Bounced Landing/Go-Around After Touchdown

Kelowna Flightcraft Air Charter Ltd.

Boeing 727-227 C-GLKF

Hamilton Airport, Ontario

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content. Masculine pronouns and position titles may be used to signify all genders to comply with the Canadian Transportation Accident Investigation and Safety Board Act (S.C. 1989, c. 3).

Summary

On 22 July 2008, a Kelowna Flightcraft Air Charter Ltd. Boeing 727-227 (registration C-GLKF, serial number 21118), with three crew members on board, was being operated as KFA281 on a cargo flight from Moncton, New Brunswick, to Hamilton, Ontario. The aircraft was vectored for an approach to Runway 06 at Hamilton Airport. At 2216 eastern daylight time, the aircraft touched down hard and bounced before touching down hard a second time. Immediately after the second touchdown, a go-around was initiated. During rotation, the tailskid made contact with the runway. The thrust reverser actuator fairing and the number 2 engine tailpipe made contact with the ground off the departure end of the runway. The aircraft climbed away and then returned for a normal landing on Runway 12. There were no injuries; the aircraft sustained minor damage.

© Minister of Public Works and Government Services Canada 2009

Cat. No. TU3-5/08-1E

ISBN 978-1-100-13665-0

Factual information

Crew Information

The flight crew was certified and qualified for the flight in accordance with existing regulations. The captain had been employed with the company since January 1994. At the time of the incident, the captain had 9500 hours' total flying time. Most of the flying had been on the Boeing 727, including approximately 3500 hours as captain, and 4000 hours as first officer. In addition, the captain had accumulated 875 hours as second officer on the Boeing 727.

The first officer had 2900 hours' total flying time, mostly on small turboprops. Between 2001 and 2006, the first officer was employed outside the aviation industry. After joining Kelowna Flightcraft Air Charter Ltd. (Kelowna Flightcraft) in 2006, the first officer had accumulated 1100 hours as second officer on the Boeing 727. The first officer had recently completed line indoctrination as a new first officer on the Boeing 727, and had accumulated 75 hours on type. This was the first time this crew had operated together and it was the fourth flight of their pairing.

The second officer had 1600 hours, mostly on small aircraft. Since joining Kelowna Flightcraft in June 2007, the second officer had completed 600 hours as second officer on the Boeing 727.

The flight was conducted within existing regulations for crew rest.

Weather

The reported weather for Hamilton Airport at 2200 Footnote 1 was as follows: wind 270°T Footnote 2 at 10 knots, gusting to 16 knots, visibility 1½ statute miles (sm) in thunderstorms with heavy rain, scattered clouds at 1200 feet above ground (agl), overcast clouds at 3200 feet agl with cumulonimbus clouds associated, temperature 17°C, dewpoint 17°C, and altimeter setting at 29.96 inches of mercury.

At 2219, just over two minutes following the initial touchdown of C-GLKF (flight KFA281), a special weather report was issued as follows: wind 340° at 9 knots, visibility 7 sm in thunderstorms with light rain, few clouds at 1200 feet agl, broken cumulonimbus clouds at 3300 feet agl, broken clouds at 6500 feet agl, recent rain.

History of the Flight

The occurrence flight was the second flight of the day for this crew. The previous flight was from St. John's, Newfoundland and Labrador, to Moncton, New Brunswick. Once in Moncton, the crew changed aircraft to operate Flight KFA281 to Hamilton Airport. The flight departed Moncton Airport on schedule, estimating Hamilton Airport at approximately 2212. The first officer was the pilot flying (PF).

Approaching Hamilton Airport, the crew prepared and briefed for an approach to Runway 30, which has a landing distance available (LDA) of 9600 feet. Due to the thunderstorm activity and traffic in the area, KFA281 was given vectors for the approach. During the descent, air traffic control (ATC) advised that the winds were now favouring Runway 06 and that KFA281 could now expect an approach to Runway 06. The crew members navigated around a thunderstorm and, although they had the airport in sight, they prepared for a non-precision approach to Runway 06, which has an LDA of 6000 feet.

At 2209, the pilot of a Cessna Caravan, which had just landed on Runway 06, reported to Hamilton Airport Tower that, on the approach, flight conditions were smooth and there was no windshear present. This information was relayed to KFA281.

