Landing with partially extended landing gear

PAL Airlines Ltd.

Bombardier DHC-8-315, C-FPAE

Stephenville, Newfoundland and Labrador

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 15 November 2018, the PAL Airlines Ltd. Bombardier DHC-8-315 aircraft (registration C‑FPAE, serial number 562) departed Churchill Falls, Newfoundland and Labrador, as flight PVL1922 on an instrument flight rules flight to Deer Lake, Newfoundland and Labrador, with 4 crew members and 47 passengers on board.

At 1057 Newfoundland Standard Time, during the approach at Deer Lake, the flight crew selected the landing gear down; however, a weight on wheels caution light as well as advisory lights illuminated, indicating that the nose landing gear was not in the down‑and‑locked position. The flight crew executed a missed approach and entered a hold in order to troubleshoot the problem. At 1202, the flight crew requested a diversion to Stephenville, Newfoundland and Labrador, and declared an emergency. At 1230, the aircraft landed at Stephenville with the nose landing gear in a partially extended position. On touchdown, the nose landing gear fully collapsed, and the aircraft nose structure came into contact with the runway surface. The aircraft slid and came to a stop approximately halfway down the runway.

All occupants on board egressed the aircraft, and no injuries were reported. The aircraft sustained minor damage. There was no post-impact fire. The impact forces were insufficient to automatically activate the emergency locator transmitter. The accident occurred during the hours of daylight.

1.0 Factual information

1.1 History of the flight

The International Civil Aviation Organization’s (ICAO’s) Annex 13 requires states conducting accident investigations to protect cockpit voice recordings.Footnote 1 Canada complies with this requirement by making all on-board recordings —including cockpit voice recorders (CVR)— privileged in the Canadian Transportation Accident Investigation and Safety Board Act. While the TSB may make use of any on-board recording in the interests of transportation safety, it is not permitted to knowingly communicate any portion of an on-board recording that is unrelated to the causes or contributing factors of an accident or to the identification of safety deficiencies. The reason for protecting CVR material lies in the premise that these protections help ensure that pilots will continue to express themselves freely and that this essential material is available for the benefit of safety investigations. The TSB has always taken its obligations in this area very seriously and has vigorously restricted the use of CVR data in its reports. Unless the CVR material is required to both support a finding and identify a substantive safety deficiency, it will not be included in the TSB’s report. To validate the safety issues raised in this investigation, the TSB has made use of the available CVR information in its report. In each instance, the material has been carefully examined in order to ensure that it is required to advance transportation safety. |

On 15 November 2018, a PAL Airlines Ltd. (PAL) BombardierFootnote 2 DHC-8-315 aircraft (registration C‑FPAE, serial number 562) was conducting flight PVL1922 from Wabush Airport (CYWK), Newfoundland and Labrador, to St. John’s International Airport (CYYT), Newfoundland and Labrador, with stops at Churchill Falls Airport (CZUM) and Deer Lake Airport (CYDF). The trip from CYWK to CZUM was the first flight of the day for the crew and for the aircraft. Before takeoff, the first officer (FO) completed an exterior inspection of the aircraft.

The flight from CYWK to CZUM was uneventful and, once at CZUM, the FO completed another exterior inspection of the aircraft.

The aircraft departed CZUM for CYDF at 0925Footnote 3 with 4 crew members and 47 passengers on board. The pilots recorded a departure fuel load of 4400 pounds. The captain was the pilot flying.

At about 1048, during their descent to CYDF, the crew made initial contact with the CYDF Flight Service Station (FSS) and received the aerodrome information and a runway surface condition report. The runway in use at CYDF was Runway 25, and the winds were reported as 300° magnetic (M) at 17 knots, gusting to 30 knots. The runway surface condition report for Runway 07/25, issued at 1023, indicated the following:

- 130 feet cleared width, 55% wet snow trace, 15% compacted snow, and 30% bare and dry

- remaining width 100% dry snow over 1 inch compacted snow

At 1057, the aircraft was on final approach for landing on Runway 25 at CYDF. The crew selected the landing gear down and the amber weight on wheels (WOW) light illuminated on the caution light panel. On the landing gear selector panel, the red nose landing gear (NLG) unsafe advisory light, the amber NLG door-open advisory light, and the amber landing gear in‑transit light were all illuminated, and the green NLG down-and-locked advisory light was not illuminated.

The crew opened the landing gear alternate extension door, checked the landing gear down-and-locked verification lights to confirm that the NLG was not in the down position, and reclosed the door.

The captain re-cycled the landing gear up and down once. Although the main landing gear (MLG) successfully raised and lowered without a fault indication, the NLG indications and the WOW light did not change.Footnote 4

At 1059, the crew conducted a missed approach at CYDF, and requested that the FSS advise whether someone could visually confirm the NLG position as the aircraft flew down the runway. The FSS informed them that the NLG was visible, but not locked down. The crew then coordinated with the Gander Area Control Centre (ACC) to climb and enter a hold so that they could continue to troubleshoot the landing gear problem.

During the climb, the captain briefed the in‑charge flight attendant on the landing gear problem and made a public address announcement to notify the passengers. The crew then began to action a checklist from the PAL Dash 8 Quick Reference Handbook.Footnote 5 The quick reference handbook (QRH) WT ON WHEELS checklist (Appendix A) provides advisory information only, so the crew used the LDG GEAR INOP checklist. The QRH LDG GEAR INOP checklist requires the ALTERNATE LANDING GEAR EXTENSION checklist to be actioned (Appendix B). It states that the landing gear cannot be retracted once the checklist has been completed.

At 1104, while the crew was reading the QRH checklist items, another PAL flight, PVL1928, contacted the FSS and received a runway surface condition report in advance of their approach to CYDF. The report stated that snow drifts had formed on the runway due to deteriorating conditions, and that staff were currently on the runway taking a Canadian runway friction indexFootnote 6 (CRFI) measurement. The FSS then inquired whether PVL1928 could hold so that airport vehicles could conduct sweeping operations if necessary.

The occurrence crew initially delayed lowering the gear until the landing airport was decided, because the aircraft range would decrease with the MLG extended. The crew then heard that PVL1928 had discontinued their approach and was cleared for a hold.

At 1111, the FSS informed the crew that the CRFI was 0.19, that runway sweeping operations were underway, and that a runway condition update would be available in 10 minutes. The crew resumed actioning the QRH LDG GEAR INOP checklist and continued with the ALTERNATE LANDING GEAR EXTENSION checklist, which includes pulling the nose gear release handle.

At 1119, the crew’s smartphones were displaying a cellular service indicator. The captain’s headset was Bluetooth capable and paired to his smartphone. The captain called the PAL dispatch at CYYT, which then coordinated a conference call with the chief pilot; the director of flight operations; the director of quality, safety and training; and a maintenance shift supervisor (CYYT team). The FO was given the phone number of one of the CYYT team members so that the FO could make a video call to the CYYT team using an application on his smartphone. The FO positioned his smartphone so that the camera showed the cockpit, and the phone was paired to his Bluetooth headset so that he could hear the CYYT team’s conversation.

The captain made 4 calls to and received 1 call from the CYYT team to maintain the cellular connection because cellular service was interrupted several times. The calls lasted more than 66 minutes over the next 71 minutes, approximately until the aircraft touched down at Stephenville Airport (CYJT).

The CYYT team was briefed on the NLG condition and reviewed what tasks were completed in the checklist. The captain transferred control of the aircraft to the FO and then actioned the checklist items as the CYYT team read them out. The actions related to the ALTERNATE LANDING GEAR EXTENSION were completed for the NLG multiple times, particularly the repeated pulling of the nose gear release handle.

The FO maintained radio contact with the ACC and FSS, and followed along with the QRH checklist.

The crew received the following updated runway surface conditions: winds 310°M at 24 knots, gusting to 38 knots. The runway surface condition report for Runway 07/25, issued at 1116, indicated the following:

- 130 feet cleared width, 55% dry snow trace, 15% compacted snow and 30% bare and dry

- remaining width 100% dry snow over 1 inch compacted snow

- 0.41 CRFI

At 1127, the ACC contacted the occurrence crew to inform them that PVL1928 was conducting another approach at CYDF. At 1135, PVL1928 called the FSS to say that they were in a missed approach for Runway 25 owing to poor visibility related to blowing snow, and had diverted. The FO and FSS discussed landing intentions for PVL1922, and it was agreed to keep sweepers working to clear the runway while the crew continued troubleshooting the landing gear.

The captain and the CYYT team discussed troubleshooting options, and the captain decided to perform manoeuvres in an attempt to release the NLG and made a public address announcement briefing passengers about the manoeuvres. The FO transferred control of the aircraft to the captain, who disconnected the autopilot and, at 1149, made 3 abrupt and progressively larger aircraft pitch control inputs. Each control input caused abrupt increases in pitch angle and vertical loading on the aircraft.Footnote 7 The crew coordinated with ACC to climb for further troubleshooting.

At 1154, after the aircraft had climbed to 9600 feet, the aircraft began to descend and accelerate to 185 knots indicated airspeed (KIAS). During this descent, 7 consecutive elevator inputs were made, again causing abrupt increases in pitch angle and vertical loading on the aircraft.Footnote 8

At 1158, following a query from ACC regarding landing intentions at CYDF, the crew reviewed weather at both CYDF and CYJT. The crew consulted with the CYYT team regarding the decision to divert to CYJT. Although runway conditions and visibility at CYDF had improved, it was agreed that the longer and wider runway at CYJT, in addition to more favourable visibility, ceiling, and wind speed, made it a better landing option than CYDF.

At 1202 the crew requested a diversion to CYJT, and subsequently received clearance from the ACC to do so. The captain then declared an emergency with ACC, indicating the number of occupants on board and that there were 1300 pounds of fuel remaining.

The captain and the in-charge flight attendant reviewed the emergency landing checklist. The in-charge flight attendant made a public address announcement to brief the passengers on the emergency landing, including brace preparation and positions, call to brace, and exit locations. The evacuation briefing included emphasis to leave all belongings in the aircraft when exiting the aircraft.

