Loss of control on takeoff and collision with ground

Cargair Ltd.

Piper PA-23-250 Aztec, C-GDUL

Trois-Rivières Airport, Quebec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 17 June 2019, a Piper PA-23-250 (registration C-GDUL, serial number 27-3986), operated by Cargair Ltd., was conducting a night visual flight rules cross-country flight, departing from Montréal/St-Hubert Airport, Quebec, with an approach followed by a missed approach at Québec/Jean Lesage International Airport, Quebec, and Trois-Rivières Airport, Quebec. There was 1 pilot and 1 passenger, who was also a flight instructor, on board. On approach for Trois-Rivières Airport, Quebec, a decision was made to conduct a touch-and-go. During the take-off roll, the propellers of both engines struck the surface of the runway. The aircraft took off, turned left, and then the pilot lost control of the aircraft. The aircraft collided with the ground 222 feet south of Runway 23 at 0009 Eastern Daylight Time on 18 June. No signal was detected from the emergency locator transmitter. The aircraft was destroyed by a post-impact fire. The 2 occupants were able to evacuate the aircraft. One received minor injuries, and the other received serious injuries.

1.0 Factual information

1.1 History of the flight

On 17 June 2019, the pilot was conducting his last night visual flight rules (VFR) cross-country flight as a pilot-in-command under supervisionFootnote 1 on a Piper PA-23-250 Aztec (registration C‑GDUL, serial number 27-3986). The purpose of the flight was to complete the pilot’s hours for the Integrated Airline Transport Pilot – Aeroplane (ATP-A) training program. A passenger, who was also a flight instructor,Footnote 2 was on board to supervise the flight, and was in the right seat.

The departure from Montréal/St-Hubert Airport (CYHU), Quebec, was scheduled for 2230.Footnote 3 The route included an approach followed by a pull-up at Québec/Jean Lesage International Airport (CYQB), Quebec, and Trois-Rivières Airport (CYRQ), Quebec, then the aircraft was to return and land at CYHU (Figure 1).

At 2243, the occurrence aircraft took off from CYHU. As the aircraft approached CYQB, the pilot and passenger-instructor agreed that from that point on, the passenger-instructor would be in charge of radio communications. At CYQB, they conducted a simulated approach using the Runway 06 instrument landing system (ILS) under visual meteorological conditions.

At 2335, the aircraft was on short final. It then pulled up and headed to CYRQ to conduct a simulated area navigation (RNAV) approach to Runway 23 using the global navigation satellite system (GNSS), still under visual meteorological conditions. Inbound for CYRQ, the pilot and passenger-instructor agreed to conduct a touch-and-go rather than a missed approach with the flaps remaining in the approach position (¼) for the landing. They also agreed that once on the ground, the passenger-instructor would raise the flaps before takeoff. When the aircraft intercepted the final approach path, the pilot lowered the landing gear and carried out the Before Landing checklist, which required a total of 3 checks to ensure the landing gear was down and locked.

At 0007:54 on 18 June, the aircraft crossed the threshold of Runway 23 and touched down. The passenger-instructor placed the flap handle in the UP position. Then, at 0008:07, he noticed that the flaps did not go back up as planned and took action to fix the problem. With his attention focused on the centre console, at 0008:11, he noticed that the landing gear handle was still in the DOWN position (which blocked movement of the flaps) instead of returning automatically to the neutral position. At the same time, the pilot was increasing power to the 2 engines and the aircraft was accelerating on the runway. Experiencing the sensation of low-speed flight, the passenger-instructor moved the landing gear handle to the UP position. The pilot, who was conducting the takeoff, was unaware of the problem with the landing gear handle. He was also not aware that the flaps that were still in the approach position or that the landing gear handle had been moved to the UP position.

At 0008:18, at a speed of approximately 90 mph, the propellers on both engines struck the runway surface, causing an unusual loud noise, damage to the propellers, and significant vibrations. The aircraft nosed up, took off at low speed with the damaged propellers, and began turning left despite the pilot’s attempts to maintain the runway heading with flight controls (ailerons and rudder) at full deflection. A few seconds later, at 0009, the pilot lost control of the aircraft, which hit the ground approximately 222 feet south of Runway 23 (Appendix A).

A post-impact fire broke out. Given that the fire was burning near the right wing, on the side where the main door was located, the pilot and the passenger-instructor went to the back of the aircraft with the intention of opening the emergency exit window on the left side, but they could not get it open. They were still able to evacuate the aircraft through this window because the plexiglass had been shattered on impact.

Firefighters from the City of Trois-Rivières, who were already at CYRQ for another aircraft, responded immediately. No emergency locator transmitter (ELT) signal was reported. The 2 occupants were taken by ambulance to a hospital in Trois-Rivières. The aircraft was destroyed.

1.2 Injuries to persons

| Degree of injury | Crew | Passengers | Persons not on board the aircraft | Total by injury |

|---|---|---|---|---|

| Fatal | 0 | 0 | 0 | 0 |

| Serious | 0 | 1 | 0 | 1 |

| Minor | 1 | 0 | 0 | 1 |

| Total injured | 1 | 1 | 0 | 2 |

1.3 Damage to aircraft

The aircraft was destroyed by the force of the impact and by the post-impact fire that broke out after the fuel tank on the right wing ruptured.

1.4 Other damage

A few litres of 100LL fuel were recovered in the ditch on the edge of the runway.

1.5 Personnel information

| Pilot-in-command under supervision | Passenger-instructor | |

|---|---|---|

| Pilot licence | Commercial pilot licence - aeroplane (CPL) | Commercial pilot licence - aeroplane (CPL) |

| Medical expiry date | 01 April 2020 | 01 October 2019 |

| Total flying hours | 218.4 | 791.7 |

| Total night flying hours | 18.8 | 74.6 |

| Total night flying hours (past 6 months) | 6.2 | 19.8 |

| Flight hours on type | 34 | 25 |

| Flight hours on type at night | 4.4 | 0 |

| Flight hours on type in the 90 days before the occurrence | 34 | 1.5 |

| Hours on duty before the occurrence | 2 | 16 |

| Hours off duty before the work period | 12 | 12 |

1.5.1 Pilot information (pilot-in-command under supervision)

The pilot was certified and qualified for the flight in accordance with existing regulations.