ATC vectors allowed KFA281 to join the downwind leg for Runway 06. Shortly thereafter, at 2213, Hamilton Airport Tower reported the winds as 050°M at 10 knots and the Runway surface conditions as bare and wet with possible standing water. KFA281 was cleared to land.

Because the first officer had little flying experience on this aircraft type, the crew members assessed the option of switching flying duties because the landing would now be on the shorter runway. They concluded that it was acceptable for the first officer to fly the approach and landing. They flew a stabilized approach, using guidance from the precision approach path indicator (PAPI).

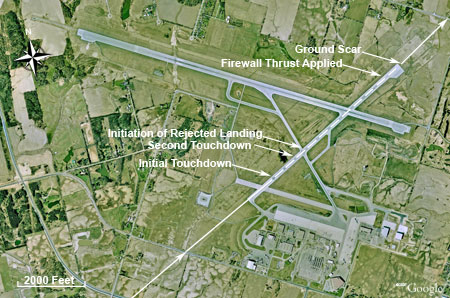

At 2216, the aircraft touched down hard, approximately 1200 feet past the threshold (see Photo 1), with a rate of descent of approximately 350 feet per minute. It then bounced approximately eight feet vertically, before landing firmly. The vertical acceleration for the first touchdown was recorded on the flight data recorder (FDR) at 1.9 g. Footnote 3 The maximum vertical acceleration was recorded on the second touchdown when it reached 2.3 g. Both these values indicate touchdown forces greater than normally experienced. Due to the limited FDR parameters, it could not be determined why, after a stabilized approach, the aircraft touched down at a high rate of descent.

Following company procedures, after the second touchdown, the first officer deployed the spoilers using the speedbrake lever. As the first officer was reaching for the thrust reverser handles, the captain took control of the aircraft and initiated a go-around. The captain applied go-around thrust; however, the spoilers were not stowed. The flaps were raised out of the 30° position. It could not be determined if they were selected to the 25° or the 15° position. However, both settings are approved by Boeing for take-off and go-around and neither setting would have had a detrimental effect on this event.

During the go-around manoeuvre, the take-off configuration warning horn Footnote 4 sounded. At approximately 115 knots, the captain started to rotate the aircraft for take-off. The aircraft did not become airborne and the tailskid began to drag on the runway. Approximately 300 feet before reaching the end of the runway, the captain applied firewall thrust. Footnote 5 Shortly thereafter, the main wheels came off the ground and the landing gear was retracted. At the same time, the captain noticed that the spoilers were deployed and immediately stowed them. The aircraft began climbing normally and eventually returned for a normal landing on Runway 12.

After the occurrence, airport personnel inspected Runway 06. They found a 12-foot-long ground scar in the turf off the end of the runway, starting approximately 44 inches from the hard surface and parallel to the Runway heading. The scar was up to 9 inches wide and 2 inches deep (see Photo 2), and was caused by the number 2 engine thrust reverser actuator fairing and tailpipe.

There was some dirt and grass found in the number 2 engine cascade vane openings.

Performance

The aircraft weight and centre of gravity were within the prescribed limits. Performance charts indicate that, at its landing weight of 130 095 pounds, the aircraft would require approximately 2625 feet to stop on a dry runway. Footnote 6 This distance would have increased to 3950 feet on a wet runway.

With the wet Runway conditions present at the time, calculations showed that a normal landing could have been completed with the aircraft stopping on the remaining runway. The Hamilton Airport Tower reported possible standing water on the runway. Had this been the case, the required stopping distance would have been greater. However, the preceding aircraft had reported the braking action as fair.

The go-around was initiated approximately 2500 feet down the Runway at a speed of 110 knots. It was determined that the aircraft could have safely flown away, if the spoilers had been stowed.

Use of Speedbrakes/Spoilers

A speedbrake lever located on the left side of the control stand operates panels on the wing called spoilers. In flight, by extending the flight spoilers upward into the airflow, the lift is spoiled and drag is increased. In flight, the flight spoilers can be used as speedbrakes assisting in slowing down the aircraft. The Boeing 727 Operations Manual specifies that speedbrakes are not to be operated in flight with wing flaps extended.

