Loss of engine power and collision with terrain

Privately registered

Piper PA-32-260 Cherokee Six, C-GEEV

Sherbrooke Aerodrome (CYSC), Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Background

On 07 May 2024, the pilot and owner of the privately registered Piper PA-32-260 Cherokee Six aircraft (registration C-GEEV, serial number 32-1073) was informed by Handfield Aviation,Under its AMO certificate, Handfield Aviation is authorized to certify work performed on several aircraft types and models, including the Piper PA-32-260 Cherokee Six in the Aircraft, Avionics, and Structures categories. an approved maintenance organization (AMO) located at the Montréal/St-Hubert Airport (CYHU),All locations mentioned in this report are in Quebec, unless otherwise noted. that maintenance work on his aircraft was complete and he could come to retrieve it.On 02 March 2024, the owner of the occurrence aircraft had taken the aircraft to Handfield Aviation so that major modifications could be carried out, including the replacement of classic flight instruments with a screen-based avionics suite.

At approximately 1530All times are Eastern Daylight Time (Coordinated Universal Time minus 4 hours). on 09 May 2024, the pilot and a passenger (who was a flight instructor) went to CYHU to retrieve the aircraft. They performed the usual pre-flight inspection and noticed that the oil level indicator showed 8¾ U.S. quarts (U.S. qt).Oil amounts are expressed in U.S. quarts (U.S. qt). One U.S. quart is equal to 946 mL. The engine can hold 12 U.S. qt of oil. The dipstick is calibrated from 3 to 12 U.S. qt.

After fuelling the aircraft and conducting a run-up, the pilot and passenger took off from CYHU at about 1716, bound for Sherbrooke Aerodrome (CYSC).

When the aircraft reached 3000 feet above sea level, the engine oil pressure, which is usually around 75 psi, quickly dropped to 3 psi. Given that a new oil pressure sensor had been installed and that the other engine parameters and performance indicators were normal, the pilot believed there was an indication problem. The pilot decided to turn back and return to CYHU when the aircraft was 18 nautical miles from there.

The pilot contacted the AMO at 1726 to report he was returning. At that point, the pilot noticed that the engine oil pressure had fallen to 0 psi, but the other engine parameters remained normal. The aircraft landed at CYHU without incident at 1740.

When the aircraft arrived at the AMO hangar, where a team of technicians awaited, the belly of the aircraft was coated with oil up to the tail. According to information gathered, the passenger checked the dipstick and quickly read the amount of oil remaining in the engine (which was estimated to be approximately 3 U.S. qt),The minimum safe quantity of oil in the engine is 2¾ U.S. qt. (Source: Lycoming, Operator’s Manual, Lycoming, 0-540, IO-540 Series, Part No. 60297-10, 4th edition [June 2006, revised March 2009], p. 3-8A/B.) without wiping the dipstick (not having a rag), or putting it back in the engine. No other reading was carried out to confirm the quantity of oil remaining in the engine upon arrival.

The investigation was unable to determine the exact amount of oil remaining in the engine upon arrival or if the AMO had understood that the oil pressure had reached 0 psi in flight because information gathered on the matter is inconsistent.

Furthermore, the low oil pressure indication malfunctions during the flight, the oil leak observed on the ground, and the quantity of oil remaining in the engine upon arrival were not recorded in the aircraft journey log as required by existing regulations.Transport Canada, SOR/96-433, Canadian Aviation Regulations, subsection 605.94(1), Schedule I, Item 9.

AMO staff began cleaning the aircraft. They removed the flexible oil line between the engine and the oil pressure transmitter and then tested the oil line under pressure. No leaks were found. The staff then opened and inspected the oil filter; there were no signs of deficiencies or contamination. A new filter was installed and oil was added to the engine, after which an engine test was performed. All parameters were normal and there were no visible signs of a leak. The aircraft was returned to the hangar to complete the cleaning procedure, and during the cleaning a technician detected a leak in the lower line of the engine oil cooler. The 90° fitting between the flexible line and the cooler body was tightened a full turn. Another engine test was then carried out. No leaks were detected.

