Runway excursion on takeoff and in-flight fuel imbalance resulting in diversion

Jazz Aviation LP

Mitsubishi Heavy Industries, Ltd. CL-600-2D24 (Regional Jet Series 900), C-GJZV

San Diego International Airport, California, United States

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Executive summary

On 29 November 2021, the Mitsubishi Heavy Industries, Ltd. CL-600-2D24 aircraft (Regional Jet Series 900) (registration C-GJZV, serial number 15424) operated by Jazz Aviation LP was conducting flight JZA767 from San Diego International Airport, California, United States, to Vancouver International Airport, British Columbia, with 2 flight crew members, 2 cabin crew members, and 69 passengers on board. At about 1842 Pacific Standard Time, during the hours of darkness, the aircraft took off to the left of the centreline on Runway 27, and the left main landing gear wheels contacted 3 runway edge lights before the aircraft's trajectory was corrected towards the runway centreline.

While the aircraft climbed, the flight crew detected a fuel imbalance that they were unable to correct, so they shut down the right engine and declared an emergency. The aircraft diverted to Los Angeles International Airport, California, United States, where it landed and stopped on the runway at approximately 1946. Passengers disembarked and were transported to the terminal. None of the passengers or crew members were injured. Emergency personnel reported that 1 of the left main landing gear tires was deflated and that smoke was coming from the wheel. The aircraft’s No. 1 tire sidewall was later found to have been damaged, and the aircraft’s left flap had sustained 2 punctures.

In this occurrence, the misaligned takeoff and the fuel imbalance were 2 separate and unrelated events, and the investigation treated them as such.

To determine the factors that contributed to the aircraft’s misalignment on the runway, the investigation examined the visibility conditions in which the aircraft took off from San Diego International Airport. From pushback to takeoff, the aircraft was operating at night and in fog, in an area where visibility was between ¼ statute mile and ½ statute mile and deteriorating. As a result, there were few visual cues available to the flight crew to identify and verify the aircraft’s position on Runway 27. One of these cues was the portion of the lead-on taxiway centreline marking that was visible in front of the aircraft; however, when taxiing to position on the runway, the captain taxied the aircraft off the taxiway centreline marking in order to increase the runway distance available for takeoff. In doing so, he had even fewer visual cues on which to rely to determine the aircraft’s position on the runway. When the aircraft subsequently turned left to establish the runway heading in preparation for takeoff, the captain perceived the left runway edge marking as the runway centreline. The limited and ambiguous visual cues that were available likely met the captain’s expectations and, as a result, the aircraft was aligned laterally with the left edge, rather than with the centre of the runway.

Runway 27 had a displaced threshold, and the investigation compared the visual environment of a displaced threshold area with that of a runway threshold. It was found that if flight crews line up on runways in the area before the displaced threshold or conduct intersection departures, both under degraded or nighttime visual conditions and without confirming the aircraft's lateral position on the runway, there is an increased risk of runway misalignments or runway side excursions. This is because displaced threshold areas and runway-taxiway intersections do not have runway threshold markings or runway numbers, 2 distinctive features that allow flight crews to define the width—and therefore, the centreline—of the runway.

The nature of operations at the occurrence airport was also considered. San Diego International Airport, one of the busiest single-runway commercial service airports in the world, has a high volume of arrivals and departures that occur in very quick succession, producing a cadence that flight crews must follow. It was found that the complexity of instrument flight rules operations on a single runway surface, with arrivals on one end and departures from the other end, created an environment in which the flight crew perceived a time pressure for the takeoff. As a result, the first officer was completing the line-up checks while the captain taxied to position, and the first officer therefore did not monitor the progress of the taxi. Due to the reduced number and quality of visual cues and the perceived time pressure felt by the first officer, he did not recognize that the aircraft’s nose was aligned with the left edge of the runway when he assumed the role of pilot flying shortly before the take-off roll commenced.

The investigation determined that shortly afterwards, during the take-off roll, the aircraft’s left main landing gear wheels contacted and severed 3 runway edge lights, causing damage to the aircraft’s tires and flaps. However, this contact was not recognized by the flight crew because they perceived the sounds and vibrations as normal contact with the embedded runway centreline lights, and consequently, they continued with the departure. This aspect of the occurrence revealed a particular safety risk to other aircraft. Owing to the fact that the airport is not equipped with a foreign object debris detection system, the debris was not discovered by the airport operator or controllers until several hours after the misaligned takeoff. If foreign object debris on runways is not detected and identified in a timely manner, there is a risk that it will result in aircraft damage during critical phases of flight.

The investigation also examined the causes of the fuel imbalance during the occurrence. It is likely that, during the completion of either the before-takeoff or after-takeoff checklists, the flight crew inadvertently pressed the gravity crossflow push-button switch instead of the co-located crossflow auto override push-button switch. As a result, during the flight, fuel periodically transferred between the aircraft’s wing tanks by gravity when the aircraft was banked left or right, leading to a worsening fuel imbalance condition.

The guidance provided to flight crews by the air operator, Jazz Aviation LP, and the manufacturer, the Mitsubishi Heavy Industries Regional Jet Aviation Group, to address fuel imbalances was found to be unclear and inconsistent. When the wording in a checklist is ambiguous or unclear, or when the wording in an operator’s checklist differs from that in the checklist provided by the manufacturer, a flight crew may, in an effort to correct an abnormal or emergency condition, conduct procedures in ways not intended by the manufacturer, increasing the risk of entering into an undesired aircraft state. With the auto pilot on, the aircraft was unintentionally placed in a sideslip toward the wing tank with the greater quantity of fuel, and this opposite bank was not recognized by the flight crew. As a result, the lateral fuel imbalance was not controlled, and continued to increase. The fuel imbalance, which was unrelated to the damage sustained during the take-off roll, led the crew to declare an emergency and divert to a nearby airport for an emergency landing. Furthermore, the aircraft checklists did not require the flight crew to close the gravity crossflow valve following the attempted Gravity Crossfeed Procedure. As a result, the open valve occasionally made the fuel imbalance worse during the subsequent manoeuvring and was at one point more than 3 times the maximum permissible.

Following the occurrence, Jazz Aviation LP included additional warnings in its airport charts to highlight the risks of departing from within displaced threshold areas. For example, the San Diego International Airport charts now include a departure consideration informing flight crews of the threat of incorrect runway verification in reduced visibility and prescribes additional measures that should be used to verify the runway and the aircraft’s alignment with the centreline. Jazz Aviation LP also issued a company memo regarding departures from displaced threshold areas. In addition, the air operator revised its line-up check procedure as well as its Gravity Crossfeed Procedure, which now contain more guidance on initiating a sideslip.

1.0 Factual information

The National Transportation Safety Board (NTSB) of the United States (U.S.) delegated the investigation of this occurrence to the TSB in accordance with International Civil Aviation Organization (ICAO) Annex 13.Footnote 1

1.1 History of the flight

On 29 November 2021, the occurrence flight crew were scheduled to fly from Vancouver International Airport (CYVR), British Columbia (BC), to San Diego International Airport (KSAN), California, U.S., and back on the occurrence aircraft, the Mitsubishi Heavy Industries, Ltd. (MHI) CL-600-2D24 (Regional Jet Series 900) aircraft, which was being operated by Jazz Aviation LP (Jazz). At 1706,Footnote 2 the aircraft arrived at KSAN as flight JZA766. Directly after this inbound flight, the crew, which consisted of 2 flight crew members and 2 cabin crew members, began to prepare for the return flight (instrument flight rules flight JZA767) on the same aircraft.

At 1758, after 69 passengers had boarded and the aircraft had been loaded with more fuel (to a total of approximately 17 700 poundsFootnote 3), the flight crew started the right engine while the aircraft was still parked at the gate. The aircraft pushed back from the gate at 1803. The left engine was started, and at 1809, the captain taxied the aircraft on Taxiway B for departure from Runway 27. At this time, 6 other aircraft were ahead of the occurrence aircraft awaiting departure from Runway 27, and an additional 9 aircraft were inbound to KSAN and would be landing in the opposite direction, on Runway 09.

Due to an anticipated delay in reaching the runway for takeoff, a number of aircraft, including the occurrence aircraft, shut down 1 engine during their taxi to the runway to conserve fuel. The flight crew shut down the occurrence aircraft’s left engine at 1822.

At approximately 1830, the KSAN air traffic control (ATC) tower controller informed the next 3 aircraft in line (which included the occurrence aircraft) that their departure would begin in approximately 5 minutes. Two minutes after this notification, the flight crew of the occurrence aircraft restarted the left engine using Jazz’s cross-bleed engine start procedure, completed the after-start checklist, and then began the before-takeoff checklist.

At 1841:16, the occurrence aircraft was given clearance to line up and wait on Runway 27. The captain initially taxied the aircraft along the taxiway centreline across the runway holding position marking, but then continued straight ahead, diverging to the right of the taxiway centreline until reaching the runway edge (Figure 1). During this time, the first officer was completing the before-takeoff and line-up checks and checklists. By 1841:46, the aircraft had turned onto the runway but was aligned with the left runway edge, unbeknownst to the flight crew. At 1841:53, the first officer read back the ATC take-off clearance and was then given control of the aircraft from the captain. The first officer assumed the role of pilot flying (PF), and the captain took on the role of pilot monitoring (PM). At 1841:59, the PF advanced the aircraft power levers and began the take-off roll approximately 1500 feet before the displaced threshold of Runway 27.