The pilot had begun his pilot training with Cargair Ltd. in February 2018, registering for the Integrated Airline Transport Pilot – Aeroplane (ATP-A) training programFootnote 4 for foreign pilots. He obtained instrument and multi-engine ratings, as well as a commercial pilot licence, in May 2019.

1.5.2 Passenger-instructor information

The passenger-instructor had obtained instrument and multi-engine ratings, as well as a commercial pilot licence in 2017. In May 2018, he received a Class 4 instructor rating,Footnote 5 and in June 2018, he was hired as an instructor by Cargair Ltd. In April 2019, he received a Class 3 instructor rating. In May 2019, he took additional training to become a flight instructor for the instrument rating on Piper PA-23-250 aircraft for students who already had a multi-engine rating.

The occurrence flight was the second flight of his first day as a passenger-instructor supervising flights with a pilot-in-command under supervision on Piper PA-23-250 aircraft.

1.5.3 Fatigue

The following risk factors were assessed to determine whether fatigue was present: acute or chronic sleep disruption, prolonged continuous wakefulness, and the effects of circadian rhythm, sleep issues, a medical condition, or a side effect of medication.

Fatigue can be caused by prolonged continuous wakefulness. Fatigue generally occurs past the normal period of being awake, which is 17 to 18 consecutive hours, and gradually becomes more pronounced around the threshold of 22 hours.Footnote 6 A combination of risk factors increases the possibility of fatigue.

1.5.3.1 Pilot (pilot-in-command under supervision)

In the 2 days preceding the occurrence, the pilot conducted only 1 flight for training purposes. The flight was less than 1 hour in length, and took place in the afternoon. On the day of the occurrence, the aircraft took off at 2243. However, there were no signs of any fatigue-related risk factors.

1.5.3.2 Passenger-instructor

The passenger-instructor did not work in the 4 days preceding the work day that began on 17 June 2019 and ended on 18 June 2019. On 17 June 2019, the passenger-instructor woke up at 0700 and began his work day at 0800. He was on 2 flights that morning, each less than 2 hours in length, with a break of approximately 30 minutes between the 2 flights. That afternoon, he supervised a flight with a pilot-in-command under supervision bound for the Ottawa/Rockcliffe Airport (CYRO), Ontario, with a 2-hour waiting period in the pilot lounge. The passenger-instructor then provided ground training from 1900 to 2200 before supervising the occurrence flight. At the time of the accident, the passenger-instructor had been awake for approximately 17 consecutive hours. His workload was considered to be moderate that day. The passenger-instructor’s schedule included a training flight at 0800 on 18 June. There was no indication that fatigue affected the passenger-instructor’s performance.

1.6 Aircraft information

Technical records indicate that the aircraft was equipped and maintained in accordance with existing regulations and approved procedures, based on a maintenance schedule approved by Transport Canada (TC), and no deficiencies were noted before the occurrence flight.

The aircraft was equipped with a Garmin GNS 430W GPS (global positioning system), mounted on the instrument panel. The GPS could not be recovered, as it was completely destroyed by the post-impact fire. The occurrence aircraft was used by Cargair Ltd. to provide flight training for multi-engine and IFR ratings on a multi-engine aircraft.

| Manufacturer | Piper Aircraft Corporation |

|---|---|

| Type and model | PA-23-250 (Aztec) |

| Year of manufacture | 1969 |

| Serial number | 27-3986 |

| Certificate of airworthiness issue date | 16 November 2011 |

| Total airframe time | 9448.4 hours |

| Engine type (number of engines) | Lycoming IO-540-C4B5 (2) |

| Propeller/Rotor type (number of propellers) | Hartzell HC-E2YR-2RBSF (2) |

| Maximum allowable takeoff weight | 5200 lb |

| Recommended fuel type(s) | AVGAS 91/96 (minimum) |

| Fuel type used | AVGAS 100LL |

The weight and centre of gravity were within the prescribed limits. The takeoff weight from CYHU was 4359 pounds.

The stall speed at the maximum allowable weight, without power, was 74 mph with the landing gear and flaps up, and 68 mph with the landing gear and flaps down.

1.6.1 Landing gear and flap hydraulic system

The Piper PA-23-250 has 2 separate hydraulic systems that are physically independent of one another: 1 for the braking system, and 1 for the landing gear and flaps.

The landing gear and flap hydraulic system is fed by a mechanical pump driven by the left engine. From the pump, the pressurized hydraulic fluid flows to the hydraulic power pack, located in the centre console, below the instrument panel (Figure 2). The hydraulic power pack has handles and valves that control the movement of the landing gear and flaps.

The landing gear handle controls the gear position hydraulic selector, and has 3 positions: UP, neutral and DOWN. In either the UP or DOWN position, the pressurized hydraulic fluid is directed toward the landing gear retraction-extension control switches and the landing gear doors.

When the landing gear reaches the selected position, the hydraulic pressure increases in the system, causing the handle to return to the neutral position. Once the landing gear handle is back to the neutral position, the pressurized hydraulic fluid can continue flowing toward the flap position hydraulic selector (Table 4).

| Condition | Handle position | Aircraft configuration |

|---|---|---|

| Cruise flight: the landing gear and flap handles are at the neutral position, and the landing gear and flaps are up. | ||

| The landing gear handle is moved to the DOWN position and the landing gear extends. | ||

| Once the landing gear is down and locked, the landing gear handle automatically returns to the neutral position. |

The position of the landing gear is shown by 4 indicator lights on the centre console. When the 3 green indicators are lit, the 3 landing gear legs are down and locked in place. When the amber 4th indicator is lit, the landing gear is up and the doors are closed. The pressurized hydraulic fluid in this part of the system holds everything in place. If no indicators are lit, the landing gear is in transition.