The FO’s smartphone lost connection with the CYYT team, and he could no longer hear them on his headset. The CYYT team and the captain continued to discuss the position of the NLG and actions required to lower it.

From 1202 until the landing, pulling the NLG release handle was discussed several times, such as whether to do so by pulling the handle from a standing position. The captain and the CYYT team also discussed the required actions to be taken at touchdown, and discussed multiple times what the landing flap position should be.Footnote 9

Also during this time, the FO attempted to coordinate with the captain regarding the descent, approach, and landing. The captain was often communicating with the CYYT team during these attempts, requiring the FO to repeat prompts or questions asked. The review of the LANDING GEAR FAILS TO EXTEND checklist was carried out primarily between the captain and the CYYT team, and landing considerations such as whether the propellers were a hazard for ground contact, or what flap setting was recommended, were confirmed late in the flight. A plan was developed in discussion with the CYYT team that the flight crew would intentionally land firmly on the main landing gear and the FO would simultaneously pull the NLG release handle in an effort to release the NLG.

The crew flew the instrument landing system (ILS) approach to Runway 27 as cleared. The in‑charge flight attendant informed the captain once the cabin was secured in accordance with standard operating procedures (SOPs). At 1227, when the aircraft was at 6 NM from the airport on final approach, the captain decided on a flap setting of 35 degrees , which was selected about 1 minute later.

At 1230, with the CYYT team still on the phone, the aircraft touched down firmly on the main landing gear as the FO simultaneously pulled the nose gear release.Footnote 10 The captain narrated the landing for the CYYT team as the nose dropped lower and the partially extended NLG made contact with the runway. The aircraft slid on the partially extended NLG, in a nose-low attitude initially. The NLG was subsequently forced into the up position, and the aircraft nose slid briefly on the runway surface. The aircraft came to rest about halfway down the runway (Figure 1). The emergency locator transmitter did not activate.

Once the aircraft stopped, the captain shut down the aircraft engines and electrical power. The passengers and crew evacuated through the forward left passenger door and forward right emergency exit door without incident. No injuries were reported. The airport authority had arranged for taxis to be available to transport the occupants to the terminal.

1.2 Injuries to persons

| Crew | Passengers | Others | Total | |

|---|---|---|---|---|

| Fatal | 0 | 0 | – | 0 |

| Serious | 0 | 0 | – | 0 |

| Minor/None | 4 | 47 | – | 51 |

| Total | 4 | 47 | – | 51 |

1.3 Damage to aircraft

The aircraft sustained minor damage.

1.4 Other damage

Not applicable.

1.5 Personnel information

| Captain | First officer | |

|---|---|---|

| Pilot license | Airline transport pilot licence | Commercial pilot licence |

| Medical expiry date | 01 May 2019 | 01 July 2019 |

| Total flying hours | 19 000 | 1200 |

| Flight hours on type | 10 000 | 700 |

| Flight hours in the 7 days before the occurrence | 17.6 | 15.7 |

| Flight hours in the 30 days before the occurrence | 74.3 | 88.5 |

| Flight hours in the 90 days before the occurrence | 238.7 | 207.5 |

| Flight hours on type in the 90 days before the occurrence | 238.7 | 207.5 |

| Hours on duty before the occurrence | 4.5 | 4.5 |

| Hours off duty before the work period | 14 | 14 |

The flight crew were certified and qualified for the flight in accordance with existing regulations. Both of them had completed and were current with respect to all required training including company-provided crew resource management (CRM) training.

The captain had been with PAL since 1997, and the FO had been with PAL since 2018.

Based on a review of the flight crew’s work and rest schedules, fatigue was not considered to be a factor in the occurrence.

1.6 Aircraft information

| Manufacturer | Bombardier |

|---|---|

| Type, model and registration | DHC-8-315, C-FPAE |

| Year of manufacture | 2001 |

| Serial number | 562 |

| Certificate of airworthiness | 30 September 2010 |

| Total airframe time | 36 072.8 hours |

| Engine type (number of engines) | Pratt & Whitney Canada PW123E (2) |

| Propeller (number of propellers) | Hamilton Standard 14SF-23 (2) |

| Maximum allowable takeoff weight | 19 504.47 kg |

| Recommended fuel type(s) | Jet A, Jet A-1, Jet B |

| Fuel type used | Jet A-1 |

The DHC-8-315 is a twin-engine turboprop airliner in the de Havilland Dash 8 series of aircraft. The occurrence aircraft was configured for 50 passengers.

1.6.1 Landing gear

1.6.1.1 General

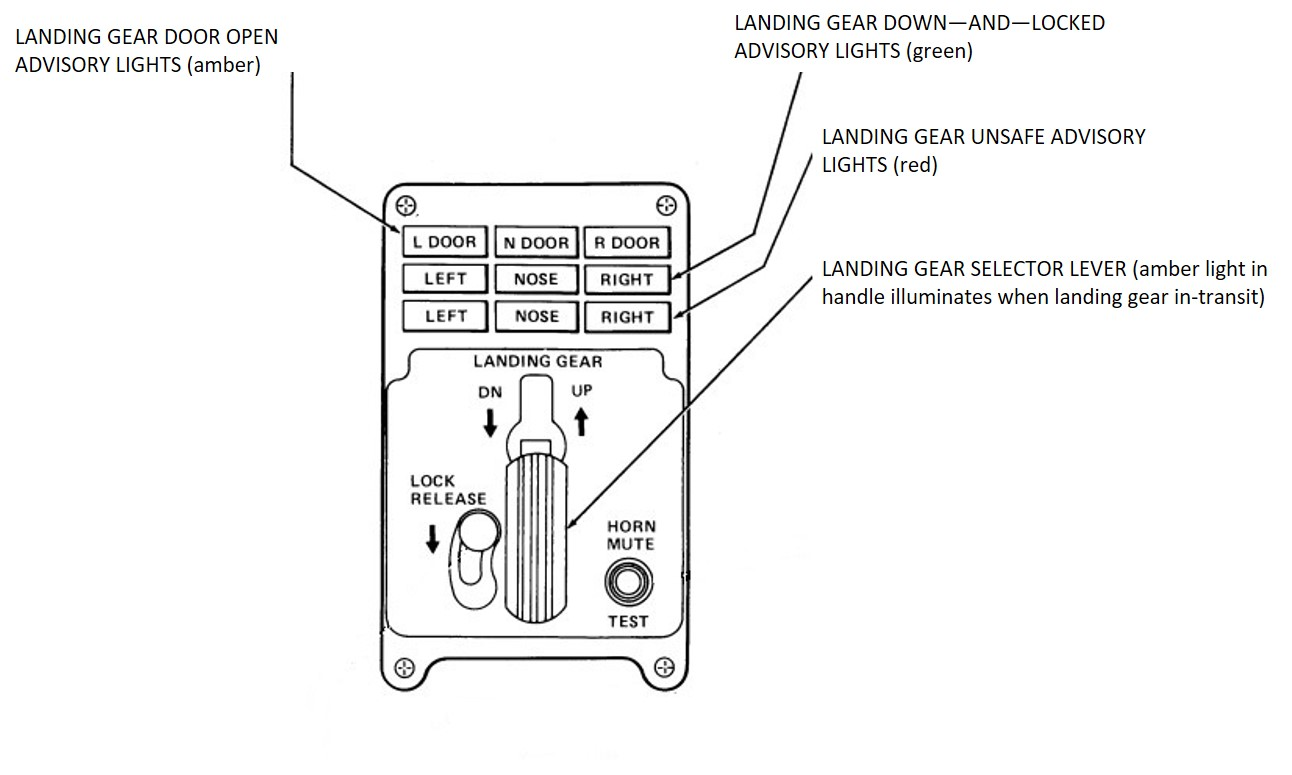

The aircraft has a retractable landing gear in a tricycle configuration. The landing gear is electrically controlled, hydraulically operated, and is mechanically locked in the up and down positions. Landing gear operation is controlled and monitored from the landing gear selector panel located on the instrument panel (Figure 2).

The landing gear is raised or lowered using the landing gear selector lever. An amber light in the lever illuminates when the landing gear is in transit (i.e., the actual position does not match the selected position). Nine advisory lights at the top of the panel indicate the landing gear and landing gear door positions. An amber gear door open advisory light illuminates when its respective door is open. A green landing down‑and‑locked advisory light illuminates when the respective gear is down‑and‑locked. A red landing gear unsafe advisory light illuminates when the respective gear is neither uplocked nor downlocked.

1.6.1.2 Alternate landing gear extension system

An alternate landing gear extension system can be used to extend the landing gear if the primary extension system fails.

An alternate landing gear extension is carried out by opening the landing gear alternate release door in the cockpit ceiling, which activates the landing gear bypass valve to isolate the aircraft hydraulic supply to the main and nose gear retraction actuators. Pulling the alternate extension release handle behind this door allows alternate extension of the main landing gear.

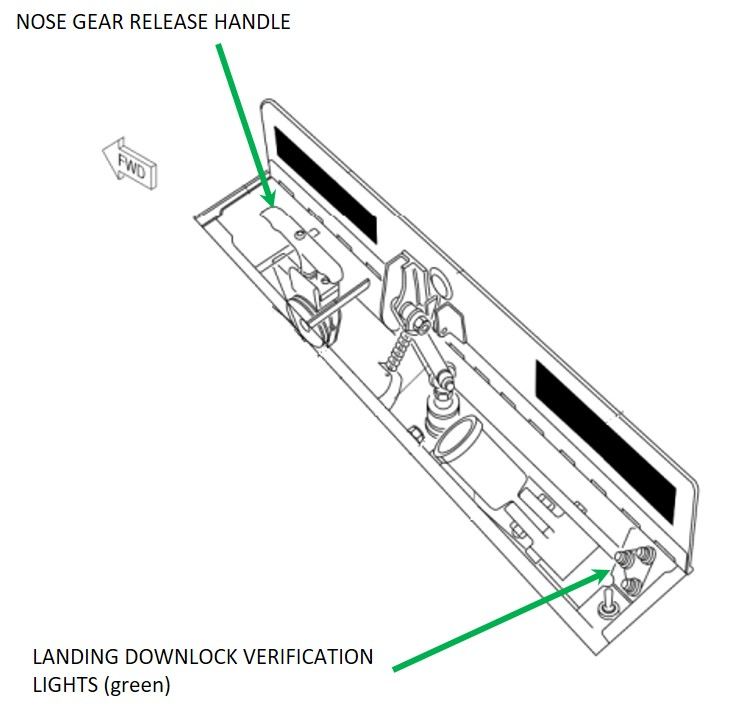

The landing gear alternate extension door in the cockpit floor is then opened and a handpump is available to fully extend the main landing gear if required. Adjacent to the handpump is the nose gear release handle (Figure 3). The first stage of the pull on the nose gear release handle unlocks the NLG forward doors. The second stage of the pull unlocks the NLG from the up position. Complete extension of the NLG is by free fall and airflow encountered inflight. An alternate down lock verification system provides a means to verify that the associated landing gear is in the down‑and‑locked position.