During the take-off roll, the wheels on the aircraft’s left main landing gear struck and damaged 3 consecutive runway edge lights. The flight crew heard sounds and felt vibrations, but they thought they were rolling over embedded runway centreline lights and were thus unaware of the contact with the runway edge lights. Around this time, the PF visually identified the misalignment with the runway and began to correct toward the runway centreline. As the aircraft crossed the runway’s displaced threshold, its lateral position on the runway had moved approximately 40 feet to the right (closer to the runway centreline). When the aircraft began to rotate, approximately 4650 feet from the point at which it had begun the take-off roll, it remained about 40 feet to the left of the runway centreline. At no point did the aircraft reach the centreline.

Following the takeoff, the aircraft climbed normally. Approximately 1 minute after takeoff, while climbing through 2500 feet above sea level (ASL), the PM set climb power.

About 3 minutes after departure, as the aircraft climbed through approximately 6500 feet ASL, the flight crew were presented with a “XFLOW PUMP” caution message on the aircraft’s engine indication and crew alerting system (EICAS). The PM then actioned the XFLOW PUMP Caution Message procedure in the aircraft’s quick reference handbook (QRH).Footnote 4 The procedure’s checklist instructs the flight crew to determine whether a lateral fuel imbalance between the left- and right-wing fuel tanks exists. The flight crew did not identify a significant imbalance so, as instructed by the checklist, they continued to monitor for an imbalance periodically as the aircraft continued to climb.

As the aircraft climbed through flight level (FL) 310, approximately 17 minutes after the “XFLOW PUMP” caution message had been displayed, the quantity of fuel in the left-wing tank began to increase while the quantity in the right-wing tank decreased. At this time, although not evident to the flight crew, fuel was transferring at a rate in excess of 5000 pounds per hour (lb/h). Shortly afterwards, the flight crew recognized this increasing imbalance and levelled out the aircraft at a cruising altitude of FL340. While the lateral fuel imbalance continued to increase, the flight crew attempted to use additional thrust on the left engine and less on the right engine to balance the fuel in the tanks.

Approximately 25 minutes after the initial “XFLOW PUMP” caution message had appeared, the fuel imbalance exceeded 800 pounds—the maximum permissible in-flight imbalance as specified by the manufacturer—and a subsequent “FUEL IMBALANCE” caution message activated on the EICAS display. This caution message has its own procedure outlined in the QRH.Footnote 5 The first step is to verify that the automatic crossflow is operating; however, the appearance of the “XFLOW PUMP” caution message indicated that it was not. So, the PM again completed the XFLOW PUMP Caution Message procedure checklist which, in the case of a fuel imbalance condition, instructs the flight crew to proceed to the Gravity Crossfeed Procedure.

Performing the QRH’s Gravity Crossfeed Procedure includes placing the aircraft in a sideslip condition.Footnote 6Footnote 7 The PF applied right rudder pressure for the next 4 minutes (approximately), leading to a sideslip, while continuing to fly the aircraft on autopilot. During this procedure, the flight attendants experienced a left-wing-down motion and communicated with the flight crew to inquire about the abnormal flight attitude. In addition, the quantity of fuel in the left-wing tank continued to increase until the tank was full, while the quantity of fuel in the right-wing tank continued to decrease.

The QRH’s Gravity Crossfeed Procedure concludes that if a fuel imbalance persists and cannot be controlled within limits, the engine fuelled by the tank containing the lower fuel quantity must be shut down. The flight crew requested a diversion to Los Angeles International Airport (KLAX), California, U.S., approximately 112 nautical miles (NM) away, and were instructer to turn left to begin the arrival procedure. During the left turn, the flight crew carried out the precautionary engine shutdown of the right engine. The PF continued to fly the aircraft, while the PM’s duties for the minutes that followed included the coordination with ATC and Jazz dispatch for the diversion, the notification of the flight’s cabin crew and passengers, and the planning and programming of the flight management computers for the arrival and approach. At this point, the imbalance had reached approximately 1700 pounds, with the greater amount in the left tank.

The flight crew declared a MAYDAY with ATC, and as the flight proceeded toward KLAX, the fuel imbalance continued to worsen, reaching a maximum recorded valueFootnote 8 of 2464 pounds. Approximately 11 minutes before landing, fuel began to transfer back into the right-wing tank without any prompting or action from the flight crew. The fuel transfer continued for approximately 7 minutes, reducing the imbalance to approximately 1120 pounds.

Approximately 3 minutes before landing, following the aircraft’s right turn onto the final approach course to KLAX, the aircraft was level, and fuel began transferring into the left-wing tank again. At the time of landing (approximately 1946), the fuel was recorded at 1568 pounds out of balance, with the higher fuel level in the left tank.

The flight crew brought the aircraft to a stop on the runway, where KLAX aircraft rescue and fire fighting services personnel found that the No. 1 tire from the left main landing gear was flat and reported the presence of smoke coming from the left main landing gear wheel. Water was sprayed on the wheels and the smoke dissipated.

All passengers and crew members deplaned via the airstairs onto the runway and were transported to the passenger terminal. The aircraft was towed to a maintenance hangar.

1.2 Injuries to persons

There were no injuries to passengers or crew members.

1.3 Damage to aircraft

After the aircraft had landed at KLAX, damage to the left tire on the left main landing gear was immediately noted by the attending emergency crews. This tire was flat and its outside sidewall was torn. Upon closer inspection of the aircraft by the emergency crews and aircraft flight crew, 2 puncture holes through the lower skin of the left-wing inboard flap were discovered.

Contract maintenance personnel replaced the left main landing gear wheels to allow the aircraft to be towed from the runway. Jazz maintenance personnel conducted functional and operational checks of the landing gear, and no further faults were found.

Following the occurrence, Jazz maintenance personnel noted no obvious indications of a fuel leak and validated the computer indications of fuel quantity by manually measuring the fuel quantity in each tank, which was later supported by data from the aircraft’s flight data recorder (FDR).

As part of the examination of the fuel system, Jazz maintenance personnel inspected the maintenance diagnostic computer and found, while running an aircraft history operational check of the fuel quantity gauging computer (FQGC), that an internal fault code, B1-006805, had been recorded. The FQGC was replaced and an operational check was completed with no fault found. The occurrence FQGC was sent to the manufacturer for further analysis, but it was determined to have no system faults in its hardware. Jazz maintenance personnel found no other indications of mechanical faults in either the crossflow pump or gravity crossflow valve, and there was no record of reoccurrence subsequent to the occurrence flight.

On 04 December 2021, the occurrence aircraft was flown to Jazz’s maintenance base at Calgary International Airport (CYYC), Alberta, under a ferry permit. The puncture holes in the left-wing inboard flap were repaired per a repair engineering order by the manufacturer.

The aircraft was returned to service on 09 December 2021.

1.4 Other damage

Since the flight crew, at the time of the occurrence, were unaware of the aircraft’s contact with the runway edge lights, they did not communicate with ATC to report a possible contact.

The runway edge light debris was found at 0228 on 30 November 2021 by a member of the airport operations ground crew conducting a routine nightly inspection. Airport electricians immediately replaced the 3 damaged lights.

There was no indication of any negative impact on airport operations from the time the lights were damaged until the time they were discovered, a period of 7 hours and 46 minutes.

1.5 Personnel information

| Captain | First officer | |

|---|---|---|

| Pilot licence | Airline transport pilot licence | Airline transport pilot licence |

| Medical expiry date | 01 May 2022 | 31 August 2022 |

| Total flying hours | 24 826 | 20 213 |

| Flight hours on type | 11 517 | 7157 |

| Flight hours in the 7 days before the occurrence | 22 | 16 |

| Flight hours in the 30 days before the occurrence | 48 | 55 |

| Flight hours in the 90 days before the occurrence | 162 | 202 |

| Flight hours on type in the 90 days before the occurrence | 162 | 202 |

| Hours on duty before the occurrence | 6 | 6 |

| Hours off duty before the work period | 120 | 49 |

The flight crew held the appropriate licences and met the recency requirements for the flight in accordance with existing regulations. Both pilots had been employed with Jazz for a number of years and had flown together numerous times. They had also both flown the CYVR-KSAN route regularly, sometimes together as a flight crew.

1.6 Aircraft information

| Manufacturer | Bombardier Inc.* |

|---|---|

| Type, model, and registration | CL-600-2D24, Regional Jet Series 900, C-GJZV |

| Year of manufacture | 2016 |

| Serial number | 15424 |

| Certificate of airworthiness/flight permit issue date | 30 November 2016 |

| Total airframe time | 11 227.4 hours |

| Engine type (number of engines) | General Electric CF34-8C5 (2) |

| Maximum allowable take-off weight | 38 329 kg (84 500 lbs) |

| Recommended fuel types | Jet A, Jet A-1, Jet B |

| Fuel type used | Jet A |

* Effective 01 June 2020, the aircraft type certificate was transferred to Mitsubishi Heavy Industries, Ltd.

1.6.1 General

The Regional Jet Series 900, originally developed by Bombardier Inc. and approved by Transport Canada (TC) in 2002, is a lengthened version of the Series 700 aircraft. The Series 900 can seat 76 to 90 passengers; the 35 aircraft owned by Jazz are configured for 76. There have been 487 Series 900 aircraft delivered to 24 different air operators worldwide.