The flap handle controls the flap position hydraulic selector. It has 3 positions: UP, neutral and DOWN. It works the same way as the landing gear handle, except that the pilot can return the handle to the neutral position at any time to set the flaps to an intermediate position. For example, to set the flaps at the ¼ position, the pilot generally lowers the flap handle to the DOWN position for 3 seconds, then returns the handle to the neutral position. However, on the night of the occurrence flight, after the handle was lowered for 3 seconds and then returned to the neutral position, the flaps were at the ½ position and, for an undetermined reason, the flaps remained in this position for the landing.

The landing gear and flap handles can be used simultaneously, but the landing gear always has priority over the flaps, and the flaps will not move until the landing gear handle has returned to the neutral position (figures 3 and 4).

During the occurrence flight, for an undetermined reason, the landing gear handle did not return to the neutral position, blocking retraction of the flaps (Appendix B). On some Cargair Ltd. Piper PA-23-250 aircraft, the landing gear handle would sometimes not return automatically to the neutral position. Generally, the problem was intermittent: the instructor would move the landing gear handle back to the neutral position, then the handle would return to the neutral position during subsequent movements of the landing gear. An examination of the technical records for the occurrence aircraft revealed that a similar problem with the landing gear handle had been recorded in December 2018. No other similar problems were recorded after that.

To prevent accidental retraction of the landing gear when the aircraft is on the ground, the handle has a stop. This stop must be released manually before the handle can be moved from the neutral position to the UP position. Also, an anti-retraction valve on the leg of the left landing gear unit prevents build-up of hydraulic pressure in the retraction system when the aircraft’s weight is on the wheels.

1.6.2 Emergency exit window

An emergency exit window is located behind the pilot’s seat on the left side of the aircraft (Figure 5). The panel has a weatherproof plastic cover when it is installed, and this cover should only be removed in case of emergency.

To remove the emergency exit window (figures 6 and 7), the procedure is as follows:

- Remove the clear plastic placard covering the handle.

- Turn handle.

- With hands apart on bottom sill, apply a steady sustained pressure outward until window is dislodged.Footnote 7

Instructors and pilots receive theory training on how to open the emergency exit window on the Piper PA-23-250. However, this training does not include a practical exercise on how to use the handle to remove the window. Regulations do not require that flight schools provide a practical aspect for this training.

1.7 Meteorological information

The regions of Montréal, Trois-Rivières, and Québec were under a ridge of high pressure and weather conditions were favourable for VFR flight at the time of the accident.

The CYRQ automated weather observation system (AWOS) issued an aerodrome routine meteorological report (METAR), which indicated the following conditions at 0000:

- winds calm

- visibility 9 statute miles

- clear skies

- temperature 11 °C

- dew point 10 °C

- altimeter setting 29.96 inches of mercury (inHg)

1.8 Aids to navigation

Not applicable.

1.9 Communications

On approach to CYRQ, the passenger-instructor communicated on the mandatory frequency (122.35 MHz) and obtained the relevant information from the universal communications station (UNICOM).

1.10 Aerodrome information

Located approximately 5 nautical miles northwest of the City of Trois-Rivières, CYRQ is certifiedFootnote 8 pursuant to the requirements stated in Subpart 302 of the Canadian Aviation Regulations (CARs). CYRQ is open 24/7,Footnote 9 for VFR and instrument flight rules (IFR) flights during the day and at night. The UNICOM service is normally provided from 0800 to 2100 during the summer months.

1.10.1 Runway 05/23

CYRQ has a single paved runway (Runway 05/23), which is 9006 feet long and 150 feet wide. The airport’s altitude is 199 feet above sea level. At the time of the accident, Runway 23 was in service.

Runway 05/23 has the following lighting:

- white variable-intensity runway edge lights, located at 60 m intervals along both sides of the runway

- runway threshold and end lights, which appear red to aircraft taking off and green to aircraft on approach and landing

1.10.1.1 Aircraft radio control of aerodrome lighting

Runway 05/23 has type K aircraft radio control of aerodrome lighting (ARCAL), which enables pilots to turn on the aerodrome lighting and adjust the intensity, with the exclusion of obstacle lighting. The lighting intensity can be adjusted by pressing on the microphone button 7, 5, or 3 times within 5 seconds on frequency 122.35 MHz to obtain high intensity (100%), medium intensity (30%) or low intensity (10%), respectively.

At 0002:25, the passenger-instructor turned on the ARCAL by pressing 7 times on the microphone button while the aircraft was on final approach. Four minutes later, the passenger-instructor performed a second series of clicks to reduce the lighting intensity to medium.

1.10.2 Aircraft rescue and firefighting services

CYRQ does not provide aircraft rescue and firefighting services.Footnote 10 The City of Trois-Rivières fire department provides firefighting services in the event of an accident or incident at the airport. The service gives priority to fires in the City of Trois-Rivières and, if the service is available, it can reach the airport in approximately 10 minutes.

At the time of the occurrence, 2 fire trucks were at the airport at the request of a foreign operator who was stopping at CYRQ at around 0030. In addition, the UNICOM service was being provided outside normal hours.

1.11 Flight recorders

The aircraft was not equipped with a flight data recorder or a cockpit voice recorder, nor was either required by regulation.

1.12 Wreckage and impact information

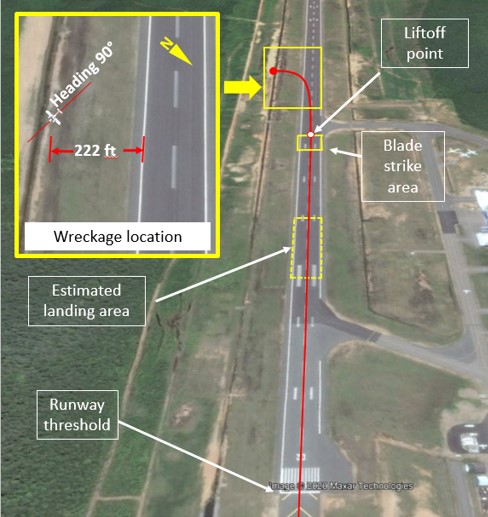

An examination of the occurrence site and wreckage determined that the left wing hit the ground first, followed by the nose and the right wing. The aircraft came to a stop upright, on a heading of 90°, 4460 feet from the threshold of Runway 23 and 222 feet south of the runway (Figure 8).

