Aviation Investigation Report A08Q0055

Landing with Nose Wheel Retracted

Service aérien gouvernemental du Québec

Challenger CL-600-2A12 C-FURG

Québec/Jean Lesage International Airport, Québec

The Transportation Safety Board of Canada (TSB) investigated this occurrence for the purpose of advancing transportation safety. It is not the function of the Board to assign fault or determine civil or criminal liability. This report is not created for use in the context of legal, disciplinary or other proceedings. See Ownership and use of content.

-

Table of contents

Summary

The Challenger CL-600-2A12 aircraft (registration C-FURG, serial number 3063), operated by the Service aérien gouvernemental du Québec, was conducting an instrument flight rules flight from the Bonaventure Airport, Quebec, to the Québec/Jean Lesage International Airport. During the approach, the nose gear failed to extend. The flight crew did a low fly-pass and the tower controller and an aircraft maintenance engineer confirmed the nose gear anomaly. The flight crew went through the checklist and prepared the six passengers for a landing with the nose gear retracted. At 0643 eastern daylight time, the aircraft landed on its nose. Damage was limited to the nose landing gear doors and the nose landing gear well structure. There were no injuries.

Other Factual Information

The flight crew was certified and qualified for the flight in accordance with existing regulations. The captain had accumulated approximately 14 000 hours of flying time, including 1550 hours on the Challenger CL-600. The first officer had accumulated approximately 8400 hours of flying time, including 2260 hours on the Challenger CL-600. The first officer was completing his training for promotion to captain. The captain, who was occupying the left seat, completed the approach and landing.

The weather conditions reported at 0700Footnote 1, 17 minutes after the landing, were as follows: wind 070° at 12 knots gusting to 17 knots; visibility 5 statute miles in light snow; scattered clouds at 800 feet above ground level (agl); overcast at 3500 feet agl; temperature −2°C; dew point −4°C; and altimeter setting 29.48 inches of mercury.

C-FURG is fitted with special equipment to conduct aeromedical evacuations of patients to large urban centres. It is operated under an exemption to section 604.03Footnote 2 of the Canadian Aviation Regulations (CARs).

C-FURG took off from its base in Québec, Quebec on 19 March 2008 at 2051 for the Kuujjuaq Airport, Quebec, and then landed in Montréal, Quebec, Chandler, Quebec, Bonaventure, Quebec and Québec, Quebec. At Chandler and at Bonaventure, three patients boarded the aircraft en route to hospitals in Québec. One doctor and two nurses accompanied them.

Upon arrival in Québec, when attempting to extend the landing gear, the flight crew received visible and audible warnings that the nose gear was not in the down and locked position. The checklist was completed and a second attempt at recycling the landing gear was made without success. The landing gear manual release handle was activated twice without satisfactory results. The cabin was prepared for a nose gear retracted landing. The aircraft then landed on its nose.

The aircraft can be used on various types of surfaces, including unpaved/gravel runways. In May 1988, the Service aérien gouvernemental du Québec installed a kit supplied by Bombardier for operation from unpaved/gravel runways. The kit (service bulletin number 601-0112) includes, among other items, two gravel deflectors for installation on the nose landing gear and other protective devices for the main landing gear. The deflectors are used to protect the aircraft exterior surfaces and engine against damage that can be caused by solid particles that are projected during take-offs and landings. Only 8 of 255 CL-600 models that were built are equipped with this kit.

When recovering the aircraft, the nose wheel oleo pneumatic shock absorber (oleo strut) was found to be flat. The nose gear was partly extended, the right deflector was stuck in the nose landing gear well, and the wheels had pivoted and were out of alignment. The nose gear torque links had dragged on the runway, which had worn flats on them at the apex. The nose landing gear doors and nose landing gear well structure were also damaged. Also, the proximity switches, located on each side of the nose gear leg, had been struck and damaged by the lips of the tires.

The aircraft was jacked and the front wheel was dislodged and extended to the lock position. The aircraft was then moved inside the hangar and quarantined.

The wheel could be moved in all directions and compressed. The nitrogen pressure was then checked and a reading confirmed a complete loss of nitrogen. The aircraft maintenance engineer had to use a wrench to loosen the second filler valve nut, which indicates that the valve was not loose and was properly seated. Nitrogen was added to verify if there was a nitrogen leak. The pressure was checked the following morning and no pressure loss was noted.