1.6.2 Recent aircraft maintenance work

During the period between 26 November and the time of the occurrence, due to an unserviceable auxiliary power unit (APU), the aircraft was being operated under the restrictions of the aircraft’s Minimum Equipment List (MEL).Footnote 9 The APU provides electrical power to the aircraft when its engines are not operating and provides a source of compressed air (from the APU bleed air) for the starting of the aircraft’s 2 engines. Since the APU had become unserviceable, flight crews on the aircraft had been starting 1 engine through use of an air start unit while parked at the airport gates. The aircraft would then be pushed back from the gate, and the other engine would be started by performing a cross-bleed start procedure (in which the bleed air from the running engine, rather than from the APU, is used). This process takes a few minutes longer than a start-up procedure that uses the APU, but it is a routine procedure at Jazz that is detailed in the company’s standard operating procedures (SOPs).

1.6.3 Fuel system

The Regional Jet Series 900 fuel system (also common to the Series 700 and 1000 aircraft) consists of 3 integral tanks within the wing box structure: a tank in each of the wings and a centre tank (Figure 2). Fuel is able to be transferred between wing tanks by either a powered (electrically pumped) or gravity crossflow system. An FQGC measures the fuel quantity and temperature; however, slight variations in fuel quantity readings can exist due to changes in aircraft attitude. The FQGC also automatically controls fuel transfer between the wing tanks, as well as fuel transfers from the centre tank to the wing tanks via the left and right transfer ejectors. The EICAS in the cockpit shows a diagram of the fuel distribution system, and any fault detected by the FQGC is announced in the form of a visual message.

1.6.3.1 Transfer ejectors

Fuel transfer from the centre tank to the wing tanks is provided by transfer ejectors (labelled as XFER EJECT in Figure 2). The ejectors are not electrically operated pumps, but rather are powered only by fuel pressure tapped from the engine supply lines. The FQGC commands the transfer ejector shut-off valves to open when the associated wing tank fuel quantity falls to 93%, or approximately 7000 pounds, and commands them to close when the fuel quantity reaches 97%, or approximately 7200 pounds. The FQGC will continue cycling the transfer system on and off until the centre tank is empty.

1.6.3.2 Fuel crossflow system

Powered or gravity fuel crossflow allows fuel transfer between the wing tanks to correct fuel imbalances and to maintain lateral stability. Flight crews can control crossflow operations through the fuel control panel (Figure 3) located on the cockpit’s overhead panel. The positions of the switches on the fuel control panel are not recorded on the aircraft’s FDR.

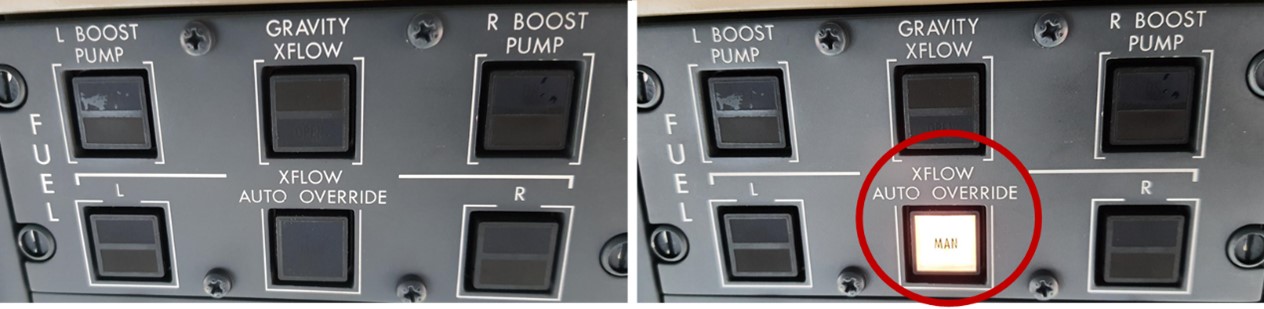

The switches are single-actuation push-button switches. Both the L and R BOOST PUMPs as well as the L and R XFLOW switches are in the off position when pressed out. Similarly, the GRAVITY XFLOW is closed when the switch is in the pressed-out position. When pressed in and lit up with white light, these switches are ON or, in the case of the GRAVITY XFLOW switch, OPEN. The XFLOW AUTO OVERRIDE switch, which is labelled as “MAN” and controls the FQGC mode, is in automatic (AUTO) mode when pressed out and manual (MAN) mode when pressed in and lit up.

The crossflow pump (XFLOW PUMP in Figure 2) provides powered crossflow operations in either automatic mode (when the XFLOW AUTO OVERRIDE push-button switch is in the OUT position) or manual mode (when the switch is in the IN position). In automatic mode, the FQGC controls the powered crossflow. When the FQGC detects a lateral imbalance of greater than 200 pounds for more than 30 seconds, the crossflow pump is activated automatically in the required direction to correct the imbalance. Also, in automatic mode, the FQGC actively monitors the position and operational status of the crossflow pump through a pair of Hall effect sensors.Footnote 10 These sensors create a feedback loop with the FQGC to sense the direction in which the fuel is transferring.

Conversely, a flight crew can control powered crossflow in manual mode by overriding automatic mode. In manual mode, the flight crew controls the flow by first pressing the XFLOW AUTO OVERRIDE switch and then selecting the direction of fuel through the crossflow pump by pressing either the L XFLOW or the R XFLOW switch. If XFLOW AUTO OVERRIDE is selected and neither L XFLOW or R XFLOW is selected, the auto transfer system is overridden, and powered crossflow does not occur.

According to Mitsubishi Heavy Industries Regional Jet Aviation Group (MHI RJ), the crossflow pump is able to transfer fuel at a rate of approximately 1700 to 2500 lb/h (approximately 28 to 42 lb/min), depending on fuel temperature and density.

In addition to the crossflow pump, all series of the Regional Jet have a gravity crossflow system that serves as a backup to powered fuel transfer. If the powered crossflow system fails, the flight crew can open the gravity crossflow shut-off valve (which connects the left- and right-wing fuel tanks) and allow fuel transfer by gravity between the tanks by pressing the GRAVITY XFLOW push-button switch on the overhead fuel control panel in the aircraft’s cockpit. The switch and the valve it controls have no connection with the FQGC, and similarly, no connection with the crossflow pump or its corresponding switch. The EICAS will display a GRAV XFLOW FAIL message when the gravity crossflow shut-off valve is not in the selected position. The flight crew did not report the message being displayed during the occurrence flight.

The design requirement of the aircraft’s gravity crossflow system establishes a transfer flow rate of at least 8000 lb/h (130 lb/min). When the system was in development, performance testing of the aircraft demonstrated that the system’s average transfer flow rate was 3000 lb/h (50 lb/min) when on the ground with 0° roll angle and the engines at idle. In-flight performance checking demonstrated that a 5° sideslip angle resulted in a transfer rate of 19 200 lb/h (320 lb/min), and a 10° sideslip angle resulted in a transfer rate of 24 000 lb/h (400 lb/min). While these are the demonstrated performance abilities of the aircraft, actual flow rates are a function of:

- a difference of fuel head pressure between both main (wing) fuel tanks due to a fuel imbalance and/or the roll angle;

- the aircraft’s lateral acceleration; and

- friction loss from the installation of the fuel tubes.

During the investigation, MHI RJ noted that a failure analysis conducted while the system was being tested had demonstrated that the gravity transfer flow rate is able to reduce the imbalance significantly in the situation of an inoperative crossflow pump. The transfer rate, as described in the MHI RJ QRH Gravity Cross-feed Procedure,Footnote 11 will be up to 100 lb/min.

1.7 Meteorological information

During the flight crew’s inbound flight to KSAN and while they were on the ground there, the weather at the occurrence flight’s destination, CYVR, as well as at the alternate airport, Calgary International Airport (CYYC), Alberta, remained favourable to visual flight conditions.

The aircraft, on its inbound flight, landed at KSAN at 1703. At that time, the most recent aerodrome routine meteorological report (METAR)Footnote 12 at the airport indicated that the weather consisted of winds from 310° true (T) at 4 knots, visibility of 10 statute miles (SM), and few clouds at 200 feet above ground level (AGL).

Sunset at the airport occurred at 1642; the inbound flight therefore arrived during evening civil twilight.Footnote 13 At 1803, during the hours of darkness, the aircraft pushed back from the terminal gate to begin the taxi for takeoff on the occurrence flight.

While the flight crew prepared for the occurrence flight to CYVR, weather conditions at KSAN deteriorated due to an advancing fog bank. At 1749, the METAR for KSAN indicated calm winds, a visibility of 3 SM, mist, and a broken ceiling at 200 feet AGL. While the prevailing visibility was 3 SM, the observed visibility around the ATC tower was variable and ranged from ¾ SM to the west and southwest, up to 4 SM to the northeast and southeast.

At approximately 1842, when the aircraft departed on the occurrence flight, the weather conditions were continuing to deteriorate. The most recent METAR, which was issued at 1835 and broadcasted on the airport’s automatic terminal information service (ATIS) frequency, indicated:

- winds from 300°T at 4 knots

- prevailing visibility of ½ SM (with an observed visibility of 2 SM toward the northeast and east and ¼SM toward the south and west)

- Runway 09 runway visual range (RVR) 1200 feet variable to 2000 feet

- fog

- broken ceiling at 200 feet AGL

Given the weather observation, the visibility conditions at various parts of the airport were highly variable during the aircraft’s take-off roll. While the visibility at the western end of the runway had been degraded to about ¼ SM, visibility at the eastern end, where the aircraft began its takeoff, was degraded but not as low (at least ½ SM). At the time of takeoff, the flight crew did not have a clear view of the end of the runway or the airport’s buildings.