An AMO staff member reportedly reassured the pilot that the aircraft was working properly and invited the pilot to come back after 15 flight hours to have the oil filter and lines checked. The aircraft left the hangar at 2045 and took off again at 2057, bound for CYSC. The maintenance work carried out after the oil leak was not recorded in the aircraft journey log before the flight, as required by regulation.Ibid., subsection 605.85(1) and section 571.10. The flight proceeded without incident. The 2 occupants did not notice any abnormal indications during the flight, and there were no oil leaks upon arrival.

History of the flight

At approximately 1700 on 10 May 2024, the pilot took off from CYSC to conduct a recreational flight to St-Georges Aerodrome (CYSG), accompanied by a passenger and their 2 dogs. During the pre-flight inspection, the quantity of oil showing was 8¾ U.S. qt. The oil temperature and pressure were normal during the flight to CYSG.

The occurrence aircraft took off again from CYSG at 1811, bound for CYSC. At 1823, the pilot noticed a drop in the engine manifold pressure, then a slight loss in engine power. At that point, the engine oil temperature was 222 °F,The manufacturer recommends that the engine oil temperature should be maintained between 165 °F and 200 °F, and it should not exceed 245 °F. (Source: Lycoming, Operator’s Manual, Lycoming, 0-540, IO-540 Series, Part No. 60297-10, 4th edition [June 2006, revised March 2009], p. 3-9.) and the oil pressure was 64 psi, which is at the low end of the normal range.The normal range for engine oil pressure is between 55 psi and 95 psi (Source: Ibid.).

At 1826, when the aircraft was 31 nautical miles northwest of CYSC, the pilot noticed that the engine was continuing to slowly lose power. He descended to maintain the aircraft’s speed and proceeded to CYSC.

At 1830, the oil temperature reached 237 °F. The oil pressure was normal, but the manifold pressure continued to drop.

At 1832, the oil temperature was 247 °F. The oil pressure had moved into the yellow range below 50 psi, and the manifold pressure was dropping at 10.7 inches of mercury, which is 32% of maximum power.

At around 1837, when he had the runway at CYSC in sight, the pilot declared an emergency on the CYSC UNICOM (universal communications) frequency. At the same time, the engine seized and stopped. A piece of metal pierced through the cowling and oil sprayed onto the windscreen. The pilot broadcast a distress call. Realizing that he would be unable to reach the runway, the pilot chose to attempt a landing in a clearing west of the terminal.

The aircraft’s wheels touched down on the grassy surface approximately 70 feet from the edge of a wooded area, and the aircraft came to rest in the trees (Figure 1).

Both occupants momentarily lost consciousness. The pilot received multiple injuries and the passenger received minor injuries. Both occupants were wearing their safety belts, which consisted of lap belts only, and the belts withstood the impact. According to regulation,Transport Canada, SOR/96-433, Canadian Aviation Regulations, subsection 605.24(1). the front seats of small aircraft built before 18 July 1978 are not required to have shoulder harnesses.The pilot had purchased shoulder harnesses for C-GEEV. They were to be installed a few weeks later. The dogs were strapped in with anchoring harnesses, which gave way under the force of the impact, but the dogs were not injured. First responders arrived quickly, and the occupants were able to exit the aircraft on their own before being placed under the care of emergency services. The aircraft’s 406 MHz emergency locator transmitter activated, and the signal was received by the Joint Rescue Coordination Centre in Trenton, Ontario. There was no post-impact fire.

Pilot information

The pilot held the appropriate licence and ratings to conduct the occurrence flight and had accumulated just over 134 flight hours.

Weather information

The weather conditions between CYSG and CYSC were suitable for a visual flight rules flight.

Aircraft information

The Piper PA32-260 Cherokee Six is a low-wing, light aircraft with a metal structure and fixed landing gear.