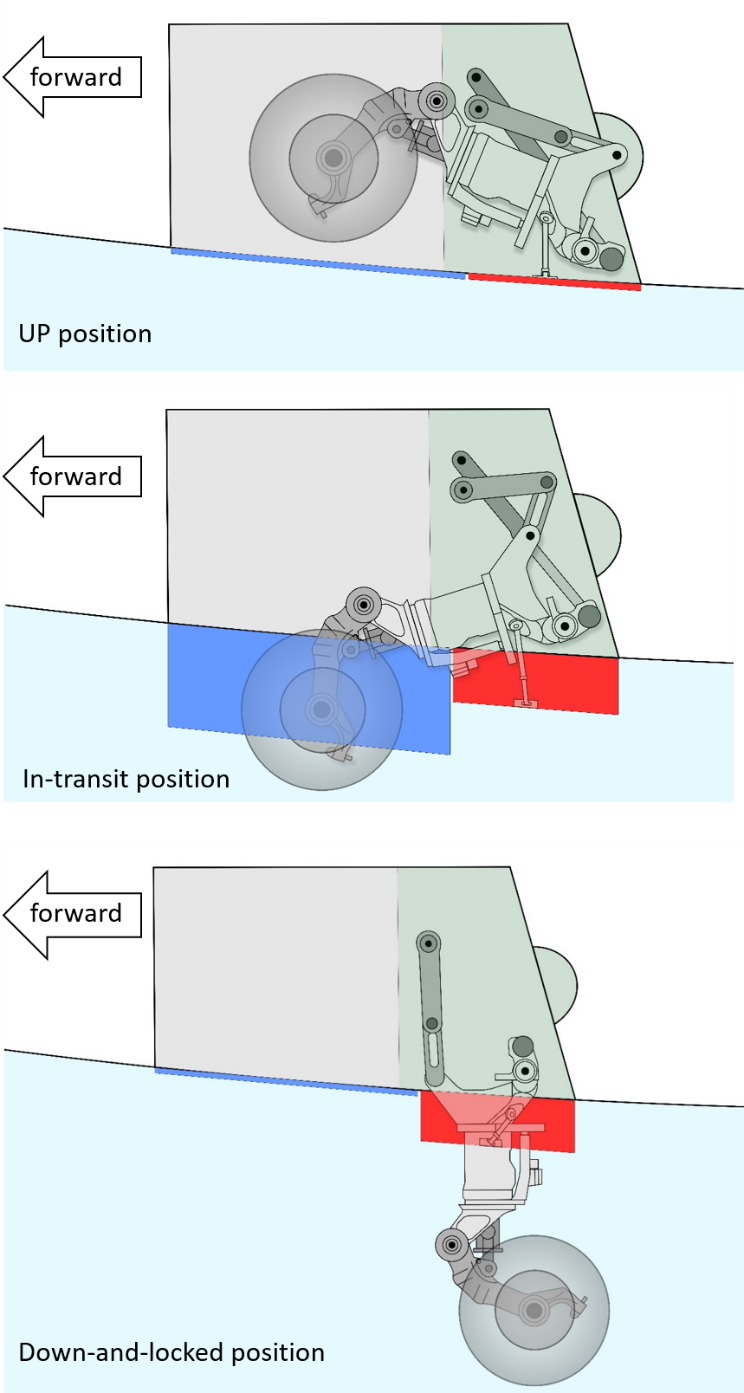

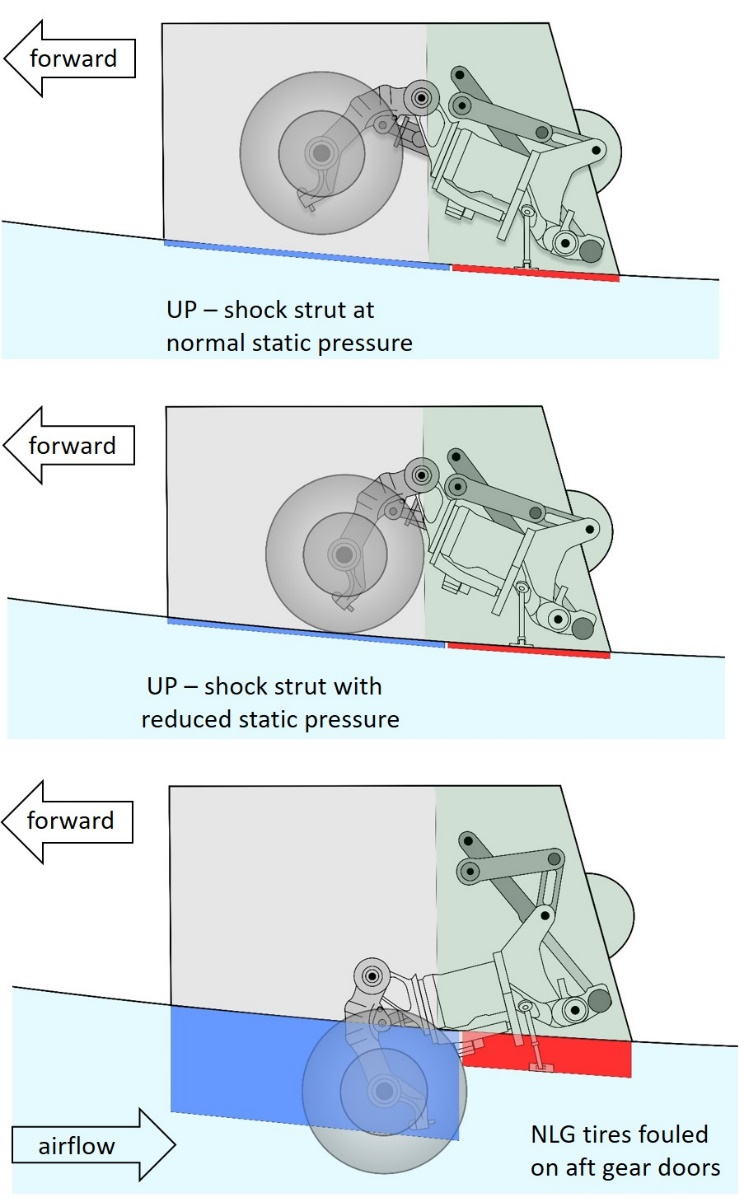

1.6.1.3 Nose landing gear

The NLG shock strut was manufactured by Safran Landing Systems, Canada Inc. (SafranLS) for Bombardier. The NLG shock strut absorbs the shock of landing and gives stability and direction control during aircraft taxi. It retracts up and forward into its wheel well in the nose section of the fuselage. When the dual-wheeled landing gear is in the up position, the landing gear doors completely enclose it. The forward doors are hydraulically opened and closed, and the aft doors are mechanically linked to the shock strut. When the landing gear is lowered into the down-and-locked position, the forward doors will normally be closed and the aft doors will remain open (Figure 4).