Due to the in-flight fuel imbalance event, the aircraft diverted to KLAX. The METARs published there during the diversion and landing all indicated clear skies, light winds, and a visibility of 10 SM.

1.8 Aids to navigation

KSAN is serviced by multiple approaches to both Runway 09 and Runway 27. Each of these runways is serviced by a separate traditional localizer (LOC), with Runway 09 also equipped with a glide path for an instrument landing system (ILS). All systems were serviceable at the time of the occurrence.

1.9 Communications

While the occurrence aircraft was waiting for departure, 9 other aircraft approached Runway 09. The flight crew of the 6th aircraft to land on Runway 09 indicated to the KSAN tower controller, at approximately 1834, that they did not see the runway environment until they reached the minimum altitude on the approach.

At 1835, KSAN issued an updated weather report (as described in 1.7 Meteorological information), and it was broadcasted on the ATIS frequency. Approximately 1 minute later, the tower controller informed aircraft on the tower frequency that the new weather report was available on the ATIS.

The next 3 approaching aircraft were all notified by the tower controller to expect to see the runway environment at the minimum altitude on the approach. Of these 3 aircraft, 2 landed; the flight crew of the 3rd executed a missed approach at approximately 1839, and soon after, indicated to the tower controller that they did not see the runway environment from the minimum altitude.

The KSAN tower controller had no knowledge of the excursion until the broken lights were discovered by airport personnel 7 hours and 46 minutes later. Therefore, the tower could not alert the occurrence aircraft’s flight crew while they were still in flight.

1.10 Aerodrome information

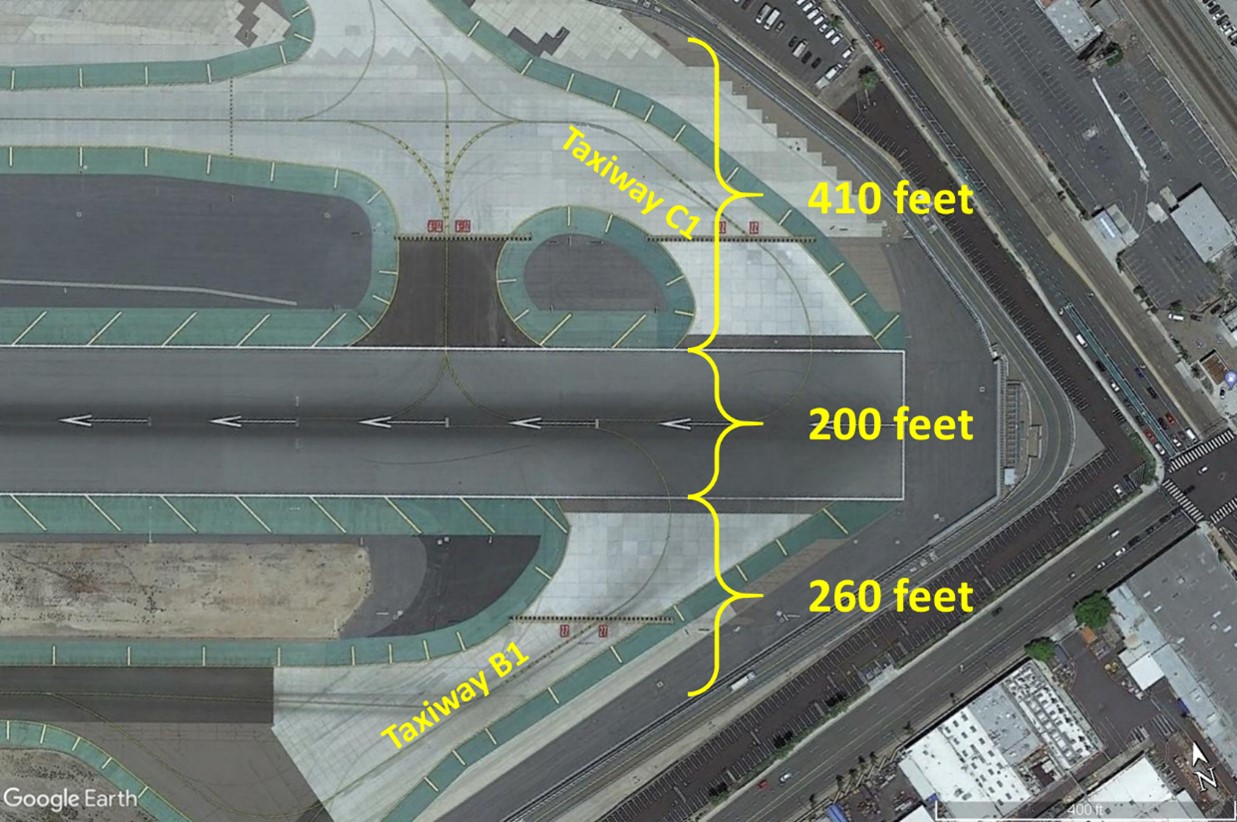

KSAN is a single-runway airport located on the northern shoreline of San Diego Bay and surrounded by the city of San Diego (Figure 4). KSAN is one of the busiest single-runway commercial service airports in the world and the 3rd-busiest airport in California. The airport’s runway, Runway 09/27, is 200 feet wide and 9400 feet long. However, Runway 09 has a permanently displaced threshold of 1000 feet, and Runway 27’s threshold is permanently displaced by 1810 feet. Runway 27 also incorporates an engineered materials arresting system (EMAS),Footnote 14 which is 315 feet long and located immediately west of the threshold of Runway 09.

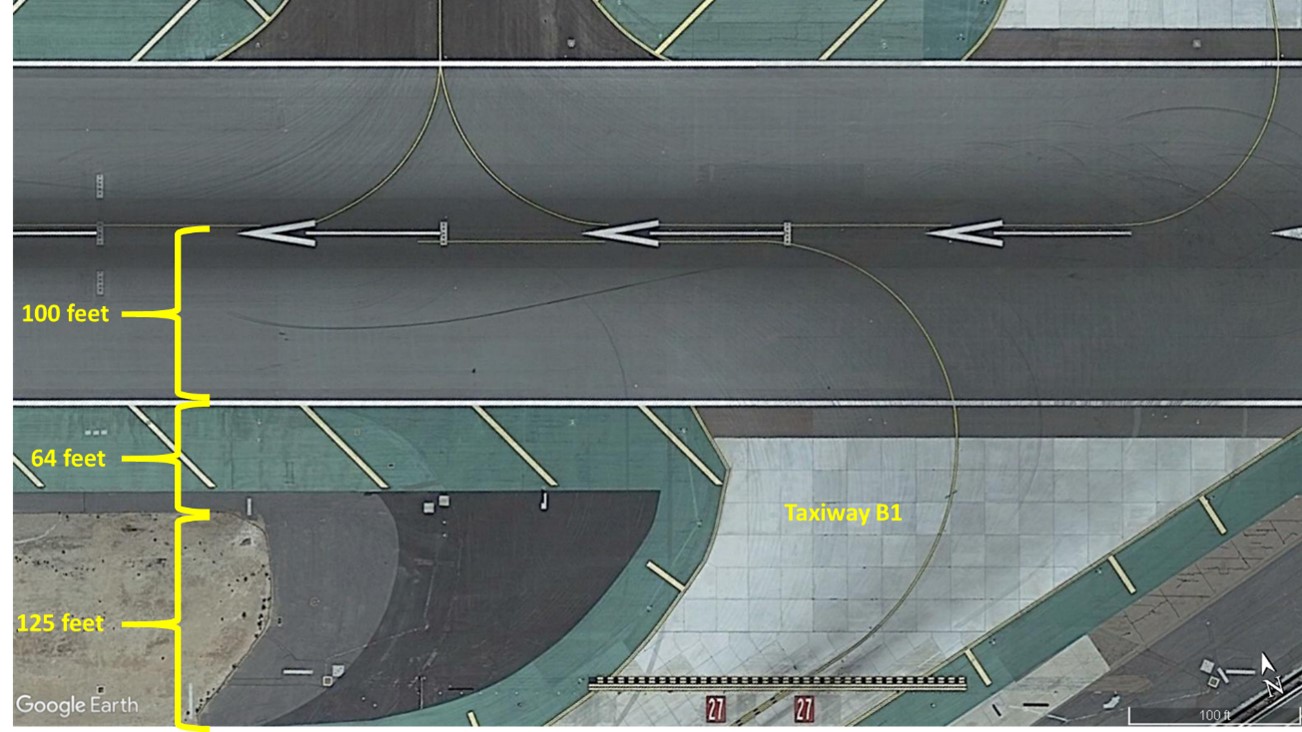

The entry point of Taxiway B1 onto Runway 27 is directly across from that of Taxiway C1, which enters the runway from the north side. The runway itself is 200 feet wide, but the width of the paved surface at this intersection, where the occurrence aircraft initiated its takeoff, is approximately 870 feet. The pavement extends approximately 260 feet to the left of the runway’s southern edge and 410 feet to the right of the runway’s northern edge (Figure 5).

Jazz conducts regularly scheduled daily flights between CYVR and KSAN. The investigation studied the typical arrival and departure patterns of the inbound (CYVR-KSAN) flights as well as the outbound return (KSAN-CYVR) flights for a 3-month period around the date of the occurrence. In the 158 individual flights studied, approximately 94% of the landings and takeoffs occurring at KSAN were conducted on Runway 27. Only 3 times in this period did an inbound flight land on Runway 09, with the return flight taking off from Runway 27.