Spoilers are also used for ground operations. When deployed on the ground, ground spoilers are used in combination with flight spoilers, destroying lift and transferring aircraft weight from the wings to the wheels, thereby improving wheel braking effectiveness. Some Boeing 727's are equipped with auto-spoilers that extend automatically on landing. However, all Kelowna Flightcraft Boeing 727's are equipped with manual spoilers that have to be extended manually after touchdown.

Procedures and Training

The Kelowna Flightcraft simulator training syllabus requires that flight crews practice many different procedures. Some need to be accomplished immediately and by recall, such as the windshear recovery procedure and the ground proximity warning system (GPWS) pull-up terrain avoidance procedure. Both these procedures specify that speedbrakes have to be retracted to achieve maximum climb performance.

Section 725.124 of the Commercial Air Service Standards (CASS) requires that crews practice the normal go-around procedure, in different configurations, including at least one go-around in the low-energy regime. These procedures are initiated before touchdown. Both the Boeing and the Kelowna Flightcraft go-around procedures direct the crew as follows:

- Set go-around thrust,

- Rotate to go-around attitude,

- Select flaps to 25 and then to 15,

- Select landing gear up when positive rate of climb is confirmed,

- Retract flaps and slats on schedule.

Since wing flaps are used on approach and spoilers are not to be operated in flight with wing flaps extended, crews always practice the go-around manoeuvre with spoilers stowed. The go-around procedure does not specify that speedbrakes have to be retracted.

Boeing's Maneuvers Manual describes the bounced landing recovery procedure. It states, in part:

- hold or re-establish normal landing attitude and add thrust as necessary to control the rate of descent;

- if only a shallow bounce or skip occurs, thrust need not be increased;

- if a hard high bounce occurs and excessive Runway is used, a go-around is mandatory. Apply go-around thrust and use normal go-around procedures.

In other words, with a shallow bounce, a pilot may continue with the landing, while a high bounce requires a go-around. While these procedures are described in Boeing's Maneuvers Manual, Kelowna Flightcraft does not train its pilots on the bounced landing procedure, nor are they required by regulation to do so.

In a report released on an accident that occurred on 09 May 2004 in Puerto Rico, Footnote 7 the United States National Transportation Safety Board (NTSB) made the following recommendation:

Require all 14 Code of Federal Regulations [CFR] Part 121 and 135 air carriers to incorporate bounced landing recovery techniques in their flight manuals and to teach these techniques during initial and recurrent training.

Transportation Safety Recommendation A-05-30

On 06 September 2006, referencing the above occurrence, the United States Federal Aviation Administration (FAA) issued Safety Alert for Operators (SAFO) 06005 to certificate holders operating under Title 14 of the CFR, parts 121 and 135. The stated purpose of the SAFO was to emphasize the importance of operators, ensuring that they have procedures and training for bounced landing recovery. Pending results from a survey of Part 121 and 135 carriers that demonstrates that they have adopted the recommendations of the SAFO, Safety Recommendation A-05-30 is classified by the NTSB as Open Acceptable Response.

In addition, during initial type training, crews complete touch-and-go training, which is similar to a go-around after wheel touchdown in that, following touchdown, the aircraft is reconfigured, thrust is applied and a take-off is carried out. For the touch-and-go training, crews are directed to verify that the spoilers are retracted before take-off.

It should be noted that, during touch-and-go training, it would not be unusual for the take-off configuration warning horn to sound as the thrust levers are advanced while the flaps and trim are being re-set for the take-off portion of the manoeuvre.

In contrast, the normal go-around procedure is silent on the use of spoilers.

Previous Occurrences

Three relevant occurrences in Canada or involving Canadian aircraft were identified, as follows:

- On 22 May 2001, a Boeing 737-210C with 104 persons on board experienced a bounced landing on arrival in Yellowknife, Northwest Territories. It was determined that incorrect bounced landing recovery procedures were applied. The aircraft sustained 3.2 g and was substantially damaged (TSB report A01W0117).

- On 20 May 2007, a CL-600-2B19 Regional Jet with 40 persons on board experienced a bounced landing on arrival at Toronto/Lester B. Pearson International Airport, Ontario. The aircraft was substantially damaged when both main landing gear attachment brackets failed, and the landing gear collapsed (TSB report A07O0124).