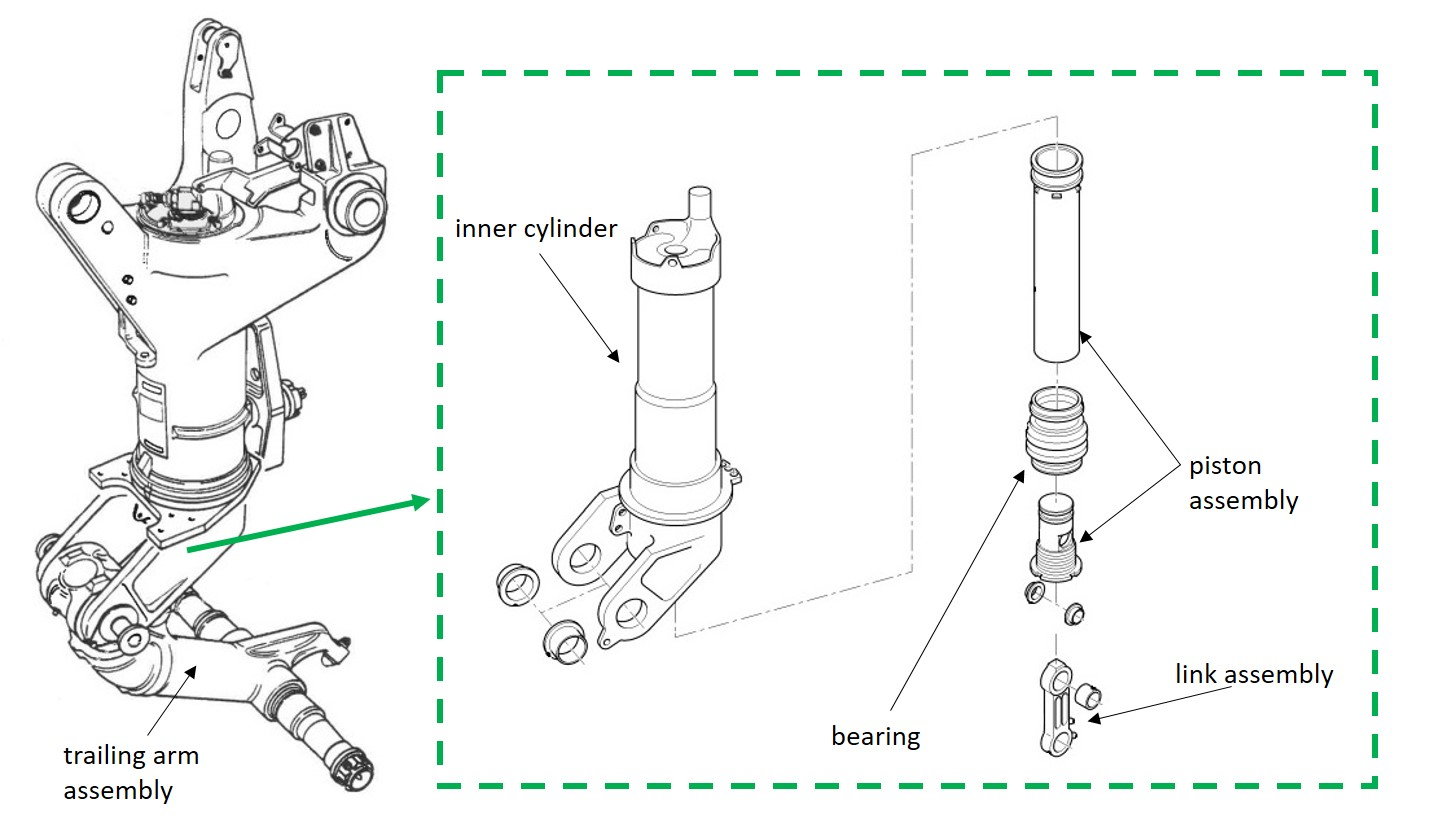

The NLG shock strut assembly uses trailing arm suspension geometry. The shock strut assembly includes an outer cylinder, an inner cylinder, and a trailing arm assembly (Figure 5). The dual wheels are installed on an axle mounted near the aft end of the trailing arm.

The inner cylinder and piston assembly components absorb landing shock. The assembly is filled with hydraulic fluid and charged with nitrogen gas. The trailing arm assembly pivots at the inner cylinder attach lugs, and uses a link to connect to the piston assembly that moves in and out of the inner cylinder. The piston slides in a bearing that is mounted inside the lower bore of the inner cylinder.Footnote 11

The inside diameter of the bearing has a groove machined for the installation of a seal ring assembly to prevent the leakage of hydraulic fluid and nitrogen gas past the sliding joint made between the inside surface of the bearing and the piston. A similar seal ring, installed in an outer diameter groove on the bearing, prevents leakage at the static joint between outside diameter of the bearing and the lower bore of the inner cylinder.

SafranLS requires overhaul at 10 years of service or 25 000 landing cycles for the NLG shock strut, whichever happens first. Overhauls are carried out in accordance with the SafranLS component maintenance manual (CMM), which provides disassembly, inspection, measurement, repair, refinish, and reassembly instructions for the NLG shock strut assembly.Footnote 12

The bearing is secured inside the bore of the inner cylinder, thereby forming a static joint not normally subject to relative movement or wear. The outside diameter of the bearing and the lower bore of the inner cylinder are inspected for condition during an overhaul. Dimensional measurement of these areas is only required if an unserviceable condition such as wear or corrosion is observed.

A prescribed repair published in the CMM requires rework to the lower bore of the inner cylinder to remove heavy corrosion if discovered. The rework establishes a larger inside diameter for the lower bore of the inner cylinder, and requires a specific permanent marking be made on the inner cylinder attach lug to identify that the repair has been carried out and an oversized inner cylinder condition exists. The CMM explains that an inner cylinder with this specific marking requires that a special, oversize bearing arrangement (that has a larger outside diameter) be selected from the instructions provided, and installed during the reassembly process.Footnote 13

Installing a standard size bearing assembly in an inner cylinder reworked to a larger lower bore creates an excessive clearance between these components.

1.6.1.4 Examination of nose landing gear

After the landing occurrence at CYJT, the aircraft was lifted with a boom truck using straps. The NLG was observed to be in a fully up position, having been forced up during the landing. When the nose gear release handle was pulled, the NLG was unlocked from the up position and swung down into the fully down‑and‑locked position. The NLG shock strut showed evidence of hydraulic fluid leakage and required nitrogen gas service due to low piston extension height.Footnote 14 Damage and marks observed on the tires and on the aft landing gear doors indicated that the NLG tires were moved into a position where the aft doors were caught between the tires.Footnote 15 A similar occurrence involving a Dash 8 aircraft, where an NLG shock strut with a low piston extension height contributed to a partially extended NLG, had been previously identified by both Bombardier and the TSB (see section 1.18.1 of this report).Footnote 16

When the landing gear was lowered, slipstream acted to compress the NLG shock strut due to its lower internal static pressure. With the NLG shock strut shortened and compressed, the nose gear tires were able to come into contact with the aft landing gear doors, causing the NLG to become jammed in a partially extended position (Figure 6).

A successful leak check was conducted on the NLG shock strut, and the aircraft was prepared for a ferry flight for further repairs to be conducted.Footnote 17 Subsequent disassembly and examination of the NLG shock strut determined that the hydraulic fluid volume was about 450 mL less than specified.

The inner cylinder was found to have been repaired on its lower bore, where the bearing is installed. The repair increased the diameter of the inner cylinder bearing bore, as specified in the CMM.

The inner cylinder was not permanently marked to indicate that the rework repair to the lower bore of the inner cylinder had been carried out. The bearing installed in the inner cylinder was a standard-size bearing, whereas an oversize bearing is required by the CMM for this repair. This resulted in an actual clearance that was 0.015 inch larger than required between the bearing and the lower bore of the inner cylinder, measured at the seal ring location.

The excessive clearance resulted in the seal ring having less interference on it (i.e., the seal ring was deformed, or squeezed less) compared to a seal ring installed with the required clearance. This condition had the effect of allowing the seal ring to have less sealing force.

At the time of the occurrence, the NLG shock strut installed in the occurrence aircraft had accumulated 6364 landing cycles since the last overhaul, and 46 573 cycles since new. It was last overhauled on 02 December 2014 by SafranLS at 40 209 landing cycles since new after having been removed from an aircraft operated and registered in the United States.

No rework or repair related to the lower bore of the inner cylinder was recorded by SafranLS at the 2014 overhaul. The records from the previous overhaul—when the aircraft was operated in the United States—were no longer available; therefore, it could not be determined where the overhaul was conducted and what work was accomplished.

On 09 October 2018, a low NLG shock strut extension height was identified on the occurrence aircraft following a pilot-reported defect described as “nosewheel rough on taxi.” Maintenance personnel rectified the low NLG shock strut extension height by replenishing the NLG shock strut hydraulic fluid volume and nitrogen gas pressure in accordance with the aircraft maintenance manual servicing instructions.Footnote 18 No other defects related to the NLG shock strut were recorded for the next 37 days until the occurrence flight. The NLG shock strut had accumulated 233 cycles since servicing.

1.6.2 Fuel quantity indication

Usable fuel quantity for the left and right fuel tanks is displayed in 2 fuel quantity indicators on the lower centre instrument panel in the flight compartment of the aircraft. The indicators show left and right fuel quantity by their respective positions and read in thousands of pounds, with markings graduated in hundreds of pounds.Footnote 19

Data on fuel quantity are also entered into the flight management system (FMS). The FMS uses data on fuel flow from the engine fuel flow sensors to provide the inputs necessary to integrate real-time fuel management information with the navigational functions. During a flight, the FMS automatically updates the data regarding fuel on board and gross weight, as well as the fuel requirements based on fuel flow and ground speed. This information is displayed to the pilots.

1.6.3 Emergency locator transmitter

Based on information from the flight data recorder (FDR), there were insufficient impact forces to automatically activate the emergency locator transmitter.Footnote 20

1.6.4 Aircraft airspeed limitations

The aircraft flight manual provides certification airspeed limitations related to landing gear operations.Footnote 21 It limits the alternate landing gear extension speed to 140 KIAS because all landing gear doors are open in this configuration. The manual also indicates that the maximum speed at which the airplane can be safely flown with landing gear extended (VLE) is 173 KIAS, and that the maximum speed at which it is safe to extend or retract the landing gear (VLO) is 163 KIAS.

The airspeed reached 185 KIAS during the alternating climb and descent manoeuvres, as recorded by the FDR.

1.7 Meteorological information

The aerodrome forecast (TAF) for CYDF, issued at 1008, indicated the following conditions between 1030 and 1430:

- winds 280° true (T) at 20 knots, gusting to 30 knots

- visibility 1 statute mile (SM) in light snow and blowing snow

- broken ceiling at 1500 feet above ground level (AGL)

The following temporary change in conditions was forecast for between 1030 and 1430:

- visibility 6 SM in light snow

- broken ceiling at 3000 feet AGL

The aerodrome routine meteorological report (METAR) at 1030 for CYDF indicated the following:

- winds 280°T at 22 knots gusting to 33 knots

- visibility 1 SM in light snow and blowing snow

- scattered clouds at 1000 feet AGL

- broken ceiling at 2200 feet AGL and broken clouds at 16 000 feet AGL

- temperature −3 °C, dew point −6 °C

The METAR at 1130 for CYDF indicated the following:

- winds 280°T at 21 knots gusting to 38 knots

- visibility 1 SM in light snow and blowing snow

- scattered clouds at 1000 feet AGL

- broken ceilings at 1900 feet AGL and at 16 000 feet AGL

- temperature −3 °C, dew point −6 °C

An aerodrome special meteorological report (SPECI) issued at 1158 for CYDF indicated the following:

- winds 290°T at 23 knots gusting to 38 knots

- visibility of 2½ SM in light snow and blowing snow

- few clouds at 700 feet AGL

- scattered clouds at 1700 feet AGL

- broken ceiling at 16 000 feet AGL

- temperature −3 °C, dew point −7 °C

The TAF for CYJT, issued at 0808, indicated the following conditions between 0830 and 1430:

- winds 300°T at 30 knots, gusting to 40 knots

- visibility greater than 6 SM

- overcast ceiling at 2000 feet AGL

The following temporary change in conditions was forecast for between 0830 and 1430:

- visibility 4 SM in light snow showers and blowing snow

- broken ceiling at 3000 feet AGL

The forecast for this period also included a 30% probability of 2 SM visibility in light snow showers and blowing snow.