The occurrence aircraft was manufactured in the United States in 1968 by the Piper Aircraft Corporation. It was imported from the United States into Canada in 2024. When it was imported, and at the time of the occurrence, it was equipped with an O-540-E4B5 engineSerial number L-10618-40. manufactured by Lycoming Engines, which is a normally aspirated, direct-drive, horizontally opposed, 6-cylinder, air-cooled 260 hp engine, equipped with a carburetor, an external oil cooler, and a variable pitch, constant-speed, metal 2-blade Hartzell propeller.

At the time of the occurrence, the aircraft had accumulated 10 242.5 total flight time hours. The total recorded engine operation hours were 8089.3, of which 540.3 hours were since its last overhaul.

The last scheduled maintenance was performed on 16 January 2024 at 10 218.7 flight time hours, when the aircraft was imported. At that time, a 100-hour inspectionIn accordance with appendices B and C of Canadian Aviation Regulations Standard 625 as well as the manufacturer’s recommendations. was carried out. Following this inspection, the No. 2 cylinder had been refurbished and then reinstalled.

Wreckage examination

When TSB investigators arrived at the accident site, the aircraft was lying on its right side. The wings had been torn off by the impact with the trees.

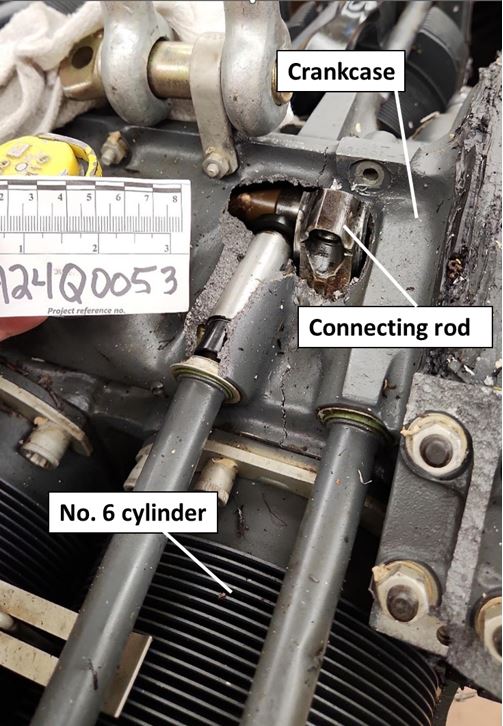

The left engine cowlings were damaged, exposing the engine, which had seized. A hole caused by the connecting rod was visible in the crankcase (or engine block) at the base of the No. 6 cylinder. A tear from the nose to the tail could be seen on the belly of the fuselage on the pilot’s side. The propeller blades were bent backwards, and the damage was consistent with a propeller that was not turning at the time of impact.

The engine and avionic instruments were removed and sent to the TSB Engineering Laboratory in Ottawa, Ontario, for examination.

Engine examination

The engine was completely disassembled on 27 August 2024 at the TSB laboratory. No anomalies were found when the following systems were examined:

- ignition system, magnetos, coils, and wires, including the spark plugs;

- fuel system;

- intake system, including the carburetor;

- exhaust system;

- accessory gearbox.

Lubrication system

The lubrication system was examined during the engine teardown.

The oil pump, which is part of the accessory gearbox, was disassembled and inspected. Scoring and small indentations were found on the crankcase adjacent to the pump gears. The oil filter adapter, the filter, the thermostatic oil cooler bypass valve, and part of the adapter had broken off the accessory gearbox during the impact sequence.

The lubrication system showed no signs of blockage and the oil outlets around the crankshaft were free of debris.

Cylinders Nos. 1 to 4 were removed and inspected. They showed signs of normal wear.

The No. 5 cylinder had been damaged by internal debris that had detached from the No. 6 cylinder. Heat signatures and scoring were observed on the connecting rod bearings.

The No. 6 cylinder was removed and inspected. The connecting rod was bent downward and had punched through the casing of the upper portion of the crankcase at the base of the No. 6 cylinder (Figure 2).

The No. 6 connecting rod cap was found at the bottom of the oil sump, in 2 separate pieces. An examination of the fractured surface of 1 of the 2 connecting rod cap bolts under a microscope revealed signs of ductile overload failure.Ductile overload is the failure mechanism that occurs when a material is loaded beyond its ultimate tensile strength.