1.10.1 Visual environments of runway thresholds and displaced thresholds

Canadian and U.S. standards for runway threshold markings are very similar. Runway threshold markings help identify the beginning of the runway that is available for landing. These markings are longitudinal stripes that are painted white and extend laterally across the approximate width of the runway. The specifications of the stripes are determined by the certification of the runway, by its width, as well as by the approach category servicing the runway.

In addition, the runway designation marking (known as the runway landing designator marking in the U.S.) is the painted runway number marking centred on the runway centreline and located 12 m from the top edge of the runway threshold marking.

In some instances, the landing threshold may be relocated or displaced; for example, when natural or fabricated obstacles interfere with runway approach paths and require limitations to their use. In the U.S.

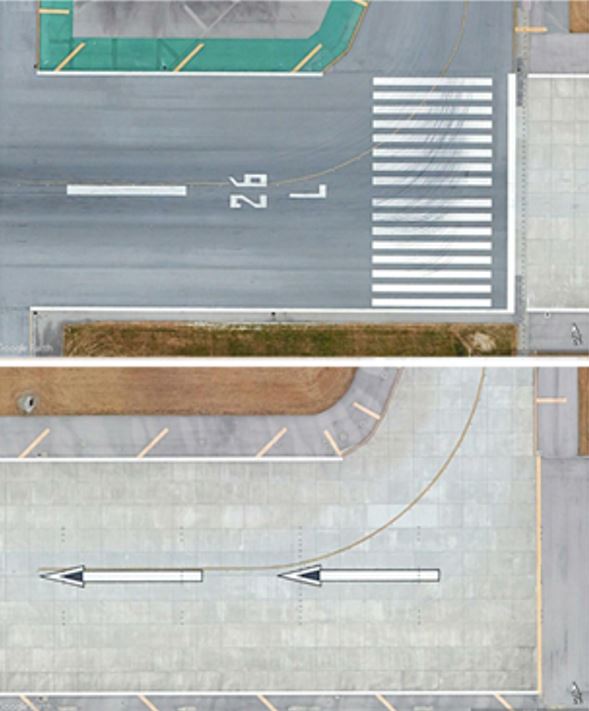

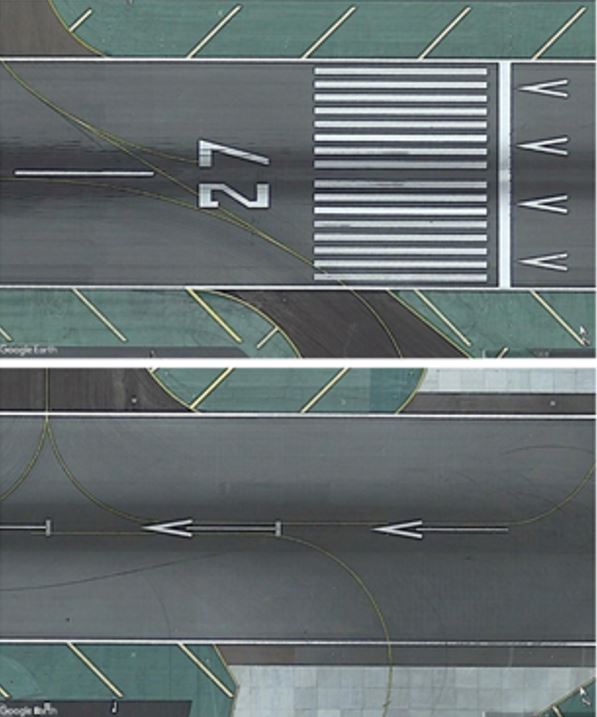

[a] displaced threshold is a threshold located at a point on the runway other than the designated beginning of the runway. Displacement of a threshold reduces the length of runway available for landings. The portion of runway behind a displaced threshold is available for takeoffs in either direction and landings from the opposite direction. A ten feet wide white threshold bar is located across the width of the runway at the displaced threshold. White arrows are located along the centerline in the area between the beginning of the runway and displaced threshold.Footnote 15

Standards in Canada indicate that the arrowhead must be 10 m long and the shaft at least 20 m.Footnote 16 Standards in the U.S. are similar, with required lengths of 13.5 m and 24 m, respectively (figures 6 and 7). The displaced portion of a runway can be used for taxiing and takeoff. It can also be used for rollouts after landing on the opposite end.

Intersections between runways or taxiways, such as the intersection from which the occurrence aircraft began its take-off roll, have a visual environment similar to that of displaced threshold areas (in that neither has markings defining width). Many air operators have policies concerning intersection departures. For example, Jazz does permit takeoffs from intersections, but the policy is predicated on the flight crew being able to ascertain whether sufficient runway length exists.Footnote 17

1.10.2 Taxiway centreline marking

Taxiway centreline markings provide flight crews with continuous visual guidance along a designated path. According to the U.S. Federal Aviation Administration (FAA) standard for airport markings, the centreline markings on a lead-on taxiway can terminate at the runway edge, but for taxiways that enter onto the runway in a displaced threshold area, the taxiway centreline markings continue onto the runway and extend parallel to the arrows that lead to the displaced threshold for at least 200 feet beyond the point of tangency or to the displaced threshold bar, whichever is less.Footnote 18

Taxiway centreline markings thereby provide cues to flight crews for reaching the runway; however, they reduce slightly the length available for takeoff if a flight crew taxis to where these markings become tangent with the displaced threshold markings. At KSAN, the taxiway centreline marking on Taxiway B1 reaches tangency approximately 425 feet beyond the beginning of Runway 27.

During the occurrence, the aircraft entered Runway 27 from Taxiway B1, where the taxiway centreline marking extended to the centre of the runway. In addition, the Taxiway B1-Runway 27 intersection also has embedded lighting along a portion of the taxiway centreline marking. However, this is not taxiway centreline lighting, but rather, the runway status light (RWSL) system. RWSLs are a fully automatic advisory system (that is, they require no activation by air traffic controllers) designed to reduce runway incursions. When illuminated, they indicate to flight crews or airport vehicle operators that the runway is occupied or that an aircraft is approaching the runway. When the system detects an aircraft on the runway and in the vicinity of the intersection, the embedded lighting automatically turns red. At the time of this occurrence, RWSL systems were installed at 20 airports in the U.S. The RWSL system was functioning at KSAN on the night of the occurrence, and the red lighting illuminated toward the occurrence aircraft while the preceding aircraft was occupying the Runway 27–Taxiway B1 intersection at the beginning of its take-off roll. The red lights automatically extinguished, and shortly thereafter, the occurrence aircraft was cleared by ATC to take position on Runway 27.

1.10.3 Runway edge markings

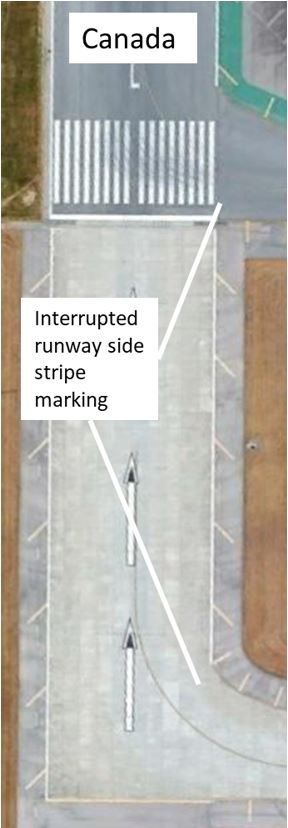

Runway edge markings (known as runway side stripe markings in Canada) provide enhanced visual contrast between the runway edges and the surrounding terrain or runway shoulders and define the runway width. The side stripe markings consist of 1 parallel stripe on each edge of the runway. The Canadian aerodrome standard for runway markings states that side stripes are interrupted at intersections between 2 runways or at intersections between a runway and a taxiway (Figure 8).Footnote 19,Footnote 20 By contrast, the U.S. standardFootnote 21 for runway edge markings specifies that runways shall have uninterrupted edge markings (Figure 9).

The runway edge markings at KSAN had been most recently painted in May 2020—18 months before the current occurrence. Furthermore, in June 2021, the FAA had conducted its annual safety inspection at KSAN, in which an element was the inspection of runway markings for compliance with existing standards.

1.10.4 Runway shoulder markings

Runway shoulders are the areas adjacent to the defined runway edges that provide resistance to blast erosion and accommodate the passage of maintenance and emergency equipment. Paved shoulders assist in reducing the amount of dirt and debris that enters the runway, providing a smoother runoff area for runway side excursions and allowing for the passage of airport operations vehicles without the use of the runway surface.

While the U.S. standardsFootnote 22 for runway geometry indicate that stabilized surfaces, such as turf or low-cost paving, are suitable for the shoulder, paved shoulder surfaces are required for runways that accommodate aircraft with a wingspan of 36 m or longer and a tail height of 13.7 m or higher (the approximate measurements of a Boeing 767 aircraft).

In the U.S., runway shoulders can have markings to further delineate the shoulder from the runway. If used, they consist of stripes oriented 45° from the runway centreline and painted yellow.Footnote 23

Runway and taxiway shoulders at KSAN are painted dark green and striped yellow. The runway shoulder on the south side of Runway 27 in the vicinity of the Taxiway B1 entrance is 64 feet wide, 50 feet of which is painted and striped. However, there is also an unmarked and unpainted paved area that extends 125 feet between the shoulder of Runway 27 and the north edge of Taxiway B1. It covers the inside radius of the turn where Taxiway B1 meets Runway 27 (Figure 10). At the point where the occurrence aircraft aligned with the runway and came to a stop, the painted shoulder was approximately 180 feet ahead. Figure 12 in 1.10.5 Runway lighting provides a representation of the flight crew’s visual environment in which the shoulder is visible.