The METARs issued at 1030, 1130, and 1230 for CYJT were similar in the following:

- visibility 12 SM, which became 15 SM at 1130

- broken ceiling at 2100 feet AGL

- temperature −3 °C and dew point −8 °C, which became −7 °C at 1230

The winds indicated in these METARs were as follows:

- At 1030, winds were 310°T at 19 knots, gusting to 31 knots.

- At 1130, winds were 310°T at 22 knots, gusting to 32 knots.

- At 1230, winds were 330°T at 19 knots, gusting to 27 knots.

1.8 Aids to navigation

The flight crew flew the ILS approach to Runway 25 in CYDF and the ILS approach to Runway 27 in CYJT. There were no reported anomalies in either of the approaches or their associated systems.

1.9 Communications

No anomalies in the quality of radio transmissions with air traffic services were noted during the flight.

1.10 Aerodrome information

CYDF has 1 asphalt runway, Runway 07/25, that is 8005 feet long and 150 feet wide.

CYJT has 1 asphalt runway, Runway 09/27, that is 10 011 feet long and 200 feet wide.

There were no reported anomalies with the aerodrome systems.

1.11 Flight recorders

The aircraft was equipped with a solid state FDR and a solid state cockpit voice recorder (CVR). The CVR and the FDR were sent to the TSB Engineering Laboratory with the occurrence data intact.

The FDR recorded and stored more than 26 hours of flight data, including the occurrence flight.

The CVR recorded and stored the last 30 minutes of cockpit sounds. At the time of report writing, section 625.34 of the Canadian Aviation Regulations (CARs) states that for aircraft manufactured after 31 December 2002, a CVR “shall retain all information recorded during the aircraft’s operation, or all information recorded during the last two hours of the aircraft's operation, whichever is less.”Footnote 22 For all other aircraft required to be equipped a CVR, the required recording capacity is at least 30 minutes. Given that the occurrence aircraft was manufactured in 2001, the CVR on board met the current Canadian regulatory requirements.

The benefits of longer CVR recordings are well known. The lack of longer periods of recorded voice and other aural information continues to inhibit occurrence investigations and delay or prevent the identification of safety deficiencies.

1.11.1 Previous TSB recommendation on recording capacity of cockpit voice recorders

On 02 September 1998, Swissair Flight 111, a McDonnell Douglas MD-11 aircraft, struck the water near Peggy's Cove, Nova Scotia, fatally injuring all 229 occupants on board.Footnote 23

One of the shortcomings identified during the investigation was the limited recording capacity of the aircraft's CVR. The CVR was able to record only 30 minutes, and therefore did not capture the timeframe when a fire started.

On 09 March 1999, the Board issued Recommendation A99-02 to both Transport Canada (TC) and the European Joint Aviation Authorities, that:

As of 01 January 2005, all aircraft that require both an FDR and a CVR be required to be fitted with a CVR having a recording capacity of at least two hours.

TSB Recommendation A99-02

In TC’s October 2019 response to Recommendation A99-02, the department stated that it agreed with the recommendation. TC also stated that the final regulations that address the CVR component of this recommendation (2-hour recording capacity) were published in the Canada Gazette, Part II, in May 2019.Footnote 24

The new regulations require all multi-engined turbine-powered aircraft that are configured for 6 or more passenger seats and for which 2 pilots are required by the aircraft type certificate or by the subpart under which the aircraft is operated, to have a CVR that can record at least 2 hours. The new regulations will be effective in May 2023, 4 years after the publication of the regulations.

The TSB’s March 2020 reassessment of TC’s response stated that the Board believed that these amendments will address the safety deficiency associated with this recommendation. The last response to Recommendation A99-02 was assessed by the Board as Fully Satisfactory, and the deficiency file was Closed.

1.11.2 Smartphone connection to cockpit voice recorder

Because the smartphones used by the flight crew were not connected to the aircraft audio system architecture, the CVR did not record voice transmission from the CYYT team during their conversation with the flight crew.

1.12 Wreckage and impact information

The forward and rear NLG doors received crush and abrasion damage. The NLG tires received abrasion damage. The aircraft structure associated with the NLG door hinge attach area was deformed. The skin aft of the NLG bay, and an antenna mounted in this area, received abrasion damage.

1.13 Medical and pathological information

Not applicable.

1.14 Fire

Not applicable.

1.15 Survival aspects

Not applicable.

1.16 Tests and research

1.16.1 TSB laboratory reports

The TSB completed the following laboratory report in support of this investigation:

- LP254/2018 – FDR Data Analysis

1.17 Organizational and management information

PAL is authorized to conduct commuter and airline operations under subparts 704 and 705, respectively, of the CARs. PAL operates 18 turboprop aircraft, including 8 Dash 8 series aircraft. The company has a TC-approved safety management system (SMS).

1.18 Additional information

1.18.1 Previous occurrence involving partially extended nose landing gear

In 1998, a similar occurrence involving a Dash 8 aircraft was documented by the TSB. Footnote 25

In that occurrence, when the landing gear was selected down, the NLG did not provide a safe, down-and-locked indication. The alternate landing gear extension was unsuccessful in lowering the landing gear, and a subsequent visual confirmation determined that the NLG was in a partially extended position. The crew landed the aircraft with the NLG partially extended and passengers evacuated without injury.

Examination of the NLG revealed that the NLG shock strut had deflated in flight due to a damaged component of the NLG shock strut seal ring assembly. It was determined that when the landing gear was lowered, slipstream acted to compress the NLG shock strut and allowed the tires to become fouled on the aft landing gear doors, thereby jamming the NLG in a partially extended position.

Bombardier did post-occurrence testing and duplicated the condition on an exemplar aircraft. Bombardier released All Operator Message No. 466 that revealed its investigation findings and stated:

Operators are reminded that the geometry of the nose landing gear extension and retraction system is such that a properly serviced and serviceable nose landing gear is required prior to dispatch. Should the nose landing gear oleo lose either it’s [sic] hydraulic fluid or nitrogen charge, the potential exists for the nosewheel tires to become jammed on the nose landing gear wheel bay aft doors, thus preventing extension. Footnote 26

The All Operator Message also suggested that operators review current maintenance practices for landing gear servicing.

1.18.2 Portable electronic devices

1.18.2.1 Interference with aircraft systems

TC Advisory Circular (AC) No. 700-005, Use of Transmitting and Non-Transmitting Portable Electronic Devices defines a portable electronic device (PED) as “any lightweight, electrically-powered equipment […] typically consumer electronic devices” such as smartphones, tablets, e‑readers, MP3 players, and electronic toys. Footnote 27 A non-transmitting PED has had its radio frequency transmitting functions turned off or disabled by setting it to airplane mode. A transmitting PED (such as cellular, Bluetooth, Wi‑Fi, satellite phones and remote control devices) contains an intentional radio frequency transmitting function. Footnote 28

Much of the regulation regarding the use of PEDs in aircraft has been related to concerns of electromagnetic interference, and the fact that PED signals “can occur at the same frequencies used by the aircraft’s highly sensitive communications, navigation, flight control, and electronic equipment.” Footnote 29

Regarding the use of PEDs, section 602.08 of the CARs states the following:

- No operator of an aircraft shall permit the use of a PED on board an aircraft if the use of the PED could adversely affect the operation of the aircraft or the functioning of the aircraft’s systems or equipment.

- No person shall use a portable electronic device on board an aircraft except with the permission of the operator of the aircraft. Footnote 30

Subsection 705.40(4) of the CARs contains an exception that permits the use of a PED on an aircraft if the air operator has established procedures that meet the Commercial Air Service Standards and are specified in that air operator’s company operations manual. Footnote 31 PAL’s company operations manual prohibits the use of cellular telephones on board its aircraft except during taxi‑in to the gate. Footnote 32

Since 2007, TC has been permitting the expanded use of PEDs through the application of exemptions. Some national exemptions for all air operators exist, since they relate to the use of PEDs during specific phases of flight (such as the use of PEDs during the taxi following landing). Additionally, multiple individual exemptions relating to specific aircraft types used by a specific air operator exist, and prescribe the conditions the air operator must follow regarding PED use.

TC conducted risk assessments between 2011 and 2013, and included reviews of various reports written by several other agencies (Radio Technical Commission for Aeronautics, the Federal Aviation Administration, and Boeing) regarding the use of PEDs on board aircraft. The potential hazards of PED interference with aircraft systems was considered, and it was acknowledged that this interference would be more severe if occurring during critical phases of flight.

PEDs can be inadvertently left on in all phases of flight; however, none of the other agencies’ reports identify incidents resulting from the use of PEDs. The TC risk assessments concluded that

various PEDs could be allowed safely on board aircraft providing additional controls were in place by the air operator (e.g., asking passengers to turn off all PEDS if there was interference identified by the pilots). Footnote 33

Since 2007, TC has not received any reports of incidents related to PED interference with aircraft systems on board Canadian aircraft. The area of concern relating to PEDs continues to be the risk of their catching fire because they have lithium batteries.

On 10 May 2019, the TC Canadian Aviation Regulation Advisory Council (CARAC) made notice of proposed amendment (NPA) No. 2019-004 proposing amendments to the CARs and to the Commercial Air Service Standards related to PED exemptions. The intent of NPA 2019‑004 is to codify existing exemptions allowing the expanded use of PEDs on board aircraft, and to make new provisions applicable to operations governed by CARs subparts 703, 704, and 705. Among the new provisions are requirements for air operators to keep records of the specific type, series, and model of aircraft on which they allow the use of PEDs on board and have validated that PEDs will not interfere with aircraft systems or equipment in all phases of flight. The new provisions would also require reporting to TC of any PED interference, and would immediately prohibit that PED for use by the operator. Footnote 34

1.18.2.2 Integration of portable electronic devices into the cockpit

Although there are regulations restricting the use of PEDs in flight, TC provides guidance for air operators to develop an electronic flight bag (EFB) program. The intent of the EFB program is to eliminate the need for paper manuals, charts, approach plates, etc. in the cockpit, and instead allow flight crews to access these items electronically on the ground and in flight. EFBs can be either portable systems such as a PED (typically a tablet), or installed units that are incorporated into aircraft systems.