An examination of the wreckage determined that the landing gear was up and the flaps were in the UP position at the time of the occurrence. Both blades of the left propeller were bent backward and both blades of the right propeller were severed approximately 29 cm from the tip of each blade. Consequently, given the nature of the damage, and the differences in the damage to the left and right propellers, engine traction became asymmetrical.

The hydraulic power pack was recovered. However, it was impossible to determine the cause of the issue with the landing gear handle due to the damage caused by the post-impact fire.

An examination of Runway 23 revealed 73 impact marks caused by the left engine propeller blades, and 65 impact marks caused by the right engine propeller blades. The first marks were found 2980 feet from the runway threshold and subsequent marks extended over a distance of approximately 200 feet (Figure 9).

Images from the airport’s surveillance camera assisted the TSB’s laboratory in performing the calculations necessary to establish the aircraft’s speed on the runway and at the moment the blades initially made contact with the runway surface. This data, combined with other information gathered during the investigation, helped to establish the sequence of significant events that occurred during the touch-and-go (Appendix A).

1.13 Medical and pathological information

There was no indication that the pilot’s or the passenger-instructor’s performance was degraded by physiological factors.

1.14 Fire

Upon impact, the right wing detached from the fuselage and the fuel tank cracked, allowing fuel to leak out, which caught on fire. The flames quickly spread to the cabin.

Firefighters, who were on site at the airport at the request of another inbound aircraft, arrived at the scene of the occurrence at 0013, approximately 4 minutes after the accident. They rescued the 2 injured occupants and extinguished the fire.

1.14.1 Concerns regarding post-impact fires

Following its aviation safety issues investigation on post-impact fires resulting from small-aircraft accidents,Footnote 11 the TSB determined that there are a large number of small aircraft already in service and the defences against post-impact fire in impact-survivable accidents involving these aircraft are and will remain inadequate unless countermeasures are introduced to reduce the risk. Therefore, the TSB recommended that:

To reduce the number of post-impact fires in impact-survivable accidents involving existing production aircraft weighing less than 5700 kg, Transport Canada, the Federal Aviation Administration, and other foreign regulators conduct risk assessments to determine the feasibility of retrofitting aircraft with the following:

- selected technology to eliminate hot items as a potential ignition source;

- technology designed to inert the battery and electrical systems at impact to eliminate high-temperature electrical arcing as a potential ignition source;

- protective or sacrificial insulating materials in locations that are vulnerable to friction heating and sparking during accidents to eliminate friction sparking as a potential ignition source; and

- selected fuel system crashworthiness components that retain fuel.

In March 2017, when the response to this TSB recommendation was last reassessed, TC and the U.S. Federal Aviation Administration had no plans to take action to reduce the risks identified in Recommendation A06-10. However, the Board believes that the risks identified in Recommendation A06-10 have not decreased and remain significant.

From January 2015 to March 2017, there have been 4 survivable aircraft accidentsFootnote 12 in Canada that resulted in a post-impact fire, in which occupants received injuries of varying severity (2 minor injuries, 2 serious injuries and 2 fatalities).

Therefore, the response to Recommendation A06-10 is assessed as Unsatisfactory.Footnote 13

After the last reassessment of this recommendation in March 2017, there were 4 more survivable aircraft accidents involving a post-impact fire, in which occupants received injuries of varying severity (3 minor injuries, 2 serious injuries, and 1 fatality).Footnote 14

1.15 Survival aspects

The 2 occupants were unable to open the emergency exit window. Given that the window was completely destroyed by the post-impact fire, it was impossible to determine whether there was a defect in the opening mechanism or if the deformation of the fuselage caused by the force of the impact prevented the window from opening.

1.15.1 Emergency locator transmitter

The aircraft had an ARTEX ELT 200 (part number 453-0190, serial number EO1591), capable of transmitting only on frequency 121.5 MHz. As of 01 February 2009, Cospas-Sarsat satellitesFootnote 15 no longer detect signals on frequency 121.5 MHz; they detect only signals transmitted on frequency 406 MHz.Footnote 16

No distress signal was detected, and it was impossible to determine why because the ELT was completely destroyed by the fire.

1.16 Tests and research

1.16.1 TSB laboratory reports

The TSB completed the following laboratory report in support of this investigation:

- LP272/2019 – Video Analysis

1.16.2 Testing the opening of the emergency exit window

TSB investigators performed tests to open the emergency exit window using the designated handle on 2 other Piper PA-23-250 aircraft belonging to Cargair Ltd.

Further to the testing and the information gathered, the investigation identified the following:

- The emergency exit window is inspected by a technician every 100 flight hours.

- A practical exercise on opening the emergency exit window is not required or included in Piper PA-23-250 training.

- The handle can be turned only by using the tips of the fingers. The force needed to turn the handle on the 2 aircraft during testing did not exceed the maximum force of 30 pounds recommended in the U.S. Department of National Defense’s standardFootnote 17 that is also used in Canada.

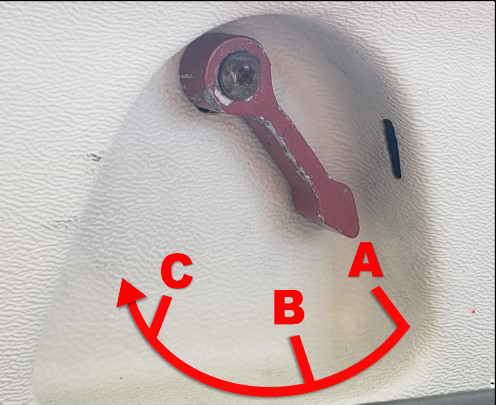

- Moving the handle from point A to point C (Figure 10) causes 2 pins to retract, which dislodges the emergency exit window from the fuselage.

- There is more resistance around point B, which requires the application of much more force to move the handle to point C, so that the pins are completely retracted.

- The handle can be turned more easily from the seat next to the handle (Figure 11).