The observations below resulted from an inspection of the crankshaft, camshaft, crankcase, and associated components:

- The crankshaft rod bearings showed increasing heat signatures and scoring from the No. 1 cylinder up to the No. 6 cylinder (Figure 3).

- The crankshaft main bearings showed varying degrees of overheating.

- The camshaft had impact damage near the Nos. 5 and 6 cylinders.

- The crankcase showed varying degrees of damage from being struck by pieces of the No. 6 cylinder assembly as they broke off.

- The engine starter ring gear was sheared and split in 2 separate parts.

The progression of the heat signatures, the increasing scoring marks, and the damage to cylinders Nos. 1 through 6 are consistent with oil starvation.

Technical publications

A “mandatory”“In states where the civil aviation authorities issue ADs [airworthiness directives] separately from the applicable service bulletins, aeronautical product manufacturers occasionally mark their service bulletins ’mandatory’. Such categorization simply indicates the manufacturer's opinion of the importance of the bulletin and has, by itself, no regulatory obligation, even if the bulletins are shown to be approved by those authorities.” (Source: Transport Canada, Canadian Aviation Regulations, Standard 625, Appendix H.) service bulletin published in 2010 by Lycoming (Mandatory Service Bulletin No. 399A), which applied to all Lycoming engines, states that “[i]f the oil pressure indication system is functioning correctly and oil pressure loss/oil starvation has been confirmed, remove and disassemble the engine and perform a complete inspection”Lycoming, Mandatory Service Bulletin No. 399A: Action to Take If Loss of Oil Pressure (09 July 2010), p. 1. because “it is difficult to predict the extent of damage to the engine or assure its future reliability.”Ibid., p. 2. The AMO did not perform a complete engine inspection after the aircraft returned to CYHU. The investigation determined that neither the occurrence aircraft owner nor the AMO knew about the mandatory service bulletin when the oil leak was discovered.

Owner’s handbook procedures

The current version of the Piper PA32-260 Cherokee Six owner’s handbook stipulates the following: “A complete loss of oil pressure indication may signify oil exhaustion or may be the result of a faulty gauge. In either case, proceed toward the nearest airport, and be prepared for a forced landing.”Piper Aircraft Corporation, Cherokee Six PA-32-260 Applicable to Serial Numbers 32-1 through 32-1075 Owner’s Handbook (Revised May 1973), Section IV: Emergency Procedures, Loss of Oil Pressure, p. 32.

During the flight that resulted in the pilot returning to CYHU on 09 May 2024, the pilot did not have the up-to-date version of the owner’s handbook.The version of the Piper Aircraft Corporation’s Cherokee Six Owner’s Handbook that the pilot had on board had been revised in 1966. The investigation determined that a newer revised version had been published in 1973. The version the pilot had did not include this procedure. Believing that there was an indication error, the pilot did not consider the option of landing at a closer aerodrome.

TSB laboratory reports

The TSB completed the following laboratory reports in support of this investigation:

- LP077/2024 – Lycoming O-540-E4B5 Engine Teardown

- LP082/2024 – NVM [non-volatile memory] Recovery - Various

Safety messages

Maintenance staff and aircraft owners should be familiar with, review, and apply, as necessary, all relevant maintenance instructions published by aeronautical product manufacturers even if their implementation is not always required by Transport Canada.

Although aircraft built before 18 July 1978 are not required to be equipped with shoulder harnesses, it is advised that they be equipped with harnesses to reduce injuries in the event of an accident.

It is important that pilots have the current versions of manuals and procedures available so that they can refer to the emergency procedures in effect.

It is important that all deficiencies discovered and all maintenance work carried out be recorded in the aircraft journey log before the next flight to avoid any ambiguity about the nature and the extent of deficiencies as well as to document that the work performed is in compliance with the applicable standards of airworthiness.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on 22 May 2025. It was officially released on 28 May 2025.