- On 28 May 2007, a Canadian-registered Airbus A320 with 142 persons on board experienced a bounced landing on arrival in Los Angeles, California, United States. The aircraft sustained 3.07 g and was substantially damaged (TSB occurrence A07F0093).

There have been several reported accidents and incidents that demonstrate that crews throughout the airline industry have experienced problems when faced with a bounced landing. A sample of other occurrences, as investigated by the NTSB, can be found in Appendix A.

Cockpit Voice Recorder

The aircraft was equipped with a Fairchild 93-A100-80 cockpit voice recorder (CVR). The recording time for this type of unit is 30 minutes. The Kelowna Flightcraft Company Operations Manual contains operational directives for CVR procedures that read, in part, as follows:

Following any landing incident or accident where aircraft electrical busses will remain powered, the CVR circuit breaker should be pulled in order to preserve recorded cockpit information for the purpose of any subsequent investigation conducted by the Transportation Safety Board of Canada.

Following engine shutdown and while reviewing their responsibilities, the crew recognized that power to the CVR should be removed. Maintenance personnel were contacted and power to the CVR was removed. However, by the time power was removed, the occurrence recording had been overwritten, resulting in the loss of potentially valuable information to the investigation. The TSB has identified the advantages in multiple aviation investigation reports that would be achieved if all CVRs were to retain at least two hours of audio.

On 09 March 1999, following the Swissair Flight 111 accident (TSB report A98H0003), the TSB released Interim Safety Recommendation A99-02 as part of its investigation. The Board recommended to both Transport Canada (TC) and the European Joint Aviation Authorities that:

As of 01 January 2005, all aircraft that require both an FDR and a CVR be required to be fitted with a CVR having a recording capacity of at least two hours.

Transportation Safety Recommendation A99-02 (issued 09 March 199)

TC's response received by the TSB on 07 June 1999 indicated support for this recommendation with the provision that the FAA and Canadian requirements remain harmonized. TC's stated intention was to introduce an appropriate Notice of Proposed Amendment (NPA) into its Canadian Aviation Regulation Advisory Council (CARAC) process.

On 07 March 2008, the FAA issued its final rule entitled Revisions to Cockpit Voice Recorder and Digital Flight Data Recorder Regulations stating that, by 07 April 2012, CVRs on all turbine engine-powered airplanes have a two-hour recording capacity. TC will be tabling NPAs regarding FDR requirements (88 parameters) at its CARAC Technical Meeting in November 2009, with a view to harmonizing, to the extent possible, with the FAA. TC will continue to work on the development of NPAs to harmonize CVR and FDR requirements in order to meet the FAA's 2012 timetable.

TSB's assessment is that the proposed regulatory change, if fully implemented, will substantially reduce or eliminate the safety deficiency as described in Recommendation A99-02. Therefore, the assessment is Satisfactory Intent and the deficiency file is assigned an Active status.

Flight Data Recorders

The aircraft was equipped with a tape-based Sundstrand 980-4120-GQUS FDR, serial number 7386. It contained approximately 26 hours of data with 11 parameters recorded, including vertical acceleration (g).

The accelerometers used in this aircraft incorporated a low-pass filter as mandated by European Organization for Civil Aviation Electronics (EUROCAE) document ED-55, Minimum Operational Performance Specification for Flight Data Recorder Systems. In a previous occurrence, the TSB Engineering Laboratory tested the frequency response of aircraft accelerometers to determine their output with respect to measured force inputs and determined that the accelerometer filtering caused attenuation of the acclerometer signal at frequencies above four cycles per second. This filtering means that, depending on the frequency content of the accelerometer data of the event, the recorded accelerometer data may be lower than that actually experienced by the aircraft.

The FDR data suggest that the vertical acceleration experienced by this aircraft during the occurrence would have had some high-frequency components. Although the FDR recorded vertical acceleration at initial touchdown was 1.9 g followed by a subsequent touchdown of 2.3 g, it is likely that, due to the accelerometer low-pass filtering, the actual values of vertical acceleration experienced by the aircraft were higher.

Analysis

While there were thunderstorms in the area, light winds prevailed at the airport at the time of the occurrence, with no indication of windshear. A stable approach was flown; however, the rate of descent at the time of touchdown contributed to a hard landing and bounce.