- The headrest on the left front seat makes it difficult to turn the handle from that seat.

1.17 Organizational and management information

1.17.1 Operator

Cargair Ltd. is a flight school that holds a valid flight training unit operator certificate, subject to CARs Subpart 406, as well as an approved maintenance organization certificate issued by TC. It is also authorized to provide the Integrated Airline Transport Pilot – Aeroplane (ATP-A) training program. At the time of the occurrence, the company was operating a fleet of 55 aircraft, which included 7 Piper PA-23-250 aircraft.

1.17.1.1 Instructor duty time

Flight schools like Cargair Ltd. are subject to the regulations stipulated in Subpart 406 of the CARs. However, there is no regulation or standard pertaining to flight time or flight duty time in this subpart of the CARs. According to the CARs General Operating and Flight Rules, a person shall not act as a flight crew member or be assigned the duties of a flight crew member if there are reasons to believe that the person is not fit for duty.Footnote 18

Cargair Ltd. plans the work and assigns it to the instructors, and monitors their workload to avoid excessive workloads or hours worked. However, there are no documented guidelines with regard to overseeing instructors’ schedules. The instructors are responsible for ensuring that they are fit for duty, and may exchange or refuse flights to minimize the risk of fatigue.

1.17.1.2 Pilot-in-command under supervision

To satisfy the requirements for an airline pilot’s licence in their country, some foreign students must fly a minimum of 10 hours as pilot-in-command of a multi-engine aircraft, including a minimum of 5 hours flown at night. Some countries agree to these hours being flown as a pilot-in-command under supervision with an instructor on board.

In Canada, under specific conditions, Standard 421 of the CARs allows co-pilots to count their flight hours as if they were pilot-in-command when the hours are flown under the supervision of a pilot-in-command.Footnote 19 However, there is no similar regulatory provision that could apply to flights conducted by flight training units like Cargair Ltd.

Under Cargair Ltd.’s integrated airline transport pilot training program for foreign students, once students have obtained a commercial pilot’s licence, an IFR rating, and a multi-engine rating, they will conduct solo day and night VFR flights on a Piper PA-23-250. Given the pilots’ overall lack of experience, and as a safety measure, Cargair Ltd. decided that a qualified instructor would be on board these flights as a passenger. The instructor is not a flight crew member and does not record the flight hours in his logbook for these flights. The instructor’s role consists of supervising flight planning and execution, and assisting the pilot if necessary, only intervening in the case of an emergency, as the situation requires. The company verbally informed program pilots and instructors of the roles and expectations pertaining to the execution and supervision of these flights with a pilot-in-command under supervision.

1.17.1.3 Standard operating procedures

Cargair Ltd. developed standard operating procedures (SOPs) for multi-engine operations (on Piper PA-23-250 aircraft) and IFR operations. The purpose of these SOPs is to standardize procedures so that pilots who have never flown together can operate the aircraft in a similar way. The SOPs emphasize the need to study and memorize all the procedures, and stipulate that for the purposes of these dual control training flights, the instructor is the pilot-in-command and is responsible for all final decisions.Footnote 20 Flight school SOPs are not reviewed or approved by TC.

1.17.1.3.1 Before-takeoff briefing

The before-takeoff briefing confirms the type of takeoff, the runway in use, application of power, take-off speeds, action to be taken if there is a problem, and the departure procedure, including procedures to follow in the event of a communications failure.

The procedure to follow if problems arise before rotation (the decision speed) specifies that the takeoff must be rejected and the ground emergency procedures executed.Footnote 21

1.17.1.3.2 Rejected takeoff

According to Cargair Ltd.’s SOPs, a rejected takeoff must be clearly announced and executed in the following situations:

- ENGINE ROUGHNESS ON TAKE-OFF ROLL

- LOSS OF AIRCRAFT CONTROL ON TAKE-OFF ROLL

- DOOR AJAR LIGHT IS ON

- AIRSPEED/FUEL FLOW ABNORMAL INDICATION

- RUNWAY INCURSION, TRAFFIC ON THE RUNWAYFootnote 22

The rejected takeoff procedure set out in Cargair Ltd.’s SOP is:

- CONTROL THE AIRCRAFT - POWER IDLE - APPLY BRAKES

- ADVICE [sic] ATC [AIR TRAFFIC CONTROL] AS SOON AS PRACTICABLE

- STOP ON THE RUNWAY OR EXIT ON THE TAXIWAY, DEPENDING ON THE SITUATION

- EVACUATE IF NECESSARY […]Footnote 23

1.17.1.3.3 Normal takeoff

The normal-takeoff procedure in Cargair Ltd.’s SOPs is:

- APPLY POWER APPROXIMATELY 1500 RPM:

- VERIFY ENGINE PARAMETERS IN GREEN

- AND CALL “ALL IN GREEN”

- APPLY FULL POWER, CHECK SPEED AND CALL:

- “MAX POWER SET”

- “FUEL FLOW ALIVE”

- “AIRSPEED ALIVE”,

- AT 80 MPH “VMC”

- AT 85 MPH “ROTATE” WHILE EXERCISING A SLIGHT BACKWARD PRESSURE ON THE CONTROL COLUMN.

WHEN AIRBORNE ACCELERATE TO VYSE, THEN VY,Footnote 24 CHECK AND CALL:

“POSITIVE RATE OF CLIMB” AND “GEAR UP” […]Footnote 25

1.17.1.3.4 Flaps on landing

During an IFR approach or simulated approach, the flaps are set to the ¼ position when the aircraft begins a procedure turn or when it is on a heading to intercept the final approach course if the procedure turn is not used. Full flaps are then applied at 500 feet above ground level when the aircraft is flying VFR, or when the runway is in sight under instrument meteorological conditions.Footnote 26

When a touch-and-go is being conducted, the flaps are set to the ¼ position for the landing, and they must be raised by the instructor immediately after landing, in accordance with an agreement made in advance with the student, before taking off again.