When the front wheels of the aircraft lift off the ground, the oleo strut, which contains hydraulic oil and nitrogen, extends fully. A cam in the nose landing gear shock strut mechanically centres the nose landing gear when the oleo is fully extended. When retracting the nose gear, the fully extended oleo strut moves forward in the nose landing gear well and the nose gear is secured by a latch located in the top of the well. To ensure that the landing gear pin and latch are perfectly aligned, the oleo strut must be fully extended and the landing gear must be perfectly centred forward. If the landing gear is not centred, the logic in the landing gear retraction function prevents gear retraction and the pilot is alerted via the landing gear caution and warning system.

The normal deployment sequence of the landing gear starts with the activation of the landing gear handle in the cockpit that controls the opening of the doors. Once the doors are fully opened, the landing gear latch activates, allowing the landing gear to drop freely. Hydraulic pressure assists in locking the landing gear to the vertical position and in closing the doors. Also, a manual release handle, located on the pedestal between the two pilots, can be used to release the landing gear latch and extend the landing gear in the event of a hydraulic failure. When the manual release handle is used, it releases the nose gear door closed lock and the nose landing gear uplock and dumps hydraulic pressure. The gear extends due to its weight.

Three inches of the oleo strut are visible when the aircraft is on the ground and the oleo strut is compressed. During the pre-flight inspection, a fully compressed oleo strut is easily visible. Also, when taxiing, a noticeable banging noise may occur which could alert the flight crew that there is a problem. In the event of a loss of nitrogen pressure when the landing gear is in the up position, the design of the uplock latch and the pin allows the wheels to move rearward, causing the landing gear to be released from the landing gear latch. The landing gear will then be released and come into contact with the wheel doors. Because the landing gear latch remains in contact with the proximity switch, nothing in the cockpit will indicate to the flight crew that the nose gear is no longer in the up and locked position. This possibility has been demonstrated during the investigation.

The aircraft was certified, equipped, and maintained in accordance with existing regulations and approved procedures. According to inspection program number Q-0547 of the Service aérien gouvernemental du Québec approved by Transport Canada, an overhaul of the nose gear is performed every 120 months and a detailed inspection is conducted every 60 months. According to the aircraft's maintenance file, the overhaul was completed on 10 January 2000 and the detailed inspection was done on 27 February 2006. A check of the oleo strut oil level and nitrogen pressure is done every six months and had been completed on 05 December 2007. Also, maintenance personnel carried out a visual inspection of the nose landing gear on 12 March 2008. This visual inspection is repeated every 300 hours.

The nose landing gear of the CL-600-2A12 is manufactured by Messier-Dowty. Following the occurrence, oleo strut model 601-85002-15 (serial number DEC0099/01) was sent to Messier-Dowty so its nitrogen pressure could be checked and for a complete disassembly. It was impossible to duplicate the loss of nitrogen and/or hydraulic oil during the tests. Moreover, disassembly did not reveal any anomaly likely to cause a loss of nitrogen. The level of hydraulic oil in the oleo strut was within prescribed limits. Messier-Dowty dismantling report number DS-989 determined that the nitrogen could only have leaked from the second filler valve nut.

The filler valve is located in the upper section of the oleo strut. This valve is used to fill hydraulic oil and nitrogen; it is also used to check the nitrogen pressure. The filler valve is screwed into the oleo strut and a locking wire prevents it from loosening. A second nut located on the valve is used for routine servicing and for adding nitrogen; this nut is not secured by a locking wire, nor is it required. However, it has a dead band that creates forces great enough to require the use of a wrench to open the valve.

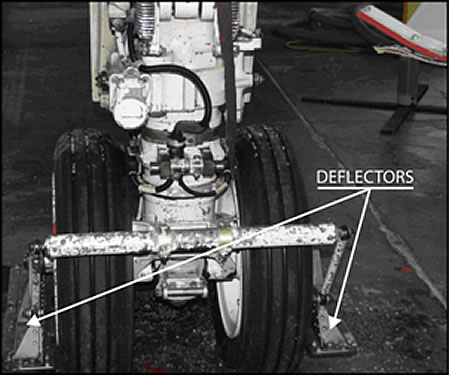

The nose gear consists of a set of dual wheels and two gravel deflectors installed on each side of the tires (see Photo 1). The total width of the landing gear set equipped with the two gravel deflectors is 23.125 inches. The opening of the nose landing gear well structure is 23.625 inches wide. To allow the gravel deflectors to move freely, a modification to the width of the well was done. A notch was made in each side of the well, making the total width 24.250 inches (see Photo 2).

When retracting the landing gear, the fully extended oleo strut goes through the notches and the clearance between the deflectors and the nose landing gear well structure is 0.562 inches on each side. When the oleo strut does not extend and thus does not pass through the notches, the clearance is reduced by 0.250 inches on each side. For comparison purposes, the clearance between the tires and the structure is 3.562 inches on each side for aircraft not equipped with gravel deflectors. Service history on Challenger 601 aircraft indicates no record of oleo nitrogen depletion leading to the inability to extend nose landing gear for aircraft not equipped with a gravel runway kit.