After the second touchdown, the captain decided to carry out a go-around and not to stop on the Runway in the remaining distance. The investigation determined that the aircraft could have stopped on the remaining runway, which was bare and wet. It could also have safely flown away, following a go-around after wheel touchdown, if the spoilers had been stowed.

However, in this occurrence, the go-around was initiated with the spoilers deployed. This resulted in added drag that precluded a safe lift-off and caused the tail and the number 2 engine to strike the ground. While the manufacturer's manual contains guidance on how to respond to a bounced landing event, during simulator training, crews are not required to conduct the bounced landing recovery procedure. Furthermore, this crew had not practiced the go-around after touchdown manoeuvre during simulator training. Therefore, they were never exposed to either scenario and never had the opportunity to learn to retract the spoilers when conducting a go-around.

The decision of the captain to carry out a go-around was based on the concern that insufficient Runway remained to bring the aircraft to a stop, especially with the potential for standing water on the runway. This is consistent with Boeing's bounced landing recovery procedure for a hard high bounce where excessive Runway is used; in this circumstance, a go-around is mandatory.

While the take-off configuration warning horn should have warned the crew that the aircraft was not properly configured, the aircraft was moving at high speed, leaving the crew with very little time to analyse the situation. The crew had to reconfigure the aircraft and these actions had to be completed under conditions of high stress and workload. The complexity level of the manoeuvre was also increased due to the transfer of control that took place. Combined with the fact that the bounced landing recovery manoeuvre had not been practised previously, this likely contributed to the crew not stowing the spoilers.

When the take-off configuration warning horn sounded, the crew did not immediately recognize that the spoilers were not stowed. This could be because the crew members had heard the warning horn during touch-and-go training in the past and did not recognize it as a warning and that they expected it to stop sounding once the aircraft was reconfigured, or simply that they were too busy to hear it. Ultimately, the warning horn did not provide the signal necessary to draw the crew's immediate attention to the position of the spoilers.

The crew carried out the go-around procedure as described in the manufacturer's and the operator's manuals. However, unlike the windshear recovery procedure and the GPWS pull-up terrain avoidance procedure, this procedure does not specify that speedbrakes have to be retracted. Without procedures to ensure that the spoilers are retracted in the event of a go-around after touchdown, crews may leave the speedbrake lever in the extended position, increasing the risk of the aircraft not being able to meet the required climb gradient.

By the time power was removed by maintenance staff, all CVR information regarding the incident had been overwritten. The lack of information from the 30-minute CVR regarding the go-around event hampered investigators' ability to obtain a timely and complete understanding of the event and hindered the investigation. A two-hour CVR would have captured the event and provided important information.

The following TSB Engineering Laboratory report was completed:

- LP 100/2008 – FDR/CVR Analysis

This report is available from the Transportation Safety Board of Canada upon request.

Findings

Findings as to causes and contributing factors

- The go-around was initiated with the spoilers deployed. This resulted in added drag that precluded a safe lift-off and caused the tail and the number 2 engine to strike the ground.

- The crew had not received any training for a bounced landing or a go-around after touchdown and therefore did not retract the spoilers.

Findings as to risk

- The bounced landing recovery and go-around procedures do not direct crews to stow the spoilers. In the event of a go-around after touchdown, crews may leave the speedbrake lever in the extended position, increasing the risk of the aircraft not being able to meet the required climb gradient.

- Cockpit voice recorder (CVR) information regarding this incident was overwritten. The lack of CVR data hampered investigators' ability to obtain a timely and complete understanding of the event.

Other Finding

- While vertical acceleration was recorded at 1.9 g and 2.3 g, it is likely that the actual g values experienced by the aircraft were higher.

Safety action

Action Taken

Boeing

Boeing has stated that it will publish an article in Fleet Team Digest in the latter part of 2009. This article will remind crews to stow the spoilers when rejecting a landing or executing a go-around after touchdown.

Kelowna Flightcraft Air Charter Ltd.