TC requires the certification, airworthiness and operational approval of PEDs used in an EFB program by air operators. In Advisory Circular No. 700‑020 entitled Electronic Flight Bags, TC describes many aspects of an operator’s EFB program that are considered during an evaluation, including the following considerations: Footnote 35

- Has the operator developed crew procedures and integrated them into the SOPs?

- Has the operator developed a training program, including human factors and CRM training?

- Has it been determined that the device does not distract pilots during critical phases of flight?

- Has the device been assessed for display view issues such as critical line of sight, colour‑coding, glare, and nighttime readability?

- Has the operator mitigated hardware and software failure situations?

TC has not provided similar guidance to air operators for the use of PEDs such as smartphones by crews in-flight. PAL had not developed procedures to integrate smartphone PEDs for in-flight use by a flight crew.

1.18.3 Fuel quantity

The fuel requirements for reserve fuel in PAL’s company operations manual are consistent with the stated CARs requirement: Footnote 36

- IFR [instrument flight rules]: An aircraft operated in IFR flight shall carry an amount of fuel that is sufficient to allow the aircraft:

- Where an alternate aerodrome is specified in the flight plan or flight itinerary, to fly to and execute an approach and a missed approach at the destination aerodrome, to fly to and land at the alternate aerodrome and then to fly for a period of 45 minutes for propeller‑driven aeroplane; Footnote 37

This reserve fuel allows mitigation strategies that require additional flight endurance when delays are encountered before landing at the alternate airport, such as unforeseen circumstances at the alternate airport.

For the occurrence flight, the designated alternate airport was Sydney/J.A. Douglas McCurdy airport (CYQY), Nova Scotia, and the fuel quantity recorded in the operational flight plan was sufficient to meet the fuel requirement. The operational flight plan identified the required reserve fuel of 45 minutes as 894 pounds. At CYJT, PAL maintenance personnel documented the post-landing fuel quantity indication, which showed about 600 pounds.

1.18.4 Daily inspection

Bombardier’s scheduled maintenance requirements do not include a daily inspection of the aircraft.

Bombardier requires that a line maintenance inspection be completed every 12 days or 50 hours of airtime, whichever occurs first. Footnote 38 PAL created a line check (also known as an L-check) based on the list of items required by Bombardier. Footnote 39 The portion of this check related to the aircraft exterior identifies the specific flight control, fuselage, engine, propeller, and landing gear items to be inspected and, when applicable, inspection criteria for maintenance personnel to use. The serviceability of these items is critical to the safety of flight.

PAL also created an inspection checklist (also known as a lay-over check) for maintenance personnel to use when aircraft remain overnight at one of its maintenance bases. This checklist is used to inspect items critical to the safety of flight between L-check intervals.

Both the L-check and the lay-over check include inspecting the landing gear shock strut for leaks, checking its condition, and confirming that the extension height is correct.

No NLG shock strut anomalies were recorded by maintenance following any of the L-checks or lay-over checks conducted between the 09 October 2018 maintenance rectification for low NLG shock strut extension height and the occurrence.

When aircraft remain overnight at locations where no company maintenance personnel are based, such as CZUM, the flight crew’s pre-flight check is the only aircraft inspection that is completed.

1.18.5 Pre-flight check

Bombardier requires that an exterior inspection be conducted as a pre-flight check of the aircraft. In the normal procedures section of the Dash 8 flight manual specific to this aircraft, Bombardier provides the following pre-flight check for ramp procedures:

4.1.1 BEFORE ENTERING THE AIRPLANE. Perform an exterior inspection including the following:

- Remove main gear safety lock pins.

- Disengage nosegear lock.

- Check oxygen discharge indicating disc.

- Check fire extinguisher indicating discs.

If door locking provisions are installed:

- Remove airstair and baggage door external locking devices.

Upon entering the airplane:

- Remove all internal locking devices from the forward, mid‑cabin emergency doors and the right hand aft service door. Footnote 40

Bombardier relies on airline operators to determine the specific flight control, fuselage, engine, propeller, and landing gear items to be inspected in their pre-flight checklists, and what criteria to use when inspecting them.

PAL pilots were taught how to conduct a pre-flight check in the initial ground school training for the aircraft type. At the time of the occurrence, PAL had SOPs requiring a thorough pre-flight check during the exterior walk-around inspection; however, there was no list identifying the items to inspect or criteria to be used.

No NLG shock strut anomalies were identified during either of the pre-flight checks conducted by the FO on the day of the occurrence, nor during other pre-flight checks since the last servicing.

1.18.6 Checklists

1.18.6.1 General checklist use

In complex, multi-crew aircraft like the Dash 8, the foundation for aircrew decision making is based on formalized training coupled with pilot aptitude (i.e., skill and judgement), derived from experience. Aircrew performance is supported by avionics systems designed to alleviate demand on pilots’ cognitive resources by displaying specific logic-based cues such as landing gear position and condition indications. Footnote 41 Indications displaying undesired states require actions conducted by memory, or by consulting pre-specified criteria found in checklists.

A checklist is a simple way of standardizing cockpit procedures. While the primary function of achecklist is to ensure that the crew will correctly configure the airplane for any given segment of flight, they also:

- Provide a standard foundation for verifying aircraft configuration that will attempt to defeat any reduction in the flight crew's psychological and physical condition.

- Provide a sequential framework to meet internal and external cockpit operational requirements.

- Allow mutual supervision (cross checking) among crew members.

- Dictate the duties of each crew member in order to facilitate optimum crew coordination as well as logical distribution of cockpit workload.

- Enhance a team concept for configuring the plane by keeping all crew members “in the loop.”

- Serve as a quality control tool by flight management and government regulators over the flight crews. Footnote 42

The PAL SOPs describe normal checklist structure, and require that the descent and approach checklist be conducted using a read and do method, where checklist items are read aloud. The landing checklist is identified as a combination of read and do, and challenge and response items.

In many cases, checklists are designed in an order that establishes what is known as a “flow.” A flow designates a path for a crew member to follow so that items on the checklist (switches, levers, instruments, etc.) are actioned in a specific order.

At PAL, the normal checklists for approach and landing are predicated on items being completed according to a specific flow prior to verbalizing the checklist.

1.18.6.2 Quick reference handbook landing gear checklists

In an abnormal situation, the PAL SOPs require the crew to assess the problem, conduct appropriate memory check items, and then consult the QRH.

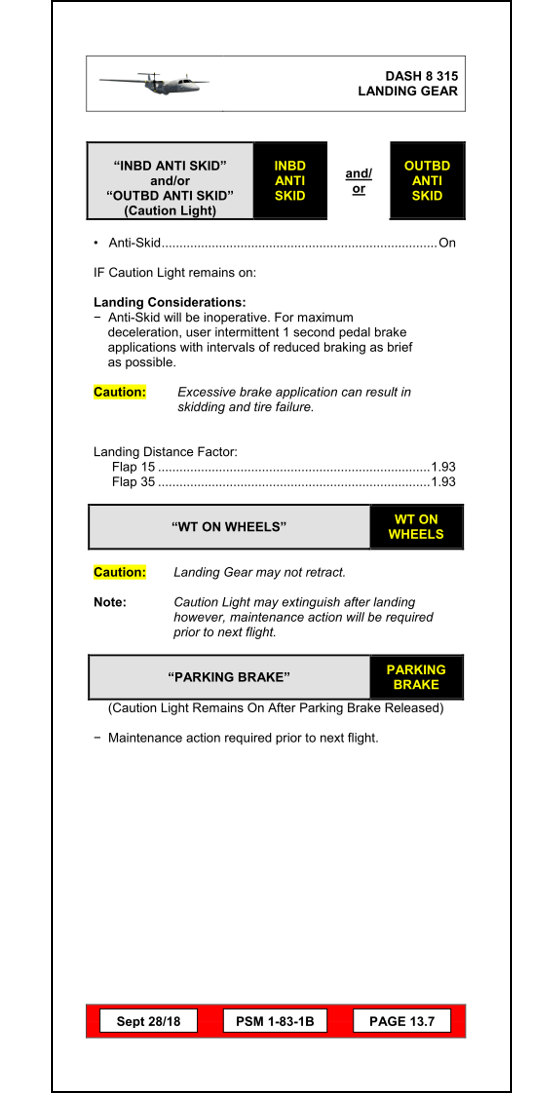

In this occurrence, following landing gear selection to the DOWN position, the aircraft displayed a WT ON WHEELS caution light, a red NOSE landing gear unsafe advisory, an amber N DOOR landing gear door open advisory, and an amber selector handle landing gear in transit light. The green NOSE down-and-locked advisory light was not illuminated.

For a WT ON WHEELS caution indication (WOW), no procedural actions are listed in the landing gear malfunction section of the QRH. It provides a caution explaining that the landing gear might not retract, and a note that advises that the indication requires maintenance action prior to the next flight (Appendix A). The landing gear malfunction section of the QRH contains various other landing gear indication and landing gear door malfunction scenarios; however, it does not contain a specific procedure for the indication combination encountered.