1.17.1.3.5 Before landing checklists

Three green indicator lights will illuminate on the instrument panel when the landing gear is down and locked. According to the Before Landing and Final Checks checklists, the pilot must check 3 times to ensure that the green indicator lights are lit (Figure 12).

1.17.1.3.6 Landing

The landing procedure includes the following note: “It is normal procedure to perform stop and goes instead of touch and goes.”Footnote 27 However, during his training on Piper PA-23-250 aircraft, the pilot conducted several touch-and-go manoeuvres with his instructors.

1.18 Additional information

1.18.1 Somatogravic illusion

Somatogravic illusion is a phenomenon that occurs in conditions of poor visibility or darkness, when there is an absence of visual references. This illusion occurs when a person relies on the sensory organs of their inner ear to maintain balance and, without visual references, the signals transmitted by these organs may create an inaccurate perception. Acceleration on takeoff stimulates the otolithic organs in the vestibular system in a manner that is similar to tilting one’s head backward, creating the perception that the pitch attitude is greater than it actually is, which may give the impression that the aircraft is climbing.

In this occurrence, the TSB estimated that the application of power to initiate the takeoff produced acceleration that generated a nose-up attitude that was perceived as being 10° more than it actually was.

1.18.2 Surprise and startle effects on the flight deck

Surprise and the startle effect can affect human performance, and result in reactions ranging from being distracted to taking inappropriate action or making hasty decisions. Surprise can be defined as a cognitive and emotional response to an unexpected situation arising from a disparity between what is expected and what is perceived. Surprise tends to interrupt an action and focus attention on certain elements to the detriment of the overall situation, and may lead to inappropriate actions being taken.

The startle effect can be defined as an involuntary physiological reflex or conditioned response to a sudden intense stimulus. The startle reflex can cause hasty actions that may not be appropriate for the situation.Footnote 28

1.19 Useful or effective investigation techniques

Not applicable.

2.0 Analysis

The pilot was certified and qualified for this night visual flight rules cross-country flight in accordance with existing regulations. This flight was designated as a flight with a pilot-in-command under supervision under Cargair Ltd.’s integrated airline transport pilot training program for foreign pilots. A passenger-instructor was on board, but he was not acting as a flight crew member.

There was no indication that the pilot’s performance was affected by fatigue.

The investigation determined that a problem with the landing gear handle prevented the flaps from retracting after landing, which triggered a series of events that led to the propellers coming into contact with the runway surface, followed by a loss of control of the aircraft.

Consequently, the analysis will focus on the following elements:

- flight instructor duty time

- flights with a pilot-in-command under supervision

- problem with the landing gear and flap handle

- managing problems on takeoff

- evacuation through the emergency exit window

2.1 Flight instructor duty time

There is no regulation or standard specifically related to flight time and flight duty time for instructors (including passenger-instructors) working at flight training units. However, Cargair Ltd. plans and assigns work for instructors, and monitors their workload to avoid excessive workloads or hours worked. The information gathered during this investigation raises the possibility of prolonged continuous wakefulness, particularly when night flights precede flights scheduled for the next morning. A short period of sleep between 2 shifts increases the risk of fatigue. In the context of a flight school offering day and night flights, scheduling changes and weather conditions favourable for flying after a period of inclement weather, instructors could experience long periods of continuous wakefulness over consecutive days.

In the case of the occurrence flight, although the passenger-instructor had been continuously awake for 17 hours, the lack of other fatigue-related factors and the moderate workload established that his performance was not likely affected by fatigue. However, if instructors are assigned training or in-flight supervision duties that result in prolonged continuous wakefulness, especially over consecutive days, it increases the risk of fatigue-related incidents.

2.2 Flights with a pilot-in-command under supervision

In the absence of a regulatory framework specific to their training program’s flights with a pilot-in-command under supervision, Cargair Ltd. developed a supervisory program for these flights and verbally informed pilots and instructors of their roles and the expectations for the conduct of these flights. In this context, the pilot of the occurrence flight was the pilot-in-command and the instructor was not a member of the flight crew. However, the company expected the instructor to supervise the flight and only intervene in case of emergency, if required by the situation. The instructor had just completed his instructor training on Piper PA-23-250 aircraft. The occurrence flight was the second time he was supervising a flight with a pilot-in-command under supervision on this type of aircraft.

Although the pilot was aware that he was the pilot-in-command, it is likely that the instructor’s presence influenced his actions and decisions during the flight. It is also likely that the instructor had difficulty assuming the passive role of passenger, since he still had to supervise the flight and be ready to intervene if the situation required.

The pilot had conducted solo touch-and-go manoeuvres on single-engine aircraft; however, he had not conducted solo touch-and-go manoeuvres on multi-engine aircraft at Cargair because Cargair did not allow solo flights on the PA-23-250.

While the aircraft was on approach to Québec/Jean Lesage International Airport (CYQB), Quebec, the pilot and passenger-instructor agreed that the passenger-instructor would be in charge of radio communications with air traffic services. Although it was an effective sharing of duties to help manage the pilot’s workload, it may have reinforced the pilot’s impression that he was not flying completely solo.

The pilot and passenger-instructor’s interpretation of the company’s verbal instructions regarding flights with a pilot-in-command under supervision led them to believe that the passenger-instructor could supervise the flight while playing an active role, bringing them closer to the context of a normal training flight. When they were inbound for the Trois-Rivières Airport (CYRQ), Quebec, the pilot and passenger-instructor agreed to conduct a touch-and-go as practised on training flights with an instructor on a Piper PA-23-250. In this context, the flaps were to be set to the ¼ position for the landing, and the instructor would raise the flaps after landing. Therefore, on the occurrence flight, the pilot and passenger-instructor shared the same interpretation of the instructions and agreed on a clear plan. However, if passenger-instructor and pilot procedures, roles, and responsibilities on flights with a pilot-in-command under supervision are not clearly stated, there is a risk of differences in interpretation, which could create confusion on board and compromise flight safety.

2.3 Problem with the landing gear handle

Because the pilot and passenger-instructor had agreed to conduct a touch-and-go at CYRQ, the flaps were to be set to the ¼ position for the landing. The pilot used the usual technique to do this, which meant moving the flap handle to the DOWN position for 3 seconds before bringing it back to the neutral position. However, the investigation determined that the flaps were set to the ½ position, and for an undetermined reason, they remained in that position for the landing.