Canadian standards do not include provisions necessitating the addition of runway shoulders or their markings. The investigation assessed 18 Canadian airports regularly serviced by Jazz.Footnote 24 Of these, 9 had runway complexes with no defined shoulders, and the other 9 had defined runway shoulders of widths ranging from 5 feet to a maximum of 25 feet.

1.10.5 Runway lighting

In both Canada and the U.S., the standard for runway edge lighting is to emit white light. As an aircraft nears the end of the runway lighting, the colour changes from white to yellow, signifying the final 600 m (or 610 m in the U.S.) of the runway, which can include a displaced threshold. When a runway threshold is displaced, the runway edge lighting located in the area before the displaced threshold emits red light toward the aircraft on approachFootnote 25Footnote 26 and yellow in the opposite direction (Figure 11).

All runway edge lights are placed in 2 parallel rows, each equidistant from the runway centreline, and with uniform spacing of not more than 60 m (or 61 m in the U.S.).

If a runway is equipped with runway centreline lighting, these lights emit a white light in the direction of the approaching aircraft. To warn flight crews of the impending end of a runway, the colouring changes to alternating red and white for the final 900 m, then to red for the final 300 m (Figure 11).Footnote 27,Footnote 28

Runway 27 at KSAN is equipped with runway edge and centreline lighting. Most edge lights are raised above the runway surface and on frangible bases, but a number of edge lights are embedded in the runway edge, including the runway edge lights that transect Taxiway B1 where it enters onto Runway 27. In addition, given the long displaced threshold area of the runway, the runway’s approach lighting is also embedded within the paved surface. As such, the 1st runway edge light in front of the occurrence aircraft as it lined up on the runway edge was embedded in the runway surface, in the same fashion as the approach lighting on the centreline (Figure 12).

Runway 09/27 at KSAN has medium-intensity approach lighting on both ends. The majority of the approach lighting on each runway is embedded in the runway’s surface, in the area before the displaced threshold. The embedded lights protrude slightly from the surface and can make for bumpy taxiing and take-off rolls. According to the configuration standard for lighting installation:

the control of the approach lights and displaced threshold area centreline lights is interlocked to ensure that when the approach lights are “on”, the displaced area centreline lights are “off”, and vice versa.Footnote 29

Runway 09 was being used for approaches during the time of the occurrence, meaning that the centreline lights in the Runway 09 displaced threshold area were off, but the ones in the Runway 27 displaced threshold area were on.

Canada and the U.S. have similar standards for the operation of airport lighting. Between sunset and sunrise, or when other specific environmental conditions persist, runway edge and centreline lights (if installed) must be on for departing aircraft. Approach lighting is required to be on only for the landing runway served by the lights. However, controllers can activate lights otherwise, as they deem necessary, and pilots can also request that approach lighting be activated.

During the occurrence aircraft’s takeoff, the runway edge and centreline lights were on. Since Runway 09 was being used for arrivals, the embedded approach lighting on Runway 27 in the area behind the displaced threshold was off.

During the take-off roll, the occurrence aircraft struck and severed 3 consecutive raised runway edge lights (labelled E-14, E-16, and E-18 in Figure 13).

1.10.6 San Diego International Airport departure and arrival operations using both ends of the runway

In degraded weather conditions, the use of Runway 09 for approaches and landings is often necessary due to it having a precision approach with lower published visibility and altitude limitations compared to those for Runway 27. Runway 27, on the other hand, is the preferred runway for departures due to the lower required climb gradient (aircraft depart toward the ocean instead of rising terrain) and less noise over the city. In a practice commonly referred to as “9/27 operations,” the control tower collaborates with the approach/departure controller in a specific period in which successive departures take off, followed by another period in which successive arrivals will land. There are no detailed procedures for the switching of the approach lights for these periods and this runway configuration, and controllers are to follow the standards set forth by the FAA for airport lighting systems.Footnote 30

1.10.7 San Diego International Airport tower aids

KSAN is 1 of 35 towered airports in the U.S. that use airport surface detection equipment – model X (ASDE-X). The system uses ATC radar, multilateration sensors, and satellite-based sensors to provide air traffic controllers with the position and identification of all aircraft and vehicles on the airport movement area. ASDE-X was developed to help reduce runway incursions, and at KSAN, it works in concert with the airport’s RWSL system, which provides flight crews and vehicle operators with visual identification of a runway’s status. ASDE-X also provides air traffic controllers with automatic alerts for potential runway conflicts.

However, given that it is not designed to send alerts for the lateral misalignment of an aircraft on a runway, the air traffic controller received no such alert. As a result, the air traffic controller, who was working at night and with degraded visibility conditions, remained unaware that the occurrence aircraft was misaligned for takeoff.

Furthermore, KSAN is not equipped with a foreign object debris detection system, which is designed to detect objects on runway surfaces and alert airport staff to their presence. Once the aircraft had completed the misaligned takeoff, the controllers and the airport operator therefore remained unaware of the missing runway edge lights and debris on the runway for the next 7 hours and 46 minutes.

1.10.8 San Diego International Airport runway side excursion history

The FAA was able to provide the investigation with details of known side excursion events at KSAN. These records show that in the 5 years preceding this occurrence, there were 6 runway side excursions at the airport. Two of them were the direct result of an aircraft mechanical issue. The remaining 4 side excursions indicate that each aircraft exited the runway as a result of flight crew visual perception of the paved surface environment, and specifically, the asphalt areas painted green with yellow stripes and contained within the runway shoulders, as well as the painted islands.

In the U.S., the National Aeronautics and Space Administration (NASA) maintains the Aviation Safety Reporting System (ASRS) which receives, processes, and analyzes voluntarily submitted incident reports describing occurrences or hazardous situations from pilots, air traffic controllers, and others within the aviation system. The ASRS contains 7 voluntary reports of side excursions that have occurred at KSAN since 1990. Two of the 7 occurrence reports describe flight crews exiting the runway onto the runway shoulders and painted islands while perceiving these areas as a taxiway. The other 5 occurrences describe nighttime runway misalignments in which flights crews attempted to take off, or successfully departed, while mistaking the runway edge markings and runway side lights within the Runway 27 displaced threshold area as the centreline.

The FAA Accident and Incident Data SystemFootnote 31 contains an additional occurrenceFootnote 32 involving a flight crew conducting a nighttime takeoff from the area before the Runway 27 displaced threshold in which the aircraft was aligned with the runway edge and struck 4 runway edge lights during its takeoff.

1.11 Flight recorders

The aircraft was equipped with a digital FDR and a cockpit voice recorder (CVR).

Data was recovered from the digital FDR and processed at the TSB Engineering Laboratory in Ottawa, Ontario. The data contained 444 recorded parameters and covered more than 500 hours.

The CVR was removed by a Jazz contracted maintenance organization and shipped to the TSB Engineering Laboratory. The recording contained 2 hours and 4 minutes of recording from 4 channels. The laboratory noted that the recording quality of the cockpit area microphone was excellent. There were no crew communications data because the CVR was not isolated until approximately 4 hours after the aircraft had landed at KLAX. As a result, the occurrence flight was overwritten, and information that could have been valuable to the investigation was lost.

1.12 Wreckage and impact information

Not applicable.

1.13 Medical information

According to information gathered during the investigation, there was nothing to indicate that the flight crew’s performance was degraded by medical factors.

1.14 Fire

Not applicable.

1.15 Survival aspects

Not applicable.

1.16 Tests and research

1.16.1 Runway threshold visual environment testing

To better appreciate the visual environment encountered by the occurrence flight crew when taking off within the displaced threshold area of Runway 27, the investigation simulated a representative runway model that approximated the runway shoulder, markings, and lighting at KSAN. The environmental conditions were varied between ½ SM visibilityFootnote 33 and unlimited visibility; conditions were also varied between daytime and nighttime. Images captured from the displaced threshold area (Figure 14) demonstrated to the investigation the level of saliency of runway markings when a flight crew judges an aircraft’s lateral alignment with the runway. They also showed how the paved runway shoulder contributes to the overall visual environment.

1.16.2 Flight data analysis

The recorded flight data indicate that the occurrence aircraft departed from KSAN at 1842:38 (Appendix A). The flight data also show an engine thrust reduction to climb thrust by the flight crew approximately 1 minute later. At this time, the fuel load was laterally balanced. Over the next 2 minutes, the recorded fuel quantity in both the right-wing tank and the centre tank decreased, but the quantity in the left-wing tank remained steady.

Approximately 3 minutes after departure, the FQGC detected a minor lateral imbalance—the left fuel tank was approximately 220 pounds heavier.

The minor imbalance persisted as the aircraft continued to climb. During this period, the quantity of fuel in the right-wing tank fluctuated approximately around the scheduled thresholds for the FQGC utilization of the centre tank’s transfer ejectors. However, in the same period, the fuel quantity in the left-wing tank remained relatively unchanged. Once the aircraft climbed above 10 000 feet ASL, FDR data show the aircraft was being flown in a consistent left bank of approximately 1°, compared to an average left bank on the ground before takeoff of approximately 0.5°.

The investigation further calculated that the total amount of fuel consumed by both engines was consistent with the quantity of fuel transferred from the centre tank to the right-wing tank via the transfer ejectors. Since there is no route by which the fuel can travel from the centre tank directly to the engines, this calculation indicates that the total fuel consumed by both engines was generally being supplied by only the right-wing tank.