C-FURG was built by Bombardier in 1986 in accordance with the construction standards contained in the United States Federal Aviation Regulations, Part 25 (FAR 25). At the time of the occurrence, the aircraft had accumulated 27 973 hours and 33 227 cycles. Subpart 25, paragraph 25.733 (d) states that "Each tire installed on a retractable landing gear system must, at the maximum size of the tire type expected in service, have a clearance to surrounding structure and systems that is adequate to prevent unintended contact between the tire and any part of the structure or systems."

The investigation revealed that the front tires of this aircraft are replaced on a regular basis, mostly due to premature wear and excessive vibrations that are caused by the wheels and/or tires being out of balance. Using the aircraft on unpaved/gravel runways is probably the principal cause of this.

Analysis

The compression of the oleo strut allowed the landing gear to migrate out of the uplock latch and fall on to the nose landing gear doors. Some nose wheel rotation was also permitted in this unsecured position because the centring cam was no longer engaged in the compressed oleo strut, thereby resulting in the wheel/deflector assembly not having sufficient clearance for the landing gear to extend normally. The rotation of the nose gear in the well resulted in the right-side gravel deflector becoming stuck, preventing extension of the nose landing gear.

C-FURG is equipped with a kit enabling it to operate on unpaved/gravel runways. When the oleo strut does not extend, the clearance between the gravel deflectors and the nose landing gear well is reduced to 0.250 inches on each side. Tests with the oleo strut compressed revealed that the gravel deflectors need only pivot a few inches to become jammed in the well. Nevertheless, when the oleo strut operates correctly, the clearance available is sufficient for the landing gear to deploy as designed.

Before leaving Bonaventure, Quebec, a walk-around inspection was done, but it did not reveal any anomaly to suggest that there was a nose landing gear malfunction. During take-off from Bonaventure, the crew noted nothing unusual and the up-and-locked landing gear indications were normal. If the oleo strut had been off-centre once airborne, the system's logic would have prevented retraction of the landing gear. It is therefore conceivable that the oleo strut was operating normally during the take-off from Bonaventure and that it collapsed in flight.

The design of the landing gear latch and pin allows movement rearward and ensures that the nose gear is released and comes into contact with the wheel doors. Because the landing gear had already exited the uplock latch and was mechanically jammed in the nose wheel well, the use of the manual release handle in this case was ineffective.

Testing was done, but it was impossible to duplicate the loss of nitrogen and/or hydraulic oil. Disassembly did not reveal any anomaly likely to cause the loss of nitrogen. The level of hydraulic oil in the oleo strut was within prescribed limits. According to the manufacturer, Messier-Dowty, the only location where the loss of pneumatic pressure could occur is through the second nut on the filler valve; in that case, the second nut must have backed off. The investigation could not determine that this nut had backed off during the occurrence. Therefore, it is possible that the nitrogen leaked gradually.

The FAR 25 construction standards were drafted specifically for tires, but contain no clearance standards other than that the manufacturer must ensure that the tires have adequate clearance for all situations, that is to say when filled to maximum pressure. Also, the standards do not define what is meant by "adequate". Without gravel deflectors, the clearance between the tires and the nose landing gear well structure is clearly greater.

Using this aircraft on different types of unpaved/gravel runways and under exceptional operating conditions makes it vulnerable to damage. In light of the damage to the proximity switches and the replacement of the front tires on a regular basis, there is reason to believe that this aircraft is subject to significant vibration during take-offs and landings.

Findings

Findings as to causes and contributing factors

- The oleo pneumatic shock absorber (oleo strut) was found to be compressed due to a loss of nitrogen. As a result, the nose landing gear was released from the landing gear uplock latch, which allowed the wheel assembly to pivot and become jammed in the well.

- The right deflector remained jammed in the nose landing gear well, preventing extension of the landing gear.

- The design of the landing gear latch and pin allows the landing gear to be released from the landing gear uplock latch and to drop into the well during flight, causing the right gravel deflectors to jam, preventing extension of the nose landing gear.

- The clearance between the gravel deflectors and the nose landing gear well structure is very narrow when compared to similar aircraft that are not equipped with gravel deflectors. Another oleo pneumatic shock absorber (oleo strut) compression could result in the same situation occurring again.

This report concludes the Transportation Safety Board's investigation into this occurrence. Consequently, the Board authorized the release of this report on .