During final approach, the landing gear handle was moved to the DOWN position, but it did not automatically return to the neutral position once the landing gear was down and locked. The landing gear has hydraulic priority over the flaps, so when the landing gear handle is not back in the neutral position, moving the flap handle has no effect because no hydraulic pressure is being sent to the flaps (Appendix B).

2.4 Flap problem

Three green indicator lights illuminate on the instrument panel when the landing gear is down and locked. According to the Before Landing and Final Checks checklists, the pilot must verify 3 times that the indicators are lit. However, these checklists do not require verifying that the landing gear handle has returned to the neutral position. Given that the problem with the landing gear handle was not detected and the flaps did not need to be repositioned before landing, neither the pilot nor the passenger-instructor noticed that the flaps were blocked.

After landing, the passenger-instructor placed the flap handle in the UP position, as agreed upon during approach, and in accordance with the normal procedure for conducting a touch-and-go. He then noticed that the flaps had remained in the approach position and that the landing gear handle had not automatically returned to the neutral position. The investigation determined that the problem with the landing gear handle, which did not automatically return to the neutral position, prevented the flaps from retracting after landing.

2.5 Managing problems on takeoff

According to the standard operating procedures (SOPs), if a problem occurs before the ROTATE call, the takeoff will be rejected. A reminder of this is included in the Before Takeoff briefing. During a take-off roll, there is little time to recognize, analyze and solve problems. Therefore, the SOPs state that the takeoff should be stopped immediately so that the problem can be analyzed on the ground, with no time pressures, and to avoid inappropriate actions by pilots, especially when they are surprised or startled, as they were in this occurrence.

To try and understand the actions taken by the passenger-instructor and the pilot, we must examine their perception and understanding of the situation at the time their actions were taken, in the context of a touch-and-go at night. During the occurrence take-off roll, the passenger-instructor noticed that the flaps were stuck in the approach position before the ROTATE call was made. This problem created a situation that was counter to the passenger-instructor’s expectations, which may have taken him by surprise. Surprise tends to interrupt an action (in this case, monitoring takeoff), focus attention on certain elements to the detriment of the overall situation, and lead to hasty actions. Therefore, at that precise moment, the passenger-instructor, who may have been taken by surprise, began to address the problem with the flaps (which were stuck in the extended position) during the take-off roll, before the takeoff decision speed.

While the passenger-instructor was focusing his attention on the cause of the flap problem, the pilot was increasing engine power for takeoff as the aircraft was travelling down the runway at approximately 65 mph. The increased air from the propellers onto the wings while the flaps were still in the approach position (½) caused lift to increase, consequently reducing the aircraft’s weight on the landing gear. This increase in lift raised the aircraft slightly. Given the limited number of visual references at night and the fact that the passenger-instructor’s attention was focused inside the aircraft, this lift gave the impression of an early takeoff.

Acceleration can create a somatogravic illusion if external visual references are not perceived simultaneously. The aircraft’s acceleration on the runway generated a vestibular perception that the nose-up attitude was 10° higher than the aircraft’s actual attitude. Given that the passenger-instructor’s attention was focused inside the aircraft, it is quite likely that he also experienced this illusion. Consequently, the impression of flying at low speed, combined with the illusion of a pronounced nose-up attitude, influenced the passenger-instructor to move the landing gear handle to the UP position when, in fact, the aircraft was still rolling on the runway.

The lightening of the aircraft’s weight on the landing gear due to the increased lift during the take-off roll was enough to disable the anti-retraction valve and launch the retraction cycle. The landing gear retracted during the take-off roll, the aircraft dropped, and the propellers came into contact with the runway surface, causing asymmetrical damage to the propellers. At that point, the aircraft was close to the takeoff decision speed and the ROTATE call had not yet been made. The impact of the propeller blades generated an unusual loud noise, damage to the propellers, and significant vibrations.

When a person is startled by a sudden, intense stimulus, they may take hasty actions that may not be appropriate for the situation. The pilot, who was not aware that there was a problem with the landing gear, that the flaps were still in the approach position, or that the passenger-instructor had moved the landing gear handle to the UP position, was surprised by the aircraft’s drop onto the runway, the loud noise, and the considerable vibrations. Consequently, it is likely that the pilot, having been startled, pulled back on the control column, causing the aircraft to nose up enough to get off the ground with the flaps in the ½ position, before reaching the takeoff decision speed.

The aircraft took flight at a low speed (approximately 80 mph). The damage to the propellers resulted in reduced traction that was asymmetrical: the right engine had greater traction than the left engine. Consequently, the aircraft immediately began a left turn, even though the rudder and ailerons were fully deflected to the right.

Approximately 6 seconds after takeoff, the landing gear was fully retracted and the gear handle automatically returned to the neutral position. Since the flap handle was still in the UP position, the flaps began retract, reducing the aircraft’s lift. The reduction in lift caused by flap retraction while the aircraft was flying at low speed, combined with the asymmetrical low engine traction, resulted in the loss of control of the aircraft.

2.6 Evacuation through the emergency exit window

Due to the fire near the right wing, on the side of the aircraft where the main door was located, the 2 occupants headed to the back of the aircraft to evacuate through the emergency exit window located behind the pilot’s seat. However, they were unable to open the window with the handle. It was impossible to check whether the emergency exit window mechanism was working properly because it was completely destroyed by the post-impact fire.

To check the emergency exit window opening mechanism, including the handle, TSB investigators performed tests on similar Piper PA-23-250 aircraft. These tests showed that a significant amount of force was needed to use the handle, even though the structure around the emergency exit window was intact in the aircraft used for the tests. Furthermore, due to changes in resistance in the handle mechanism, the handle needs to be turned all the way to the end to release the window from the fuselage. It is possible that, under pressure from the urgency of the situation, the pilot and passenger-instructor did not realize that the handle had not been turned all the way.