The significant lateral fuel imbalance began as the aircraft climbed through FL310. This portion of the flight coincides with the fuel consumption by the engines being reduced to a flow rate approximately equal to the crossflow pump rate of transfer. When the aircraft neared its cruise altitude of FL340, the lateral imbalance continued to worsen, reaching approximately 400 pounds. During this period, while the aircraft maintained a steady bank of 1° to the left, the 2 fuel amounts were diverging, with the left-wing tank slowly increasing in quantity, and the right-wing and centre tanks decreasing in quantity.

As the lateral imbalance reached approximately 700 pounds, the flight crew attempted to use differential engine thrust settings, using less thrust on the right engine and thus enabling less fuel flow. Following this attempt, the flight crew were presented with a “FUEL IMBALANCE” caution message because the imbalance had, at that time, reached the maximum permissible in-flight imbalance of 800 pounds. Calculations made by the investigation show that the amount of fuel consumed by the engines in this period was equal to the rate of change of fuel from the centre tank, and that the fuel amount in the left-wing tank was increasing at approximately the same rate as the fuel decrease in the right-wing tank.

When the flight crew continued with the original checklist (in the XFLOW PUMP Caution Message procedure), it led them to action the Gravity Crossfeed Procedure, which required them to perform a sideslip. With the autopilot system remaining on, the flight crew established the sideslip; however, they applied pressure to the right rudder (in the direction of the low-quantity fuel tank), which resulted in the autopilot banking the aircraft approximately 2.2° to the left (toward the higher-quantity fuel tank) for approximately 3 minutes. This manoeuvre resulted in the left-wing tank reaching its maximum quantity and additional fuel likely being forced through the tank vents and reaching the centre tank.

When the lateral fuel imbalance reached approximately 1400 pounds, the flight crew began to divert to KLAX. The flight crew were provided with a left turn and descent clearance by ATC, and meanwhile, the open gravity crossflow valve continued to exacerbate the lateral fuel imbalance. It was during this descending turn that the flight crew shut down the No. 2 engine as directed by the Gravity Crossfeed Procedure. After the turn, the aircraft maintained an average angle of bank to the left, in part due to the routing by ATC, but also due to a likely contribution of the left wing’s weight, which, at this time, was approaching 2000 pounds heavier than the right wing. As a result, the left-wing tank remained at its maximum quantity, and despite the fact that only the left engine was operating, the only reduction in fuel quantity was from the right-wing tank.

As the data show, the left-wing tank continued to be full and the aircraft reached a peak lateral fuel imbalance of 2464 pounds when it was descending through approximately 10 000 feet ASL. Over the following 9 minutes, the aircraft’s angle of bank was at times oriented to the right, including during an approximate 180° right turn with an angle of bank averaging approximately 15°. During this period, the lateral fuel imbalance was reduced to approximately 1120 pounds. In addition, as the aircraft rolled onto its final approach at KLAX, the angle of bank was again slightly to the left, and the aircraft landed with a lateral fuel imbalance of approximately 1600 pounds.

1.16.3 TSB laboratory reports

The TSB completed the following laboratory reports in support of this investigation:

- LP179/2021 – CVR Download

- LP178/2021 – Flight Data Analysis

1.17 Organizational and management information

1.17.1 General

Jazz Aviation LP is a regional airline that operates 114 aircraft under Canadian Aviation Regulations (CARs) Subpart 705, including its fleet of MHI RJ Regional Jet Series 900 aircraft. In accordance with these regulations, the company has a safety management system (SMS).

1.17.2 Flight crew training

To maintain their flight qualifications, Jazz flight crews undergo annual ground training (technical training and crew resource management [CRM]) as well as flight training in a simulator and line checks. The occurrence captain had most recently completed his required recurrent training in July 2021 (4 months before the occurrence), and the first officer had done so 9 days before the occurrence.

Flight training in a simulator uses training and checking scripts—that is, scenarios including routes and failure sequences. Scripts rotate twice per year so that flight crews experience new training during each of their semi-annual simulator training sessions. Initial training scripts at Jazz include departures from runways with displaced thresholds, and the recurrent training script (as well as the flight checking) used throughout the 2nd half of 2018 included departures from Newark Liberty International Airport (KEWR), New Jersey, U.S., an airport that has displaced thresholds up to 2540 feet long. The occurrence flight crew members both received this training and checking in 2018.

Technical training for aircraft systems is taught to flight crews initially and during annual recurrent ground school training. Jazz’s ground school course for the Regional Jet Series 900 includes a module for the fuel system and the related caution messages.

1.17.3 Threat and error management

Jazz flight crews receive initial and annual recurrent training on non-technical skills in the operator’s in-house 1-day CRM training session. Flight crews are trained in non-technical skills in the morning. In the afternoon, the principles of threat and error management (TEM), covered during training, are applied and then discussed in the context of various scenarios. The scenario-based afternoon is also attended by staff from Jazz’s cabin crews, dispatchers, and aircraft maintenance controllers. During TEM training, staff discuss the potential threats within scenarios and the ways to prevent any threats from developing into errors when an undesired aircraft state persists. The desired result from Jazz’s scenario-based TEM training is for Jazz staff to be able to identify potential threats in the scenarios, as well as the errors that can result.

Jazz’s TEM methodology is built upon the ICAO TEM model (further discussed in 1.18.3.3 Crew resource management and threat and error management). The operator’s full CRM training program is updated yearly (but can be modified mid-cycle if critical data are identified) and developed using current information from safety investigation reports, the TSB Watchlist, internally identified data from flight training and line flying, and internal SMS reports and statistics. At the time of the occurrence, the most prevalent topics in Jazz’s TEM training concerned flight deck automation management and manual flying, active monitoring of flight conditions by the PM, hard landings, and unruly passengers. Additional topics of concern, namely runway overruns and runway incursions, come from the TSB’s Watchlist, and both are addressed in Jazz’s TEM training scenarios. Misaligned takeoffs, considered by the operator to carry less risk than runway overruns and incursions, were not included in these scenarios.

A practical application of Jazz’s TEM safety defence is the pre-flight briefings and approach briefings, in which flight crews are instructed to seek and identify potential threats (e.g., environmental conditions and airport hot spots). When the occurrence flight crew conducted the pre-flight briefing, they had no recent information pointing to misaligned takeoffs as a potential threat in the take-off environment and conditions in which they were about to operate, so this threat was not considered.

1.17.4 Jazz safety management system

Jazz reported that there were no SMS reports related to operational concerns or safety deficiencies at KSAN. Furthermore, there were no identified concerns, relevant to the occurrence, related to displaced thresholds, runway lighting, runway markings, or runway shoulders at any of the airports in Jazz’s network.

1.17.5 Standard operating procedures and checklists

1.17.5.1 Runway lineup

Neither Jazz’s Regional Jet aircraft operations manual (AOM) nor its company operations manual (COM) mandates that flight crews adhere to taxiway centreline markings when taxiing and entering a runway, unless operating on a contaminated surface. Therefore, deviating from the taxiway centreline marking for operational reasons (e.g., using greater runway length for takeoff) is at the discretion of the captain.

With respect to verification of runway alignment, the Jazz runway line-up check procedure in the AOM states:

Once aligned with the runway centreline, Flight Crew shall positively verify the assigned runway either by visually observing the runway identifier on the runway surface, by reference to flight deck instrumentation (e.g. localizer alignment) or HSI [horizontal situation indicator] heading. When the RVR or reported visibility is less than 2600 or ½ mile respectively, only the runway identifier or localizer alignment may be used to positively verify the runway.Footnote 34

During the occurrence aircraft’s departure, the runway identifier was not in view because the takeoff was being conducted from the area before the displaced threshold of Runway 27. The captain therefore verified the runway using only the HSI compass heading, confirming that it was on the runway heading. This method was permissible according to the procedure, given that the most recent METAR issued for KSAN had indicated a visibility of ½ SM. Although the use of the HSI alone allowed the captain to verify that the aircraft was on the correct runway, it did not provide confirmation that the aircraft was correctly aligned with the centre.

The area before a displaced threshold is considered a portion of the runway available for takeoffs (and landing rollouts). There are no regulations in the U.S. or Canada prohibiting departures from those portions of the runway in visually degraded, or any other, conditions. Similarly, Jazz’s AOM and COM provide no policies, procedures, or guidance material to pilots with respect to limitations or precautions when operating on runways with displaced thresholds.

1.17.5.2 Fuel crossflow operation

1.17.5.2.1 Normal procedures

Immediately before a departure and during Jazz’s before-takeoff checks, the first officer actions the fuel crossflow system by pressing the XFLOW AUTO OVERRIDE switch, placing it in manual mode. Jazz’s AOM illustrates the procedure as follows:

Fuel crossflow

- /man, off

XFLOW AUTO OVERRIDE switchlight

- select in

Verify that the MAN XFLOW EICAS message is displayed. Ensure there is no GRAV XFLOW OPEN or L(R) XFLOW ON messages displayed.Footnote 35

After a first officer performs the checks, he or she confirms them with the checklist, reading for this item “fuel crossflow manual off.” Per the AOM, the first officer is stating that the fuel crossflow is in manual mode and that there are no gravity crossflow or left or right crossflow messages displayed on the flight deck’s EICAS. When the XFLOW AUTO OVERRIDE push-button switch is pressed in, it becomes illuminated (Figure 15).