The QRH instructions direct that the ALTERNATE LANDING GEAR EXTENSION checklist is to be completed following any indicated malfunction not addressed by a specific procedure in the landing gear malfunction section. The checklist (Appendix B) includes a note stating that “the required pull force [of the NLG handle], to release the gear uplocks, can be as high as 41 kg”, and that “[i]t may require a repeated pull effort to achieve a landing gear down and locked indication.” Footnote 43

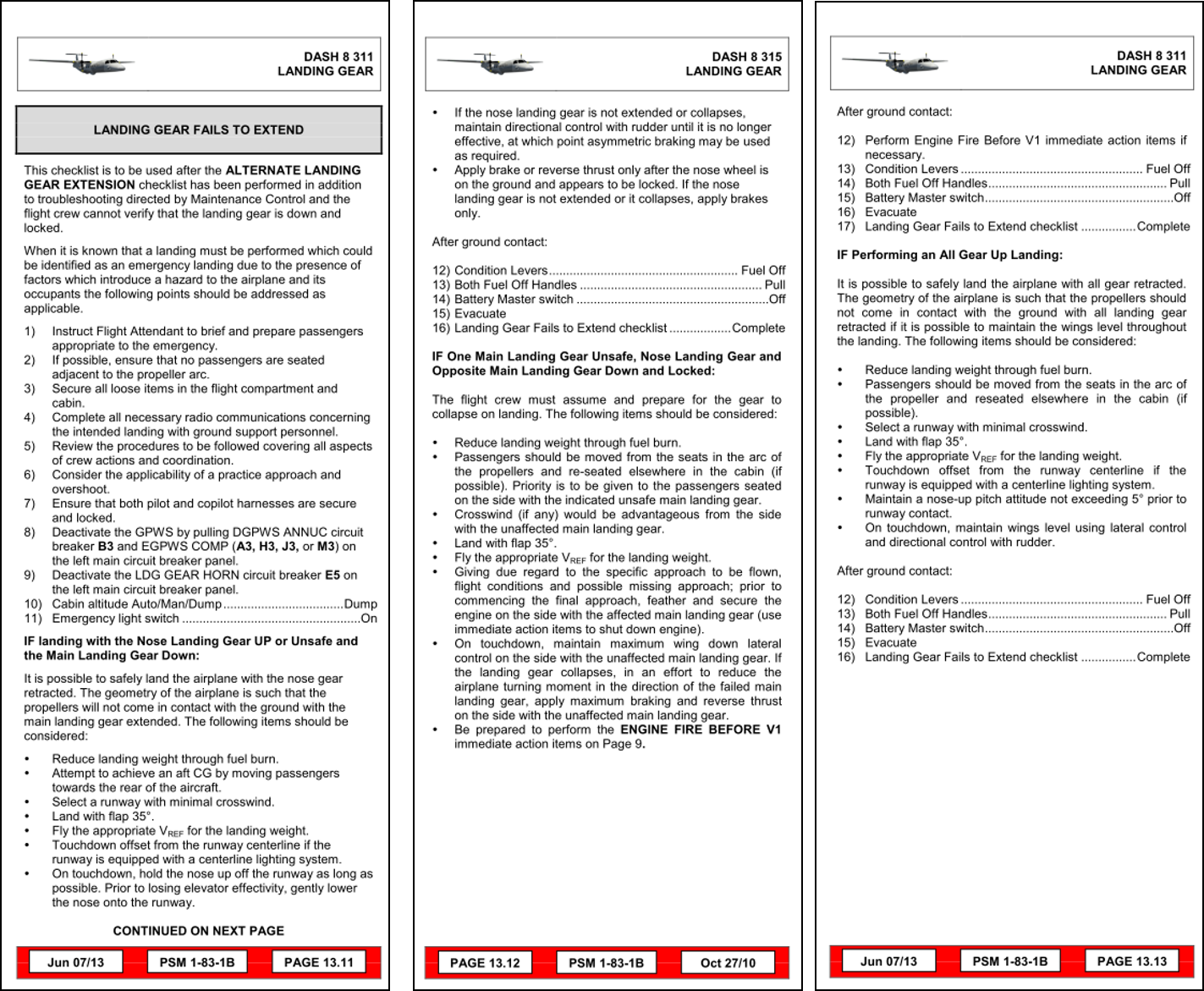

The QRH LANDING GEAR FAILS TO EXTEND checklist states that

[t]his checklist is to be used after the ALTERNATE LANDING GEAR EXTENSION checklist has been performed in addition to trouble shooting directed by Maintenance Control and the flight crew cannot verify the landing gear is down and locked. Footnote 44

The LANDING GEAR FAILS TO EXTEND checklist addresses general considerations related to landing gear unsafe conditions, as well as addressing the specific condition of landing with the MLG down and the NLG up or in an unsafe position.

The LANDING GEAR FAILS TO EXTEND checklist states that it is possible to safely land the aircraft with the NLG retracted, and that the propellers will not come into contact with the ground while the MLG is down and locked (Appendix C). The checklist provides further items to be considered for the landing, including selecting a runway with minimal crosswind, landing with flaps selected to 35°, and taking certain actions on touchdown if the NLG is not extended or if it collapses.

1.18.7 Crew resource management

CRM principles include emphasizing critical cognitive and interpersonal skills with the objective of reducing human error in aviation. When operating in a 2-crew environment, pilots must successfully interact with each other, their aircraft, and their environment to manage effectively threats, errors, and undesired aircraft states that may be encountered.

From a CRM standpoint, effective communication plays a critical role in the crew’s shared understanding of the situation. However, communication skills require practice and reinforcement to be effective, particularly during periods of high workload, such as during an instrument approach or an abnormal situation.

Modern CRM programs highlight barriers to effective communication and provide multiple communication strategies that allow individuals to select the most appropriate strategy, depending on the severity of the situation, the time available, and the other people involved in the communication process.

Situational awareness is defined as “the continuous extraction of environmental information, the integration of this information with previous knowledge to form a coherent mental picture, and the use of that picture in directing further perception and anticipating future events.” Footnote 45

Flight crew actions need to be based on a common understanding of the current state of the aircraft, the intended flight plan, and the threats to these activities in order to perform in a coordinated, efficient, and safe manner. This common understanding between the crew members is referred to as team or shared situational awareness. Footnote 46, Footnote 47 When this understanding is consistent, crews are better able to effectively anticipate and coordinate their actions toward achieving their common goal.

Shared situational awareness is developed and maintained by a crew through a number of discrete and continuous behaviours. Discrete behaviours include in-flight briefings, and identification of key points in the flight, such as those communicated during descent, approach, and landing checklists. These activities are planned checkpoints to describe current state and future plans, and to provide an opportunity for checking that all crew members have a common understanding.

Continuous behaviours include threat and error management, callouts of changes of aircraft state and instrument setting or mode, and communication of changes to plans. These behaviours ensure that information and state changes are communicated between crew members to update the shared situational awareness on an ongoing basis.

In the investigation into a collision with terrain that occurred in Grand Manan, New Brunswick, on 16 August 2014, the 2 pilots were not able to communicate effectively because only the captain wore a headset. The TSB concluded that the resulting ineffective communication between the captain and first officer contributed to the accident by preventing a shared situational awareness among the crew. Footnote 48

1.18.8 Plan continuation bias

Plan continuation is a phenomenon that can occur in a dynamic environment where a person attempts to solve an abnormal situation by adhering to a specific course of action despite the changing situation dictating that an alternate approach is required. During abnormal occurrences in a dynamic flight environment, a pilot’s continual assessment of consecutive remedial actions during the unfolding situation often replaces what is generally acknowledged as traditional decision making based on pre-defined criteria (i.e., a checklist that guides actions based on effect). As the pilot actively pursues the chosen course of action, continually checking on the effectiveness of steps to resolve it, the chain of negotiable actions influences the feasibility to continue with the original plan. Footnote 49

In other words, plan continuation is problem solving along a linear path, without reference to other prescribed options despite the situation calling for a different plan altogether.

1.18.9 Decision making

Decision making by flight crews in emergency situations is partially informed by their interpretation of external cues under conditions that may be deteriorating gradually and ambiguously. The accuracy of a crew’s perception of these cues is further informed by operational context and accountability considerations.

Departure from checklist use is a form of practical drift where local practice diverges from written procedure. Footnote 50 This can occur when local teams drift from agreed-upon rule-based logic toward a locally determined task-based procedure.

The telephone conversation between the captain and the CYYT team on the ground was unusual in that it involved direct contact with company personnel having both operational credentials and management roles, whose opinions would not normally be a part of the crew decision-making process. This team of senior personnel became an extension of the flight crew, which may have created a permissive environment in which experimentation could replace the following of written checklists.

1.19 Useful or effective investigation techniques

Not applicable.

2.0 Analysis

The loss of static pressure of the nose landing gear (NLG) shock strut allowed it to compress so that the nose wheel tires became fouled on the aft landing gear doors in a manner similar to a previous occurrence involving the Dash 8. The analysis will examine the technical issues related to the NLG partial extension.

The analysis will also discuss risks associated with the addition of the PAL Airlines Ltd. (PAL) management personnel at St. John’s International Airport (CYYT) as a cockpit resource and the resulting extended communication that ensued, including its effect on crew resource management (CRM) and the operation of the aircraft beyond certification limitations.

Additionally, the analysis will discuss risks related to the development and use of pre-flight checklists by the manufacturer and the operator.

2.1 Nose landing gear shock strut

The NLG shock strut was repaired at its first overhaul at an unknown facility by a previous operator in the United States, and no records were available from that overhaul event.

In 2014, the NLG shock strut was overhauled by Safran Landing Systems, Canada Inc. This was the second overhaul, and no rework or repair to the lower bore of the inner cylinder was conducted. Because the interface between the inner cylinder bore and lower bearing is a static joint, dimensional checks would normally occur only if an unserviceable condition such as wear or corrosion is observed. Any repair requiring oversize parts requires identification of the rework to be permanently identified on the reworked component.

For undetermined reasons, a previous repair to the inner cylinder of the NLG shock strut was not designated with a specific permanent marking as required by the approved component maintenance manual, resulting in the installation of a standard size bearing where an oversize bearing was required. This resulted in excessive clearance between the installed bearing and the lower bore of the inner cylinder. The reduced sealing force caused by the smaller-than-required bearing installation likely allowed the NLG shock strut to leak.

Similar to a previous occurrence involving partially extended nose landing gear on a Dash 8 aircraft (TSB Air Transportation Occurrence A98W0008), it was determined that the reduced hydraulic fluid volume, in addition to a possible nitrogen leak, reduced the internal static pressure of the NLG shock strut and allowed it to partially compress when it was in the up position. The airflow encountered in flight when the NLG was lowered further compressed the NLG shock strut and allowed the tires to impinge on the aft landing gear doors, thereby jamming the NLG in a partially extended position.