On 14 August 2008, a Memorandum was issued to all Kelowna Flightcraft Air Charter Ltd. (Kelowna Flightcraft) crews regarding this incident. In the course of a general discussion on sharing of pilot flying/pilot not flying (PF/PNF) duties, the Memorandum reminded crews of direction provided in the Company Operations Manual regarding the pilot-in-command (PIC) completing the approach/landing when conditions are considered less than good due to turbulence or Runway contamination. It also discussed the importance of positive and clear communication on the part of junior crew members when they are not comfortable conducting a landing for any reason.

Starting in November 2008, the Hamilton Airport landing incident was used as a case study in the company's 2008/2009 Crew Resource Management (CRM) training program. It focused on flight crew experience levels, situational awareness, communication, assertiveness, and the need for careful consideration on the part of the PIC when assigning landings to junior crew members. To date, the presentation has been attended by the majority of Kelowna Flightcraft pilots.

On 09 December 2008, the company issued Blue Bulletin 08-01, initiating a procedural change for the Boeing 727 operation. It alters the Boeing recommended procedure to include a positive statement by the PF when the speedbrakes are deployed during landing. The PF calls "SPEEDBRAKES UP" as the action is performed, and the action is confirmed visually by the PNF and second officer. This ensures that positive communication regarding aircraft configuration is announced, resulting in enhanced situational awareness.

Action Required

Bounced Landing Training

The Commercial Air Service Standards require that crews practice the rejected landing procedure and the normal go-around procedure. These procedures are all initiated before main wheel touchdown.

In this occurrence, the crew had to react to a bounced landing. While the manufacturer's manual contains guidance on how to respond to such an event, crews do not receive training for these manoeuvres. While the crew was able to conduct a go-around and return for a safe landing, the aircraft sustained some damage.

Accident data show that other crews throughout the aviation industry have also experienced problems when manoeuvring following a bounced landing.

Action has been taken in the United States to mitigate the risks associated with bounced landings through crew training. Canadian operators, however, are not required to train their crews for bounced landings. Without training to improve crew skills and awareness of the risks associated with this manoeuvre, there continues to be an unacceptable level of risk to crews and the travelling public.

Therefore, the Board recommends that:

The Department of Transport require air carriers to incorporate bounced landing recovery techniques in their flight manuals and to teach these techniques during initial and recurrent training.

Transportation Safety Recommendation A09-01

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .

Appendices

Appendix A - Bounced Landing Occurrences

| Date | Aircraft Type | Location | Remarks |

|---|---|---|---|

| 2004-09-19 | Boeing MD-11 | Memphis, Tennessee, United States |

|

| 2001-07-02 | Lockheed L-382G | Lake Minchumina, Alaska, United States |

|

| 2000-02-12 | Boeing 757-232 | San Salvador, El Salvador |

|

| 1999-06-02 | Boeing 757-232 | Phoenix, Arizona, United States |

|

| 1998-08-14 | Boeing 737-400 | Juneau, Alaska, United States |

|

| 1997-07-31 | MD-11 | Newark, New Jersey, United States |

|

| 1996-05-16 | MD-11 | Anchorage, Alaska, United States |

|

| 1994-11-04 | MD-11 | Anchorage, Alaska, United States |

|

Appendix B - Glossary

- APU

- auxiliary power unit

- ATC

- air traffic control

- CARAC

- Canadian Aviation Regulation Advisory Council

- CASS

- Commercial Air Service Standards

- CFR

- Code of Federal Regulations, United States

- CRM

- crew resource management

- CVR

- cockpit voice recorder

- EUROCAE

- European Organization for Civil Aviation Electronics

- FAA

- Federal Aviation Administration, United States

- FDR

- flight data recorder

- g

- vertical acceleration

- GPWS

- ground proximity warning system

- Kelowna Flightcraft

- Kelowna Flightcraft Air Charter Ltd.

- KFA281

- Flight KFA281

- LDA

- landing distance available

- NTSB

- National Transportation Safety Board, United States

- NPA

- Notice of Proposed Amendment

- PAPI

- precision approach path indicator

- PF

- pilot flying

- PNF

- pilot not flying

- SAFO

- Safety Alert for Operators

- sm

- statute mile

- TC

- Transport Canada

- TSB

- Transportation Safety Board of Canada

- °

- degrees

- °C

- degrees Celsius

- °M

- degrees magnetic

- °T

- degrees true