the takeoff if something does not seem right.

- Avoid interruptions and distractions during the preflight inspection to ensure that you do not skip or misevaluate the items you are checking.

- If you suspect that there is a problem with a flight control or trim system , ask qualified maintenance personnel to inspect the aircraft.National Transportation Safety Board (NTSB) Safety Alert SA-041: Pilots: Perform Advanced Preflight After Maintenance (March 2015, revised in December 2015), What can pilots do?, at https://www.ntsb.gov/Advocacy/safety-alerts/Documents/SA-041.pdf (last accessed on 31 December 2025).

Underwater egress

Blocked access to regular exits, water temperature, darkness, and disorientation caused by impact with water are all factors that reduce the ability of occupants to egress from submerged aircraft. The risk of drowning for occupants of seaplanes has been raised several times in TSB investigations, leading to TSB air transportation safety recommendations A11-05 and A13-02.TSB Recommendation A11-05 (active at the time of writing this report): Emergency egress for seaplanes (issued on 17 March 2011), at tsb.gc.ca/eng/recommandations-recommendations/aviation/2011/rec-a1105.html (last accessed on 31 December 2025).,TSB Recommendation A13-02 (closed): Underwater egress training for commercial flight crews (issued on 23 October 2013), at tsb.gc.ca/eng/recommandations-recommendations/aviation/2013/rec-a1302.html (last accessed on 31 December 2025).

In this occurrence, the 2 occupants had taken underwater egress training in the spring of 2023.

Wearing a flotation device

The Canadian Aviation Regulations (CARs) require that all occupants of a commercially operated seaplane wear an inflatable flotation device when the seaplane is operated on or above water.Transport Canada, SOR/96-433, Canadian Aviation Regulations, section 703.83. The occurrence seaplane was usually operated commercially, but the occurrence flight was a private flight; therefore, the 2 occupants were not required to wear a flotation device and neither occupant was wearing one.

Considering the time it takes to perform a rescue, the chances of survival may be reduced for a person who successfully egresses a seaplane after impact with the surface of the water, but is not wearing a flotation device, especially if the person is injured. Also, given the need to egress quickly from a submerged seaplane, it is unlikely that a person will think to grab one of the flotation devices in the seaplane. Therefore, the risk of drowning is higher for occupants who are not wearing a personal flotation device at the time of impact with the water, even when they successfully egress the aircraft.

The risks associated with not wearing a personal flotation device have been raised by the TSB and have led to TSB Recommendation A11-06.TSB Recommendation A11-06 (closed): Wearing of personal flotation devices (issued on 17 March 2011), at bst.gc.ca/eng/recommandations-recommendations/aviation/2011/rec-a1106.html (last accessed on 31 December 2025).

Safety action taken

Following this occurrence, Aviation B.L. Inc. added an additional independent check when work is done on the flight controls; this check consists of confirming the directional movement of the flight controls upon technical dispatch. Training on Airworthiness Notice – C010 is now mandatory for newly hired AMEs and apprentices.

Safety messages

When maintenance work has been carried out on flight controls, it is vital that the AME who provides certification after the maintenance and the person who conducts the independent inspection check that the flight controls are properly assembled, lock properly, have a full range of motion, and are moving in the correct direction, and they need to be able to do this inspection with no distractions or interruptions. If there is any doubt, or if any anomalies are found, it is crucial that the entire inspection procedure be repeated, following the instructions, to ensure that the aircraft is safe.

Pilots play a key role in preventing in-flight incidents. Whenever maintenance work is performed on an aircraft, it is important that pilots conduct a thorough pre-flight check, particularly related to recent maintenance work, that goes further than routine checks.

Although it is essential, a pre-flight check does not guarantee that all issues will be identified on the ground. Pilots must remain vigilant to any deviations from the flight path, vibrations, or unusual responses from the flight controls. They must be mentally prepared to abort takeoff if a directional issue presents itself during the take-off run.

Wearing a personal flotation device that is properly adjusted is an important safety measure for any flight in a seaplane. If an aircraft suddenly overturns in water, the amount of time available for the occupants to react is limited, especially since the water can considerably complicate their movements and orientation. Wearing a personal flotation device from the start of the flight—rather than just keeping one at arm’s length—considerably increases the chances of survival.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 17 December 2025. It was officially released on 13 January 2026.