In normal operations, pulling on the nose gear release handle unlocks the NLG forward doors and unlocks the NLG from the uplock position. In this occurrence, because the NLG had already moved from the uplocked position and was jammed in a partially extended position, pulling the nose gear release handle had no effect.

2.2 Crew resource management

Standard operating procedures are developed to optimize communication, and therefore crew resource management (CRM) for the flight crew. Having a third party provide input during an emergency can be helpful. However, PAL had not developed procedures for such third party input to flight crew using smartphones. As a result, including the PAL personnel at CYYT (the CYYT team) as an additional channel of communication for an extended period of time decreased the crew’s shared situational awareness during critical phases of flight, and therefore disrupted checklist flow and coordination normally required to complete checklists effectively. The absence of formal in-flight procedures for flight crews to consult third parties using smartphones increases the risk of distraction, leading to a breakdown in CRM during critical phases of flight.

Additionally, the flight crew improvised communication by having the captain call the CYYT team’s phone using his Bluetooth headset, and the first officer (FO) use a smartphone application to connect to a smartphone in that same room. During the descent and approach phases, the FO’s smartphone connection was lost while the captain continued the conversation with the CYYT team. This led to breakdowns in communications in the cockpit, with the captain having 2 conversations at once, and requiring the FO to prompt the captain several times during critical phases of flight.

If crew members are unable to communicate effectively with each other, they are less likely to anticipate and coordinate their actions, which could jeopardize the safety of the flight.

2.3 Flight endurance and delay to divert

The crew departed Churchill Falls Airport (CZUM), Newfoundland and Labrador, with enough fuel for their instrument flight rules (IFR) flight to Deer Lake Airport (CYDF), Newfoundland and Labrador, with their designated alternate airport as Sydney/J.A. Douglas McCurdy Airport (CYQY), Nova Scotia. After the missed approach in CYDF due to the unsafe gear indication, the crew entered a hold in order to troubleshoot the landing gear issue. However, while in the hold, the crew learned that another company aircraft performed a missed approach due to decreased visibility at CYDF. The occurrence crew continued efforts to lower the landing gear for approximately 25 minutes before deciding to divert to Stephenville Airport (CYJT), Newfoundland and Labrador.

The troubleshooting discussion between the captain and the CYYT team lasted for more than 66 minutes, during which the crew continued using the ALTERNATE LANDING GEAR EXTENSION checklist, and repeatedly attempted to lower the landing gear using the alternate landing gear extension handle, to no effect.

The checklist includes a note stating that a repeated pull may be required to achieve a landing gear down and locked indication; however, the crew’s adherence to the same course of action without achieving a change to the landing gear condition is consistent with plan continuation bias. Having feedback from the senior CYYT team may have further influenced the captain to drift from written checklists and extend the flight’s duration.

The time the crew spent continuing their efforts to lower the landing gear before deciding to divert caused them to use some of their reserve fuel. If pilots delay making a decision to divert, there is a risk that the fuel remaining will be insufficient to provide the flight endurance required to mitigate unforeseen circumstances at the diversion airport.

2.4 Aircraft airspeed limitation exceedances

The crew’s continuance of the plan to free the NLG delayed the completion of the LANDING GEAR FAILS TO EXTEND checklist, as well as the review of diversion options. Additionally, the real-time input from the CYYT team may have created a permissive environment that allowed experimentation to occur, influencing the captain to depart from written checklist procedures.

The crew began to improvise procedures that they thought would allow the landing gear to become freed from the partially extended position. These pitch manoeuvres resulted in the aircraft exceeding airspeed limitations. If aircraft are operated beyond airspeed limitations, there is a risk that the aircraft will be subject to forces that cause damage to the aircraft or injury to the occupants .

2.5 Pre-flight check

The NLG shock strut had leaked on an earlier occasion, and the low shock strut was rectified by servicing.

The NLG shock strut leaked again before becoming jammed in this occurrence. The investigation could not determine when the leak that caused the NLG to jam occurred nor whether a pre-flight check could have detected it.

Bombardier’s scheduled maintenance requires inspection of the aircraft every 12 days, or at 50 hours of airtime, and includes inspection of the shock strut. Between these inspection intervals, PAL maintenance conducts a company-developed lay-over check when the aircraft is at a maintenance base. When the aircraft is away from a base, the only inspection of the aircraft that is carried out is the pre-flight check completed by pilots. At the time of the occurrence, the flight crew carried out the pre-flight check without a formal checklist developed.

Bombardier requires an exterior inspection to be conducted as a pre-flight check of the aircraft, which includes safety locking devices to be disengaged or removed, and the inspection of 2 indicating discs. For the serviceability of other items critical to the safety of flight, such as specific flight control, fuselage, engine, propeller, and landing gear items, Bombardier relies on airline operators to develop their own checklists, and also to determine what criteria to use when inspecting these items. If manufacturers require an aircraft inspection of items critical to the safety of flight without providing a checklist of items and inspection criteria, there is a risk that operators will not identify unserviceable items or conditions.

2.6 Cockpit voice recorder

The occurrence flight duration was 3 hours, and the NLG jammed in a partially extended position about 1 hour and 32 minutes before landing. However, the cockpit voice recorder (CVR) was designed to record and store the last 30 minutes of cockpit sounds of a flight. Additionally, the CVR did not record voice transmissions from the CYYT team during their conversation with the flight crew using their smartphones.

If voice recordings and cockpit sounds are not available to an investigation, the identification and communication of safety deficiencies to advance transportation safety may be precluded.

3.0 Findings

3.1 Findings as to causes and contributing factors

These are conditions, acts, or safety deficiencies that were found to have caused or contributed to this occurrence.

- For undetermined reasons, a previous repair to the inner cylinder of the nose landing gear shock strut was not designated with a specific permanent marking as required by the approved component maintenance manual, resulting in the installation of a standard size bearing where an oversize bearing was required.

- The reduced sealing force caused by the smaller-than-required bearing installation likely allowed the nose landing gear shock strut to leak.

- The reduced hydraulic fluid volume, in addition to a possible nitrogen leak, reduced the internal static pressure of the nose landing gear shock strut and allowed it to partially compress when it was in the up position.

- The airflow encountered in flight when the nose landing gear was lowered further compressed the nose landing gear shock strut and allowed the tires to impinge on the aft landing gear doors, thereby jamming the nose landing gear in a partially extended position.

3.2 Findings as to risk

These are conditions, unsafe acts, or safety deficiencies that were found not to be a factor in this occurrence but could have adverse consequences in future occurrences.

- The absence of formal in-flight procedures for flight crews to consult third parties using smartphones increases the risk of distraction, leading to a breakdown in crew resource management during critical phases of flight.

- If crew members are unable to communicate effectively with each other, they are less likely to anticipate and coordinate their actions, which could jeopardize the safety of the flight.

- If pilots delay making a decision to divert, there is a risk that the fuel remaining will be insufficient to provide the flight endurance required to mitigate unforeseen circumstances at the diversion airport.

- If aircraft are operated beyond airspeed limitations, there is a risk of compromising flight safety, resulting in injury to the occupants or damage to the aircraft.

- If manufacturers require an aircraft inspection of items critical to the safety of flight without providing a checklist of items and inspection criteria, there is a risk that operators will not identify unserviceable items or conditions.

- If voice recordings and cockpit sounds are not available to an investigation, the identification and communication of safety deficiencies to advance transportation safety may be precluded.

3.3 Other findings

These items could enhance safety, resolve an issue of controversy, or provide a data point for future safety studies.

- Because the nose landing gear had already moved from the uplocked position and was jammed in a partially extended position, pulling the nose gear release handle had no effect.

4.0 Safety action

4.1 Safety action taken

4.1.1 Safran Landing Systems, Canada Inc.

Following the disassembly and examination of the nose landing gear (NLG) shock strut on 18 December 2018, Safran Landing Systems, Canada Inc. (SafranLS) issued an internal document, Quality Alert No. 50633, on 19 December 2018. The Quality Alert instructed maintenance, repair, and overhaul personnel to inspect for the possibility of components received with prior repairs, but not properly identified.

On 28 February 2019, Revision No. 13 of the component maintenance manual 32-20-01 for the NLG assembly was issued with an additional note to the assembly section of the manual, alerting users of the need to check the dimensions on the inner cylinder to ensure that the correct components are installed.

On 25 April 2019, SafranLS published Service Letter No. SLDHC8-32-7 on its technical publication website. The service letter provided background on this occurrence and emphasized the importance of following all instructions provided in the component maintenance manual, including those related to the methods of identifying components after repair. The service letter also informed operators and technicians that an additional note had been included in the assembly section of the manual instructing users to check the dimensions of the components before assembly to ensure that the correct mating parts are installed.

4.1.2 PAL Airlines Ltd.

On 23 November 2018, PAL Airlines Ltd. (PAL) amended its company-designed Dash 8 lay-over check to include emphasis on the NLG shock strut minimum and maximum extension measurements. Additionally, the amendment required maintenance personnel to record the NLG shock strut extension measurement during the NLG inspection.

On 30 November 2018, PAL amended Section 3.4 of its standard operating procedures to include a formal checklist of items to be inspected when pilots conduct the exterior inspection of the Dash 8 aircraft during the pre-flight check.

On 13 December 2018, immediately after being informed by the TSB that an overspeed condition had occurred in flight, PAL completed an overspeed inspection of the occurrence aircraft, and no faults were found.

This report concludes the Transportation Safety Board of Canada’s investigation into this occurrence. The Board authorized the release of this report on . It was officially released on .

Appendices

Appendix A – Weight on wheels checklist (WT ON WHEELS)

Source: PAL Airlines Ltd., Dash 8 Quick Reference Handbook, DASH 8 315, Revision 31 (December 2018).

Appendix B – Dash 8 Quick Reference Handbook – ALTERNATE LANDING GEAR EXTENSION and LDG GEAR INOP checklists

Source: PAL Airlines Ltd., Dash 8 Quick Reference Handbook, DASH 8 315, Revision 31 (December 2018).

Appendix C – Dash 8 Quick Reference Handbook – Landing gear fails to extend

Source: PAL Airlines Ltd., Dash 8 Quick Reference Handbook, DASH 8 315, Revision 31 (December 2018).