Practical exercises help pilots to be better prepared in an emergency and enable them to better inform the passengers on the specifics pertaining to the opening of emergency exits before the flight begins. Neither the pilot nor the passenger-instructor had performed practical exercises on opening the emergency exit window during their training on this type of aircraft.

Given the force with which the occurrence aircraft struck the ground, it is likely that the damage or deformation to the aircraft’s structure caused the window to be jammed in place. Nevertheless, if pilots do not practise opening emergency exits, they could experience difficulty opening them and may not properly inform passengers how to open them in an emergency, reducing the chances of evacuating the aircraft quickly.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts or safety deficiencies that were found to have caused or contributed to this occurrence.

- A problem with the landing gear handle, which did not automatically return to the neutral position, prevented the flaps from retracting after landing.

- The passenger-instructor, who may have been taken by surprise, began to address the problem with the flaps (which were stuck in the extended position) during the take-off roll, before the takeoff decision speed.

- The impression of flying at low speed, combined with the illusion of a pronounced nose-up attitude, influenced the passenger-instructor to move the landing gear handle to the UP position when, in fact, the aircraft was still rolling on the runway.

- The landing gear retracted during the take-off roll, the aircraft dropped, and the propellers came into contact with the runway surface, causing asymmetrical damage to the propellers.

- It is likely that the pilot, having been startled, pulled back on the steering column, causing the aircraft to nose up enough to get off the ground with the flaps in the ½ position, before reaching the takeoff decision speed.

- The reduction in lift caused by flap retraction while the aircraft was flying at low speed, combined with the asymmetrical low engine traction, resulted in the loss of control of the aircraft.

3.2 Findings as to risk

These are conditions, unsafe acts or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- If instructors are assigned training or in-flight supervision duties that result in prolonged continuous wakefulness, especially over consecutive days, it increases the risk of fatigue-related incidents.

- If passenger-instructor and pilot procedures, roles, and responsibilities on flights with a pilot-in-command under supervision are not clearly stated, there is a risk of differences in interpretation, which could create confusion on board and compromise flight safety.

- If pilots do not practise opening emergency exits, they could experience difficulty opening them and may not properly inform passengers on how to open them in an emergency, reducing the chances of evacuating the aircraft quickly.

4.0 Safety action

4.1 Safety action taken

4.1.1 Cargair Ltd.

In July 2019, Cargair Ltd. took the following measures:

- A safety notice was sent to affected personnel on 09 July 2019 regarding a vulnerability in using the landing gear and flaps at the same time, and a modification to the standard operating procedures (SOPs).

- The Before Landing checklist was modified, adding “HANDLE NEUTRAL” after “GEAR… DOWN, WAIT 3 GREENS.”

- The role and responsibilities of a pilot-in-command under supervision have been specified in the SOPs.

- SOPs pertaining to visual flight rules circuits and the execution of touch-and-go manoeuvres have been amended.

- SOPs now contain directives on measures to be taken if a landing gear handle problem arises.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

Appendices

Appendix A — Significant events

| Time | Significant event |

|---|---|

| 2237 | Beginning of flight at CYHU |

| 2243 | Takeoff from Runway 24R at CYHU |

| 2335 | Final approach on Runway 06 at CYQB |

| 0006 | Final approach on Runway 23 at CYRQ |

| 0007:54 | Aircraft on the threshold of Runway 23 at CYRQ |

| 0008:05 | Wheels touch down |

| 0008:07 | Flap handle set to UP position |

| 0008:11 | Passenger-instructor notices that flaps are at ½ position |

| 0008:13 | Passenger-instructor notices that the landing gear handle is set to DOWN position |

| 0008:15 | Increase in power (approximately 65 mph) |

| 0008:16 | Landing gear handle set to UP position |

| 0008:18 | Start of propeller strike (approximately 90 mph) |

| 0008:20 | End of propeller strike and aircraft takeoff (approximately 80 mph) |

| 0008:26 | Landing gear handle returned to neutral and flaps retracted |

| 0008:28 | Flaps finish retracting |

| 0008:28 | Loss of control of the aircraft |

| 0008:31 | Impact with the ground (4460 feet from the threshold and 222 feet south of the runway) |

| 0008:34 | Fire breaks out near the right wing of the aircraft |

| 0008:45 | Occupants exit the wreckage |

| 0008:49 | Firefighters turn on the flashing lights |

| 0009:12 | Explosion at the site and post-impact fire |

| 0009:12 | Firefighters notify airport personnel |

| 0011:38 | Firefighters escorted to the site |

| 0013:00 | Firefighters arrive at the site |

Notes:

- The following data were gathered and used to determine the sequence of events: air traffic control audio tapes, radar recordings, witness statements, time for the landing gear to retract and the handle to return to the neutral position, flap retraction time (obtained during flight tests), and recordings from airport surveillance cameras.

- The times in this table have a margin of error due to the multiple sources used. Recording times may differ by a few seconds. However, using definite anchor points (e.g., impact marks on the runway made by the propellers and the position of the wreckage), combined with speed calculations based on video images and confirmed by the marks on the runway, the margin of error for times does not change the sequence of events as presented.

Appendix B — Movement of the landing gear and flap handles during the occurrence

| Condition | Handle position | Aircraft configuration |

|---|---|---|

| Cruise flight: flap and landing gear handles were in the neutral position, and the landing gear and flaps were up. | ||

| Approach: the flap handle was moved to the DOWN position, which initiated the deployment of the flaps. | ||

| Once the flaps were in the desired position, the pilot moved the flap handle back to the neutral position. | ||

| Final approach: the landing gear handle was moved to the DOWN position and the landing gear extended. | ||

| The landing gear was down and locked, but the landing gear handle did not automatically return to the neutral position. | ||

| After landing: the flap handle was moved to the UP position, but the flaps did not move because the landing gear handle was not in the neutral position. | ||

| Take-off roll: the landing gear handle was moved to the UP position and the landing gear began to retract. | ||

| After takeoff: once the landing gear was up, the landing gear handle automatically returned to the neutral position, and since the flap handle was still in the UP position, the flaps began to retract. |