Following takeoff, the PM sets climb thrust, and then when workload permits, completes the after-takeoff checklist. This checklist requires the PM to deselect the XFLOW AUTO OVERRIDE switch (push button out and light off), placing the system back into automatic mode. During the occurrence flight, the captain was the PM and was required to action this checklist. The XFLOW AUTO OVERRIDE switch is not actioned again throughout the remainder of the flight unless it is required by abnormal or emergency checklist procedures.

1.17.5.2.2 Abnormal/emergency procedures

According to Jazz and MHI RJ procedures, when the “XFLOW PUMP” caution message is displayed, the PF will instruct the PM to carry out the XFLOW PUMP Caution Message procedure checklist, which instructs the flight crew to determine whether a fuel imbalance exists. If so, the instruction is to proceed to the Gravity Crossfeed Procedure, and if not, the flight crew is instructed to monitor fuel quantities.

When the flight crew determined that the lateral fuel imbalance existed and was unable to be corrected, the PM proceeded with the Gravity Crossfeed Procedure in the Jazz QRH:

Gravity Crossfeed Procedure

L XFLOW

- OFF

R XFLOW

- OFF

XFLOW AUTO OVERRIDE

- OFF

GRAVITY XFLOW

- OPEN

Steady-Heading Sideslip

- ACCOMPLISHFootnote 36

This crossfeed procedure is virtually identical to the one published in the manufacturer’s QRH.Footnote 37

“OFF,” the response to the instruction provided in the 3rd step of the procedure, is not 1 of the 2 available positions of the XFLOW AUTO OVERRIDE push-button switch, which are AUTO (push-button switch pressed out and not illuminated) and MAN (switch pressed in and illuminated).

When the PM reached this step, he completed the instruction of “OFF” by checking that the XFLOW AUTO OVERRIDE switch was deselected and pressed out, thereby causing the fuel crossflow to be in automatic mode. This switch position was logical to the PM because it was consistent with the adjacent L XFLOW and R XFLOW push-button switches, which were both in their respective off positions (i.e., pushed out and not illuminated).

The PM’s action was, in fact, what the manufacturer had intended to prescribe in this step of the crossfeed procedure: the XFLOW AUTO OVERRIDE switch remains in the AUTO position, so that the FQGC’s control over the fuel-transfer process would therefore be maintained.

The Jazz procedure then includes a note to flight crews: “Establish a bank angle of 10 degrees down on the low quantity side by use of the rudder pedal (rudder trim may be required), while maintaining a constant heading.”Footnote 38 This note is slightly different from the instruction given in the QRH published by MHI RJ, which states: “Establish a bank angle of 10 degrees down on the low quantity side. Use rudder pedal/trim to maintain a constant heading/course.”Footnote 39

Although the difference is subtle, the 2 procedures are distinct. The Jazz procedure describes establishing the bank angle with the rudder, whereas the MHI RJ procedure is to establish a bank angle and then use the rudder to hold a heading/course.

A sideslip is normally performed to counteract the effect of drift when landing in a crosswind by holding the aircraft’s longitudinal axis parallel with its flight path. However, the intention of the sideslip prescribed by the Jazz and MHI RJ QRHs is to bank the aircraft and use gravity to transfer the weight of the fuel from one side to the other. The application of rudder prevents the aircraft from turning.

The Gravity Crossfeed Procedure checklist goes on to state that if the fuel tank quantities balance as a result of the sideslip, the gravity crossflow valve is to be closed, and the crew can return to coordinated flight. If, however, the fuel quantities do not balance and cannot be controlled within limits, the engine on the side with the lower fuel quantity must be shut down.

The occurrence flight crew continued with the instruction in the Gravity Crossfeed Procedure checklist and actioned the In-Flight Engine Shutdown checklist.Footnote 40 Step 7 of this checklist instructs flight crews to place the fuel crossflow system into automatic mode, which is achieved by deselecting the XFLOW AUTO OVERRIDE switch so that it is pushed out, consistent with the position already selected during the Gravity Crossfeed Procedure.

The rest of the In-Flight Engine Shutdown checklist, as well as the subsequent Single-Engine Approach and Landing checklist,Footnote 41 provides no further instruction to a flight crew to close the gravity crossflow valve other than a note halfway through the In-Flight Engine Shutdown checklist explaining that flight crews “may have to perform the Gravity Cross-feed procedure when required and time permits.”Footnote 42

1.18 Additional information

1.18.1 Other occurrences and investigations of misaligned takeoffs

The TSB has previously reported on runway side excursions resulting from misaligned takeoffs. TSB records indicate 10 occurrencesFootnote 43 in which flight crews lined up with and commenced a take-off roll on a runway edge rather than the runway centreline. All occurrences had in common operations in nighttime conditions, and 1 occurrence specifically noted degraded visual conditions.

One of the occurrences resulted in the 2006 TSB investigationFootnote 44 of the misaligned takeoff of a Canadian registered Airbus A319-114 from Harry Reid International Airport (KLAS), Las Vegas, U.S., which was bound for Montréal/Pierre Elliott Trudeau International Airport (CYUL), Quebec. That investigation found that the runway markings, combined with the PF’s primary focus on the preceding aircraft’s departure and his use of peripheral vision when orienting the aircraft onto the runway, contributed to the aircraft being aligned on the runway’s asphalt shoulder rather than on the centreline and damaging runway edge lights during the take-off roll. Of note is the fact that this misalignment was not known to ATC or to the airport until 2 hours after the event, and during that time, potential debris from broken lights could have been a hazard to departing aircraft.

In 2009, the Australian Transport Safety Bureau (ATSB) researched the factors influencing occurrences of misaligned takeoffs. The published study identified 7 prevalent safety factors contributing to misaligned takeoffs, with the presence of each factor increasing the risk of an occurrence. The 7 factors are:

- night time operations

- the runway and taxiway environment, including confusing runway entry markings or lighting, areas of additional pavement on the runway, the absence of runway centreline lighting, and recessed runway edge lighting

- flight crew distraction (from within the cockpit) or inattention

- bad weather or poor/reduced visibility

- conducting a displaced threshold or intersection departure

- provision of air traffic control clearance when aircraft are entering the runway or still taxiing

- flight crew fatigueFootnote 45

These factors can be categorized as either human factors, environmental factors, or operational factors. A key human factor identified in the research was distraction resulting in divided attention. Distraction causes a flight crew’s attention to be divided, with a focus on completing tasks inside the cockpit at the expense of accurately assessing the external environment. This often occurs during the taxi, when the flight crew must have their eyes inside the cockpit for significant periods of time. As explained in the ATSB report,

instead of maintaining a visual look out from when they enter the runway, their attention is drawn inside for some reason such as checking instruments, confirming aircraft configuration or performing checklist items. While multi-crew operations partially mitigate this risk by articulating and dividing aircraft handling and monitoring roles between the pilots, there are still times when both crew members may not be processing the external environmental cues accurately. This divided attention is often a necessary part of lining up or beginning the take-off roll […].Footnote 46

The environmental factors outlined in the ATSB report include runway threshold markings. Colloquially known as piano keys, they assist flight crews by defining the width of the runway. As the report explains,

aircraft using a displaced threshold will not be able to see the normal threshold markings, such as the runway number or ‘piano keys', which provide important cues during the line up phase of flight. Footnote 47

An operational factor highlighted in the report is the necessity of following any available lead-on taxiway centrelines and lights to maximize the flight crew’s opportunity to correctly align the aircraft on the runway for takeoff, especially when ATC clearances are transmitted while the aircraft is lining up or when the aircraft is departing from an area other than a runway’s threshold, with fewer cues for lateral runway alignment.

The ATSB provides examples of the occurrence reports it used in constructing the list of safety factors that increase the risk of a misaligned takeoff. One exampleFootnote 48 obtained from NASA’s Aviation Safety Reporting System (ASRS) described the misaligned takeoff of a Cessna Citation X from KSAN that had lined up on the runway edge lights after entering the runway’s displaced threshold area before the threshold of Runway 27. Observations from the flight crew in that occurrence highlighted the large amount of asphalted surface in that area and that the lack of centreline lighting contributed to their misaligned takeoff.

1.18.2 Other fuel imbalance occurrences

1.18.2.1 Jazz Aviation LP 2022 occurrence

During the course of the investigation, Jazz reported to the TSB a similar occurrence on a different aircraft flown by a different flight crew.Footnote 49 On 03 February 2022, the flight crew of a Jazz Regional Jet Series 900 departing from Winnipeg/James Armstrong Richardson International Airport (CYWG), Manitoba, were presented with a “XFLOW PUMP” caution message, followed by an increasing fuel imbalance. Jazz provided the TSB with the flight data of that event, and they were examined in concert with the data from the November 2021 occurrence investigated in this report.

While the data demonstrate that the actions of each flight crew were slightly different, the initiating event of the 2022 occurrence showed compelling similarities to that of the 2021 occurrence. The aircraft that had departed from CYWG transferred the fuel from the centre to the wing tanks on a schedule relatively consistent with the specifications of the FQGC,Footnote 50 and the centre tank was empty approximately 8 minutes after departure.

About 14 minutes after departure, a lateral fuel imbalance of 200 pounds developed and continued for 30 seconds. Approximately 12 to 14 seconds later the “XFLOW PUMP” caution message displayed. Since the fuel in the centre tank had already been consumed, the flight crew were more easily able to monitor the changing imbalance condition. According to calculations, the rate of change in the fuel tanks was in excess of the amount of fuel being consumed by the engines. The flight data show that, in the 16 minutes following the caution message (until the imbalance was approximately 1000 pounds), the lateral transfer out of the right tank was between 2000 and 2200 lb/h (33 and 37 lb/m).